Abstract

A novel forming process was developed to create rotating elements in collector coins by shaping thin-walled tubes into toroidal shells in a single stage. This process introduces new aesthetic effects and functionalities to the coin market. By controlling the end-forming of a tube, a gap is created between the toroidal shell and the coin blank, allowing free rotation. The technique, a modification of conventional tube end inversion, results in distinct deformation mechanics. Through finite element modeling and experimentation, key process variables were identified, ensuring sound hollow toroidal shells with efficient rotation.

1. Introduction

The combination of joining by forming with coin minting has been applied to the development of disruptive collector coins with innovative functionalities and alternative materials such as a new type of bi-material coin with a polymer centre and a metal ring , where the deformation of the polymer core can be controlled to enable the incorporation of advanced security features and/or aesthetic effects [1].

Coin minting, an ancient metal-forming process, continues to evolve as mints globally compete to produce advanced products [2] with complex shapes and innovative materials [3]. Like other forming processes, finite element models are used to predict plastic flow, strain, stress, damage, and force requirements [4]. This software helps address production challenges, extending tool life and reducing costs [5].

Recent developments in incremental forming and hybrid metal manufacturing continue to expand functional possibilities in collector coins [6]. Additive manufacturing has also played a growing role in coin minting and component integration [7,8].

The integration of tube-forming operations such as tube joining through asymmetric plastic instability applied to inclined tube attachments [9], the use of mechanical interlocks concealed within the inner diameters of the tubes to be joined [10], and tube flaring for the formation of single-lap flanges by compressing the free tube end with a contoured die [11] has been employed in the fabrication of joints between tubes and tubesheets, as well as between tubes and sheet panels [12]. These tube-forming operations are thereby extended to the production of double-lap flanges obtained by axial compression of the ends of a tube with two hemi-toroidal shaped dies until achieving the desired geometry and producing a loose connection with a disk blank that allows the two elements to rotate upon each other. The forming process follows the principle of shaping thin-walled tubes into toroidal shells [13] in a single- or double-stage operation according to the coin design specifications.

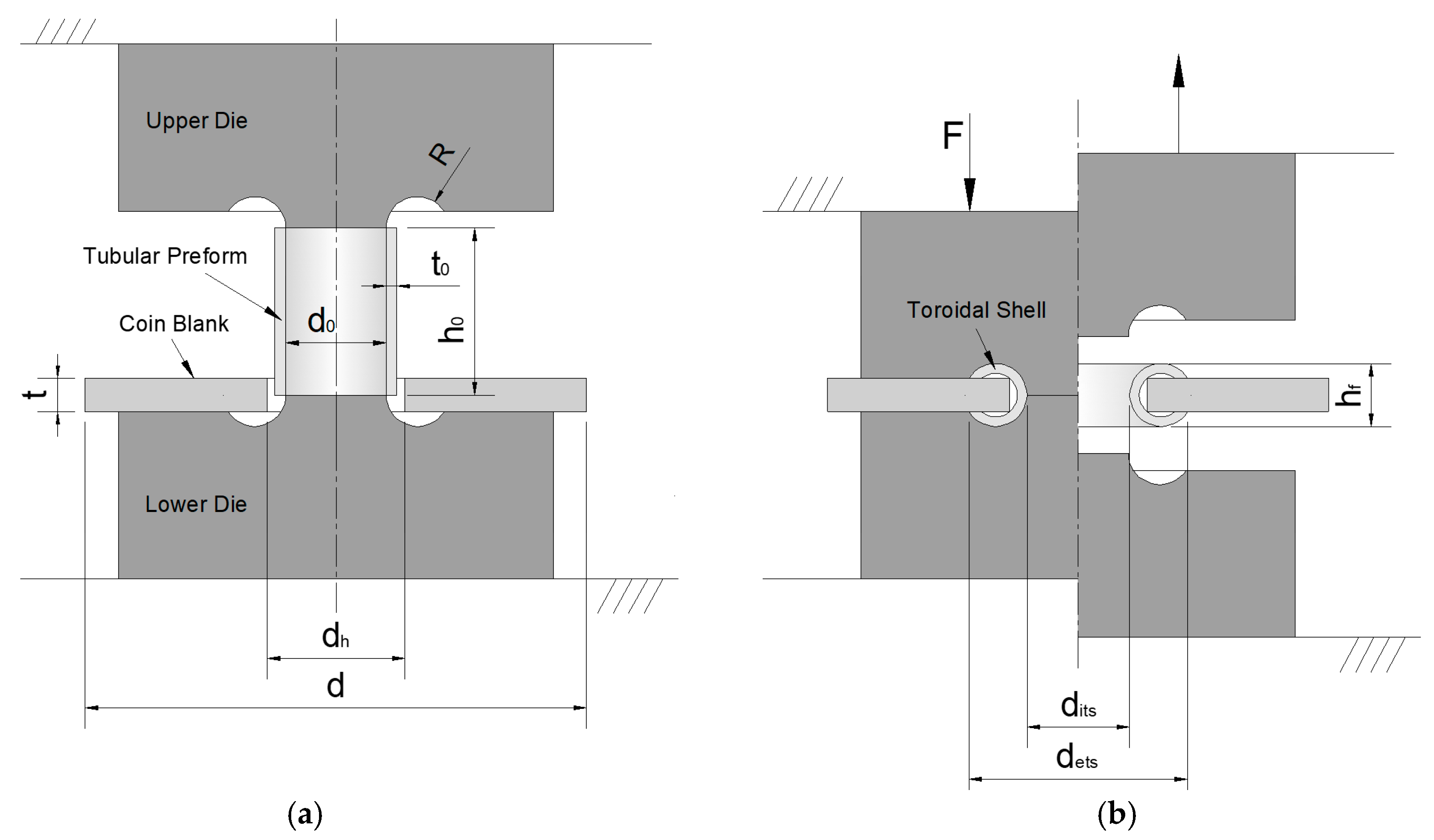

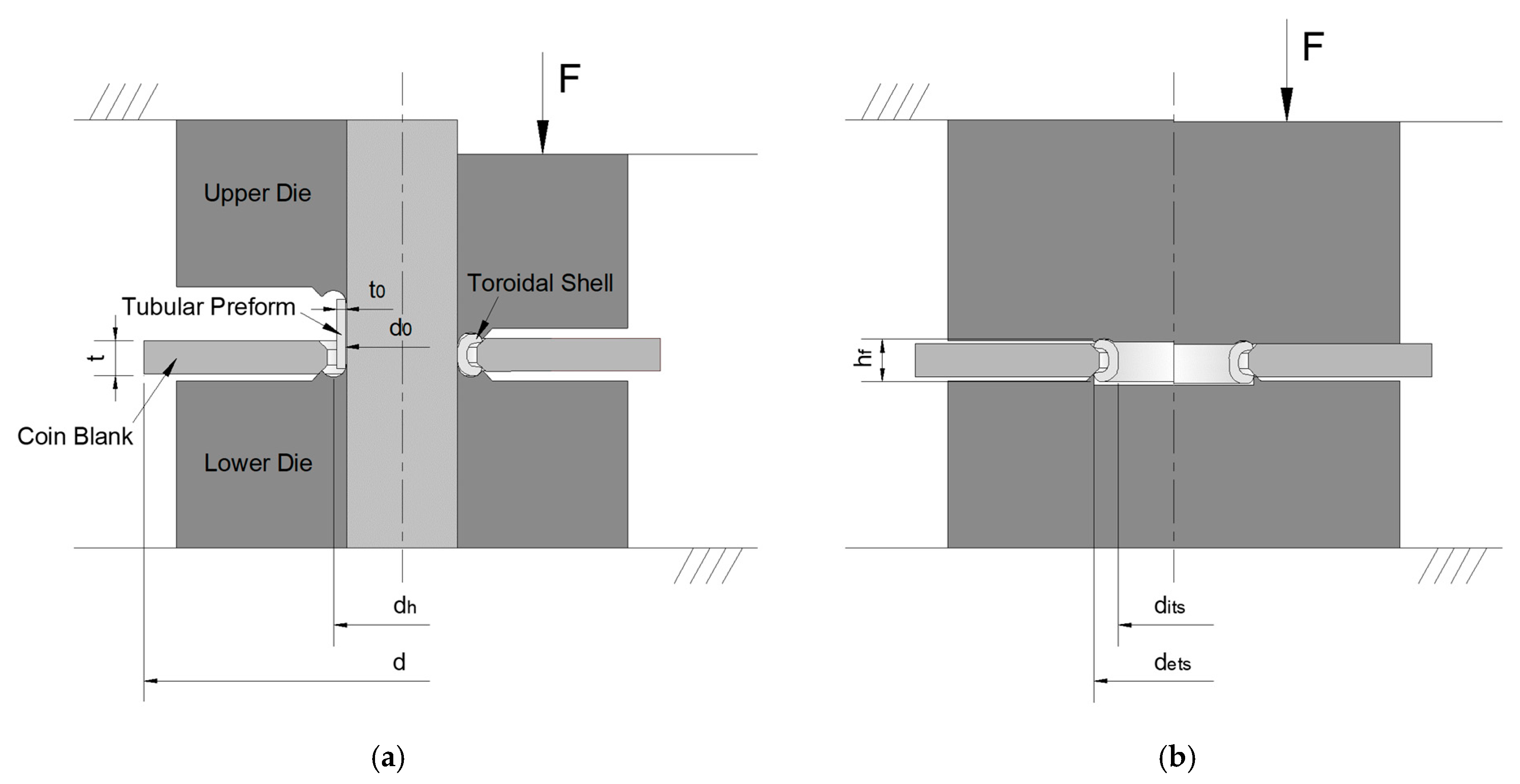

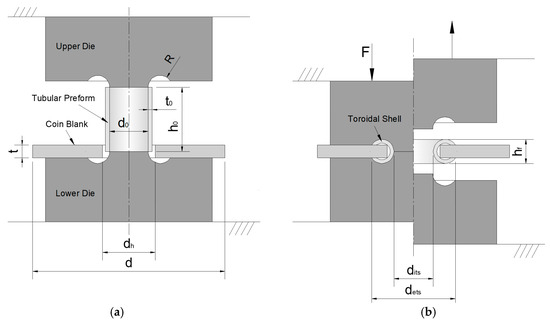

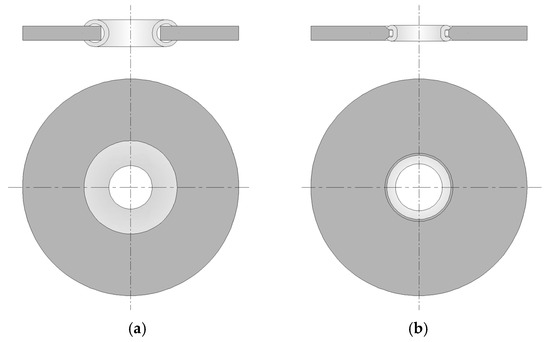

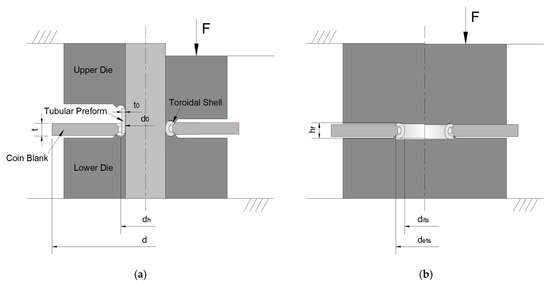

The tool setup is presented in Figure 1 where the process variables of the tube and the flaring radius R define the axis of rotation and the cross-section of the shell. To avoid crushing the tube ends against the disk and/or to prevent fracture during forming, restrictions need to be introduced to both the dies and the geometry of the preforms, as discussed in the paper.

Figure 1.

Schematic representation of the main concept for producing a coin with a rotating toroidal shell at the (a) start and (b) end of the die stroke for a single-stage operation.

The main purpose is to introduce a solution for coin minting that relies on conventional external inversion of tubes [11] to obtain sound hollow toroidal shells from end-forming of thin-walled tubes [13] with free rotation of the coin blank, creating new effects and possibilities for the coin collector market. The appropriate geometries of both the tube and blank are evaluated with different designs, along with the force and energy requirements for each solution, as well as their feasibility, employing numerical and experimental analysis [14,15,16,17,18,19]. This allows to understand the mechanics of deformation behind the joining process of the two elements and to identify the main operating parameters that establish the limits of the process. Two different cross-sections for the toroidal shells are analysed and strategies are provided to produce the free mechanical connection in one single stage or two consecutive operations according to the intended coin design to offer an effective contribution to the knowledge transfer of this technology. Further insights from micro-tube forming [20], incremental expansion techniques [21], and strain-hardening sheet bending [22] broaden the relevance of the proposed approach. Simulations incorporating finite element hydroforming [23,24], as well as applications in biomedical forming [25], illustrate the generalizability of the process across industries.

2. Materials and Methods

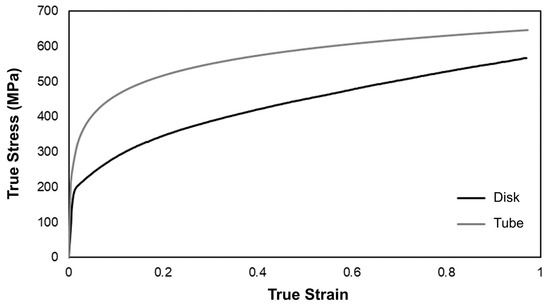

2.1. Stress–Strain Behavior of the Tube and Disk Material

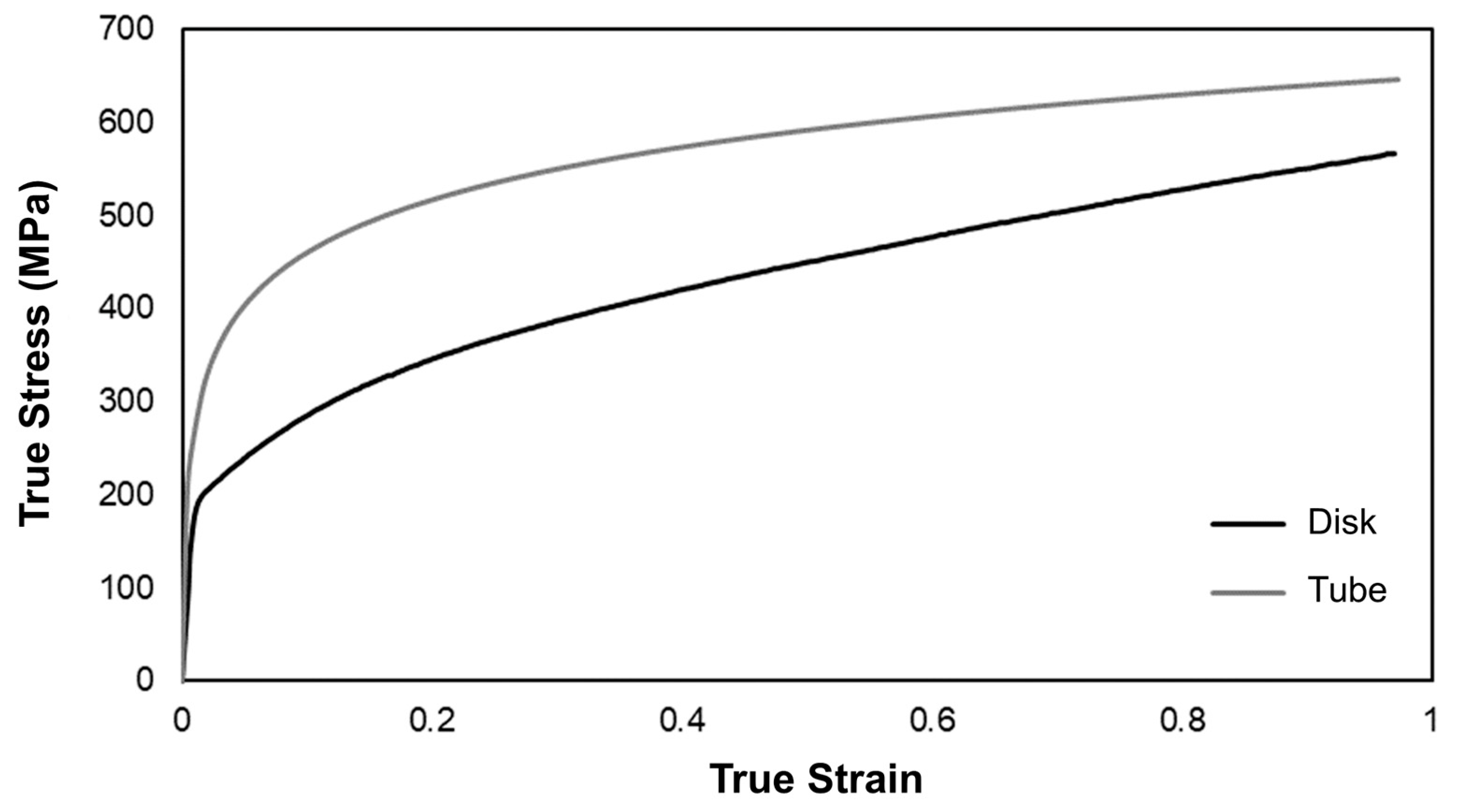

The research started with the mechanical characterization of the materials of each element to be employed in the fabrication of the coins with a rotating element. Since this concept is initially applied to proof coins, the chosen material for both elements was Silver (Ag925). The stress–strain response of the material was obtained from stack compression tests performed in piled-up cylindrical specimens cut from the original geometries in which the materials were supplied. Due to their manufacturing process, the stress–strain curve of the tube and disk presents slight differences, as can be observed in Figure 2. Those differences can also be justified by the different levels of superficial micro hardness verified, with the tubes having a Vickers hardness of 128 HV while the disks have a Vickers hardness of 114 HV, which confirms the higher levels of strain-hardening suffered by the tubes as a result of their manufacturing process and justifies that for the same strain levels, the tube material presents higher stress levels than the disk, despite their similar chemical composition.

Figure 2.

Flow curves of Ag925 supplied in disk and tube shapes.

The principal mechanical properties of 925 silver are outlined in Table 1. The values may vary depending on the tempering process and the method of manufacture.

Table 1.

Main mechanical properties of 925 silver.

Coin blanks with a diameter of 32.65 ± 0.05 mm and a thickness of 1.65 mm have a central hole with a diameter of 8.25 mm. The tubes with an external diameter of 7.50 mm, a thickness of 0.5 mm, and different heights (refer to Table 2) were utilized in the entire set of tests that were performed at the hydraulic testing machine INSTRON SATEC 1200 kN (manufactured by Instron, ITW group, located in Norwood, MA, USA) with a constant crosshead speed of 10 mm/min at ambient temperature.

Table 2.

Specifications of the different dimensional parameters analyzed.

2.2. Forming of Toroidal Shell

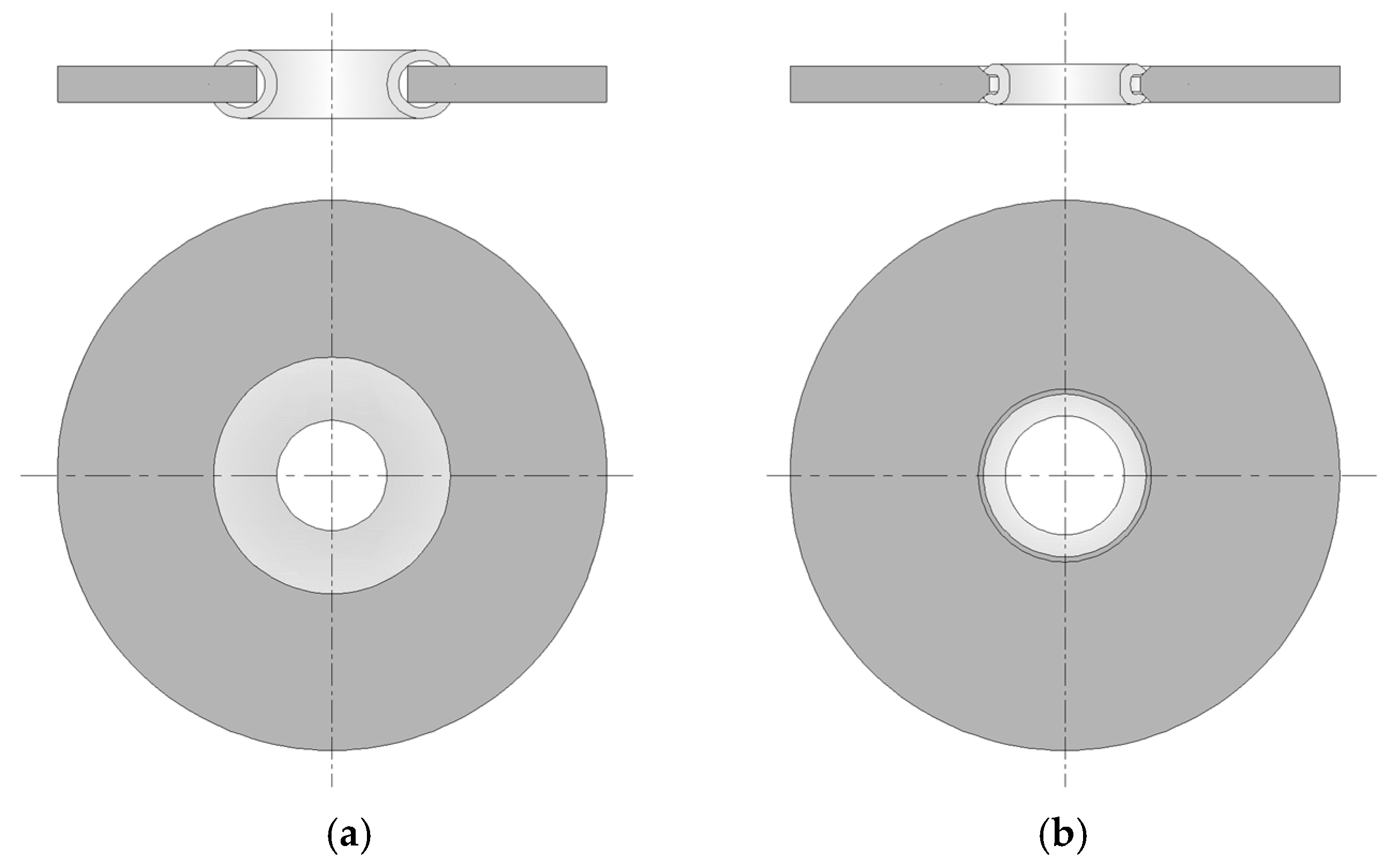

Two different cross-sections were analyzed for the fabrication of the toroidal shells that are the basis of the coin with a rotating element: a circular section (Figure 3a) and a non-circular C-shaped section (Figure 3b). These two types of sections allow to produce different aesthetic effects and at the same time offer a proper control of the gap between the toroidal shell and the disk.

Figure 3.

Comparison between (a) a circular and (b) a C-shaped section.

The main process variables other than the initial variables of the tubular preform are the internal diameter and external diameter of the correspondent toroidal shell and its final height . That internal diameter cannot be lower than the initial disk thickness if a totally circular toroidal shell that embraces the disk is to be guaranteed.

The main differences between the two iterations are that the non-circular section allows to have a toroidal shell with much lower volume than the circular section, without a protrusion above the disk and with a straight inner wall. This allows to have a larger area for engraving while the rotation is guaranteed by the chamfered hole that acts as a rotation pivot.

The free rotation in the non-circular section is assured by a localized and discontinuous contact in-between the toroidal shell and disk, which in comparison with the larger contact verified on the circular section allows for higher levels of rotation of the two elements upon each other.

3. Numerical Simulations

The finite element software i-form (Version 8.01) [14] was employed to produce numerical predictions of the forming of thin-walled tubes into toroidal shells since they were performed under a quasi-static constant displacement rate and no inertial effects nor dynamic effects in the forming mechanisms need to be considered. An extension of the finite element flow formulation to include the relaxation of the incompressibility condition of the velocity field by means of a penalty function and the contact between rigid and deformable objects is the basis of the numerical modelling software. This approach aligns with emerging mesh-free numerical methods used for the simulation of complex forming processes [15,16].

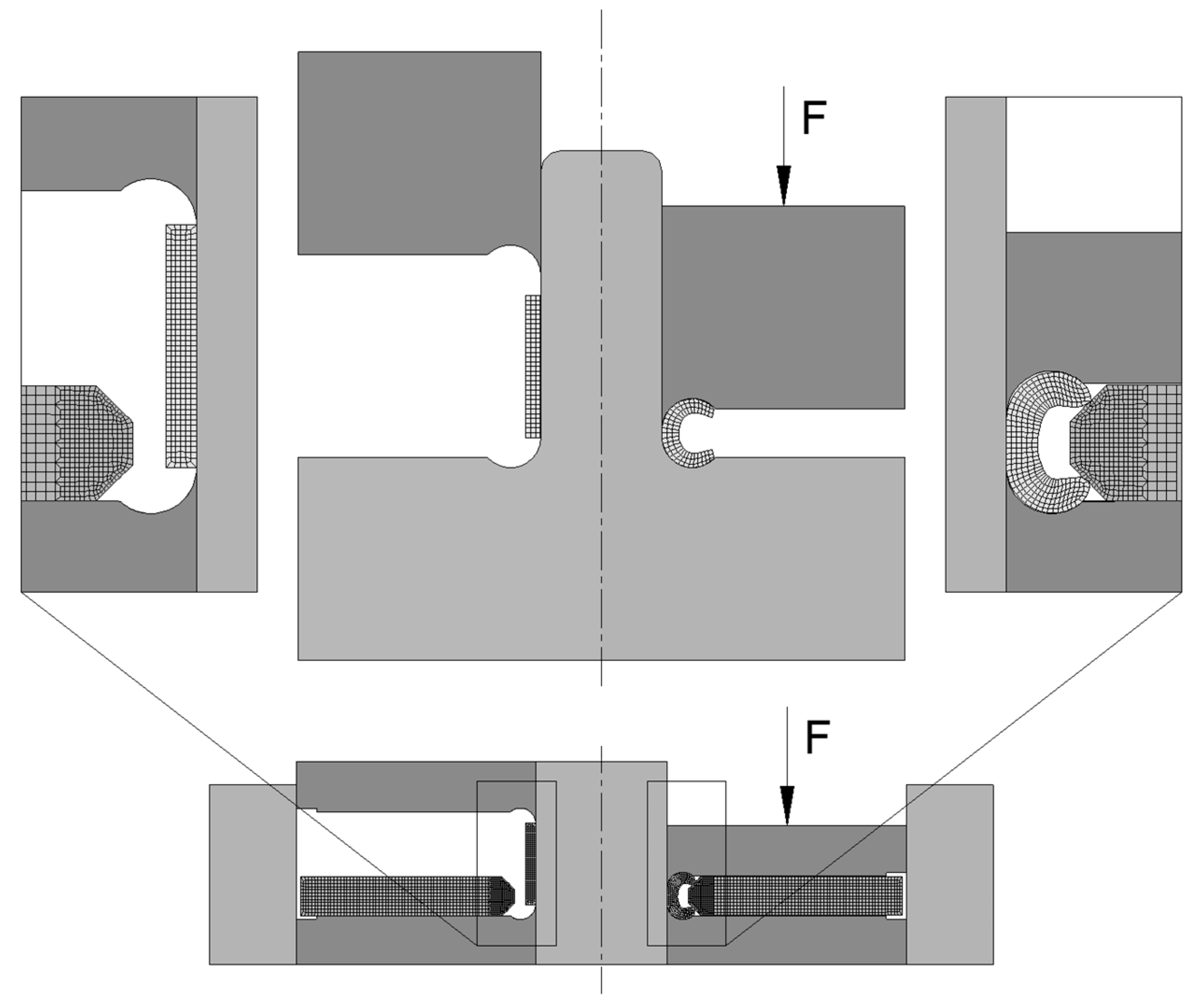

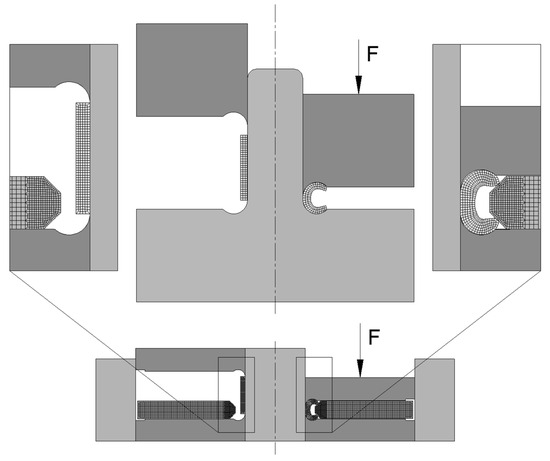

The initial cross-sections of the tubular and disk preforms were modelled as deformable isotropic objects subjected to axisymmetric loading, discretized by means of four-node axisymmetric quadrilateral elements as depicted in Figure 4, given the rotational symmetry of the forming operation and that no anisotropy effects were considered.

Figure 4.

Numerical meshes for the beginning and end of the forming of the toroidal shell and respective fabrication of the free mechanical joint with the coin blank.

The number of quadrilateral elements was selected based on various convergence studies to ensure accurate representation of the field variable distribution and the force–displacement response. Around 300 quadrilateral elements were used to discretize the tube cross-section, and about 1500 for the disk cross-section.

As the field variables and force–displacement curves showed no significant variation, the finer mesh was adopted for its superior geometric accuracy. For this reason, the convergence study was not discussed in detail in the manuscript.

Moreover, the simulation runs in only 2 min on a standard personal computer (Intel(R) Core i7-8565U, 1.99 GHz, 16 GB RAM), making the computational cost negligible.

Regarding friction, the dies were discretized by contact friction linear elements and modelled as rigid objects. A law of constant friction τf = mk was employed to model friction on the forming operation, where m is the friction factor and k is the flow shear strength friction.

A friction factor m of 0.1 was utilized on the contact interfaces between the dies and objects, which provided the most compatible results between the predicted numerical forces and experimental results. This modelling approach is supported by tube hydroforming benchmarking studies [24] and validated experimental investigations on tubular component deformation [18].

4. Results and Discussion

4.1. Forming of a Toroidal Shell of Circular Section

For the analysis of the production of a toroidal shell of circular section, tubes with initial heights of 7 and 9 mm were employed in the tool presented in Figure 1. The numerical analysis of those preforms allowed us to conclude which are the conditions for the existence of a free rotation of the toroidal shell over the disk.

The plastic deformation of the tubular preforms during forming results from the mechanisms of flaring and friction. The first takes place when the tube starts to be axially compressed being forced to flare along the tool radius, whereas the influence of friction becomes noticeable until the toroidal shell is completely formed. As seen, the surface of the forming tools in contact with the silver tubes and disk needs to provide lower levels of friction to avoid aesthetic defects and/or material flow defects.

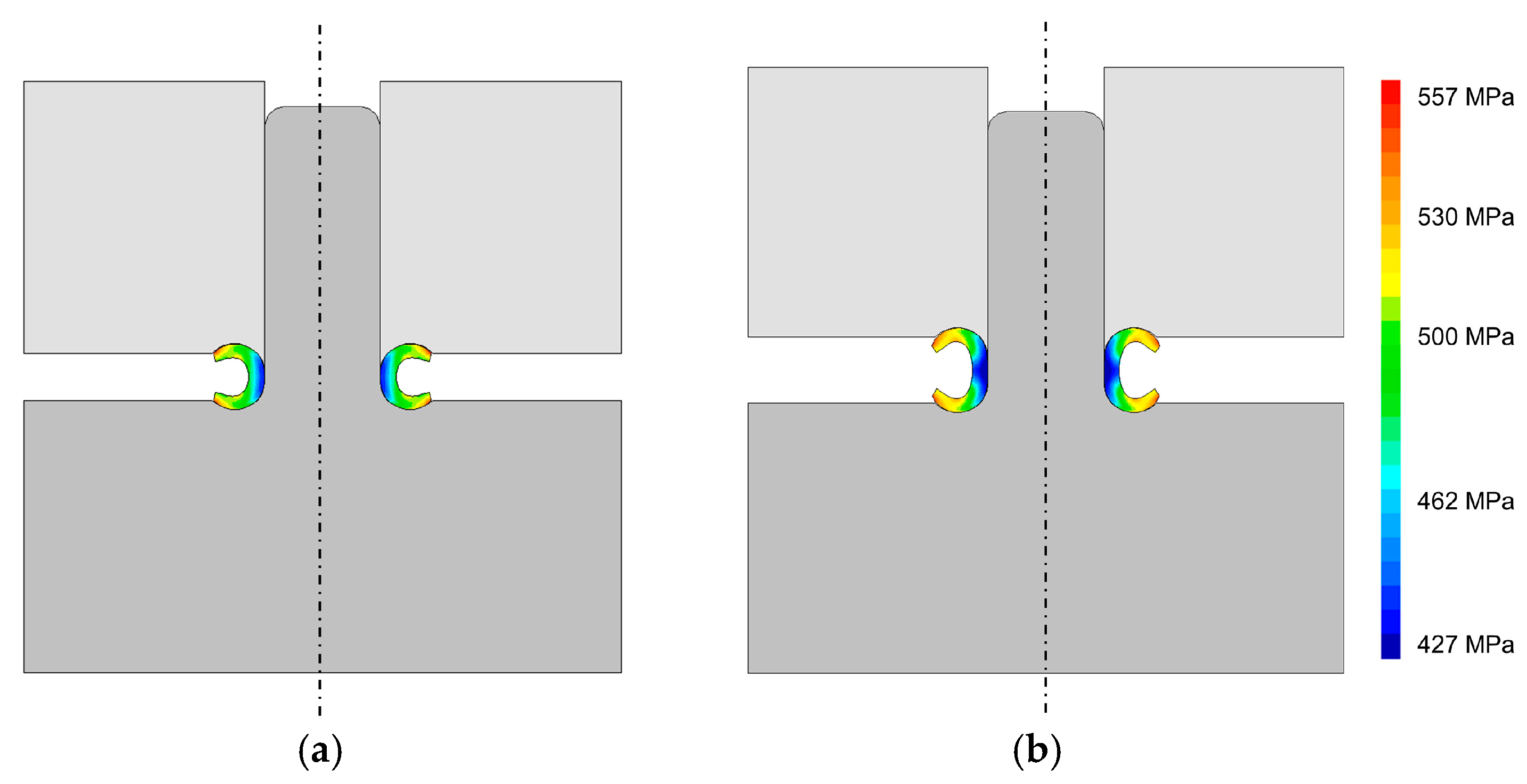

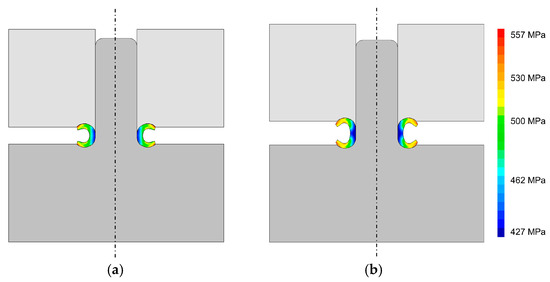

Two different situations are presented in Figure 5, starting with an initial tube height of 7 mm (Figure 5a) and 9 mm (Figure 5b) without a gap between the tube and mandrel. As can be observed by the distributions of effective stress in the initial and final stages of deformation, both the upper and lower sections of the circular toroidal shell are subjected to high levels of stress which may create defects in the torus surface as well as premature tool wear. With regard to the cross-section, the utilization of a larger tube height (Figure 5b) gives rise to the creation of a toroidal shell that is not completely circular but instead has a straight vertical inner wall that may produce an undesirable mechanical interlocking that constrains the rotation movement of the shell as intended.

Figure 5.

Distribution of effective stress for tubes with an initial tube height of (a) 7 and (b) 9 mm.

Utilizing a gap between the tubular preform and mandrel plays an important role in the operation’s success. In fact, when no gap exists between the tubular preform and mandrel as shown in Figure 6a, it allows to produce a fully circular toroidal shell with reduced stress levels due to reduced friction between the tube and dies, since the beginning of the forming operation is mostly localized at the radius of the flaring dies. This gap needs, however, to be controlled to avoid the risk of the occurrence of plastic instability, since when a gap of 0.75 mm is created between the tubular preform and mandrel as shown in Figure 6b, the contact between the tube and flaring dies is initiated near the top of the flaring radius.

Figure 6.

Effective stress distribution on tubes with an initial tube height of 7 mm without (a) and (b) with a gap between the tubular preform and mandrel.

Due to strain hardening of Ag925, a symmetrical deformation between the upper and lower regions of the torus free from defects can then be produced, as seen from the isolated tube forming operation (without the disk) of Figure 6a. The dimension of the internal diameter of the toroidal shell, which is necessary to machine the hole in the disk in where the tubular preform is positioned, as well as the value of the other process variables, are summarized in Table 3.

Table 3.

Values of the process variables for the forming of toroidal shells of circular section.

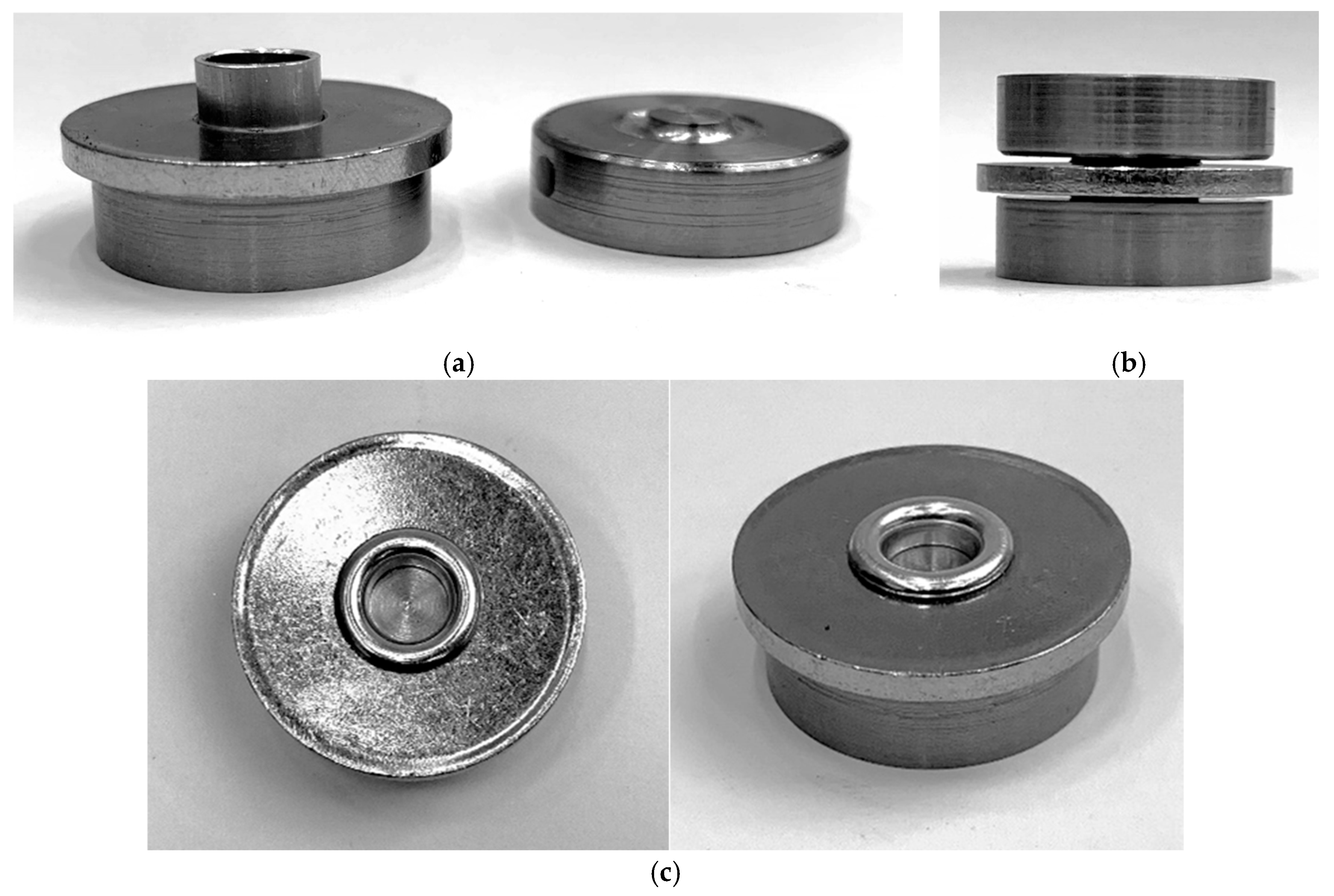

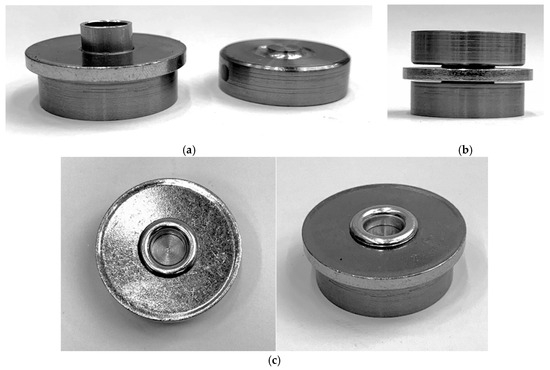

The photographs of the experimental tests obtained under the conditions of Figure 6a are presented in Figure 7 where a toroidal shell of circular section is formed in a raw disk. The tube is first positioned in the disk hole (Figure 7a), then the upper die which contains a flaring radius of 1 mm is positioned at the top of the tube (Figure 7b), producing an axial compression that is responsible for forming the toroidal shell.

After the process is finished, the dies are removed and the disk with the rotating element is completed (Figure 7c). If the disk is already engraved, the coin is produced in a single stroke.

Under these conditions, a free rotation exists between the toroidal shell and disk with a reduced gap between the two elements, thus increasing the perceived quality of the final product. At the same time, in functional terms, this reduced gap leads to a soft rotation movement and avoids the penetration of debris that may block the rotation of the assembly. In energetic terms, the necessary force to produce the coin with a rotating element is limited to the forming force of the toroidal shell since only the deformation of the tube is verified. The elastic recovery of the tube material is reduced and does not seem to have a significant influence on the rotational movement. The same is verified with the anisotropy of the tube material and the resulting differences in the cylindricity of the toroidal shell.

This circular cross-section produces coins that are excessively thick, making them aesthetically unappealing to collectors. Therefore, the authors focus solely on the study of the C-shaped cross-section, as it is deemed the most suitable for the desired design and functionality.

4.2. Forming of a Toroidal Shell of Non-Circular Section

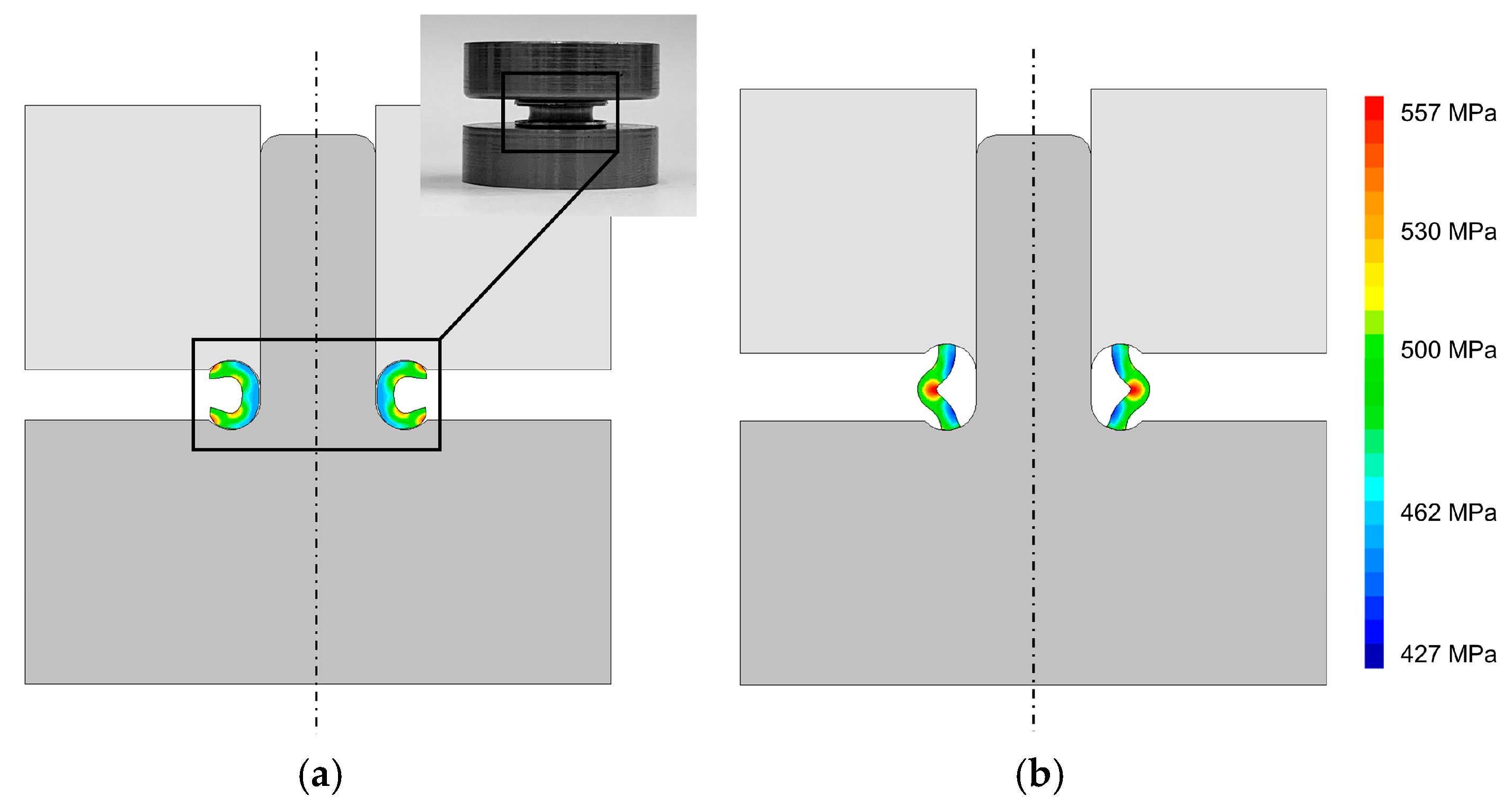

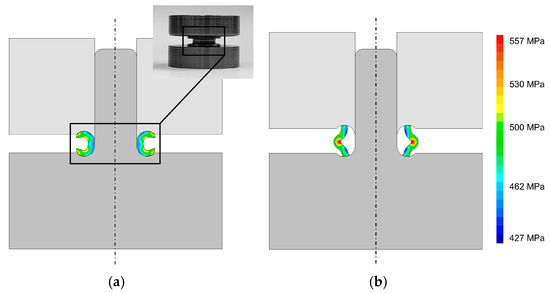

While the production of a toroidal shell of circular section demands a considerable volume that braces the circular disk, the production of a non-circular toroidal shell allows to obtain a bigger engraving area and it utilizes a chamfered disk hole as a rotation pivot. This toroidal shell presented in Figure 8 also reduces the overall thickness of the assembly, but it still allows the utilization of disks of larger thickness without protrusions above its surfaces by producing a straight inner torus wall. The free rotation is guaranteed in this case by a discontinuous and localized contact that offers higher levels of rotation than the previous technique.

Figure 8.

Schematic representation of (a) the tooling system for the production of a non-circular toroidal shell with the notation of the main process variables and of (b) the tool system to control the gap between torus and disk.

The different set of tools (refer to Figure 8) consists of an upper and lower punch with a given flaring radius that performs the forming operation of the non-circular torus up to a displacement where it is very close to the chamfered hole of the disk. To ensure inner straight walls, the tool setup also includes a removable internal mandrel, and in contrast with what was observed for toroidal shells of circular sections, no gaps are now necessary between the tubular preform and mandrel. A relief angle should, however, be introduced in the mandrel to allow the extraction of the coin without damaging the toroidal shell. A small radius of 0.05 mm should also be included in the boundary regions of the punches to create a support region for the engraved disk to be correctly positioned, thus avoiding rotation defects and/or damage to its surfaces.

The tool for controlling the gap (Figure 8b) is composed of two punches with the same radius utilized for the first stage where the torus is formed (refer to Figure 8a). The operation consists of the axial compression of the toroidal shell with those punches to force the material of the torus to flow in the opposite direction of the disk, thus creating the desired gap between the surfaces if not admissible due to possible material variations.

For the determination of the optimal flaring radius that allows to obtain the C-shaped section, tubes with initial heights of 4 and 6 mm were selected, and disks with a chamfered hole were prepared. An initial height of 4 mm has been shown as the critical height above which plastic instability of the tube wall is verified for the tooling system employed. For this height of 4 mm, only a local thickening of the tube wall is observed, and the values of the remaining working variables before the calibration of the gap with the tool of Figure 8b are summarized in Table 4.

Table 4.

Values of the process variables for the forming of toroidal shells of non-circular section.

Regarding the flaring radius R, a value of 1 mm was previously used to produce a toroidal shell with a circular cross-section. Numerical simulations revealed that a small radius of 0.5 mm cannot form a non-circular toroidal shell without defects and flow constraints during the forming process. Consequently, the radius must range from 0.5 to 1 mm due to geometric limitations, with 0.75 mm being selected based on the coin design as the optimal compromise. This is evident from the evolution shown in Figure 8a, where the toroidal shell forming continues until it almost contacts the chamfer of the disk. At this point, the process is stopped to ensure free rotational movement between the elements. If necessary, a secondary operation can be performed using the tool in Figure 8b to calibrate the gap between the torus and the disk, ensuring the desired rotation levels.

In comparison with a toroidal shell of circular section, this variant demands lower forming force due to the reduced tube height, and consequently a reduced tool displacement becomes necessary to produce the disk with the rotating element.

Both techniques are characterized by a load–displacement curve where the load increases gradually with the axial compression of the tube and the main deformation mechanisms that govern the material flow behavior start to be triggered. Those mechanisms are the bending as the tube initiates the contact with the dies and stretching along the circumferential direction as the tube is forced to deform against the surface contour of the dies. The contact is not uniform along those interfaces but rather limited to specific regions where high contact pressure values are found and where reduced friction conditions can positively influence the overall forming process.

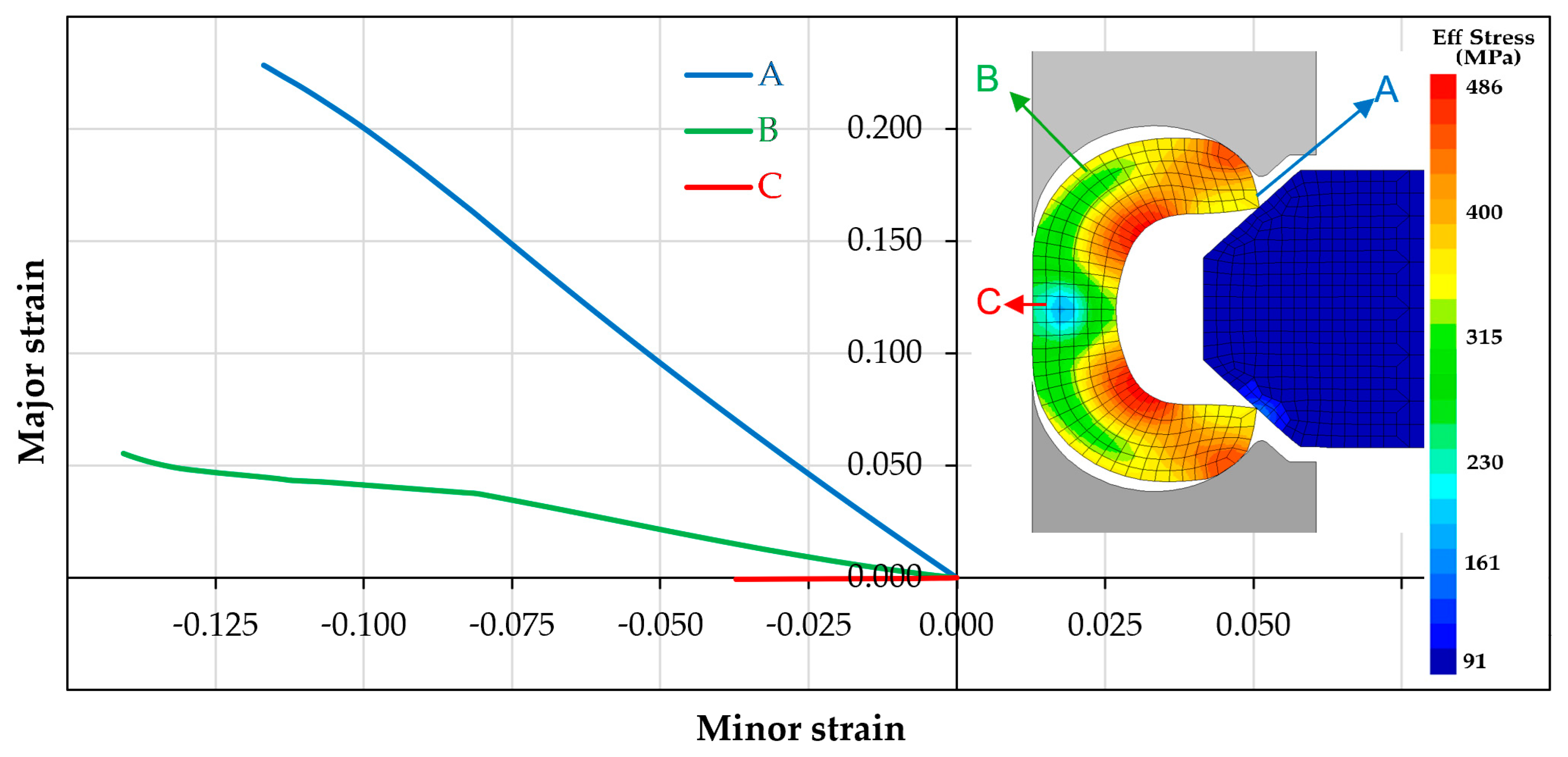

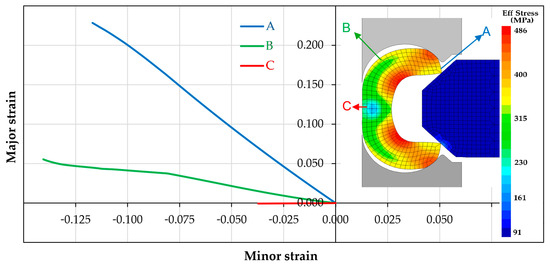

With regard to the strain paths, they range from a tensile strain state A, to a near plane strain state C, , corresponding to elements located at the extremity and at the midsection of the torus cross-section, respectively.

The effective stress varies from a minimum of 195 MPa near the middle of the central section to a maximum of 485 MPa at the inner surface and where it contacts the die. This can be seen in the image on the right side of the strain path diagram.

Concerning the thickness variation, it remains approximately equal to the initial thickness at the midsection, increases from 0.5 mm to a maximum of 0.6 mm near the first quarter of the cross-section, and subsequently decreases to a minimum at the extremity of the torus cross-section. These previous statements can be observed in Figure 9.

Figure 9.

Evolution of strain paths for representative elements in the forming process of a non-circular toroidal shell.

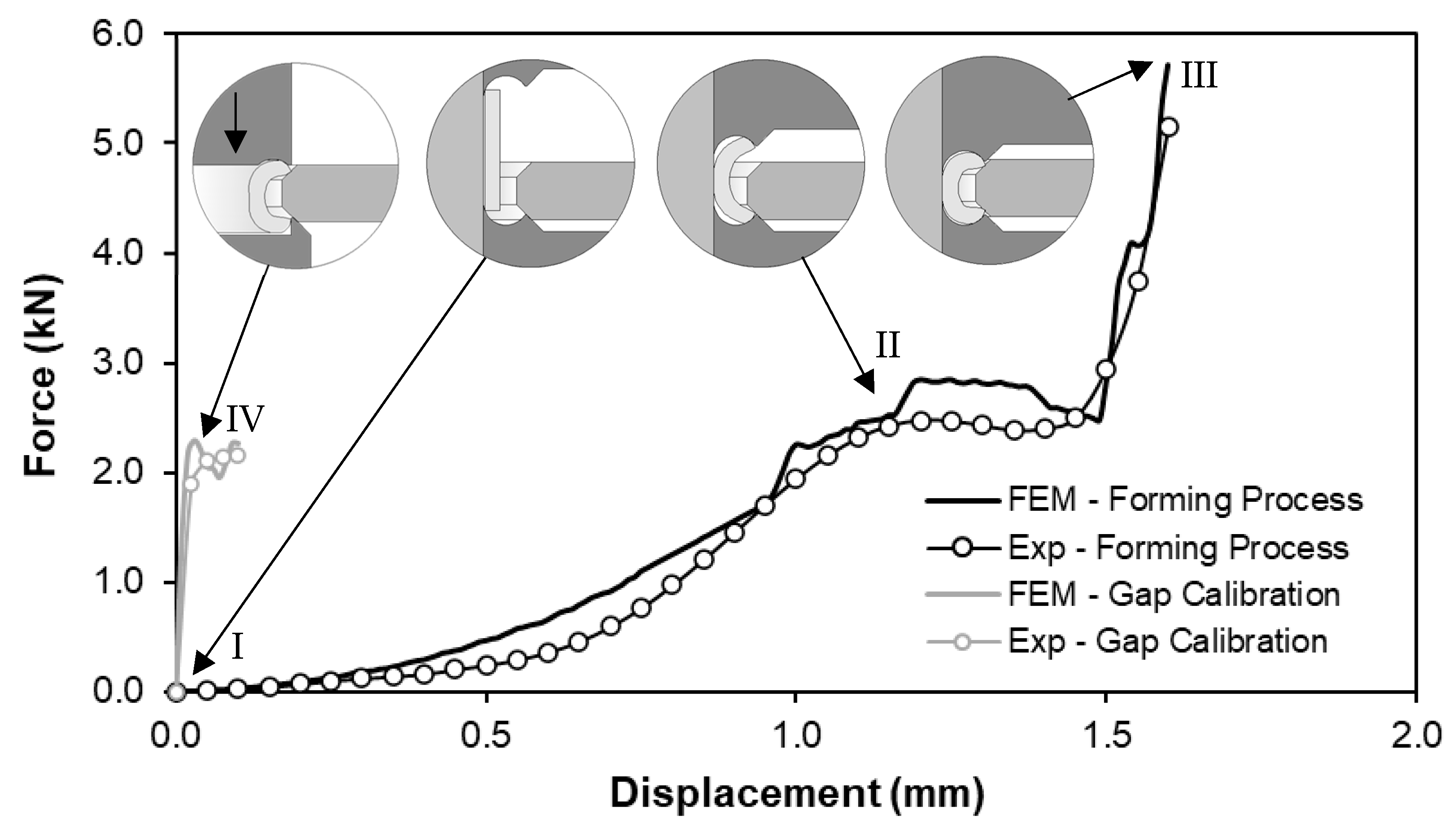

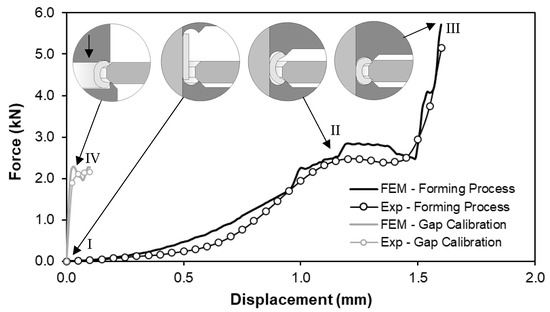

By analyzing the force–displacement evolution of Figure 10 for the production of a toroidal shell of non-circular section, as that to be utilized in the industrial coin production, it can be seen that both evolutions, numeric and experimental, compare well and allow to identify specifics instants of deformation where significant changes in material flow are found to occur. The minor discrepancies between the experimental and numerical evolutions may be ascribed to simplifications in boundary conditions, material characterization, fracture mechanics, frictional factors, and other contributing factors. The load starts to increase from Point I to Point II due to a more pronounced bending effect of the tube as it adapts to the contour of the dies. Then, after Point II, where the deformation mechanics change from sliding and bending to bending, the overall forming load decreases moderately and then grows rapidly until Point III, where the upper and lower dies are in full contact with the surfaces of the fully formed toroidal shell, which in turn makes contact with the disk. From this point, the tool setup is changed and the calibration of the gap between the toroidal shell and disk is performed according to the evolution at Point IV. The inserts of Figure 10 allow us to identify the corresponding stage of each point identified in the graph.

Figure 10.

Experimental and numerical evolution of force–displacement for the production of a toroidal shell of a non-circular section.

Photographs of the set of tools for the fabrication of the non-circular toroidal shell are presented in Figure 11. The conditions of the deformation can be controlled by the tolerances and surface finish of the tools.

Figure 11.

Set of tools for (a) forming the toroidal shell in the chamfered hole of the circular disk and (b) for calibration of the gap between them.

After the toroidal shell is formed at the disk hole with the tool from Figure 11a, the tool from Figure 11b can then be utilized to increase the gap between the two parts and produce the desired levels of rotation.

The punches to perform the coining of the disk are presented in Figure 12, where the dimensions of the centre hole at the disk are controlled by a mandrel that is integrated into one of the punches during coin minting.

Figure 12.

Engraving punches for coin minting of the disk.

The original tube with the engraved disk and the final coin after forming of the toroidal shell are presented in Figure 13a and Figure 13b, respectively.

Figure 13.

(a) Preforms and (b) manufactured coin with a rotating element of C-shape section.

5. Conclusions

Different techniques are presented that are capable of shaping silver thin-walled tubes into circular and non-circular toroidal shells, which act as rotating elements in silver disk coins. The deformation mechanisms are consistent with those of single tube forming in which bending and circumferential stretching are gradually developed as the tubular preform deforms against the contour of the die. The control of the gap between the torus and disk was revealed to be essential to allow for relative rotational movement while ensuring a mechanical connection between those two elements.

The finite element analysis combined with experimentation allowed us to identify and understand the influence of the working variables on the overall process of forming toroidal shells of different sections to obtain the desired geometry.

The strain paths vary from tensile strain to plane strain, corresponding to the extremity and midsection of the torus cross-section, respectively. As a result, the torus thickness remains nearly constant at the midsection, increases near the first quarter, and then decreases towards the extremity.

The surface finish of the dies plays an important role, with reduced friction conditions and parallel surfaces being of the upmost importance for the correct forming of the toroidal shells. The force requirements of the new solution are only dependent on the complexity of the coin reliefs since the forming forces of the different toroidal shells are very reduced. In some cases, the force value can be utilized to control material flow and obtain the desired gap between the coin components, which facilitate the quality assessment of the newly manufactured coins with rotating elements.

In conclusion, the strategies developed under this research work allowed for a successful industrial implementation of these concepts at the Portuguese Mint, which was able to industrialize the process and create new high-added-value coins. The new concepts can be easily extended to different material combinations and more complex designs.

Author Contributions

Experimentation: L.M.A., P.A. and S.P.; Numerical modelling: L.M.A.; Writing—original draft preparation: L.M.A.; Writing—review and editing: L.M.A., P.A. and S.P.; Coordination: L.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge Fundacão para a Ciência e a Tecnologia (FCT) for its financial support via the projects LAETA Base Funding (https://doi.org/10.54499/UIDB/50022/2020) and LAETA Programatic Funding (https://doi.org/10.54499/UIDP/50022/2020).

Informed Consent Statement

Not applicable.

Data Availability Statement

The authors confirm that the data and material supporting the findings of this work are available within the article.

Acknowledgments

The authors acknowledge the support provided by the Portuguese Mint (INCM—Imprensa Nacional Casa da Moeda). The authors also thank the technical assistance of Nuno Caetano and the support of Sílvia Garcia and Alcides Gama from INCM.

Conflicts of Interest

Authors Paulo Alexandrino and Sónia Pereira were employed by the INCM, Imprensa Nacional Casa da Moeda. The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Afonso, R.M.; Alexandrino, P.; Silva, F.M.; Leitao, P.J.; Alves, L.M.; Martins, P.A. A new type of bi-material coin. Proc. IMechE Part B J. Eng. Manuf. 2019, 233, 2358–2367. [Google Scholar] [CrossRef]

- Bocharov, Y.; Kobayashi, S.; Thomsen, E.G. The mechanics of the coining process. J. Eng. Ind. 1962, 84, 491–501. [Google Scholar] [CrossRef]

- Rosado, P.M.; Sampaio, R.F.; Pragana, J.P.; Bragança, I.M.; Silva, C.M.; Martins, P.A.; Alexandrino, P.; Leitao, P. Joining by forming of bi-material collector coins with rotating elements. J. Adv. Join. Process. 2024, 10, 100265. [Google Scholar] [CrossRef]

- Alexandrino, P.; Leitão, P.; Alves, L.; Martins, P. Numerical and experimental analysis of coin minting. Proc. IMechE Part L J. Mater. Des. Appl. 2017, 233, 842–849. [Google Scholar] [CrossRef]

- Alexandrino, P.; Leitão, P.J.; Alves, L.M.; Martins, P.A. Finite element design procedure for correcting the coining die profiles. Manuf. Rev. 2018, 5, 3. [Google Scholar] [CrossRef]

- Tekkaya, A.E.; Hirsch, J.; Heingärtner, J.; Haase, R. Metal forming beyond the limits: Research and applications in incremental and hybrid technologies. CIRP Ann. 2020, 69, 601–623. [Google Scholar]

- Pragana, J.P.M.; Rosenthal, S.; Bragança, I.M.F.; Silva, C.M.A.; Tekkaya, A.E.; Martins, P.A.F. Hybrid additive manufacturing of collector coins. J. Manuf. Mater. Process. 2020, 4, 115. [Google Scholar] [CrossRef]

- Pragana, J.P.M.; Rosenthal, S.; Alexandrino, P.; Araújo, A.; Bragança, I.M.F.; Silva, C.M.A.; Leitão, P.J.; Tekkaya, A.E.; Martins, P.A.F. Coin minting by additive manufacturing and forming. Proc. IMechE Part B J. Eng. Manuf. 2021, 235, 819–828. [Google Scholar] [CrossRef]

- Gonçalves, A.; Alves, L.M.; Martins, P.A.F. Tube joining by asymmetric plastic instability. J. Mater. Process. Technol. 2014, 214, 132–140. [Google Scholar] [CrossRef]

- Alves, L.M.; Silva, C.M.A.; Martins, P.A.F. Joining tubes by internal mechanical locking. J. Mater. Process. Technol. 2017, 242, 196–204. [Google Scholar] [CrossRef]

- Sekhon, G.S.; Gupta, N.K.; Gupta, P.K. An analysis of external inversion of round tubes. J. Mech. Work. Technol. 2003, 133, 243–256. [Google Scholar] [CrossRef]

- Alves, L.M.; Reis, T.J.; Afonso, R.M.; Martins, P.A. Single-stroke attachment of sheets to tube ends made from dissimilar material. Materials 2021, 14, 815. [Google Scholar] [CrossRef]

- Alves, L.M.; Martins, P.A.F. Forming of thin-walled tubes into toroidal shells. J. Mech. Work. Technol. 2010, 210, 689–695. [Google Scholar] [CrossRef]

- Nielsen, C.V.; Zhang, W.; Alves, L.M.; Bay, N.; Martins, P.A.F. Coupled Finite Element Flow Formulation. In Modelling of Thermo-Electro-Mechanical Manufacturing Processes; Springer: London, UK, 2013; pp. 11–36. [Google Scholar]

- Yin, Y.; Xu, J.; Dong, J.; Li, Y.; Wang, Y.; Zhong, W.; Zhang, Z. CUDA-based parallel dual-grid material point method for simulating bimetallic coining process. Comput. Part. Mech. 2025. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Li, J.; Wang, H. Numerical simulation of metal flow in coin minting using MPM. Materials 2023, 16, 456. [Google Scholar]

- Liu, Y.; Zhang, W.; Wang, Y.; Yin, Y.; Xu, J. A hybrid FEM–MPM approach for high-accuracy modeling of axisymmetric forming processes. Int. J. Mech. Sci. 2023, 236, 107820. [Google Scholar]

- El-Morsy, M.; Mohamed, M.; Eltaib, M.; Attia, H. Experimental and numerical analysis of tubular component deformation using die-based forming. J. Mater. Process. Technol. 2022, 305, 117690. [Google Scholar]

- Gavrilă, C.C.; Lateş, M.T.; Grebenişan, G. Sustainable Approach to Metal Coin Canceling Methods, Using 3D Modeling and Finite Element Method Analysis. Sustainability 2024, 16, 2322. [Google Scholar] [CrossRef]

- Hartl, C. Review on Advances in Metal Micro-Tube Forming. Metals 2019, 9, 542. [Google Scholar] [CrossRef]

- Suntaxi, C.; Ghassemieh, E.; Roy, A. Tube expansion by single point incremental forming. Metals 2021, 11, 1481. [Google Scholar] [CrossRef]

- Alexandrov, S.; Lyamina, E. Analysis of strain-hardening viscoplastic wide sheets subject to bending under tension. Metals 2022, 12, 118. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, T.P. Finite element analysis of tube hydroforming process for automotive applications. Metals 2021, 11, 1002. [Google Scholar]

- Koç, M.; Altan, T. Process simulation of tube hydroforming: Benchmarking study. J. Mater. Process. Technol. 2002, 125–126, 361–368. [Google Scholar]

- Palumbo, G.; Sorgente, D.; Tricarico, L. Design and manufacturing of titanium cranial prostheses via sheet metal forming. Metals 2022, 12, 293. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).