Advanced Energy Modeling and Prediction of Integrated Micro-Generator System for Useful Heat Harvesting

Abstract

:1. Introduction

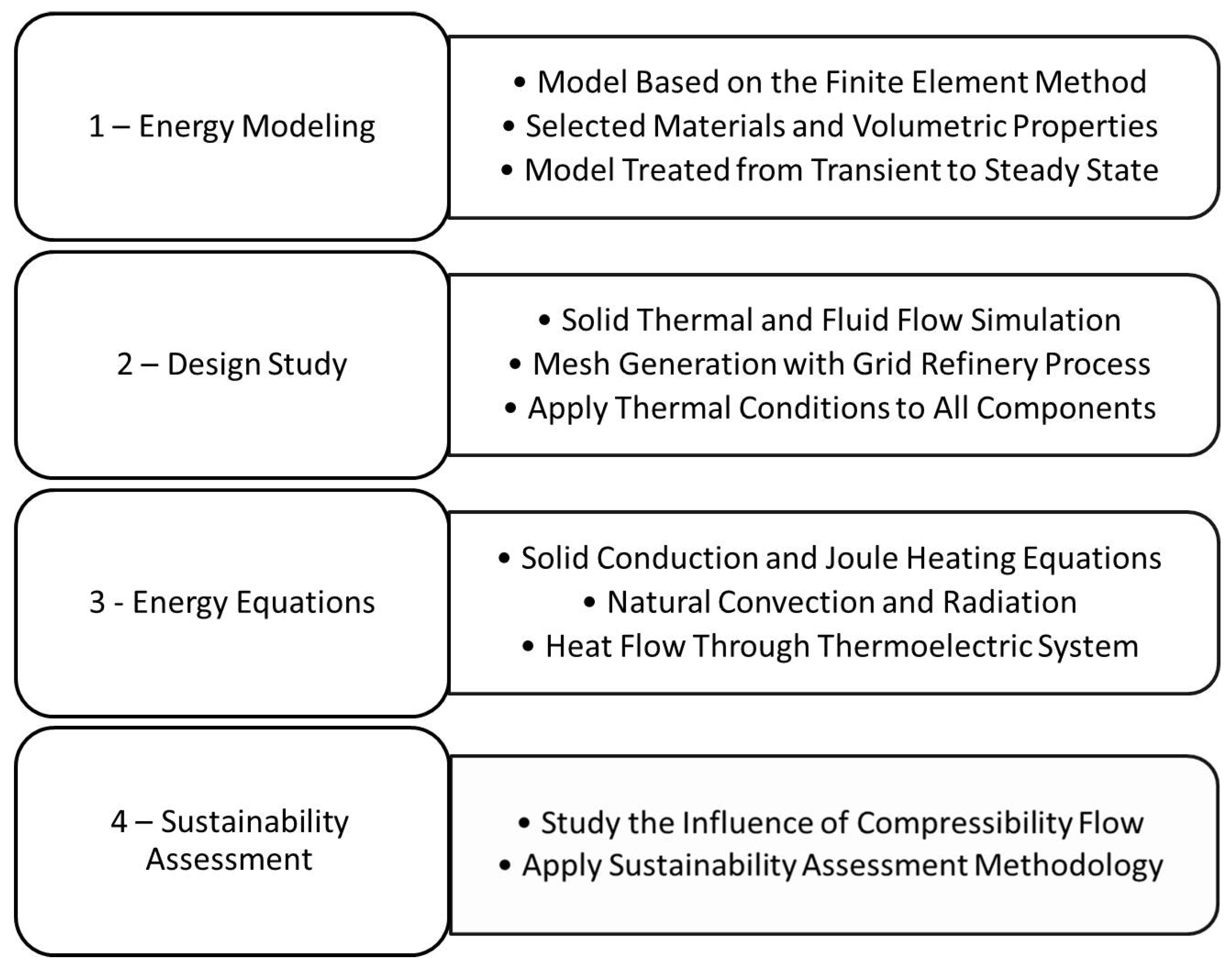

2. Methodology

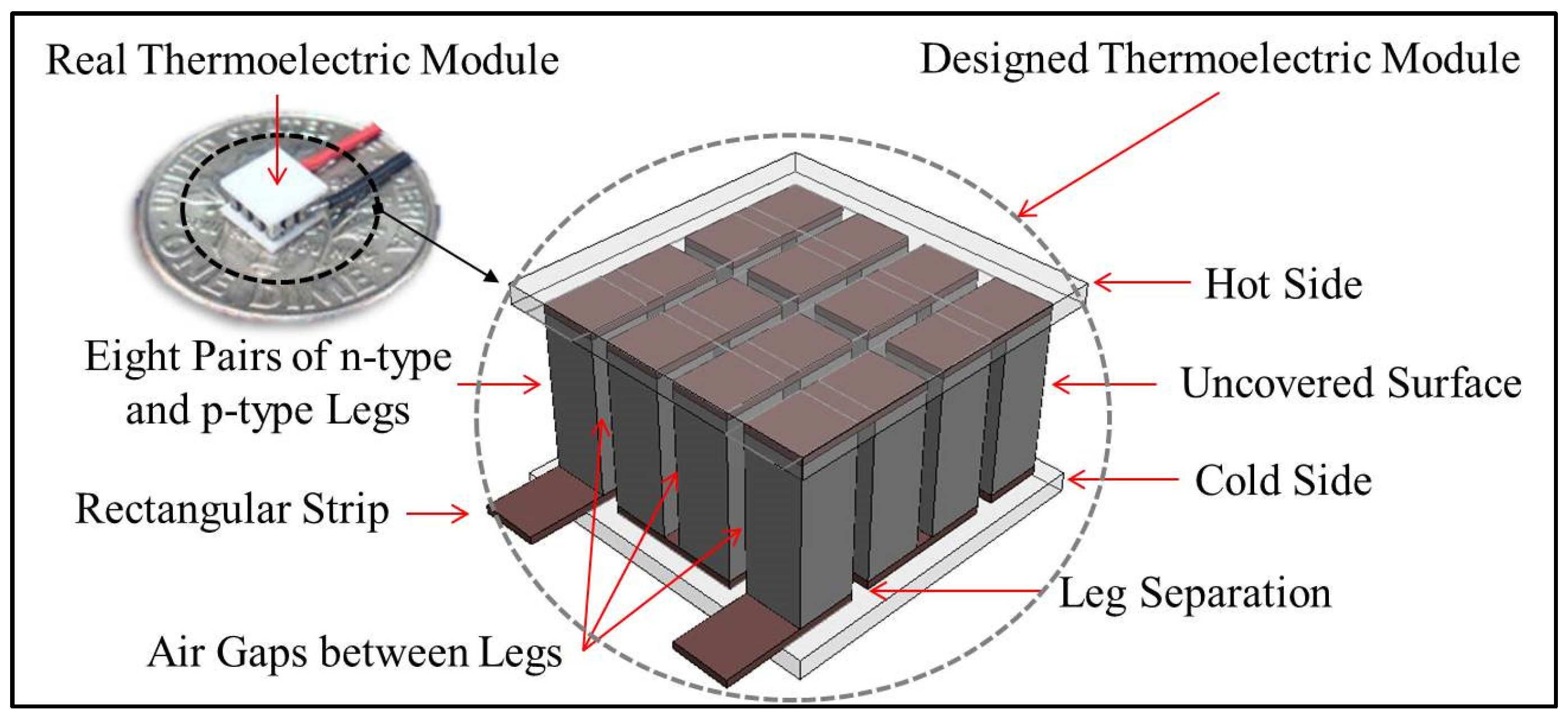

2.1. Integrated System Description

2.2. Energy Analysis—Theoretical Modeling

2.2.1. Assumptions

2.2.2. The Heat Balance

2.3. Energy Modeling—Thermal and Flow Simulations

2.3.1. Material and Volumetric Properties

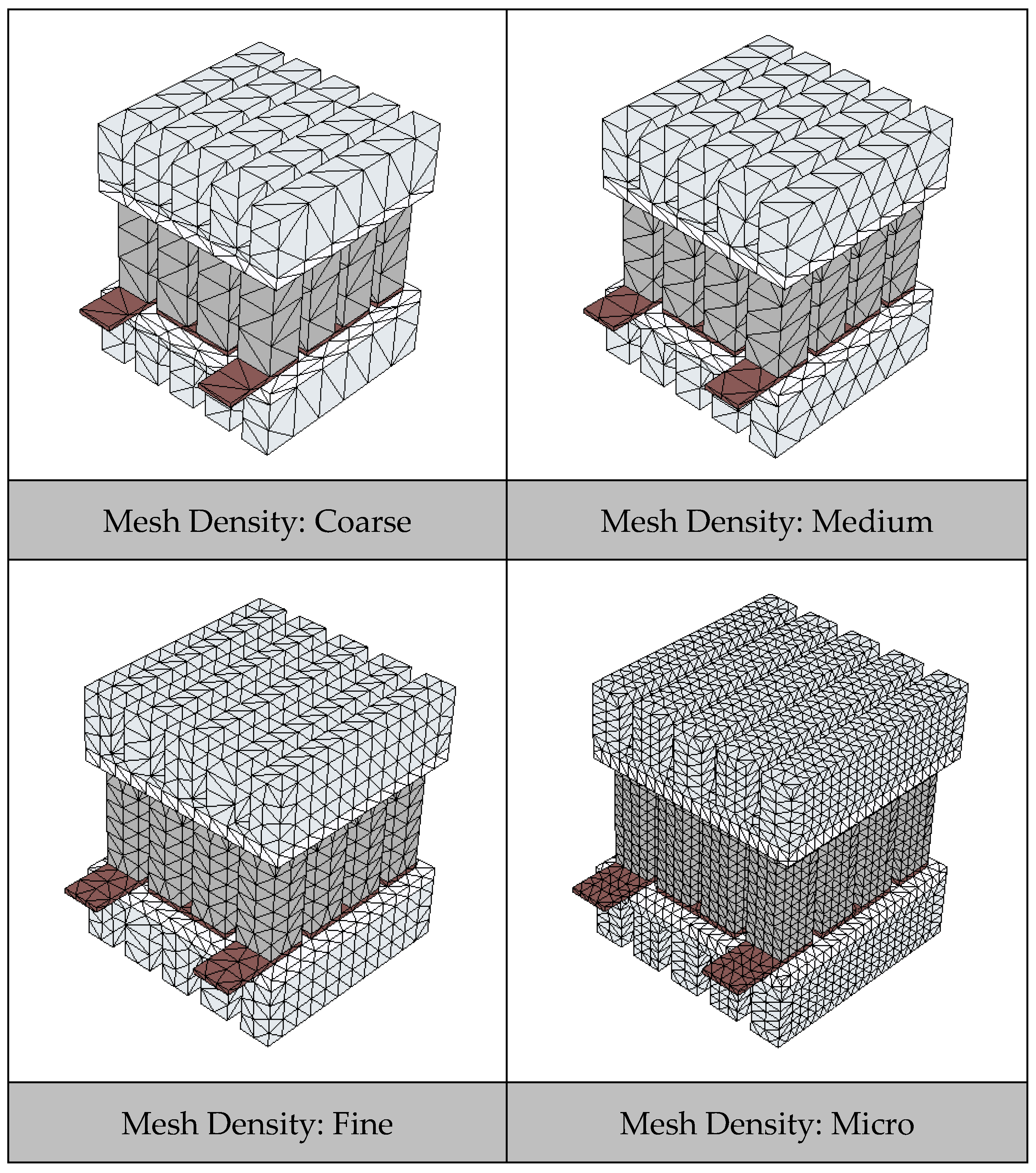

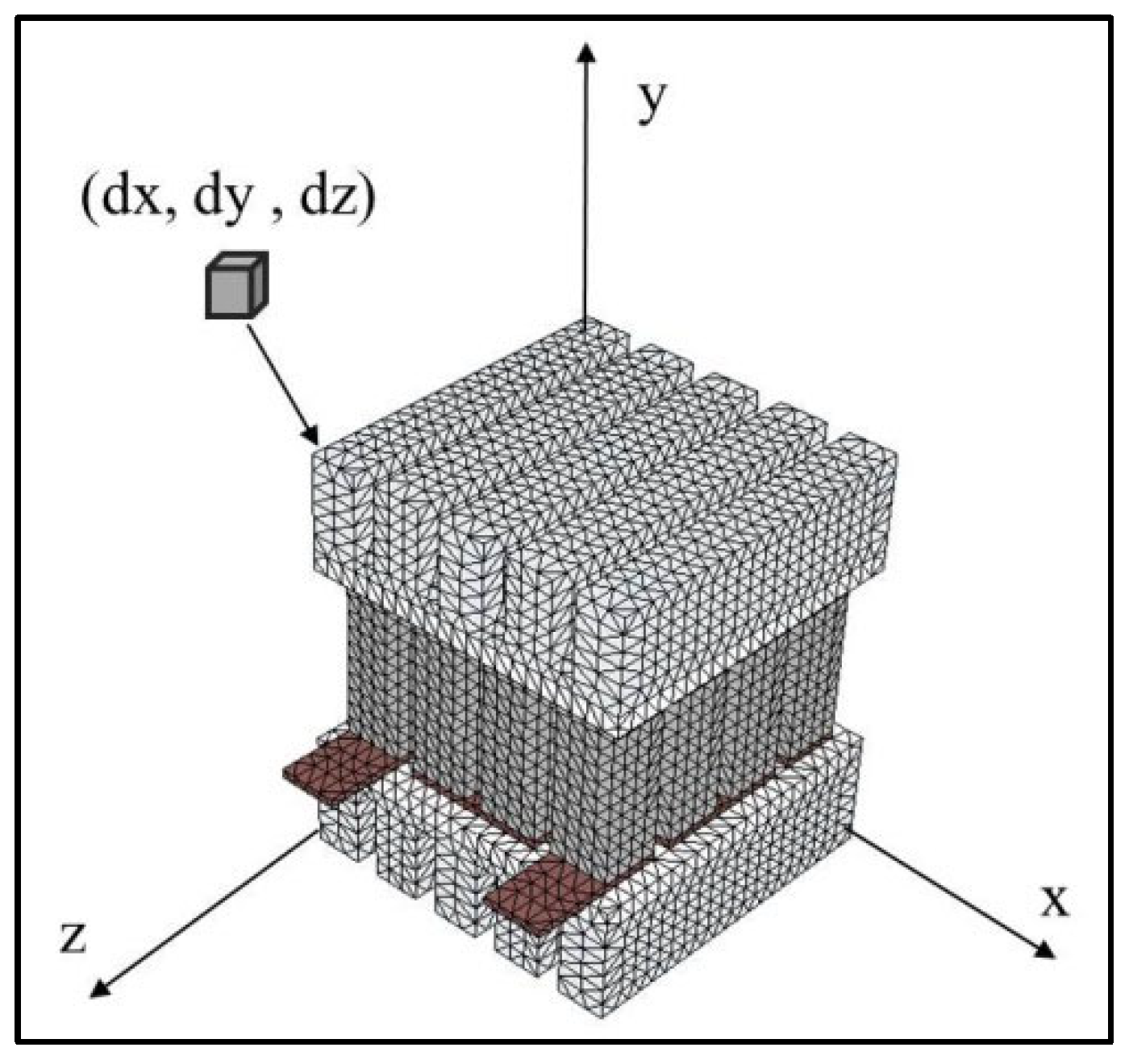

2.3.2. Mesh Generation

2.3.3. Thermal Conditions

- The model was improved to deal with the components of the micro-thermoelectric module (ceramic, semiconductor and copper strip) separately.

- The model was improved to calculate the conversion efficiency of the system at maximum temperature difference of the thermoelectric module.

- The model was improved to analyze the transfer of useful heat to electrical power and the thermal losses at maximum temperature difference of the module.

- The model can optimize the power output of the integrated micro-thermoelectric generator system.

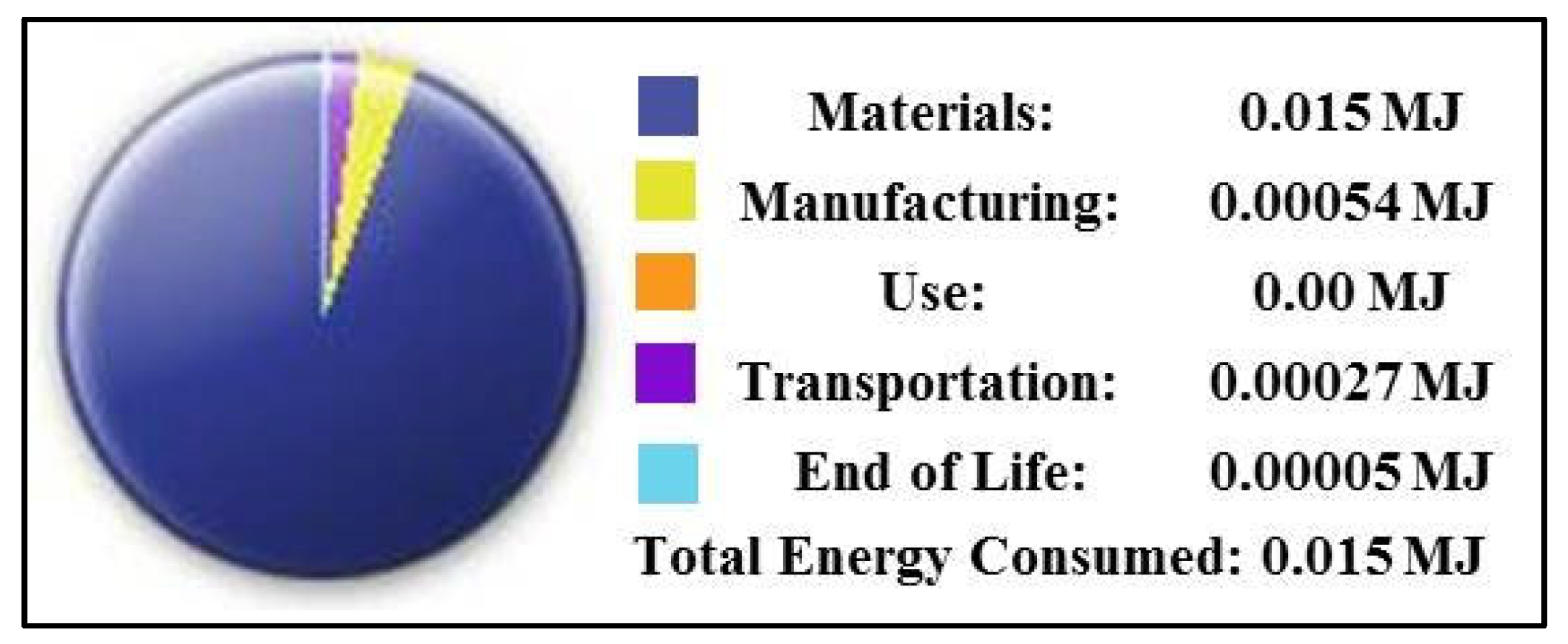

- The model was improved to estimate the total energy consumed to produce the integrated micro-thermoelectric generator system.

- The model was improved to be employed for medical and electronic micro-applications.

3. Results and Discussions

3.1. Temperature Difference

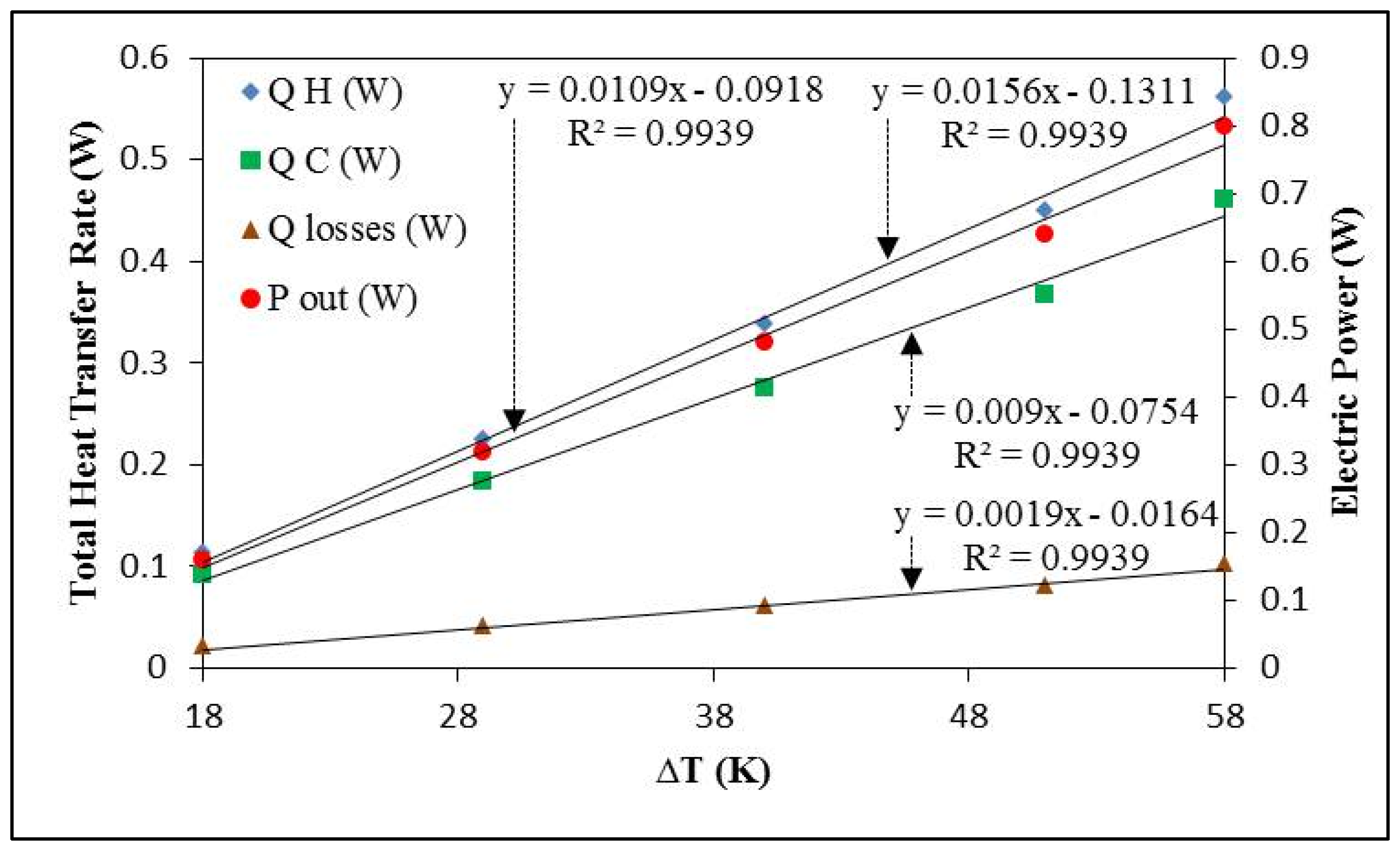

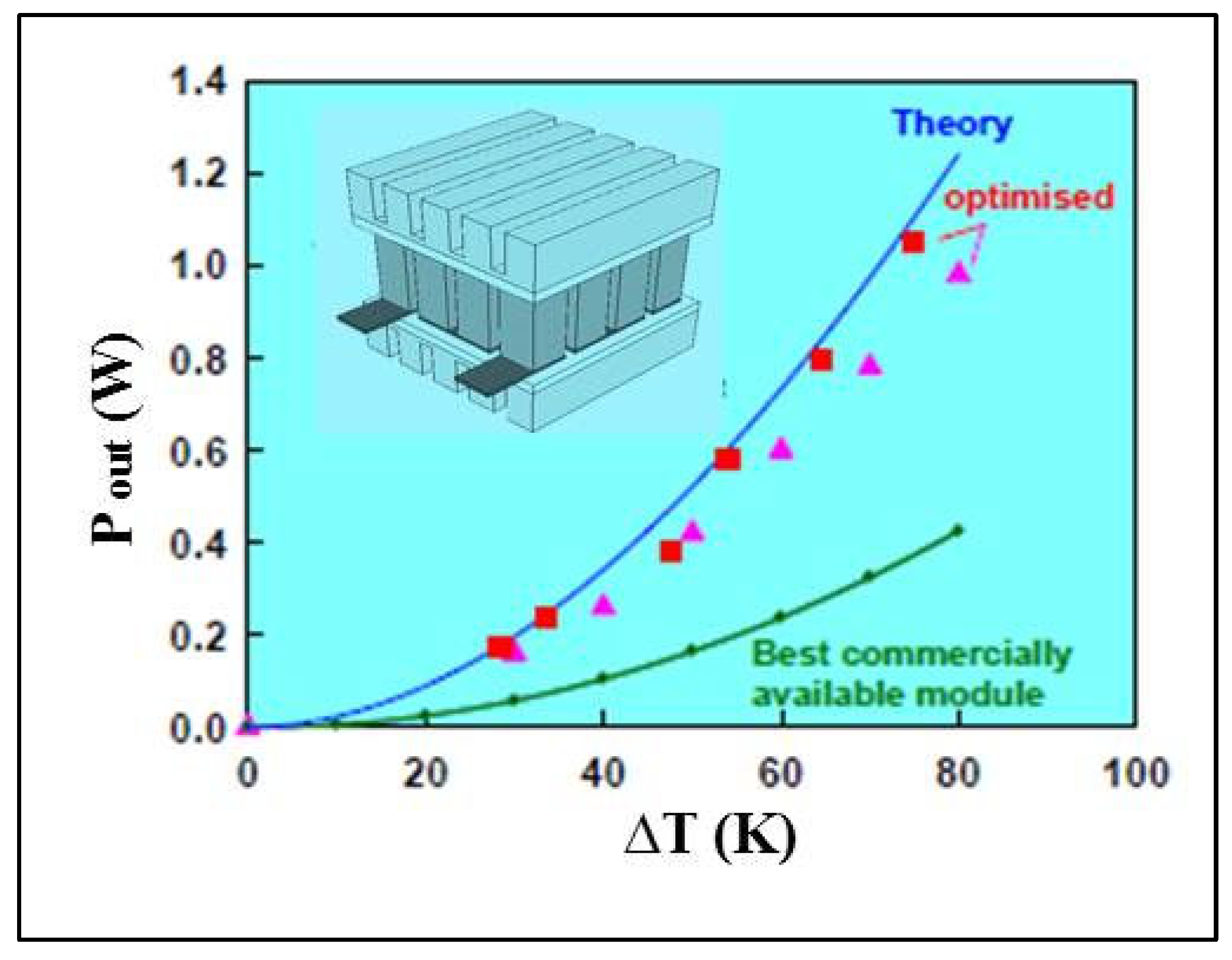

3.2. Total Heat Transfer Rate and Power Optimization

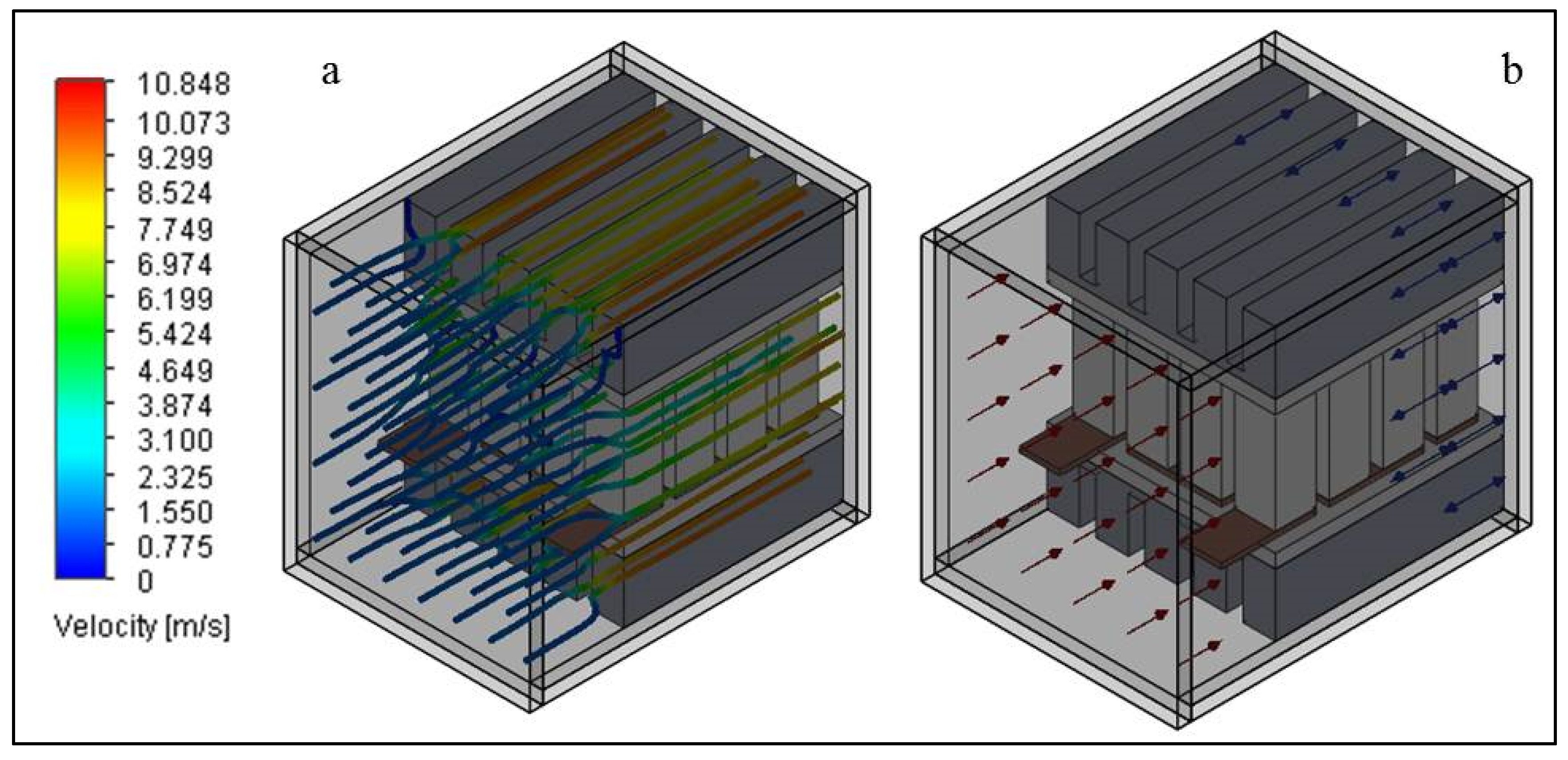

3.3. Influence of Compressibility inside the Integrated System

3.4. Conversion Efficiency of the Integrated System

3.5. Environmental Impacts

3.6. Validation of the Model with Experimental Works

3.7. Comparison between Different Modeling Strategies

4. Conclusions and Future Works

4.1. Conclusions

- The model is developed to deal with the components of the micro-thermoelectric module (ceramic, semiconductor, and copper strip) separately.

- We improved the conversion efficiency of the system by about 50% when we increased the temperature difference of the thermoelectric module from 18 K to 58 K.

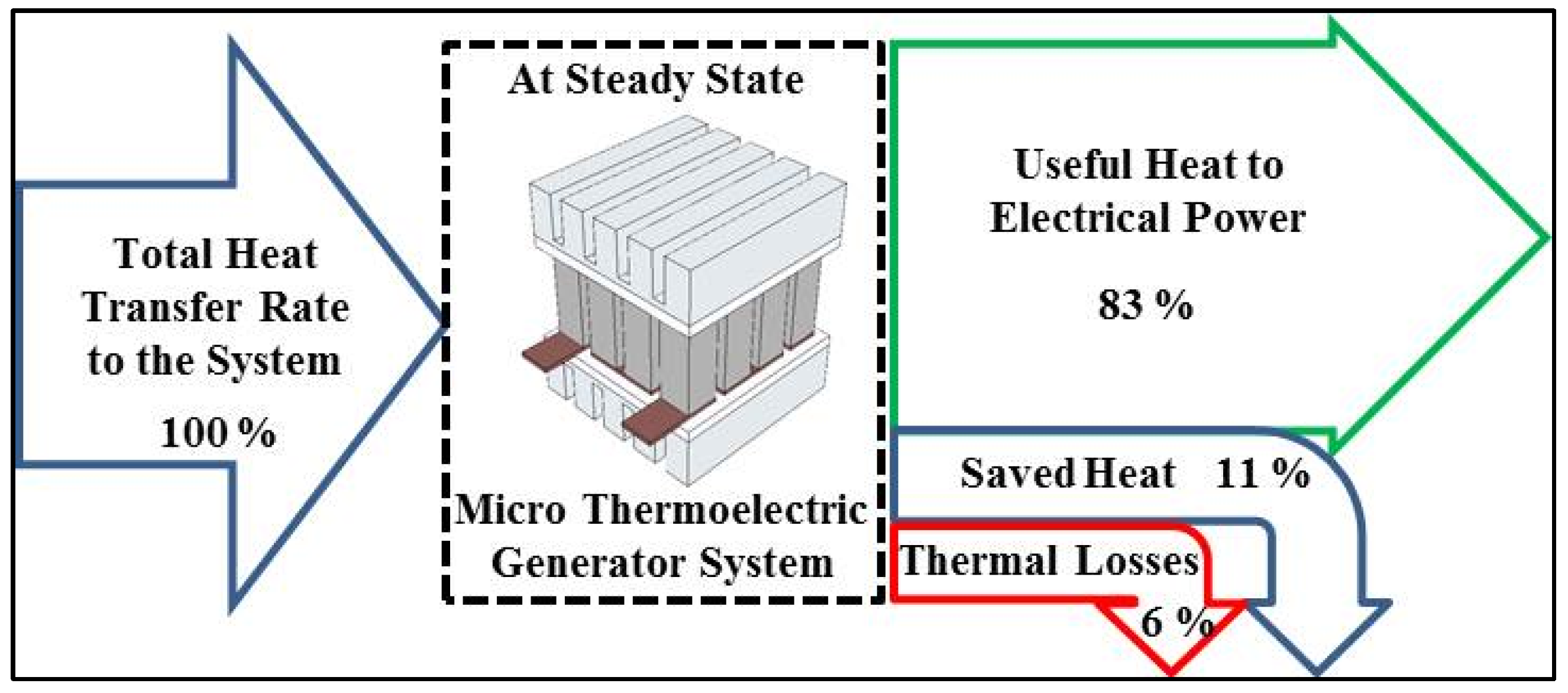

- We achieved a transfer of useful heat to electrical power of 83%, with 11% saved heat and thermal losses of 6% W at the maximum temperature difference of the module.

- We optimized the power output in the integrated micro-thermoelectric generator system at diverse temperature differences.

- We compared the present work with different modeling strategies to confirm that the computational modeling is accurate and efficient.

- The total energy consumed to produce the integrated micro-thermoelectric generator system was 0.015 MJ.

- The model can be employed for medical and electronic micro-applications.

- The model offers a promising route to utilize nano fluids for medical applications.

4.2. Future Works

4.2.1. Medical Application

- A.

- In the winter season, pumping heat from inside the face mask to the outside of the face mask (cooling mode);

- B.

- In the summer season, absorbing heat from inside the face mask to the outside of the face mask (heating mode).

4.2.2. Electronic Application

- Reducing the thermal losses because of the convection heat transfer in the thermoelectric legs through computational software;

- Using different thermoelectric semiconductor materials, such as lead telluride and silicon germanium;

- Comparing the performance of the integrated micro-thermoelectric generator system with micro chemical batteries and mobile electronics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| List of Symbols | ε | Emissivity | |

| A | Surface Area (m2) | ξ | Conversion Efficiency (%) |

| h | Heat Transfer Coefficient (W/m2.K) | σ | Stefan Boltzmann Constant |

| I | Electrical Current (A) | Subscripts | |

| K | Thermal Conductivity (W/m.K) | Al | Aluminum |

| N | Number of TE Legs | avg | Average |

| P | Electrical Power (W) | C | Cold Side of TE Module |

| Heat Transfer Rate (W) | Conv | Convection | |

| R | Electrical Resistance (Ω) | H | Hot Side of TE Module |

| T | Temperature (K) | hs | Heat Sink |

| TE | Thermoelectric | in | In the System |

| U | Overall Heat Transfer Coefficient (W/m2.K) | loss | Losses |

| Greek Letters | out | Out the System | |

| α | Seebeck Coefficient (V/K) | rad | Radiation |

| ∆ | Difference | s | Saved Heat |

References

- Wielosz, S.E.; Clifford, C.E.; Yu, K.; Barry, M.M. Fully-coupled thermal modeling of thermal generators. Energy 2023, 266, 126324. [Google Scholar] [CrossRef]

- Zhang, A.; Pang, D.; Wang, B.; Wang, J. Dynamic responses of wearable thermoelectric generators used for skin waste heat harvesting. Energy 2023, 262, 125621. [Google Scholar] [CrossRef]

- Wu, W.; Smaisim, G.F.; Sajadi, S.M.; Fagiry, M.A.; Li, Z.; Shamseldin, M.A.; Aybar, H.Ş. Impact of phase change material-based heatsinks on lithium-ion battery thermal management: A comprehensive review. J. Energy Storage 2022, 52 Pt B, 10487. [Google Scholar] [CrossRef]

- Liu, J.; Yadav, S.; Kim, S. Performance of a thermoelectric generator system for waste heat recovery utilizing plate fin heat sink in bronze ingot casting industry. Case Stud. Therm. Eng. 2022, 38, 102340. [Google Scholar] [CrossRef]

- Al-Madhhachi, H.; Min, G. Effective use of thermal energy at both hot and cold side of thermoelectric module for developing efficient thermoelectric water distillation system. Energy Convers. Manag. 2017, 133, 14–19. [Google Scholar] [CrossRef]

- Al-Madhhachi, H.; Min, G. Key factors affecting the water production in a thermoelectric distillation system. Energy Convers. Manag. 2018, 165, 459–464. [Google Scholar] [CrossRef]

- Champier, D. Thermoelectric generators: A review of applications. Energy Convers. Manag. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Min, G.; Rowe, D.M. Cooling performance of integrated thermoelectric microcooler. Solid-State Electron. 1999, 43, 923–929. [Google Scholar] [CrossRef]

- Tang, H.; Bai, H.; Yang, X.; Cao, Y.; Tang, K.; Zhang, Z.; Chen, S.; Yang, D.; Su, X.; Yan, Y.; et al. Thermal stability and interfacial structure evolution of Bi2Te3-based micro-thermoelectric devices. J. Alloys Compon. 2022, 896, 163090. [Google Scholar] [CrossRef]

- Yang, X.; Wang, C.; Lu, R.; Shen, Y.; Zaho, H.; Li, J.; Li, R.; Zhang, L.; Chen, H.; Zhang, T.; et al. Progress in measurement of thermoelectric properties of micro/nano thermoelectric materials: A critical review. Nano Energy 2022, 101, 107553. [Google Scholar] [CrossRef]

- Hu, X.; Takazawa, H.; Nagase, K.; Ohta, M.; Yamamoto, A. Three-dimensional finite-element simulation for a thermoelectric generator module. J. Electron. Mater. 2015, 44, 3637–3645. [Google Scholar] [CrossRef]

- Yu, S.; Du, Q.; Diao, H.; Shu, G.; Jiao, K. Start-up modes of thermoelectric generator based on vehicle exhaust waste heat recovery. Appl. Energy 2015, 138, 276–290. [Google Scholar] [CrossRef]

- Montecucco, A.; Buckle, J.R.; Knox, A.R. Solution to the 1-D unsteady heat conduction equation with internal Joule heat generation for thermoelectric devices. Appl. Therm. Eng. 2012, 35, 177–184. [Google Scholar] [CrossRef]

- Montecucco, A.; Knox, A.R. Accurate simulation of thermoelectric power generating systems. Appl. Energy 2014, 118, 166–172. [Google Scholar] [CrossRef]

- Naji, M.; Alata, M.; Al-Nimr, M.A. Transient behaviour of a thermoelectric device. Proc. Inst. Mech. Eng. Part A J. Power Energy 2003, 217, 615–621. [Google Scholar] [CrossRef]

- Martínez, A.; Astrain, D.; Rodríguez, A. Dynamic model for simulation of thermoelectric self cooling applications. Energy 2013, 55, 1114–1126. [Google Scholar] [CrossRef]

- Jang, B.; Han, S.; Kim, J.Y. Optimal design for micro-thermoelectric generators using finite element analysis. Microelectron. Eng. 2011, 88, 775–778. [Google Scholar] [CrossRef]

- Lee, H. Optimal design of thermoelectric devices with dimensional analysis. Appl. Energy 2013, 106, 79–88. [Google Scholar] [CrossRef]

- Li, W.; Paul, M.C.; Siviter, J.; Montecucco, A.; Knox, A.R.; Sweet, T.; Min, G.; Baig, H.; Mallick, T.K.; Han, G.; et al. Thermal performance of two heat exchangers for thermoelectric generators. Case Stud. Therm. Eng. 2016, 8, 164–175. [Google Scholar] [CrossRef]

- Sarhadi, A.; Bjork, R.; Lindeburg, N.; Viereck, P.; Pryds, P. A thermoelectric power generating heat exchanger: Part II: Numerical modeling and optimization. Energy Convers. Manage 2016, 119, 481–487. [Google Scholar] [CrossRef]

- Högblom, O.; Andersson, R. A simulation framework for prediction of thermoelectric generator system performance. Appl. Energy 2016, 180, 472–482. [Google Scholar] [CrossRef]

- Fraisse, G.; Ramousse, J.; Sgorlon, D.; Goupil, C. Comparison of different modeling approaches for thermoelectric elements. Energy Convers. Manage 2013, 65, 351–356. [Google Scholar] [CrossRef]

- Chen, M.; Rosendahl, L.A.; Condra, T. A three-dimensional numerical model of thermoelectric generators in fluid power systems. Int. J. Heat. Mass. Transf. 2011, 54, 345–355. [Google Scholar] [CrossRef]

- Wang, X.; Qi, J.; Deng, W.; Li, G.; Gao, X.; He, L.; Zhang, S. An optimized design approach concerning thermoelectric generators with frustum-shaped legs based on three-dimensional Multiphysics model. Energy 2021, 233, 120810. [Google Scholar] [CrossRef]

- Jouharaa, H.; Żabnieńska-Góraa, A.; Khordehgaha, N.; Doraghia, Q.; Ahmad, L.; Norman, L.; Axcell, B.; Wrobel, L.; Dai, S. Thermoelectric generator (TEG) technologies and applications. Int. J. Thermofluids 2012, 9, 100063. [Google Scholar] [CrossRef]

- Siegel, N.; Gross, M.; Ho, C.; Phan, T.; Yuan, J. Physical Properties of Solid Particle Thermal Energy Storage Media for Concentrating Solar Power Application. Energy Procedia 2014, 49, 1015–1023. [Google Scholar] [CrossRef]

- Sarker, S.; Gukeh, M.; Roy, T.; Gaikwad, H.; Bellussi, F.; Moitra, S.; Megaridis, C. A New Methodology for Measuring Solid/Liquid Interfacial Energy. J. Colloid Interface Sci. 2023, 633, 800–807. [Google Scholar] [CrossRef]

- Sandoz-Rosado, E.; Weinstein, S.; Stevens, R. On the Thomson effect in thermoelectric power devices. Int. J. Therm. Sci. 2013, 66, 1–7. [Google Scholar] [CrossRef]

- Liu, W.; Yin, L.; Li, L.; Yang, Q.; Wang, D.; Li, M.; Shi, X.; Liu, Q.; Bai, Y.; Gentle, I.; et al. Grain boundary re-crystallization and sub-nano regions leading to high plateau figure of merit for Bi2Te3 nanoflakes. Energy Environ. Sci. 2023, 16, 5123–5135. [Google Scholar] [CrossRef]

- Lee, H.; Sharp, J.; Stokes, D.; Pearson, M.; Priya, S. Modeling and analysis of the effect of thermal losses on thermoelectric generator performance using effective properties. Appl. Energy 2018, 211, 987–996. [Google Scholar] [CrossRef]

- Liu, X.; Deng, Y.D.; Zhang, K.; Xu, M.; Xu, Y.; Su, C.Q. Experiments and simulations on heat exchangers in thermoelectric generator for automotive application. Appl. Therm. Eng. 2014, 71, 364–370. [Google Scholar] [CrossRef]

- Tyagi, K.; Gahtori, B.; Kumar, S.; Dhakate, S.R.X. Advances in solar thermoelectric and photovoltaic-thermoelectric hybrid systems for power generation. Sol. Energy 2023, 254, 195–212. [Google Scholar] [CrossRef]

| Component—Material | Amount | Volumetric Properties | Treated as |

|---|---|---|---|

| Heat Sink—Aluminum | 2 | Mass = 41.16 milligrams Volume = 15.25 mm3 Surface Area = 85.80 mm2 | Solid Body |

| TE Plate—Ceramic | 2 | Mass = 10.14 milligrams Volume = 4.41 mm3 Surface Area = 39.48 mm2 | Solid Body |

| TE Strip—Copper | 17 | Mass 1.16 milligrams Volume = 0.13 mm3 Surface Area = 3.10 mm2 | Solid Body |

| TE Leg—Bi2Te3 | 16 | Mass = 8.59 milligrams Volume = 1.12 mm3 Surface Area = 7.13 mm2 | Solid Body |

| Mesh Density | Coarse | Medium | Fine | Micro |

|---|---|---|---|---|

| Mesh Type | Solid | Solid | Solid | Solid |

| Mesh Used | Standard | Standard | Standard | Standard |

| Jacobian Points | 16 | 16 | 16 | 16 |

| Element Length | 0.817 mm | 0.613 mm | 0.357 mm | 0.104 mm |

| Tolerance | 0.0486 mm | 0.0306 mm | 0.0178 mm | 0.0085 mm |

| Mesh Quality | High | High | High | High |

| Total Elements | 2970 | 4026 | 13,476 | 55,691 |

| Total Nodes | 5769 | 7937 | 23,563 | 88,194 |

| Maximum Aspect Ratio | 26.368 | 16.186 | 5.315 | 1.006 |

| Quality of Elements | 46.7% | 59% | 90.9% | 99.7% |

| Component | Conditions | Condition Image | Conditions Details |

|---|---|---|---|

| Hot Surface Heat Sink | 1—Initial Temperature 2—Solid Conduction 3—Natural Convection 4—Heat Radiation |  | Entities = 22 T initial = 20 °C h air = 10 W/(m2.K) Emissivity: 0.95 K Al = 237 W/(m.K) State = Transient to Steady State |

| Thermoelectric Module | 1—Initial Temperature 2—Solid Conduction 3—Natural Convection 4—Heat Radiation |  | Entities = 178 T initial = 20 °C U overall = 1.72 W/K Emissivity: 0.95 K overall = 0.01 W/(m.K) State = Transient to Steady State |

| Cold Surface Heat Sink | 1—Initial Temperature 2—Solid Conduction 3—Natural Convection 4—Heat Radiation |  | Entities = 22 T initial = 20 °C h air = 10 W/(m2.K) Emissivity: 0.95 K Al = 237 W/(m.K) State = Transient to Steady State |

| Modeling Strategy | [11] | [19] | [23] | [24] | [25] | [30] | [31] | [32] | Present Work |

|---|---|---|---|---|---|---|---|---|---|

| Design a thermoelectric module with all Parts | Yes | No | No | Yes | Yes | Yes | No | No | Yes |

| Model Including Three-Dimensional Solution | Yes | No | Yes | Yes | Yes | Yes | Yes | No | Yes |

| Model Including Heat Transfer Rate in and out | Yes | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes |

| Model based on the Finite Element Method | Yes | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes |

| Model Treated from Transient to Steady State | Yes | No | Yes | No | No | No | Yes | No | Yes |

| Variable Temperatures as Boundary Conditions | No | Yes | Yes | No | Yes | No | Yes | Yes | Yes |

| Solid Conduction and Joule Heating Effects | Yes | No | Yes | Yes | Yes | Yes | No | No | Yes |

| Natural Convection and Radiation Effects | Yes | No | No | No | No | No | No | No | Yes |

| Energy Balance between Heat and Electricity | Yes | Yes | Yes | Yes | No | No | Yes | Yes | Yes |

| Analysis of Useful Heat Flow and Thermal Losses | No | No | No | No | No | Yes | No | No | Yes |

| Study the Influence of Compressibility Flow | No | No | No | No | No | No | No | No | Yes |

| Apply Sustainability Assessment Methodology | No | No | No | No | No | No | No | No | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ajeena, A.M.; Al-Madhhachi, H.; Almadhhachi, M. Advanced Energy Modeling and Prediction of Integrated Micro-Generator System for Useful Heat Harvesting. Eng 2024, 5, 1995-2015. https://doi.org/10.3390/eng5030106

Ajeena AM, Al-Madhhachi H, Almadhhachi M. Advanced Energy Modeling and Prediction of Integrated Micro-Generator System for Useful Heat Harvesting. Eng. 2024; 5(3):1995-2015. https://doi.org/10.3390/eng5030106

Chicago/Turabian StyleAjeena, Ahmed M., Hayder Al-Madhhachi, and Mensour Almadhhachi. 2024. "Advanced Energy Modeling and Prediction of Integrated Micro-Generator System for Useful Heat Harvesting" Eng 5, no. 3: 1995-2015. https://doi.org/10.3390/eng5030106

APA StyleAjeena, A. M., Al-Madhhachi, H., & Almadhhachi, M. (2024). Advanced Energy Modeling and Prediction of Integrated Micro-Generator System for Useful Heat Harvesting. Eng, 5(3), 1995-2015. https://doi.org/10.3390/eng5030106