Abstract

H2 is considered a practical substitute for fossil fuels, especially for transportation by road and air, created either from fossil fuels or through the process of electrolysis of water. Research questions were included based on numerous research and the analysis of articles. The cost analysis of H2 processes, techno-economic hurdles in commercialization, and the economic comparison of various H2-production methods were the basis for the study of papers. The current research examines the different methods of thermochemical, biological, and electrochemical processes utilized in converting biomass into hydrogen. The benefits, constraints, and significant enhancements of every procedure are outlined. The examination assesses the cost of production, the level of technology readiness, and the potential for scalability. Thermochemical techniques, such as gasification and steam reforming, are effective at producing hydrogen. Steam gasification is perfect for moist and dry biomass in the absence of an oxidizing agent. Dark fermentation is more efficient for biological conversion because it requires less energy. Moreover, the electrochemical procedure is viable for biomass. Thermochemical treatment is significantly more advanced than biological or electrochemical treatment when it comes to scaling opportunities based on comparisons of current processes. The results of this research show that biomass–hydrogen processes have the potential for increasing H2 production, but further enhancements are needed to produce larger quantities for competitiveness.

1. Introduction

Hydrogen is acknowledged as an environmentally friendly fuel because water vapor is the only byproduct of H2 combustion. Zero carbon dioxide emissions are achieved in the process of energy generation through the utilization of fuel cells or internal combustion engines [1], which possess a greater energy density in comparison to methane, coal, and gasoline. Hydrogen, with 100 times higher energy density than lithium–ion batteries, offers the highest energy content per unit weight among fuels. Its superior storage capacity positions it as a promising future fuel [2]. When it comes to H2 production, estimates indicate that between 50 and 82 Mt of hydrogen will be produced annually, with a projected growth rate of 5–10% per year by 2050 [3]. At the moment, natural gas accounts for 48% of H2 production, heavy oils and naphtha for 30%, and coal for 18%, with non-renewable sources accounting for 96% of the total [4].

The energy industry must find a way to supply the world’s energy needs without causing environmental damage. Eco-friendly energy systems are being adopted by both developed and developing nations, with the “H2 economy” being the long-term objective of developing nations. The only clean energy that doesn’t harm the environment is hydrogen [5]. Both nonrenewable and renewable resources can be used to create it [6]. Most frequently, nonrenewable resource-based thermochemical (TC) and biochemical (BC) conversions are used to produce H2 at a reasonable cost [7]. Every year, there is a growing need for H2; it is mostly utilized for the manufacturing of ammonia (51%), oil refineries (31%), methanol (10%), and other purposes (the remaining 8%) [8]. The majority of industrialized nations now use H2 as a fuel for vehicles. H2 is also utilized in fuel cells to produce water vapor and power.

Finding ways to lower the cost of producing H2 is crucial given its projected demand and requirements. We gathered and contrasted the techno-economic-environmental evaluations of several H2-generation techniques in this review. We suggested a few potential improvements to the production processes based on our thorough study, which should lower production costs and increase the viability of the choices. The purpose of this review is to outline the various biomass-based H2-production methods. It is structured as follows:

The Section 3 reviews the two biological pathways, DF and photobiological fermentation (PF), and the three major thermochemical processes, pyrolysis, gasification, and steam reforming of NG (natural gas). It also describes the electrochemical conversion potential of water electrolysis. The Section 4 suggests a sensitivity analysis comparison of the processes’ economics (capital cost sensitivity and IRR sensitivity). In the fourth phase, a techno-economic assessment is also established, including the capital cost, feedstock cost, IRR, and payback period (PB). Additionally, a scientific comparison of several hydrogen-production methods is carried out in this section with respect to their technology readiness level (TRL), efficiency, expenses associated with manufacturing H2, and scalability. Then, a comparison of the CO2 emissions from various methods of creating hydrogen is suggested in the fourth part. Lastly, this part highlights critical findings and proposes a commercialization challenge in terms of the financial and technical obstacles. The purpose of the Section 5 of the article’s text was to give a precise evaluation for further investigation.

2. Methodology Framework

This study investigates the methods used to convert biomass into hydrogen using electrochemical, biological, and thermochemical processes. Each method’s benefits, drawbacks, and noteworthy advancements are described. Additionally, there is a techno-economic assessment carried out, taking into account production costs, technology maturity, and industrial expandability.

The cost analysis of H2 processes, the techno-economic commercialization hurdles, and the economic comparison of different H2-production techniques were the basis for the examination of the papers. Based on a variety of studies and article analyses, new research questions were added. They are as follows:

- What kinds of H2-production methods are there?

- Is thermochemical conversion a feasible choice from an economic standpoint?

- Is it economically feasible to convert using biochemistry?

- Does producing H2 cost less when using water-splitting methods?

- What are the various technological and financial obstacles preventing the commercialization of the H2-production process?

- Is it possible to perform sensitivity analysis using capital and feedstock costs for various H2-production techniques?

- What distinct opportunities do these papers present?

- Which feedstocks are utilized in varying amounts to lower the cost of producing H2?

- Is it possible to reduce the total cost of producing H2 using diverse methods?

3. A Cost Assessment of Various H2-Production Methods

H2 can be generated through various methods, including thermochemical conversion, water electrolysis, and the reforming of renewable liquids. At present, 96% of hydrogen is produced from nonrenewable sources, with only 4% coming from water electrolysis [8]. An essential tool in determining the most cost-effective approach for H2 production is cost assessment, which is particularly valuable in the scaling up of processes.

3.1. Thermochemical Conversion (TC)

Thermochemical conversion, which includes gasification, pyrolysis, and steam reforming of natural gas, is thought to be the most beneficial method for producing H2 because of its great availability and energy density.

3.1.1. Pyrolysis

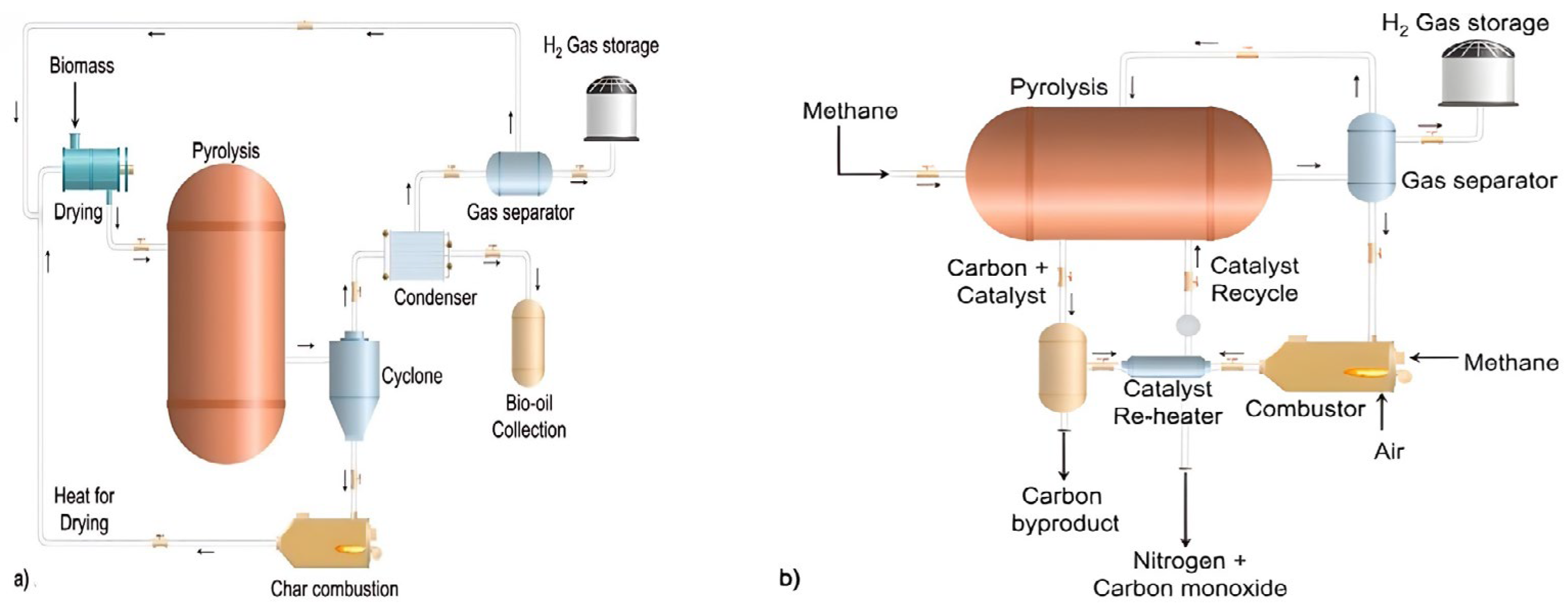

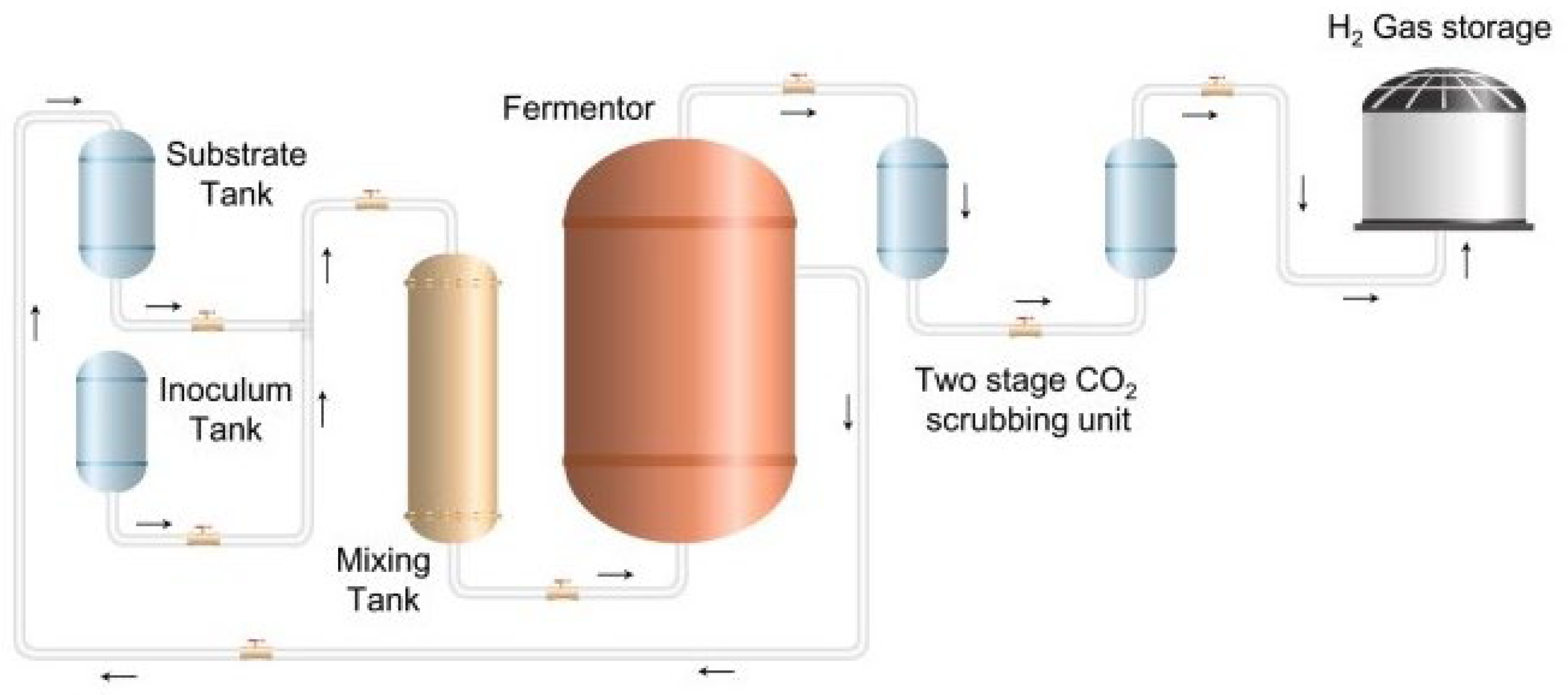

During pyrolysis (Figure 1a,b), liquid CBF (carbon-based fuel) or renewable biomass is thermally broken down at temperatures exceeding 300 °C in the absence of oxygen to create solid char, aqueous bio-oil from gaseous HC, and H2-rich gas. The main constituents of a biomass pyrolysis feedstock are cellulose, hemicellulose, and lignin.

Figure 1.

(a) Process flow diagram of pyrolysis of biomass; (b) Process flow diagram of pyrolysis of methane (Copyright with permission from Elsevier [9]).

Around 90% of the lignocellulosic biomass consists of these three components, while the remaining 10% is made up of ash and extracts [10]. Pre-pyrolysis, solid breakdown, residual char decomposition, and pre-heating and drying [11] are the four phases usually involved in biomass pyrolysis [12]. Before the pyrolysis takes place, there are additional stages, such as solid degradation, pre-heating, and drying, as well as the process of residual char decomposition. These steps are part of the intricate chemical process, which includes numerous reactions occurring simultaneously [13]. The equation below is a presentation of the general pyrolysis reaction [14]:

Biomass + Heat→ H2 + CO2 + CH4 + H2O + CO + Bio-Oil + Charcoal

Four forms of pyrolysis exist: vacuum, quick, flash, and slow or conventional. Depending on the rate of heating and the amount of time required for substrate decomposition, there are two common pyrolysis techniques, slow and rapid, that are widely used to produce hydrogen.

Biochar is created by a slow pyrolysis process, with a heating speed ranging from 5 to 30 °C/min and an extended breakdown period. At a rapid thermal decomposition rate ranging from 10 to 200 °C/S accompanied by a reduced duration of decomposition, approximately 60 to 75% of bio-oil, 15 to 20% of biochar, and 10 to 20% of syngas are produced. The preferred technique for the production of hydrogen from the two alternatives is rapid pyrolysis conducted at a high temperature. Contrasting the H2 yield and process parameters of slow and quick pyrolysis [15], quick pyrolysis at 953 K generates 45% H2, degrading in 5–7 min at 120–127 °C/min. Slow pyrolysis at 953 K yields 28% H2 at 45–50 °C/min. The degradation process took 60 min. It is evident that a faster pyrolysis process produces more H2 than a slower one. As a result, direct pyrolysis is not economically feasible and produces less H2. It is necessary to have extended decomposition periods and elevated processing energies (temperatures). To maximize the amount and quality of hydrogen generated, several chemical catalysts are used to promote conversion efficiency. This might reduce the cost of producing hydrogen by increasing substrate conversion efficiency and improving fuel quality. One mole of H2 may be produced using pyrolysis with less energy than through the SMR process, which accounts for 15–20% of the production of hydrogen.

3.1.2. Gasification

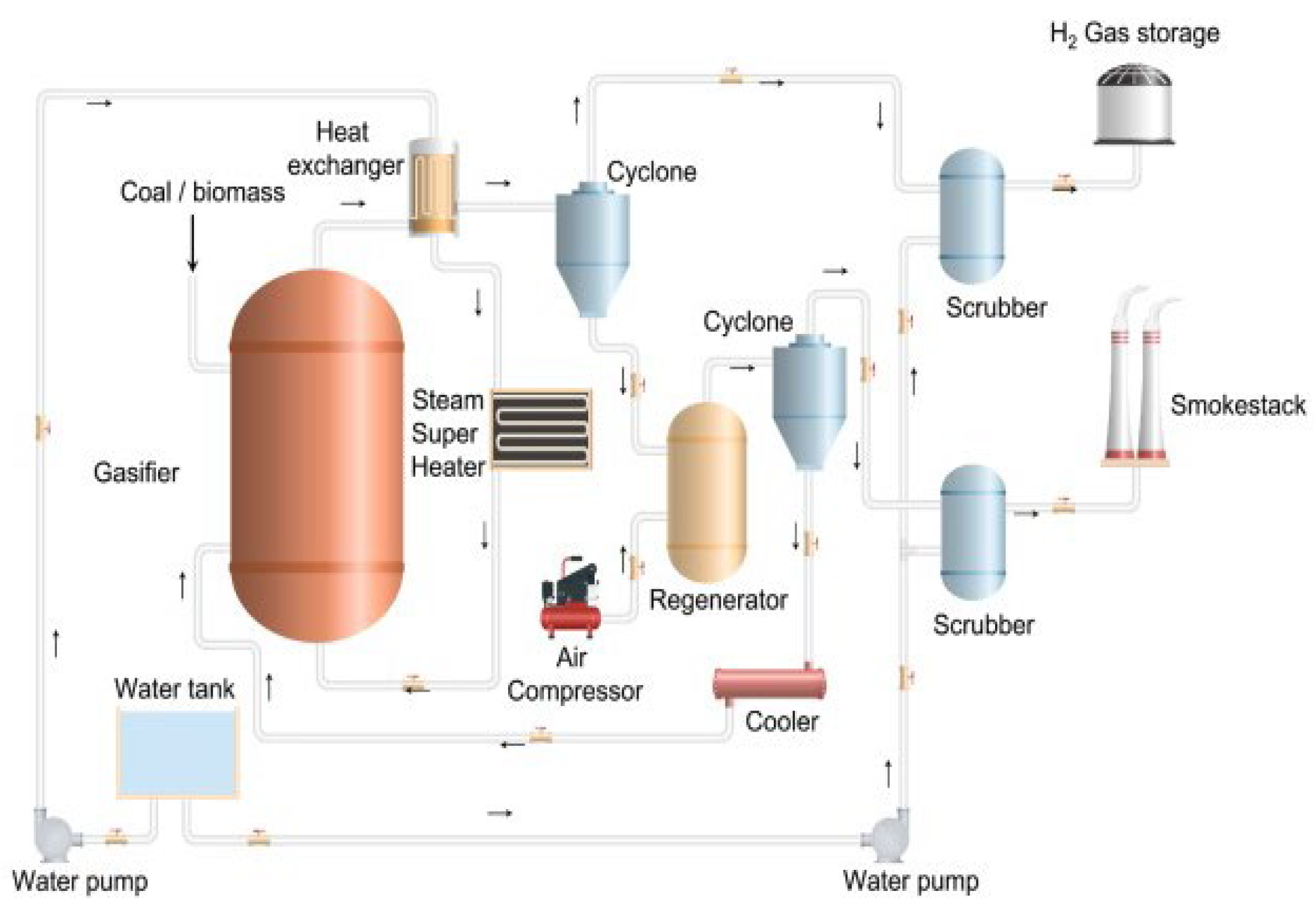

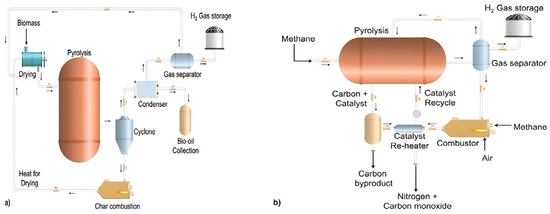

A kind of thermochemical process known as gasification occurs when biomass is broken down at high temperatures in low-oxygen settings [15]. The highly endothermic process occurs at temperatures ranging from 500 to 1400 °C and pressures ranging from atmospheric to 33 bar, dependent upon the size of the plant [11]. Depending on the kind of oxidizing agent used, the process can be categorized as air, oxygen, or steam gasification. Gasification is a traditional method used to create hydrogen by heating coal (and biomass) until it breaks down, as shown in Figure 2. The gasification of biomass leads to the generation of tar. Generating energy via gasification is a more effective method than combustion.

Figure 2.

Process flow diagram of gasification (Copyright with permission from Elsevier [9]).

Based on the structure of the process, there are three main categories for gasification: entrained flow gasification, direct-blown steam/oxygen or air fluidized-bed gasification, and dual-fluidized bed steam blown gasification (also known as indirect gasification) [16]. This is also referred to as fluidized-bed gasification, entrained flow gasification, indirect gasification, direct-blown, steam/oxygen, or air [17].

The process design may include various product gas upgrading and conditioning sequences, depending on the intended final product of the gasification process. The typical gasification reaction of biomass is shown as follows [18]:

Biomass + Air→H2 + CO2 + CH4 + H2O + CO + N2 + LHC + Tar + Char

Steam gasification acts as an intermediate option between air and oxygen gasification. This procedure can occur using damp biomass (with moisture levels ranging from 5 to 35 wt%). The equation below is the general reaction of steam gasification of biomass [19]:

Biomass + Steam→H2 + CO2 + CH4 + H2O + CO + HC + Tar + Char

Gasification also results in the production of CO and CH4, which can be processed further to generate additional hydrogen through steam reforming and the WGS (water gas shift) reaction [11].

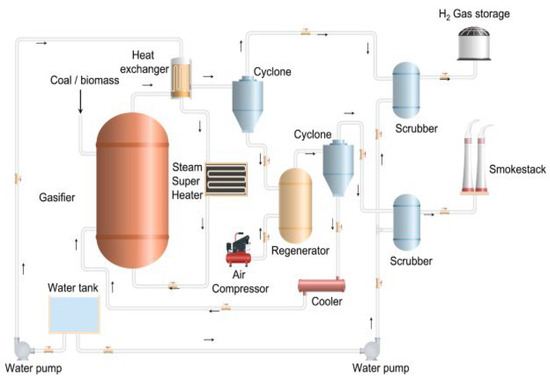

3.1.3. Steam Reforming of NG

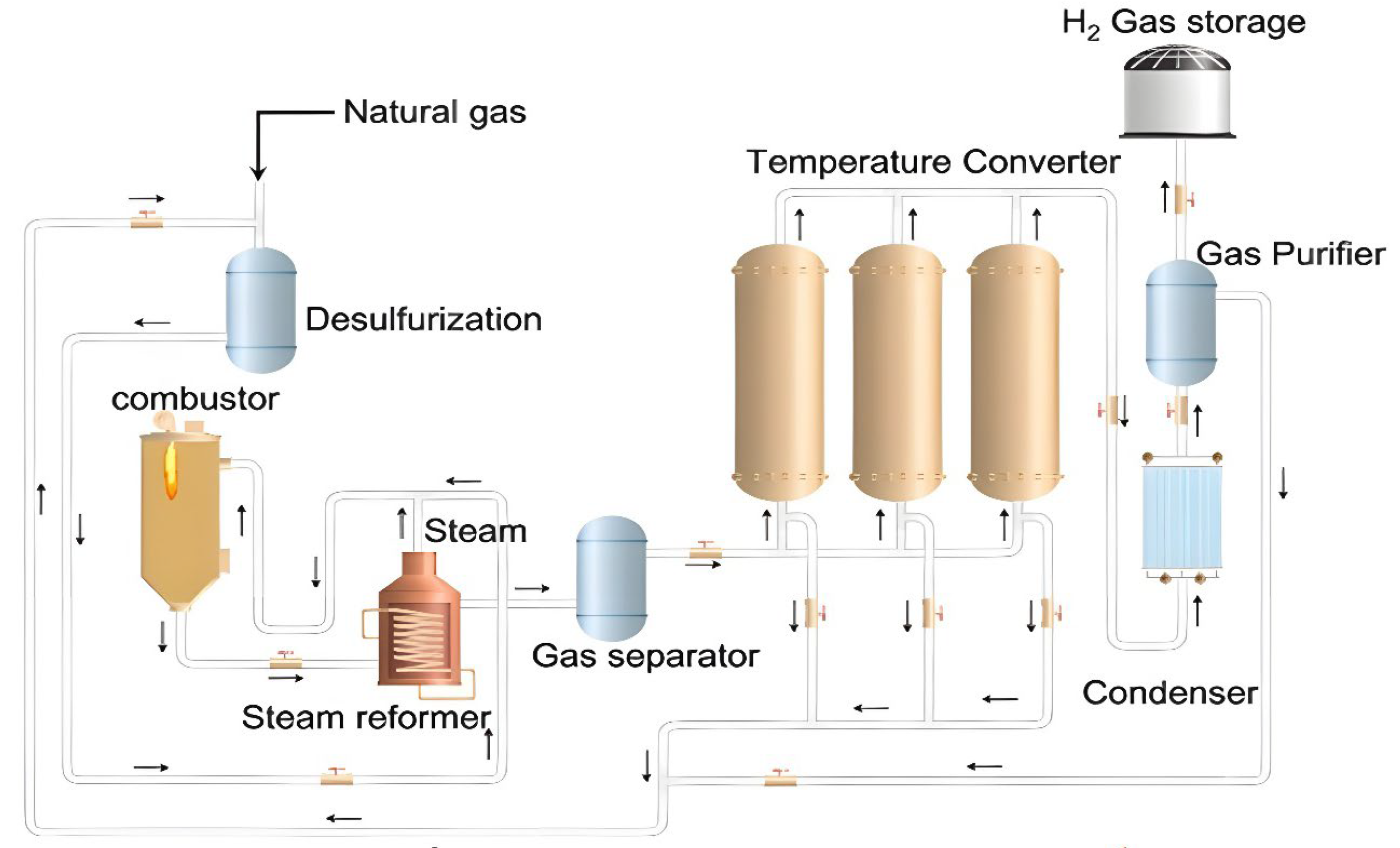

A well-known method for producing hydrogen from non-renewable resources such as methanol, diesel, propane, butane, naphtha, and jet fuel is steaming reforming (Figure 3). The cost of feedstock, global energy demand, and the growth of the hydrogen economy all have an impact on the choice of feedstock for steam reforming.

Figure 3.

Process flow diagram of steam reforming of NG (Copyright with permission from Elsevier [9]).

Recently, developed countries like the United States have been consistently using this technique to generate hydrogen. SRNG (steam reforming of natural gas) is a complicated process that needs a hot temperature input of 700–1000 °C to function, and it is endothermic. The primary fuel used in this process is natural gas, which is mostly composed of 95% methane, 1% nitrogen, 0.5% carbon dioxide, and trace quantities of sulfur compounds. Pressurized steam (ranging from 3 to 25 bar) and NG are mixed with a catalyst to produce hydrogen and a trace quantity of carbon monoxide. Insufficient feedstock quality (H:C ratio) results in an excessive release of carbon dioxide (7.05 kg CO2/kg H2), and less H2 is produced by the SRNG process. A high H:C ratio in the feedstock reduces carbon dioxide emissions while enhancing the quality of the finished product.

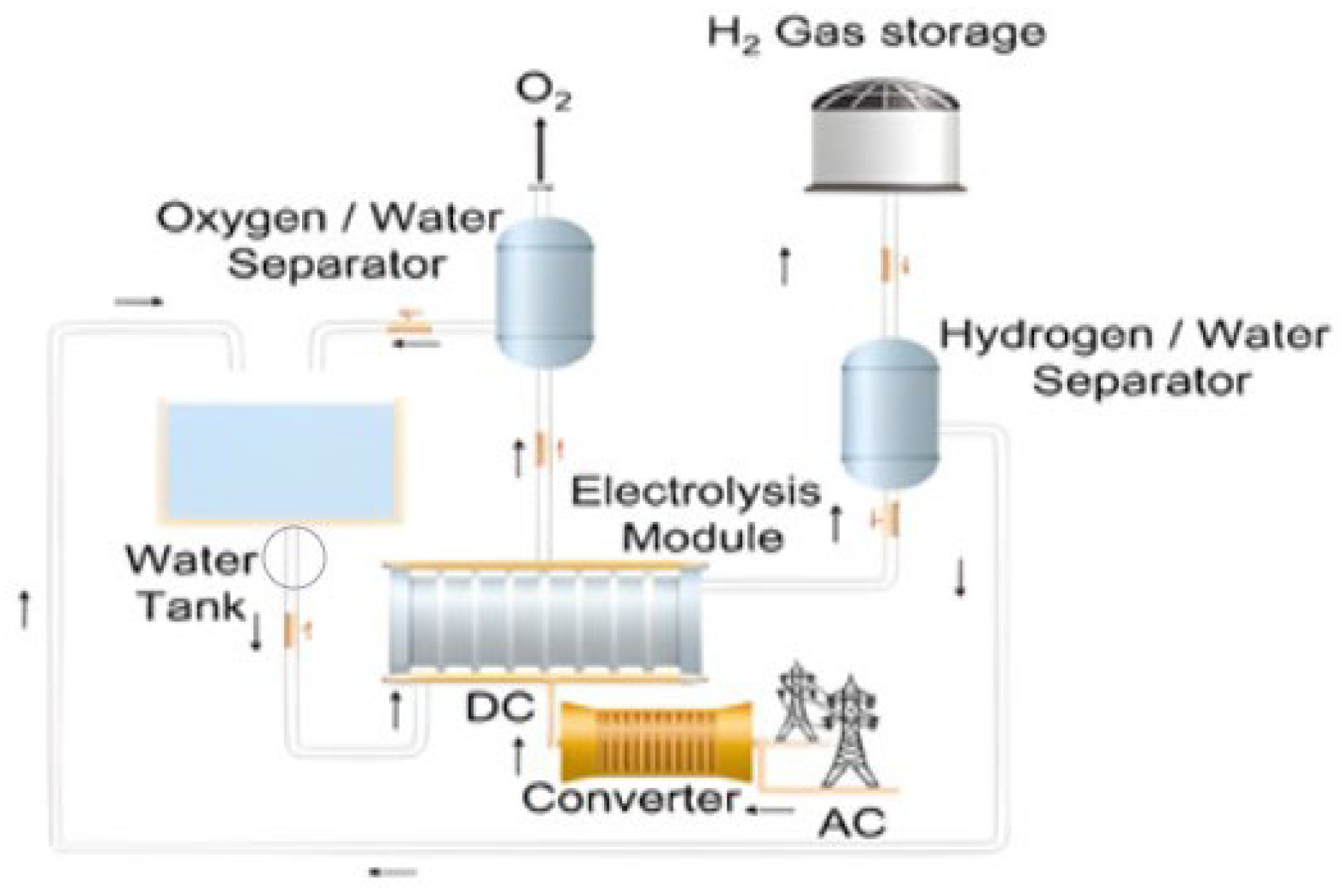

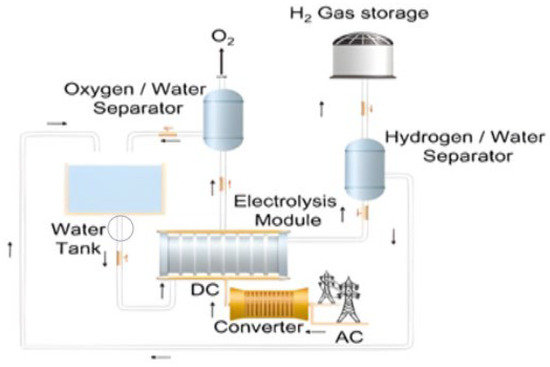

3.2. Water Electrolysis

As seen in Figure 4, electrolysis is the process of splitting water using electricity to produce oxygen and hydrogen. The technology is quite sophisticated and mostly utilized in business [20]. Solar electrolysis involves using solar energy to split H2O and produce H2, and it is viewed as a high-tech and economical method that offers a viable option for generating electricity [21]. Creating a 2D model of a water electrolyzer that is utilized in a PEM fuel system combined with a solar cell containing multiple junctions, it was determined that the incorporation of the system enhances H2 production [22]. Research was carried out to efficiently manufacture pure H2 gas using a CPV electrolyzer system. It has been demonstrated that increasing solar concentration and electrolysis temperature leads to higher hydrogen production, which decreases the cost of producing hydrogen as concentration levels rise [23].

Figure 4.

Process flow diagram of water electrolysis (Copyright with permission from Elsevier [9]).

3.3. Renewable Liquid Reforming

Reforming is a procedure used to extract hydrogen gas from biomass liquid. One of the main options for producing H2 is to convert renewable liquids such as bio-ethanol and bio-methanol. To meet the increasing energy requirements of liquid reforming, a bio-renewable feedstock was employed [24]. Research has been conducted on generating hydrogen via the bio-oil steam reforming process with phenol, acetone [25], ethanol, butanol, acetic acid [26], and glycerol [27]. A greater H2/CO2 ratio is required for the steam reformation of bio-oil, according to several studies. The bio-oil steam reforming process uses a variety of catalysts, including Pt, Pd, Rh, Ru, and Ni, supported by materials such as Al2O3, La2O3/Al2O3, MgO/Al2O3, CeO2/Al2O3 [28], CoIr/CeZrO2 [29], Ni, Fe, Co, Pd [30], Co–Ni [31], and Rh/CeSiO2 [32].

Based on the catalyst’s cost, efficiency, and feedstock cost, an economic analysis calculates the cost of H2. One method of producing H2 without having to separate carbon dioxide and oxygen is chemical looping [33]. According to an economic analysis of chemical-looping technology, integrated chemical looping water splitting using ZrO2 and MgAl2O4 decreased the cost of producing H2 by 12% and 14%, respectively, as compared to SMR. Furthermore, the synthesis of hydrogen is more efficient than steam methane reforming (SMR) [34].

3.4. Biochemical Conversion (BC)

One commonly used method is the biological production of hydrogen from organic wastes or biomass with the help of the enzyme hydrogenase, which is cost-effective. BC conversion is widely divided into two categories: dark fermentation [5] and photobiological H2 production.

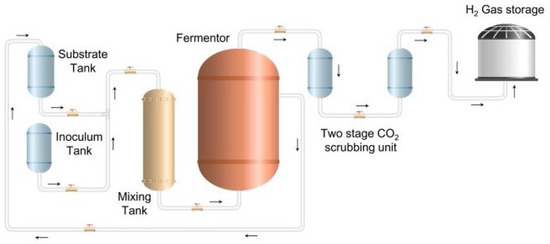

3.4.1. Dark Fermentation (DF)

It is known that some bacteria, including Enterobacter, Bacillus, and Clostridium, may create hydrogen. The Clostridium sp. group of bacteria, which includes C. beijerinckii, C. thermocellum, C. pasteurianum, and C. acetobutylicum, is the most commonly utilized group of bacteria in dark fermentation [35]. The bacteria, or microalgae, can survive in the absence of light at temperatures ranging from 25 to 80 degrees Celsius. Some strains can even survive at temperatures higher than 80 degrees Celsius [36]. Glucose is the most preferred carbon source for fermentation among all the carbohydrates. When glucose is used as the main model substrate, acetic and butyric acids account for more than 80% of the total products. It is theoretically possible to produce 12 mol of hydrogen by the bioconversion of 1 mol of glucose [11]. The following is how the response is shown [36]:

C6HI2O + 2H2O→4H2 + 2CO2 + 2CH3COOH (acetate fermentation)

C6HI2O + 2H2O→2H2 + 2CO2 + CH3CH2CH2COOH (butyrate fermentation)

A variety of carbon sources, including simple sugars like glucose, sucrose, and lactose; waste items containing starch or cellulose; leftovers from the food industry; and wastewater, can be used by anaerobic dark fermentative bacteria to create hydrogen. Different substrates have different yields; studies show that acetate and sucrose can provide large quantities of hydrogen [35].

The pH (which ranges from 5 to 6), HRT, and gas partial pressure all have an impact on the metabolic balance of the bacteria taking part in fermentation [11]. Because H2 concentration affects the pathways for hydrogen production, the H2 partial pressure is crucial. The production of H2 reduces as H2 concentrations rise. As a result, the H2 gas must be eliminated as soon as it is generated [36].

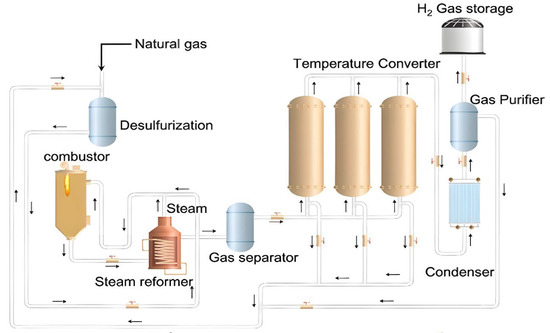

A popular and widely used technique for generating hydrogen (H2) from a range of sustainable resources includes using agricultural residues, lignocellulosic biomass [37], organic waste [38], and algal biomass [39]. Organic waste, or biomass, is subjected to dark fermentation in the absence of light, which transforms chemical energy into hydrogen. The dark fermentation process flow diagram is displayed in Figure 5. When compared to PF, DF offers many advantages, including higher H2 generation, reduced manufacturing costs, and fewer capital requirements [5]. Numerous studies have demonstrated that the costs related to producing hydrogen from biomass, organic waste, or wastewater may be decreased by using DF [40].

Figure 5.

Process flow diagram of DF (dark fermentation) (Copyright with permission from Elsevier [9]).

The total cost related to the DF process includes the original investment expenditures (which include equipment and installation costs), the yearly depreciation charges, and the ongoing operational costs (which include administrative expenses). The costs associated with setting up the H2 production facility, storage facility, purifying system, and compression unit are included in the equipment cost.

3.4.2. Photobiological Hydrogen Production

Nitrogenases catalyze the reaction, transforming organic acids like acetic, lactic, and butyric acids into H2 and CO2 with the help of photosynthetic bacteria [11]. The equation below is a demonstration of the response:

CH3COOH + 2H2O + light energy→4H2 + 2CO2

Using organic wastes as a substrate, photosynthesizing bacteria show that they can convert light energy into hydrogen. This is a phenomenon that can be seen in both batch and continuous cultures [3]. Achieving and maintaining the correct balance of carbon and nitrogen nutrients is crucial for improving nitrogenase activity and reducing energy consumption [41]. Additionally, the brightness level is a factor that impacts the rate and amount of H2 production while also decreasing the efficiency of converting light [11].

Direct biophotolysis is the process by which anaerobic, photosynthetic microorganisms such as cyanobacteria or green algae use sun irradiation to create H2 from water. CO2 served as an electron transporter between the produced H2 and the blocking O2 during indirect biophotolysis, which produced H2 and separated it from O2. By using CO2, photosynthesizing bacteria increase the amount of biomass they produce.

4. Comparison of the Economics and Technical Aspects of Several Ways of Producing Hydrogen

4.1. Comparison of the H2 Production Cost

According to Table 1, among the various thermochemical conversion (TC) processes that can be used to produce hydrogen, agricultural waste gasification, biomass pyrolysis, and methane pyrolysis have the lowest cost of production. In addition, it is the most expensive method of producing hydrogen via TC reactions connected to steam reforming of NG and biomass gasification. On the one hand, this table indicates that using AWE-based electrolysis to produce hydrogen is less expensive than using PEM-based water electrolysis for the same purpose.

Table 1.

Comparison of the H2 production cost of different methods of producing hydrogen.

Among the biological methods of production of hydrogen, the dark fermentation (DF) technique is less expensive to produce than the photobiological (PF) method. In addition, Table 1 demonstrates that the most economical technique for producing hydrogen (DF) is through the production of hydrogen from food waste, whereas the most expensive method is to produce hydrogen from wastewater and agricultural waste.

4.2. Sensitivity Analysis

4.2.1. Capital Cost Sensitivity

Sensitivity analysis aids in identifying the situation and state of any operational facility following an investment. Making a decision before making an investment is more beneficial. The ability to react to capital expenses can be assessed by figuring out the ROI (return on investment). It is an important tool for assessing the overall development of the plant from beginning to end as well as the level of return on investment during each phase of plant growth. ROI provides in-depth data on the overall return of a plant investment, though it does not take into account the time value of money. To ensure the pilot plant runs smoothly, it is crucial to carefully assess the ROI and minimize any avoidable risks that may arise during its operation. The return on investment is determined using the following formula:

ROI = (AF/FCI) × 100%

The term “FCI” refers to the fixed capital investment required for purchasing land, machinery, and installation, whereas “AF” stands for the annual profit, which is calculated as yearly revenue less annual production costs. For a fifteen-year-old hydrogen plant, the after-tax AF was reported as $146,473.6, while the FCI was $547,504. Therefore, it is anticipated that the ROI will be 26.75%, given that the facility’s total capital cost is $583,092 [48].

For a plant having produced hydrogen from bread trash for ten years using a pilot-scale continuously stirred tank reactor, the plant’s after-tax AF was stated to be $244,186 with an FCI of $874,200. Consequently, the plant’s TCC (total capital cost) was determined to be $931,020, with an ROI of 27.93% [49]. For a continuously operated immobilized sludge reactor that was used for 10 years to produce hydrogen from molasses, the reactor volume was increased from 10 to 50 m3 in order to calculate the return on investment. Consequently, the ROI for capacities of 10, 20, 30, 40, and 50 cubic meters was computed to be −37.7%, −17.7%, 4.6%, 25.2%, and 47.3%, respectively. The return on investment rose as the reactor volume increased. Usually, a return on investment exceeding 20% is viewed as successful for expanding operations. Thus, the return on investment for reactor volumes ranging from 10 to 30 m3 was minimal and not particularly appealing. For reactor volumes of 40 and 50 m3, the projected return on investment appears to be appealing and exceeds the threshold for profitability (greater than 20%) [50]. They have successfully carried out a small-scale experimental bioprocess for the generation of hydrogen utilizing food waste for 10 years that combines solid-state fermentation with dark fermentation. The plant’s after-tax AF totaled $208,100 and its FCI was $664,650. Consequently, the plant’s TCC was determined to be $707,850 with an ROI of 31.31%. The discussion shows that the capital cost of a pilot plant is influenced by equipment and reactor volume, which in turn affects AF and ROI. Conducting a sensitivity analysis on capital costs before starting the pilot plant project can help prevent unnecessary economic failure [51].

4.2.2. Sensitivity to IRR

A financial evaluation measure used to evaluate a project’s profitability is the IRR. The discount rate, known as the internal rate of return, is what brings the H2 processing plant’s net present value to zero. This may maintain an equilibrium between the factory’s present cash inflow and outflow. Longer payback periods and lower NPV (net present value) are the outcomes of greater IRR discount rates. The plant’s profitability will rise with a lower IRR discount rate as it has a greater NPV and a shorter payback period [48]. Being aware of IRR is crucial in determining the yearly increase in plant investments, and it places greater emphasis on the payback period. Typically, IRR is determined through trial and error until NPV reaches zero. Managing a smaller-scale hydrogen production facility and assessing the internal rate of return, the plant’s NPV is calculated to be $1,467,544 with a discount rate of zero. After five years of PB, the discount rate, or IRR, will be 24.07% when the NPV approaches zero. It is cost-effective to expand the process, as indicated by the IRR of 24.07% [48]. The NPV and PB periods of the hydrogen plant were estimated across a range of discount rates from 0 to 30%. Consequently, an increase in NPV was observed along with a decrease in the PB period as the DR decreased from 30% to 0%. The plant’s attractiveness and economic feasibility for scaling up the process are enhanced by the lower DR (discount rate).

The NPV is $1,266,654 in the case when DR becomes zero, and the PB time is 4.8 years. Furthermore, at the point where NPV reaches zero, the IRR of the plant is calculated to be 21.77% [49]. The estimation of the IRR was conducted by altering the volume of the H2 reactor within a range of 10 to 50 m3. Findings indicate that an increase in reactor volume results in a decrease in the payback period (PB). In particular, for reactor capacities between 10 and 30 m3, the PB period is longer than the plant’s operating life by more than 10 years. However, the PB time significantly drops to 9.7 and 6.9 years, respectively, with an increase in reactor capacity to 40 and 50 m3, falling within the plant’s operating lifespan of 10 years. Then, when the discount rate is set to zero, the net present value for reactor capacities of 40 and 50 m3 was computed to be $30,360 and $526,551, respectively. This analysis reveals that NPV rises as reactor volume increases. Upon reaching a zero NPV, the IRR for reactors with volumes of 40 and 50 m3 was determined to be 0.63% and 9.25%, respectively. The internal rate of return (IRR) numbers is used to evaluate the effectiveness of plant investments. A reactor volume of 50 m3 results in a greater IRR value. This suggests that economically feasible outcomes are more likely with reactors with larger volumes in comparison to those with smaller volumes [50].

It was mentioned that the plant’s IRR, NPV, and PB period are significantly impacted by the cost of manufacturing H2 and personnel costs. When the discount rate dropped from 30% to 0%, the authors saw an improvement in NPV. After 5 years of the PB period, the writers achieved a higher NPV of $884,115 with a discount rate of 0. The plant achieved a 20.2% IRR at zero NPV. The plant’s internal rate of return value indicates that increasing the operation will result in profitability [51]. Comparing the gasification and reforming processes’ internal rates of return (IRR) for processing bio-oil, the researchers discovered that the IRR for reforming was greater than that of gasification (8.4%) at 18.6%. As was previously discussed, DF has a faster payback period and a greater IRR. This indicates that DF is a more financially viable option than other methods for efficient production of H2 [52]. Table 2 displays the IRR sensitivity analysis for several hydrogen generation techniques.

Table 2.

An examination of the internal rate of return’s sensitivity for several hydrogen generation techniques.

4.3. Technology Readiness Level (TRL), Efficiency, and Scalability Comparison of Several Hydrogen-Production Methods

The most crucial elements of each procedure are outlined in Table 3, which is a compilation of the numerous literature references that were discussed in the preceding paragraphs. The efficiency (%), yield (kg H2/kg biomass), and TRL for each technique are highlighted in the table. The appropriate unit conversions were performed so that they could be compared.

The industrial design for thermochemical processes was previously established [3]. Similar methods were used in the development of the approach, with the essential modifications taken from steam methane reforming (SMR) [54]. The largest yields are obtained through gasification, which has an efficiency of between 35 and 50% [12], and a TRL of seven [3]. It also has a 40% H2 percentage in the gas and a higher H2/CO ratio (1.6) [55]. It is believed that this method is the most appropriate for producing hydrogen.

In terms of feedstock, wet biomass (moisture ranging from 5 to 35 weight percent) can be gasified using steam, but air gasification needs a dry raw material [56]. However, the procedures are more susceptible to catalyst deactivation due to the generation of tar and char, and the gas products must be separated and purified [3].

Additionally, it was demonstrated that ash-related problems, including agglomeration, erosion, corrosion, and sintering, make the gasification process economically unfeasible [15].

Research indicates that rapid pyrolysis of biomass releases more volatiles than slow pyrolysis at the same temperature [13]. A catalyst has been shown to enhance the production of H2 gas while decreasing the yield of CO, C2-C4, and CH4 [57] In 20 years, biomass pyrolysis and gasification employing processes akin to those used to treat fossil fuels should achieve a total relative cost (TRL) of up to nine. However, a combination of carbon capture technologies and thermochemical processes is needed to achieve negative emissions [3].

With a somewhat greater biogas efficiency of 51.7% and 27.8% at 20 bars, respectively, anaerobic digestion of biomass produces more H2 as the temperature of the reforming process rises [58]. Because of the many steps necessary in achieving high-purity hydrogen yields, scaling down would be unfeasible due to the complexity, cost, and requirement for several process units [59]. According to Antonini et al.’s [60] research, biomethane is more sustainable than natural gas since it contributes less to greenhouse gas emissions through the non-carbon cycle. The study also compares the two in terms of performance and storage systems.

Dark fermentation appears to be the most competitive biological process for biomass when assessing the potential for scale-up. Its yield ranges from 0.004 to 0.044 kg H2/kg biomass, and its efficiency is between 60 and 80% [11], with a TRL of five [1]. This straightforward, waste-recycling, CO2-neutral process generates H2 without the need for light, but it has drawbacks such as the removal of fatty acids, low H2 rates, poor conversion efficiency, and high reactor volume requirements [11]. Furthermore, poor catalyst durability and product pollutants are barriers to dark fermentation. There are currently none that are on a commercial scale. Additionally, CO2-neutral photo fermentation may be used with various organic waste and wastewater and is a waste-recycling method [11]. However, the projected yield is 0.004–0.049 kg H2/kg of biomass, and the light conversion efficiency is only 1–2%. The process has a TRL of four, is sensitive to O2, and also needs sunlight and a sizable reactor volume [3].

In sequential and combined fermentation processes, complex carbohydrates are broken down by bacteria, which results in the production of acids and alcohols during dark fermentation. These products are then utilized as substrates for photofermentation [61]. Both dark and photofermentation occur simultaneously in a single bioreactor, with the former creating volatile fatty acids that are subsequently broken down by photofermentative microorganisms.

Table 3 presents a yield comparison between thermochemical and biological approaches, emphasizing the benefits of thermochemical methods based on their substantial study and application. Thermochemical methods produce H2 at a much slower speed and with a much lower yield than biological approaches, even though dark fermentation makes them more competitive [62]. Finally, the requirement for pre-treatment during the synthesis of a complex biomass places limitations on pilot-scale procedures [3].

When comparing the costs of thermochemical and biological approaches, Table 3 demonstrates that thermochemical methods are more advantageous. On the other hand, biogas reforming is more expensive than water electrolysis, indicating that fermentation processes are more economical.

Table 3 presents a comparison between conventional technologies such as natural gas and water electrolysis and biomass-based approaches for producing hydrogen. SR and water electrolysis are in competition with gasification and pyrolysis. While thermochemical approaches are in pre-commercial demonstration, biological and electrochemical technologies are currently in development. Although yield and TRL are improved by thermochemical approaches, CO2 emission intensity, and CCS inclusion must be taken into account.

According to the life cycle evaluation by Antonini et al. [60], net-negative CO2 emissions are produced when hydrogen is produced using a biomethane-based process with carbon capture systems (CCS). These techniques put a strain on the environment since they require more energy and use more of it, which makes them perform worse with CCS.

Table 3.

Comparison of the technology readiness level (TRL), efficiency, H2 production costs, and scalability of several ways of producing hydrogen.

Table 3.

Comparison of the technology readiness level (TRL), efficiency, H2 production costs, and scalability of several ways of producing hydrogen.

| Method | Efficiency (%) | TRL | Scale |

|---|---|---|---|

| Pyrolysis | 65 (using HDPE) [63] | 7 [64] | Bench scale [8] |

| Gasification | 35–50 [11] | 4–7 [65] | Laboratory and bench scale [8] |

| Biogas Reforming | 46.2–51.7 (SR) | 9 (SMR) | Large-scale (SR) [66] |

| 24.5–27.8 (ATR) | 8 (ATR), for natural gas | plant model [67] | |

| Dark fermentation | 60–80 [11] | 5 [3] | Laboratory scale [42] |

| Photo fermentation | Light conversion efficiency 1–5 | 4 [3] | Laboratory scale [42] |

| Water Electrolysis | 51–60 (AEL) 46–60 (PEMEL) 76–81 (SOEL) [68] | 9 (AEL) 8 (PEM) [69] | Laboratory and industrial scale [70] |

4.4. Comparison of the CO2 Emissions of Several Ways of Producing Hydrogen

The CO2 emissions that each thermochemical process generates when producing hydrogen are shown in Table 4 [71]. Table 4 leads us to the conclusion that when the procedure is coupled with CCS, the TRL is always lower. Nevertheless, adding CCS to the system yields notable improvements in biomass gasification. Given that a net-zero economy is desired, which calls for carbon absorption and negative CO2 emissions into the environment, the latter shows net-negative CO2 emissions, which is a crucial component.

Table 4.

Hydrogen-production methods and CO2 emission intensity.

4.5. Commercialization Obstacle

The hydrogen economy encounters various impediments to its advancement and effective commercialization. Hydrogen produced through various processes on a large scale encounters certain techno-economic barriers.

4.5.1. Technical Obstacles

Obstacles to commercializing H2 production involve decreased efficiency and higher costs in comparison to other methods [75]. The generation of H2 through fermentation is continuing to increase from its initial stages as technology evolves [76]. To increase the amount and pace of H2 generation, several tactics must be used at the genetic and fermentation levels. Using genetic engineering, strains that are specially designed to produce hydrogen may be developed. The efficiency of the entire process is increased by the integration of hydrogen production processes.

Inoculum pretreatments and higher energy consumption are obstacles to the commercialization of the DF process. Prior to DF being commercialized, it is imperative to conduct investigations on economic and technical feasibility to prevent large-scale process inhibition [77]. The limitation of DF is the production of only 4 mol H2/mol of glucose, which remains a significant challenge [62]. To make any H2 process commercially viable, it is crucial to optimize the entire process.

The primary concerns in thermochemical conversion for H2 production involve managing the raw materials and preparing them for further processing. The technological and financial obstacles to the practical use of hydrogen thermochemical conversion techniques are presented in Table 5. The production of tar by pyrolysis and gasification is the primary goal of low-temperature gasification systems.

Table 5.

Overcoming challenges with thermochemical conversion methods for the commercialization of hydrogen, both economically and technically.

The primary hindrance in the commercial gasification process lies in the presence of organic impurities within the syngas generated, leading to significant operational challenges [83]. Additionally, environmental factors and the need to maintain optimal temperatures inside the gasifier as well as the cost-effective removal of tar pose considerable hurdles. Several other obstacles include the suboptimal efficiency of feed delivery, surplus metabolites within reactors, and decreased conversion efficiency of substrates in scenarios involving mixed organic waste. These challenges stem from either the intricate nature of the substrates or the absence of microbial populations capable of effectively hydrolyzing them [84].

4.5.2. Financial Obstacles

The DF process is particularly expensive in the field of biological hydrogen synthesis, and most research is conducted in lab environments. The challenges in both the technical and economic aspects of different biochemical conversion techniques for hydrogen are highlighted in Table 6, particularly in terms of progressing toward commercial viability. Overcoming economic challenges related to developing cost-effective photobioreactors and improving photosynthesis in biophotolysis are key objectives. A study delved into bio-hydrogen production utilizing an anaerobic membrane bioreactor, pinpointing that the primary economic hindrances revolve around the considerable operating and installation expenses, consequently resulting in diminished hydrogen yields [85]. The economic evaluation of photobiological H2 production remains predominantly speculative, given the inherently cost-intensive nature of biological H2-production processes [86]. The production rate of H2 in photobiological processes is relatively low, making it unsuitable for large-scale applications. The combined expenses related to the production of hydrogen through dark and photo fermentative processes were calculated to range from 2.5 to 2.8 dollars per kilogram [11]. Research carried out by Sharma and Kaushik in 2017 showed that $3.70 and $18.70 were used for generating hydrogen in DF and PF, respectively. Dark fermentative hydrogen production is not as economically viable as natural gas reforming because it is more expensive [76].

Table 6.

Different biological processes for hydrogen conversion face a number of technical and financial obstacles on their journey to commercialization.

Challenges in thermochemical conversion methods are caused by PSA (pressure swing absorption) and costly catalysts, leading to increased expenses in H2 production. Although the purification of H2 introduces additional expenditures to the procedure, it concurrently reduces the expenses related to biomass and augments efficiency, thereby diminishing the overall production cost of H2 [43]. The utilization of water electrolysis in the context of small-scale hydrogen manufacturing emerges as a feasible choice from an economic standpoint, given that the electrolyzer consumes more electricity, leading to a proportional increase in production costs, accounting for approximately 5% of the total expenditure in large-scale production [11].

5. Assessment and Potential Future Approaches

Centralized hydrogen production processes based on fossil fuels have proven feedstock infrastructure and commercially available, advanced technology. While carbon sequestration contributes to the continued use of fossil-fuel-based technology, there are still issues to be resolved regarding the extensive land degradation caused by fossil fuel extraction and the possibility of oil leaks during tanker transportation. With its advanced technology, water electrolysis makes use of both grid electricity and pre-existing infrastructure. The near-term hydrogen market is anticipated to be supplied by these current technologies as well. The mid-term hydrogen market may see natural gas steam reforming, coal gasification, biomass gasification, and biological fuel reforming persist, while sustainable technologies like thermochemical cycles and renewable electricity sources may supply the market.

6. Conclusions

This research provides brief perspectives on the techno-economic evaluation of several methods for hydrogen production. We also looked at the costs associated with producing hydrogen in terms of feedstock, capital, and internal rate of return. Hydrogen as a substitute energy vector has been the subject of much research and is one of the many steps being taken to mitigate global warming. Numerous conversion routes have already been looked at in order to extract H2 from biomass.

- Thermochemical technologies are the most commonly utilized methods. Numerous scholars and policymakers are intrigued by the process of steam reforming natural gas to create hydrogen due to its ability to generate hydrogen with a high efficiency of 70–85% and low operational and production expenses of 0.3 dollars per kilogram of hydrogen. More research is needed to reduce both carbon dioxide emissions and manufacturing costs during the steam reforming process. Economic obstacles to steam reforming include process and catalyst costs. Increased efficiency and extended durability of the valuable metal catalyst need to compensate for the elevated individual catalyst expense in order to address these issues. Furthermore, expanding the plant’s scale will result in higher CAPEX but far lower H2 production costs. The technical obstacles to gasification include product normalization, catalyst deactivation, corrosion, clogging, and a lack of commercial use. Economic hurdles to gasification can include high operating and investment costs since high temperatures are needed. Membrane reactors can be used to incorporate hydrogen generation processes, thereby increasing the thermochemical process’s efficacy and mitigating these problems.

- Furthermore, research has employed microbes to facilitate the biological conversion of biomass, mainly using dark fermentation techniques. The main benefits are found in moderate-use circumstances. Progress is impeded by the sluggish conversion rate and low production quantities of these technologies, which are their primary limits. The capital costs of these systems are increased by the need for costly bioreactors and separation processes. Pre-treatments are also required for biomass that is resistant to treatment since this results in the synthesis of inhibitors and lower operating costs and capital costs. The creation of novel bacterial strains, more effective bioreactors, and small-scale local production facilities should be the main goals of future advancements. Economic constraints to photofermentation include increased yields at high energy costs. To overcome these obstacles, metabolic engineering can make up for the notable advancements in the biohydrogen process. Nutrient limitation and substrate usage effects were studied in order to identify genes in microalgae that promote increased hydrogen generation. The creation of photobioreactors must have an optimal design. The inhibitory chemicals during the pretreatment generate a substantial impediment, which is one of the technical key limitations of combined dark and photofermentation. The substrate inhibits one or both of the processes. The high cost of the feedstock, the processing costs resulting from the wastewater treatment effluents’ toxicity, the sequential reactor’s operation and maintenance, and the operating costs during the pretreatment of dark fermentation effluent are additional economic barriers to this method.

Thermochemical treatment is significantly more advanced than biological or electrochemical treatment when it comes to scaling opportunities, based on comparisons of current processes. The results of this research show that biomass-hydrogen processes have the potential for increasing H2 production, but further enhancements are needed to produce larger quantities for competitiveness.

Author Contributions

Conceptualization, A.G. and H.N.R.; methodology, A.G.; software, formal analysis, A.G.; investigation, H.N.R.; resources, M.A.; writing—original draft preparation, A.G., M.A.; writing—review and editing, H.N.R. and M.A.; visualization, M.A.; supervision, A.G.; project administration, A.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

Author Hima Nikafshan Rad was employed by the company SavvyScience Tech Pty Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

| DF | Dark Fermentation |

| SR | Steam Reforming |

| TC | Thermochemical |

| BC | Biochemical |

| PF | Photobiological Fermentation |

| NG | Natural Gas |

| IRR | Internal Rate of Return |

| PB | Payback period |

| TRL | Technology Readiness Level |

| CBF | Carbon-Based Fuels |

| HC | Hydrocarbon |

| SMR | Steam Methane Reforming |

| SRNG | Steam Reforming of Natural Gas |

| WGS | Water Gas Shift |

| CPV | Concentrated Photovoltaic |

| ROI | Return on Investment |

| FCI | Fixed Capital Investment |

| AF | Annual Profit |

| TCC | Total Capital Cost |

| NPV | Net Present Value |

| DR | Discount Rate |

| ATR | Autothermal reforming |

| CCS | Carbon Capture Systems |

| PSA | Pressure Swing Absorption |

References

- Sridevi, V.; Surya, D.V.; Reddy, B.R.; Shah, M.; Gautam, R.; Kumar, T.H.; Puppala, H.; Pritam, K.S.; Basak, T. Challenges and opportunities in the production of sustainable hydrogen from lignocellulosic biomass using microwave-assisted pyrolysis: A review. Int. J. Hydrogen Energy 2024, 52, 507–531. [Google Scholar] [CrossRef]

- Sharafi, L.S.; Zeinali, M.; Mahmoudi, S.M.S.; Soltani, S.; Rosen, M.A. Biomass co-fired combined cycle with hydrogen production via proton exchange membrane electrolysis and waste heat recovery: Thermodynamic assessment. Int. J. Hydrogen Energy 2023, 48, 33795–33809. [Google Scholar] [CrossRef]

- Lepage, T.; Kammoun, M.; Schmetz, Q.; Richel, A. Biomass-to-hydrogen: A review of main routes production, processes evaluation and techno-economical assessment. Biomass-Bioenerg. 2021, 144, 105920. [Google Scholar] [CrossRef]

- Mazloomi, K.; Gomes, C. Hydrogen as an energy carrier: Prospects and challenges. Renew. Sustain. Energy Rev. 2012, 16, 3024–3033. [Google Scholar] [CrossRef]

- Rajesh Banu, J.; Kavitha, S.; Yukesh Kannah, R.; Bhosale, R.R.; Kumar, G. Industrial wastewater to biohydrogen: Possibilities towards successful biorefinery route. Bioresour. Technol. 2020, 298, 122378. [Google Scholar] [CrossRef] [PubMed]

- Dou, B.; Zhang, H.; Song, Y.; Zhao, L.; Jiang, B.; He, M.; Ruan, C.; Chen, H.; Xu, Y. Hydrogen production from the thermochemical conversion of biomass: Issues and challenges. Sustain. Energy Fuels 2019, 3, 314–342. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, S. Economic assessment of selected hydrogen production methods: A review. Energ Source Part B 2017, 12, 1022–1029. [Google Scholar] [CrossRef]

- Arregi, A.; Amutio, M.; Lopez, G.; Bilbao, J.; Olazar, M. Evaluation of thermochemical routes for hydrogen production from biomass: A review. Energy Convers. Manag. 2018, 165, 696–719. [Google Scholar] [CrossRef]

- Yukesh, K.R.; Kavitha, S.; Preethi; Parthiba Karthikeyan, O.; Kumar, G.; Dai-Viet, N.V.; Rajesh Banu, J. Techno-economic assessment of various hydrogen production methods—A review. Bioresour. Technol. 2021, 319, 124175. [Google Scholar] [CrossRef]

- Rezaei, P.S.; Shafaghat, H.; Daud, W.M.A.W. Production of green aromatics and olefins by catalytic cracking of oxygenate compounds derived from biomass pyrolysis: A review. Applied Catalysis A General. 2014, 469, 490–511. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. A comparative overview of hydrogen production processes. Renew. Sustain. Energy Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- Bi, P.; Wang, J.; Zhang, Y.; Jiang, P.; Wu, X.; Liu, J.; Xue, H.; Wang, T.; Li, Q. From lignin to cycloparaffins and aromatics: Directional synthesis of jet and diesel fuel range biofuels using biomass. Bioresour. Technol. 2015, 183, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liang, Y.; Li, S.; Yuan, Y.; Zhang, D.; Wu, Y.; Xie, H.; Brindhadevi, K.; Pugazhendhi, A.; Xia, C. A review of biomass pyrolysis gas: Forming mechanisms, influencing parameters, and product application upgrades. Fuel 2023, 347, 128461. [Google Scholar] [CrossRef]

- Holladay, D.J.; Hu, J.; King, D.L.; Wang, Y.A. overview of hydrogen production technologies. Catal. Today 2009, 139, 244–260. [Google Scholar] [CrossRef]

- Molino, A.; Chianese, S.; Musmarra, D. Biomass gasification technology: The state-of-the-art overview. J. Energy Chem. 2016, 25, 10–25. [Google Scholar] [CrossRef]

- Cortazar, M.; Santamaria, L.; Lopez, G.; Alvarez, J.; Zhang, L.; Wang, R.; Bi, X.; Olazar, M. A comprehensive review of primary strategies for tar removal in biomass gasification. Energy Convers. Manag. 2023, 276, 116496. [Google Scholar] [CrossRef]

- Hannula, I.; Kurkela, E. A semi-empirical model for pressurised air-blown fluidised-bed gasification of biomass. Bioresour. Technol. 2010, 101, 4608–4615. [Google Scholar] [CrossRef]

- Xu, C.; Chen, S.; Soomro, A.; Sun, Z.; Xiang, W. Hydrogen rich syngas production from biomass gasification using synthesized Fe/CaO active catalysts. J. Energy Inst. 2018, 91, 805–816. [Google Scholar] [CrossRef]

- Züttel, A. Materials for hydrogen storage. Mater. Today 2003, 6, 24–33. [Google Scholar] [CrossRef]

- Gondal, I.A.; Masood, S.A.; Khan, R. Green hydrogen production potential for developing a hydrogen economy in Pakistan. Int. J. Hydrogen Energy 2018, 43, 6011–6039. [Google Scholar] [CrossRef]

- Chi, J.; Yu, H. Water electrolysis based on renewable energy for hydrogen production. Chinese J. Catal. 2018, 39, 390–394. [Google Scholar] [CrossRef]

- Ferrero, D.; Santarelli, M. Investigation of a novel concept for hydrogen production by PEM water electrolysis integrated with multi-junction solar cells. Energy Convers. Manag. 2017, 148, 16–29. [Google Scholar] [CrossRef]

- Boudries, R. Techno-economic Assessment of Solar Hydrogen Production Using CPV-electrolysis Systems. Energy Proc. 2016, 93, 96–101. [Google Scholar] [CrossRef]

- Lima da Silva, A.; Müller, I.L. Hydrogen production by sorption enhanced steam reforming of oxygenated hydrocarbons (ethanol, glycerol, n-butanol and methanol): Thermodynamic modelling. Int. J. Hydrogen Energy 2011, 36, 2057–2075. [Google Scholar] [CrossRef]

- Braga, A.H.; Sodre, E.R.; Santos, J.B.O.; de Paula Marques, C.M.; Bueno, J.M.C. Steam reforming of acetone over Ni- and Co-based catalysts: Effect of the composition of reactants and catalysts on reaction pathways. Appl. Catal. B Environ. 2016, 195, 16–28. [Google Scholar] [CrossRef]

- Nabgan, W.; Abdullah, T.A.T.; Mat, R.; Nabgan, B.; Jalil, A.A.; Firmansyah, L.; Triwahyono, S. Production of hydrogen via steam reforming of acetic acid over Ni and Co supported on La2O3 catalyst. Int. J. Hydrogen Energy 2017, 42, 8975–8985. [Google Scholar] [CrossRef]

- Carrero, A.; Vizcaíno, A.J.; Calles, J.A.; García-Moreno, L. Hydrogen production through glycerol steam reforming using Co catalysts supported on SBA-15 doped with Zr, Ce and La. J. Energy Chem. 2017, 26, 42–48. [Google Scholar] [CrossRef]

- Basagiannis, A.C.; Verykios, X.E. Catalytic steam reforming of acetic acid for hydrogen production. Int. J. Hydrogen Energy 2007, 32, 3343–3355. [Google Scholar] [CrossRef]

- Cai, W.; de la Piscina, P.R.; Gabrowska, K.; Homs, N. Hydrogen production from oxidative steam reforming of bio-butanol over CoIr-based catalysts: Effect of the support. Bioresour. Technol. 2013, 128, 467–471. [Google Scholar] [CrossRef] [PubMed]

- Kwak, B.S.; Kim, J.; Kang, M. Hydrogen production from ethanol steam reforming over core–shell structured NixOy–, FexOy–, and CoxOy–Pd catalysts. Int. J. Hydrogen Energy 2010, 35, 11829–11843. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, C.; Chen, S.; Liu, Y. Co–Ni bimetal catalyst supported on perovskite-type oxide for steam reforming of ethanol to produce hydrogen. Int. J. Hydrogen Energy 2014, 39, 5644–5652. [Google Scholar] [CrossRef]

- Moraes, T.S.; Cozendey da Silva, H.N.; Zotes, L.P.; Mattos, L.V.; Pizarro Borges, L.E.; Farrauto, R.; Noronha, F.B. A techno-economic evaluation of the hydrogen production for energy generation using an ethanol fuel processor. Int. J. Hydrogen Energy 2019, 44, 21205–21219. [Google Scholar] [CrossRef]

- Song, H.; Ozkan, U.S. Economic analysis of hydrogen production through a bio-ethanol steam reforming process: Sensitivity analyses and cost estimations. Int. J. Hydrogen Energy 2010, 35, 127–134. [Google Scholar] [CrossRef]

- Bahzad, H.; Shah, N.; Dowell, N.M.; Boot-Handford, M.; Soltani, S.M.; Ho, M.; Fennell, P.S. Development and techno-economic analyses of a novel hydrogen production process via chemical looping. Int. J. Hydrogen Energy 2019, 44, 21251–21263. [Google Scholar] [CrossRef]

- Akhlaghi, N.; Najafpour-Darzi, G. A comprehensive review on biological hydrogen production. Int. J. Hydrogen Energy 2020, 45, 22492–22512. [Google Scholar] [CrossRef]

- Levin, D.B.; Pitt, L.; Love, M. Biohydrogen production: Prospects and limitations to practical application. Int. J. Hydrogen Energy 2004, 29, 173–185. [Google Scholar] [CrossRef]

- Kannah, R.Y.; Kavitha, S.; Sivashanmugham, P.; Kumar, G.; Nguyen, D.D.; Chang, S.W.; Banu, J.R. Biohydrogen production from rice straw: Effect of combinative pretreatment, modelling assessment and energy balance consideration. Int. J. Hydrogen Energy 2019, 44, 2203–2215. [Google Scholar] [CrossRef]

- Kavitha, S.; Kannah, R.Y.; Gunasekaran, M.; Kumar, G.; Banu, J.R. Rhamnolipid induced deagglomeration of anaerobic granular biosolids for energetically feasible ultrasonic homogenization and profitable biohydrogen. Int. J. Hydrogen Energy 2020, 45, 5890–5899. [Google Scholar] [CrossRef]

- Kumar, M.D.; Kannah, R.Y.; Kumar, G.; Sivashanmugam, P.; Banu, J.R. A novel energetically efficient combinative microwave pretreatment for achieving profitable hydrogen production from marine macro algae (Ulva reticulate). Bioresour. Technol. 2020, 301, 122759. [Google Scholar] [CrossRef]

- Li, Y.C.; Liu, Y.F.; Chu, C.Y.; Chang, P.L.; Hsu, C.W.; Lin, P.J.; Wu, S.Y. Techno-economic evaluation of biohydrogen production from wastewater and agricultural waste. Int. J. Hydrogen Energy 2012, 37, 15704–15710. [Google Scholar] [CrossRef]

- Das, D.; Veziroglu, T.N. Advances in biological hydrogen production processes. Int. J. Hydrogen Energy 2008, 33, 6046–6057. [Google Scholar] [CrossRef]

- Ni, M.; Leung, D.Y.C.; Leung, M.K.H.; Sumathy, K. An overview of hydrogen production from biomass. Fuel Process. Technol. 2006, 87, 461–472. [Google Scholar] [CrossRef]

- Sara, H.R.; Enrico, B.; Mauro, V.; Andrea, D.C.; Vincenzo, N. Techno-economic Analysis of Hydrogen Production Using Biomass Gasification -A Small Scale Power Plant Study. Energy Proc. 2016, 101, 806–813. [Google Scholar] [CrossRef]

- Mohammed, M.A.A.; Salmiaton, A.; Wan Azlina, W.A.K.G.; Mohammad Amran, M.S.; Fakhru’l-Razi, A. Air gasification of empty fruit bunch for hydrogen-rich gas production in a fluidized-bed reactor. Energy Convers. Manag. 2011, 52, 1555–1561. [Google Scholar] [CrossRef]

- Lv, P.; Wu, C.; Ma, L.; Yuan, Z. A study on the economic efficiency of hydrogen production from biomass residues in China. Renew. Energy 2008, 33, 1874–1879. [Google Scholar] [CrossRef]

- Lee, D.-H.; Lee, D.-J. Hydrogen economy in Taiwan and biohydrogen. Int. J. Hydrogen Energy 2008, 33, 1607–1618. [Google Scholar] [CrossRef]

- Matute, G.; Yusta, J.M.; Correas, L.C. Techno-economic modelling of water electrolysers in the range of several MW to provide grid services while generating hydrogen for different applications: A case study in Spain applied to mobility with FCEVs. Int. J. Hydrogen Energy 2019, 44, 17431–17442. [Google Scholar] [CrossRef]

- Han, W.; Fang, J.; Liu, Z.; Tang, J. Techno-economic evaluation of a combined bioprocess for fermentative hydrogen production from food waste. Bioresour. Technol. 2016, 202, 107–111. [Google Scholar] [CrossRef]

- Han, W.; Hu, Y.Y.; Li, S.Y.; Li, F.F.; Tang, J.H. Biohydrogen production from waste bread in a continuous stirred tank reactor: A techno-economic analysis. Bioresour. Technol. 2016, 221, 318–323. [Google Scholar] [CrossRef] [PubMed]

- Han, W.; Liu, Z.; Fang, J.; Huang, J.; Zhao, H.; Li, Y. Techno-economic analysis of dark fermentative hydrogen production from molasses in a continuous mixed immobilized sludge reactor. J. Clean. Prod. 2016, 127, 567–572. [Google Scholar] [CrossRef]

- Han, W.; Yan, Y.; Gu, J.; Shi, Y.; Tang, J.; Li, Y. Techno-economic analysis of a novel bioprocess combining solid state fermentation and dark fermentation for H2 production from food waste. Int. J. Hydrogen Energy 2016, 41, 22619–22625. [Google Scholar] [CrossRef]

- Zhang, Y.; Brown, T.R.; Hu, G.; Brown, R.C. Comparative techno-economic analysis of biohydrogen production via bio-oil gasification and bio-oil reforming. Biomass Bioenergy 2013, 51, 99–108. [Google Scholar] [CrossRef]

- Porcu, A.; Sollai, S.; Marotto, D.; Mureddu, M.; Ferrara, F.; Pettinau, A. Techno-Economic Analysis of a Small-Scale Biomass-to-Energy BFB Gasification-Based System. Energies 2019, 12, 494. [Google Scholar] [CrossRef]

- Stenberg, V.; Rydén, M.; Mattisson, T.; Lyngfelt, A. Exploring novel hydrogen production processes by integration of steam methane reforming with chemical-looping combustion (CLC-SMR) and oxygen carrier aided combustion (OCAC-SMR). Int. J. Greenh. Gas. Control 2018, 74, 28–39. [Google Scholar] [CrossRef]

- Cao, L.; Yu, I.K.; Xiong, X.; Tsang, D.C.; Zhang, S.; Clark, J.H.; Hu, C.; Ng, Y.H.; Shang, J.; Ok, Y.S. Biorenewable hydrogen production through biomass gasification: A review and future prospects. Environ. Res. 2020, 186, 109547. [Google Scholar] [CrossRef] [PubMed]

- Ditzig, J.; Liu, H.; Logan, B.E. Production of hydrogen from domestic wastewater using a bioelectrochemically assisted microbial reactor (BEAMR). Int. J. Hydrogen Energy 2007, 32, 2296–2304. [Google Scholar] [CrossRef]

- Nguyen, V.G.; Nguyen-Thi, T.X.; Nguyen, P.Q.P.; Tran, V.D.; Agbulut, Ü.; Nguyen, L.H.; Balasubramanian, D.; Tarelko, W.; Bandh, S.A.; Pham, N.D.K. Recent advances in hydrogen production from biomass waste with a focus on pyrolysis and gasification. Int. J. Hydrogen Energy 2024, 54, 127–160. [Google Scholar] [CrossRef]

- Hajjaji, N.; Martinez, S.; Trably, E.; Steyer, J.-P.; Helias, A. Life cycle assessment of hydrogen production from biogas reforming. Int. J. Hydrogen Energy 2016, 41, 6064–6075. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, A.; Pal, A. Overview of hydrogen production from biogas reforming: Technological advancement. Int. J. Hydrogen Energy 2022, 47, 34831–34855. [Google Scholar] [CrossRef]

- Antonini, C.; Treyer, K.; Streb, A.; van der Spek, M.; Bauer, C.; Mazzotti, M. Hydrogen production from natural gas and biomethane with carbon capture and storage—A techno-environmental analysis. Sustain. Energy Fuels 2020, 4, 2967–2986. [Google Scholar] [CrossRef]

- Kumar, G.; Saratale, R.G.; Kadier, A.; Sivagurunathan, P.; Zhen, G.; Kim, S.-H.; Saratale, G.D. A review on bio-electrochemical systems (BESs) for the syngas and value added biochemicals production. Chemosphere 2017, 177, 84–92. [Google Scholar] [CrossRef]

- Ghimire, A.; Frunzo, L.; Pirozzi, F.; Trably, E.; Escudie, R.; Lens, P.N.; Esposito, G. A review on dark fermentative biohydrogen production from organic biomass: Process parameters and use of by-products. Appl. Energy 2015, 144, 73–95. [Google Scholar] [CrossRef]

- Johan, M.A. Renewable Hydrogen Production from Biomass. Available online: https://www.etipbioenergy.eu/images/Renewable_Hydrogen_Production_from_Biomass.pdf (accessed on 26 April 2024).

- Wang, M.; Wang, G.; Sun, Z.; Zhang, Y.; Xu, D. Review of renewable energy-based hydrogen production processes for sustainable energy innovation. Glob. Energy Interconnect. 2019, 2, 436–443. [Google Scholar] [CrossRef]

- Rasul, M.; Hazrat, M.; Sattar, M.; Jahirul, M.; Shearer, M. The future of hydrogen: Challenges on production, storage and applications. Energy Convers. Manag. 2022, 272, 116326. [Google Scholar] [CrossRef]

- Madeira, J.G.F.; Delgado, A.R.S.; Boloy, R.A.M.; Coutinho, E.R.; Loures, C.C.A. Exergetic and economic evaluation of incorporation of hydrogen production in a cassava wastewater plant. Appl. Therm. Eng. 2017, 123, 1072–1078. [Google Scholar] [CrossRef]

- Lachén, J.; Durán, P.; Menéndez, M.; Peña, J.; Herguido, J. Biogas to high purity hydrogen by methane dry reforming in TZFBR+MB and exhaustion by Steam-Iron Process. Techno–economic assessment. Int. J. Hydrogen Energy 2018, 43, 11663–11675. [Google Scholar] [CrossRef]

- Panigrahy, B.; Narayan, K.; Rao, B.R. Green hydrogen production by water electrolysis: A renewable energy perspective. Mater. Today Proc. 2022, 67 Pt 8, 1310–1314. [Google Scholar] [CrossRef]

- Hassan, N.; Jalil, A.; Rajendran, S.; Khusnun, N.; Bahari, M.; Johari, A.; Kamaruddin, M.; Ismail, M. Recent review and evaluation of green hydrogen production via water electrolysis for a sustainable and clean energy society. Int. J. Hydrogen Energy 2024, 52, 420–441. [Google Scholar] [CrossRef]

- Grigoriev, S.; Fateev, V.; Bessarabov, D.; Millet, P. Current status, research trends, and challenges in water electrolysis science and technology. Int. J. Hydrogen Energy 2020, 45, 26036–26058. [Google Scholar] [CrossRef]

- Rosa, L.; Mazzotti, M. Potential for hydrogen production from sustainable biomass with carbon capture and storage. Renew. Sustain. Energy Rev. 2022, 157, 112123. [Google Scholar] [CrossRef]

- Parkinson, B.; Balcombe, P.; Speirs, J.F.; Hawkes, A.D.; Hellgardt, K. Levelized cost of CO2 mitigation from hydrogen production routes. Energy Environ. Sci. 2019, 12, 19–40. [Google Scholar] [CrossRef]

- Salkuyeh, Y.K.; Saville, B.A.; MacLean, H.L. Techno-economic analysis and life cycle assessment of hydrogen production from different biomass gasification processes. Int. J. Hydrogen Energy 2018, 43, 9514–9528. [Google Scholar] [CrossRef]

- Salkuyeh, Y.K.; Saville, B.A.; MacLean, H.L. Techno-economic analysis and life cycle assessment of hydrogen production from natural gas using current and emerging technologies. Int. J. Hydrogen Energy 2017, 42, 18894–18909. [Google Scholar] [CrossRef]

- Ren, N.-Q.; Zhao, L.; Chen, C.; Guo, W.-Q.; Cao, G.-L. A review on bioconversion of lignocellulosic biomass to H2: Key challenges and new insights. Bioresour. Technol. 2016, 215, 92–99. [Google Scholar] [CrossRef] [PubMed]

- Hsu, C.-W.; Lin, C.-Y. Using social network analysis to examine the technological evolution of fermentative hydrogen production from biomass. Int. J. Hydrogen Energy 2016, 41, 21573–21582. [Google Scholar] [CrossRef]

- Bundhoo, M.A.Z.; Mohee, R. Inhibition of dark fermentative bio-hydrogen production: A review. Int. J. Hydrogen Energy 2016, 41, 6713–6733. [Google Scholar] [CrossRef]

- Nemitallah, M.A.; Alnazha, A.A.; Ahmed, U.; El-Adawy, M.; Habib, M.A. Review on techno-economics of hydrogen production using current and emerging processes: Status and perspectives. Results Eng. 2024, 21, 101890. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, R.; Man, Y.; Ren, J. Recent developments of hydrogen production from sewage sludge by biological and thermochemical process. Int. J. Hydrogen Energy 2019, 44, 19676–19697. [Google Scholar] [CrossRef]

- Kumar, M.; Oyedun, A.O.; Kumar, A. A comparative analysis of hydrogen production from the thermochemical conversion of algal biomass. Int. J. Hydrogen Energy 2019, 44, 10384–10397. [Google Scholar] [CrossRef]

- Nguyen, T.; Abdin, Z.; Holm, T.; Merida, W. Grid-connected hydrogen production via large-scale water electrolysis. Energy Convers. Manag. 2019, 200, 112108. [Google Scholar] [CrossRef]

- Esposito, D.V. Membraneless Electrolyzers for Low-Cost Hydrogen Production in a Renewable Energy Future. Joule 2017, 1, 651–658. [Google Scholar] [CrossRef]

- Gonzalez, J.F.; Roman, S.; Bragado, D.; Calderon, M. Investigation on the reactions influencing biomass air and air/steam gasification for hydrogen production. Fuel Process. Technol. 2008, 89, 764–772. [Google Scholar] [CrossRef]

- Chandrasekhar, K.; Venkata Mohan, S. Bio-electrohydrolysis as a pretreatment strategy to catabolize complex food waste in closed circuitry: Function of electron flux to enhance acidogenic biohydrogen production. Int. J. Hydrogen Energy 2014, 39, 11411–11422. [Google Scholar] [CrossRef]

- Aslam, M.; Ahmad, R.; Yasin, M.; Khan, A.L.; Shahid, M.K.; Hossain, S.; Khan, Z.; Jamil, F.; Rafiq, S.; Bilad, M.R.; et al. Anaerobic membrane bioreactors for biohydrogen production: Recent developments, challenges and perspectives. Bioresour. Technol. 2018, 269, 452–464. [Google Scholar] [CrossRef]

- Show, K.Y.; Lee, D.J.; Tay, J.H.; Lin, C.Y.; Chang, J.S. Biohydrogen production: Current perspectives and the way forward. Int. J. Hydrogen Energy 2012, 37, 15616–15631. [Google Scholar] [CrossRef]

- Soares, J.F.; Confortin, T.C.; Todero, I.; Mayer, F.D.; Mazutti, M.A. Dark fermentative biohydrogen production from lignocellulosic biomass: Technological challenges and future prospects. Renew. Sustain. Energy Rev. 2020, 117, 109484. [Google Scholar] [CrossRef]

- Khan, M.A.; Ngo, H.H.; Guo, W.; Liu, Y.; Zhang, X.; Guo, J.; Chang, S.W.; Nguyen, D.D.; Wang, J. Biohydrogen production from anaerobic digestion and its potential as renewable energy. Renew. Energy 2018, 129, 754–768. [Google Scholar] [CrossRef]

- Kumar, G.; Shobana, S.; Nagarajan, D.; Lee, D.-J.; Lee, K.-S.; Lin, C.-Y.; Chen, C.-Y.; Chang, J.-S. Biomass based hydrogen production by dark fermentation—Recent trends and opportunities for greener processes. Curr. Opin. Biotechnol. 2018, 50, 136–145. [Google Scholar] [CrossRef] [PubMed]

- Rai, P.K.; Singh, S.P. Integrated dark- and photo-fermentation: Recent advances and provisions for improvement. Int. J. Hydrogen Energy 2016, 41, 19957–19971. [Google Scholar] [CrossRef]

- Rashid, N.; Rehman, M.S.U.; Memon, S.; Ur Rahman, Z.; Lee, K.; Han, J.I. Current status, barriers and developments in biohydrogen production by microalgae Renew. Sustain. Energy Rev. 2013, 22, 571–579. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).