Hemostatic Dressings Made of Oxidized Bacterial Nanocellulose Membranes

Abstract

:1. Introduction

2. Materials and Methods

2.1. BNC Membranes Purification

2.2. Electrochemical Setup

2.3. Oxidation Degree

2.4. Degree of Polymerization

2.5. Nuclear Magnetic Resonance Spectroscopy (NMR)

2.6. Attenuated Total Reflectance-Fourier-Transform Infrared Spectroscopy (ATR-FTIR) Analysis

2.7. Scanning Electron Microscopy (SEM)

2.8. X-ray Diffraction (XRD)

2.9. In Vitro Degradation of Oxidized BNC Membranes

2.10. Biological Assays and Hemostatic Behavior of BNC Membranes

2.10.1. Preparation of Blood Samples

2.10.2. Whole-Blood-Clotting Times

2.11. In Vivo Biocompatibility Tests of BNC Membranes

2.11.1. Surgical Procedures

2.11.2. Histological Evaluations

3. Results and Discussion

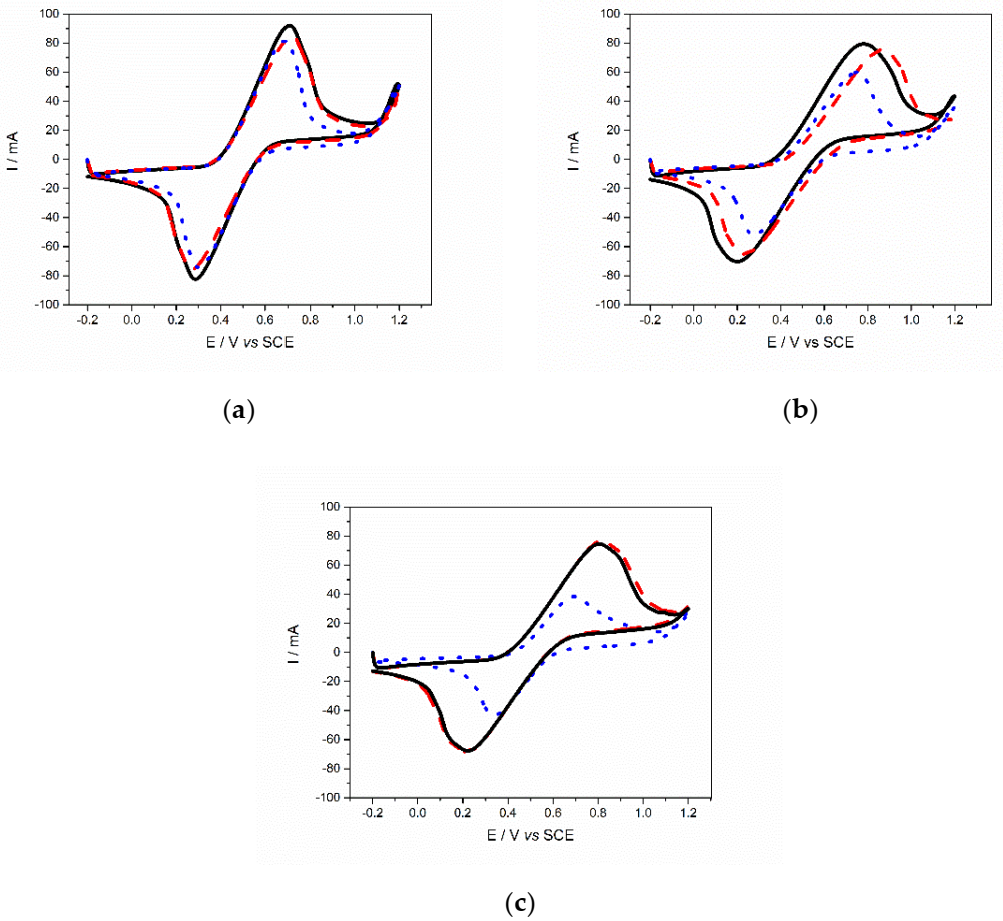

3.1. Cyclic Voltammetry (CV)

3.2. Oxidation Degree

3.3. Degree of Polymerization

3.4. NMR

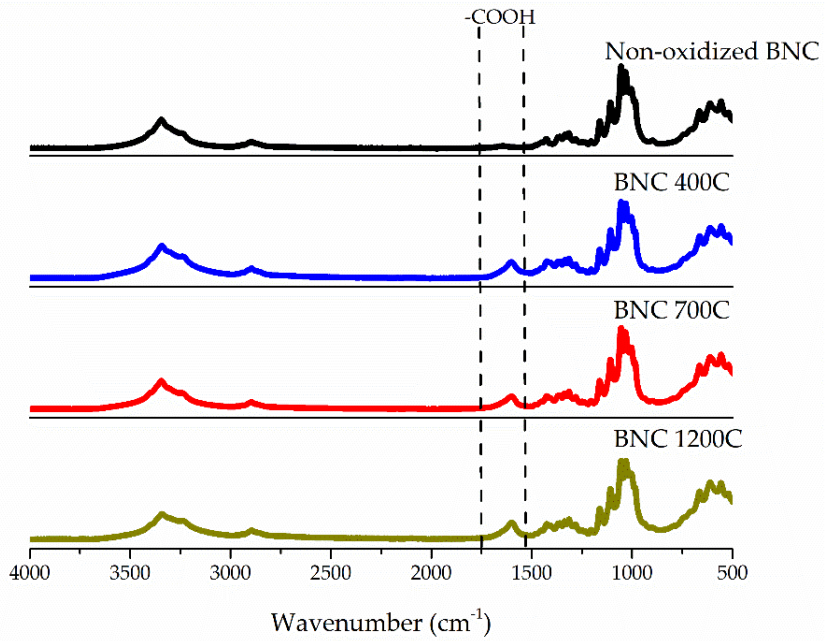

3.5. ATR-FTIR

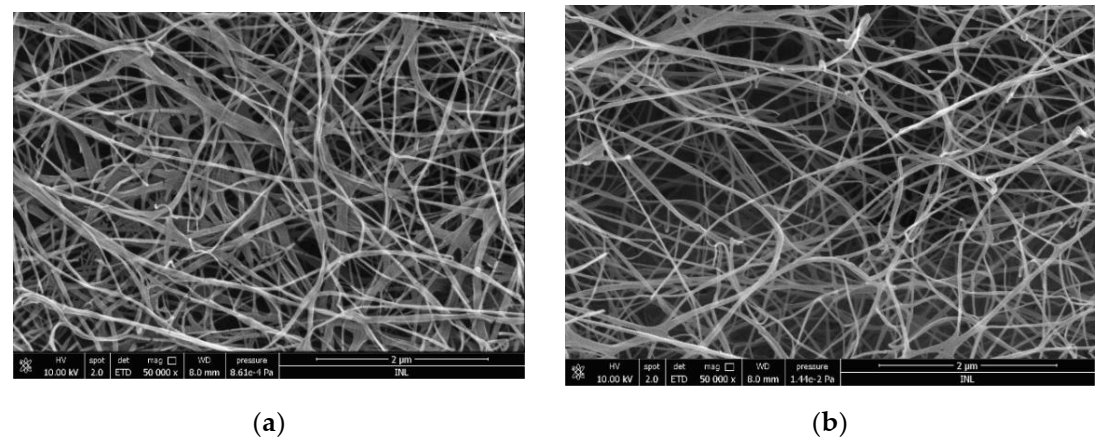

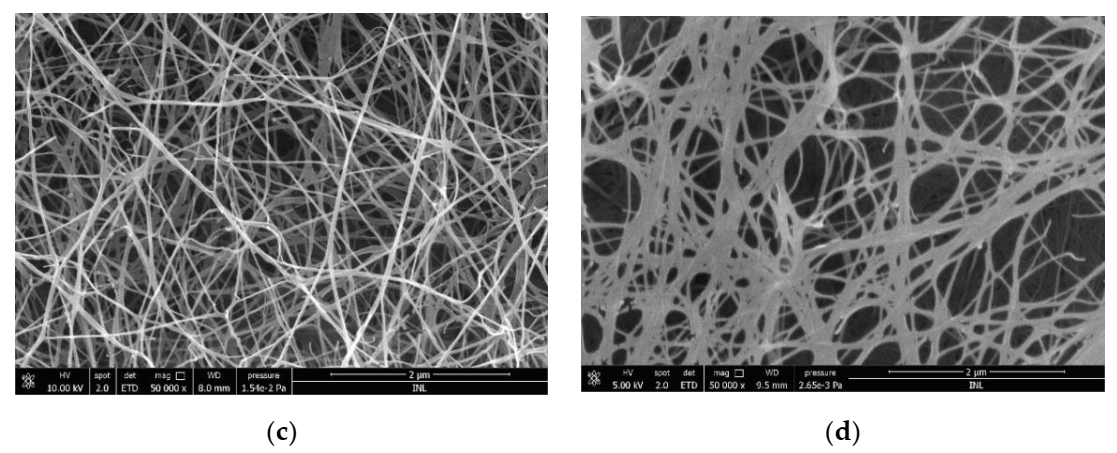

3.6. SEM

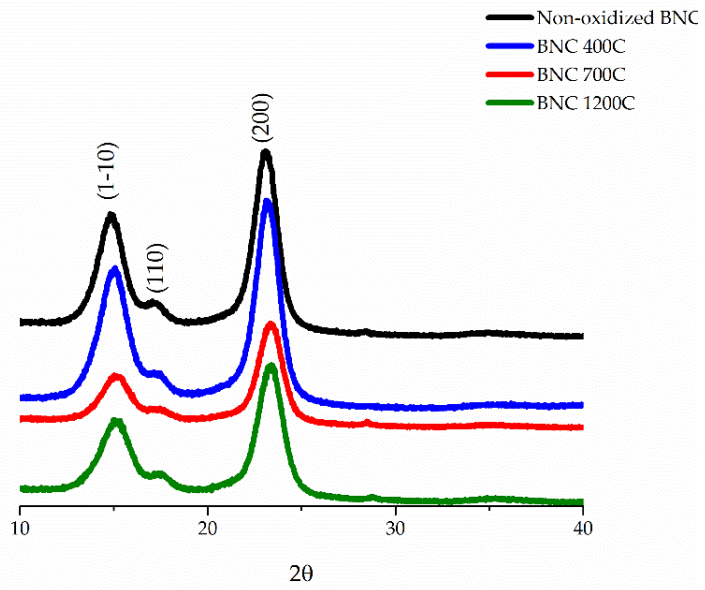

3.7. XRD

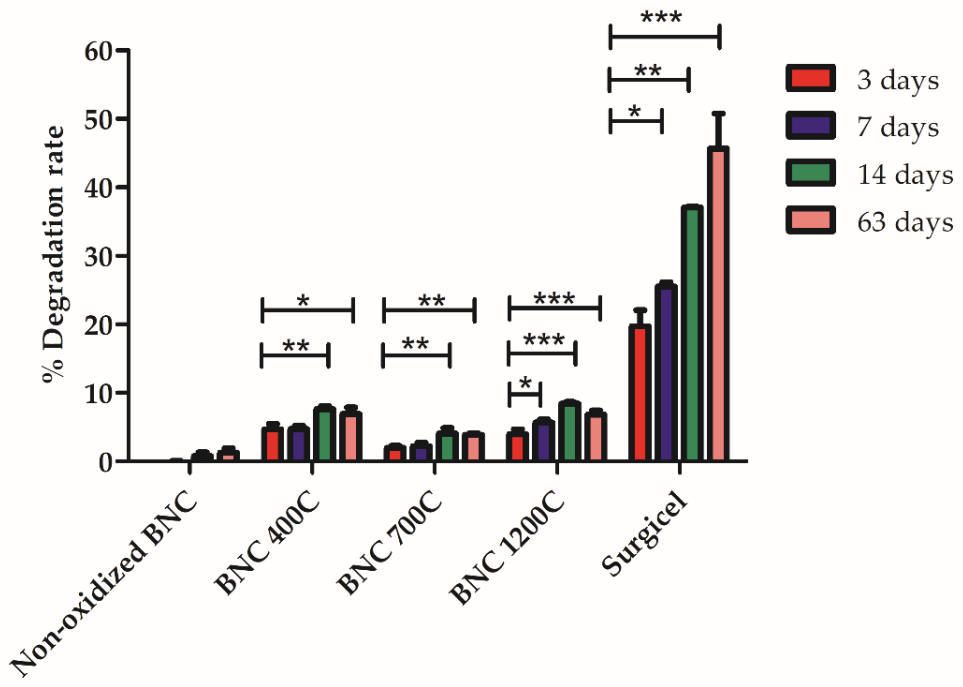

3.8. In Vitro Degradation of Oxidized BNC Membranes

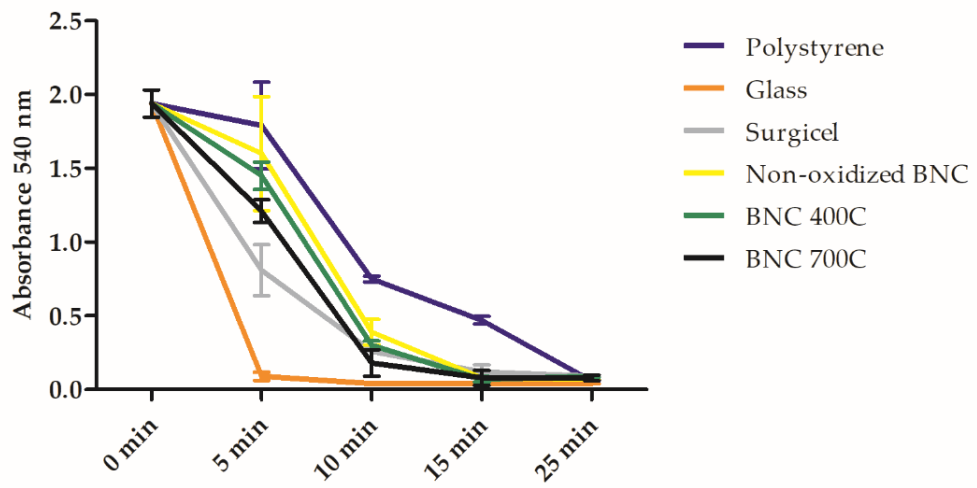

3.9. Biological Assays and Hemostatic Behavior of BNC Membranes

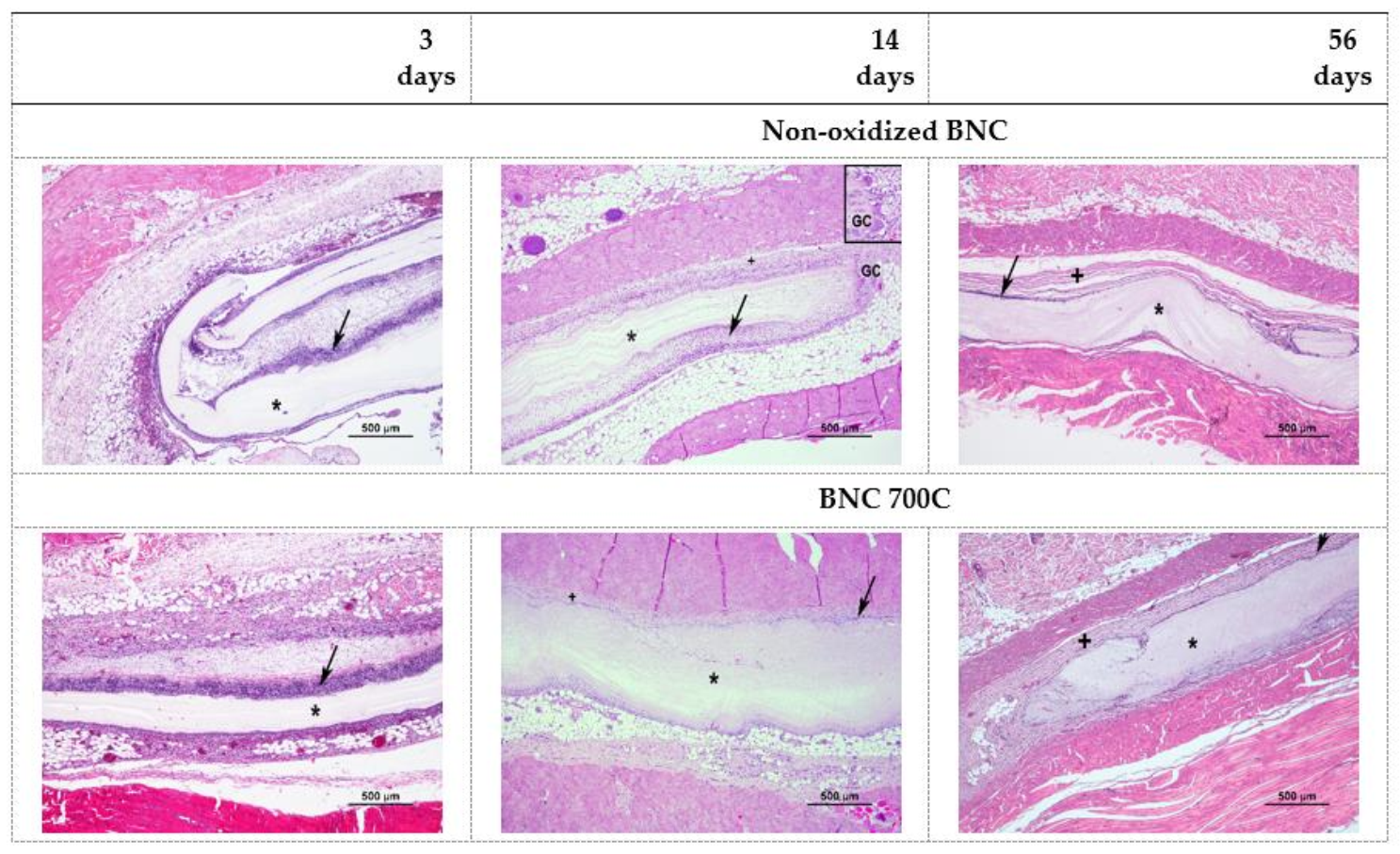

3.10. In Vivo Biocompatibility of BNC Membranes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bu, Y.; Zhang, L.; Sun, G.; Sun, F.; Liu, J.; Yang, F.; Tang, P.; Wu, D. Tetra-PEG Based Hydrogel Sealants for In Vivo Visceral Hemostasis. Adv. Mater. 2019, 31, 1901580. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Liu, W.; Shi, Y.; Xi, G.; Wang, M.; Liang, B.; Feng, Y.; Ren, X.; Shi, C. Peptide-Immobilized Starch/PEG Sponge with Rapid Shape Recovery and Dual-Function for Both Uncontrolled and Noncompressible Hemorrhage. Acta Biomater. 2019, 99, 220–235. [Google Scholar] [CrossRef] [PubMed]

- Sirlak, M.; Eryilmaz, S.; Yazicioglu, L.; Kiziltepe, U.; Eyileten, Z.; Durdu, M.S.; Tasoz, R.; Eren, N.T.; Aral, A.; Kaya, B.; et al. Comparative Study of Microfibrillar Collagen Hemostat (Colgel) and Oxidized Cellulose (Surgicel) in High Transfusion-Risk Cardiac Surgery. J. Thorac. Cardiovasc. Surg. 2003, 126, 666–670. [Google Scholar] [CrossRef] [Green Version]

- Gabay, M.; Boucher, B.A. An Essential Primer for Understanding the Role of Topical Hemostats, Surgical Sealants, and Adhesives for Maintaining Hemostasis. Pharmacotherapy 2013, 33, 935–955. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, M.M.; Mandal, A.K.; Agarwal, S.; Lal, A.; Prakash, M.; Mavuduru, R.; Singh, S.K. Surgicel Granuloma: Unusual Cause of “Recurrent” Mass Lesion after Laparoscopic Nephron-Sparing Surgery for Renal Cell Carcinoma. Urology 2010, 76, 334–335. [Google Scholar] [CrossRef] [PubMed]

- Alpaslan, C.; Alpaslan, G.H.; Oygur, T. Tissue Reaction to Three Subcutaneously Implanted Local Hemostatic Agents. Br. J. Oral Maxillofac. Surg. 1997, 35, 129–132. [Google Scholar] [CrossRef]

- Wang, H.; Chen, P. Surgicel® (Oxidized Regenerated Cellulose) Granuloma Mimicking Local Recurrent Gastrointestinal Stromal Tumor: A Case Report. Oncol. Lett. 2013, 5, 1497–1500. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.F.; Aps, C.; Young, C.P. A Foreign Body Reaction to Surgicel Mimicking an Abscess Following Cardiac Surgery. Eur. J. Cardiothorac. Surg. 2002, 22, 489–490. [Google Scholar] [CrossRef]

- Lin, B.; Yang, H.; Cui, M.; Li, Y.; Yu, J. SurgicelTM Application in Intracranial Hemorrhage Surgery Contributed to Giant-Cell Granuloma in a Patient with Hypertension: Case Report and Review of the Literature. World J. Surg. Oncol. 2014, 12, 101. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Portela, R.; Leal, C.R.; Almeida, P.L.; Sobral, R.G. Bacterial Cellulose: A Versatile Biopolymer for Wound Dressing Applications. Microb. Biotechnol. 2019, 12, 586–610. [Google Scholar] [CrossRef] [PubMed]

- Pang, M.; Huang, Y.; Meng, F.; Zhuang, Y.; Liu, H.; Du, M.; Ma, Q.; Wang, Q.; Chen, Z.; Chen, L.; et al. Application of Bacterial Cellulose in Skin and Bone Tissue Engineering. Eur. Polym. J. 2020, 122, 109365. [Google Scholar] [CrossRef]

- Gorgieva, S.; Trček, J. Bacterial Cellulose: Production, Modification and Perspectives in Biomedical Applications. Nanomaterials 2019, 9, 1352. [Google Scholar] [CrossRef] [Green Version]

- Eslahi, N.; Mahmoodi, A.; Mahmoudi, N.; Zandi, N.; Simchi, A. Processing and Properties of Nanofibrous Bacterial Cellulose-Containing Polymer Composites: A Review of Recent Advances for Biomedical Applications. Polym. Rev. 2020, 60, 144–170. [Google Scholar] [CrossRef]

- Volova, T.G.; Prudnikova, S.V.; Sukovatyi, A.G.; Shishatskaya, E.I. Production and Properties of Bacterial Cellulose by the Strain Komagataeibacter Xylinus B-12068. Appl. Microbiol. Biotechnol. 2018, 102, 7417–7428. [Google Scholar] [CrossRef] [Green Version]

- Uzyol, H.K.; Saçan, M.T. Bacterial Cellulose Production by Komagataeibacter Hansenii Using Algae-Based Glucose. Environ. Sci. Pollut. Res. 2017, 24, 11154–11162. [Google Scholar] [CrossRef] [PubMed]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating Biopolymer and Sustainable Raw Material. Angew. Chemie Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Helenius, G.; Bäckdahl, H.; Bodin, A.; Nannmark, U.; Gatenholm, P.; Risberg, B. In Vivo Biocompatibility of Bacterial Cellulose. J. Biomed. Mater. Res. Part A 2006, 76, 431–438. [Google Scholar] [CrossRef]

- Pértile, R.A.N.; Moreira, S.; Gil Da Costa, R.M.; Correia, A.; Guardão, L.; Gartner, F.; Vilanova, M.; Gama, M. Bacterial Cellulose: Long-Term Biocompatibility Studies. J. Biomater. Sci. Polym. Ed. 2012, 23, 1339–1354. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Cao, J.; Zhao, S.; Luo, H.; Yang, Z.; Gama, M.; Zhang, Q.; Su, D.; Wan, Y. Biocompatibility Evaluation of Bacterial Cellulose as a Scaffold Material for Tissue-Engineered Corneal Stroma. Cellulose 2020, 27, 2775–2784. [Google Scholar] [CrossRef] [Green Version]

- Camy, S.; Montanari, S.; Rattaz, A.; Vignon, M.; Condoret, J.S. Oxidation of Cellulose in Pressurized Carbon Dioxide. J. Supercrit. Fluids 2009, 51, 188–196. [Google Scholar] [CrossRef] [Green Version]

- Liao, S.B.; Xi, T.F.; Lai, C.; Liao, S.Y.; Huang, T.; Wang, S.Y. TEMPO-Mediated Oxidation of Bacterial Cellulose in a Bromide-Free System. Colloid Polym. Sci. 2013, 32, 699–707. [Google Scholar] [CrossRef]

- Davis, N.J.; Flitsch, S.L. Selective Oxidation of Monosaccharide Derivatives to Uronic Acids. Tetrahedron Lett. 1993, 34, 1181–1184. [Google Scholar] [CrossRef]

- Pahlevan, M.; Toivakka, M.; Alam, P. Mechanical Properties of TEMPO-Oxidised Bacterial Cellulose-Amino Acid Biomaterials. Eur. Polym. J. 2018, 101, 29–36. [Google Scholar] [CrossRef] [Green Version]

- Lai, C.; Sheng, L.; Liao, S.; Xi, T.; Zhang, Z. Surface Characterization of TEMPO-Oxidized Bacterial Cellulose. Surf. Interface Anal. 2013, 45, 1673–1679. [Google Scholar] [CrossRef]

- Isogai, A.; Kato, Y. Preparation of Polyuronic Acid from Cellulose by TEMPO-Mediated Oxidation. Cellulose 1998, 5, 153–164. [Google Scholar] [CrossRef]

- Bragd, P.L.; van Bekkum, H.; Besemer, A.C. TEMPO-Mediated Oxidation of Polysaccharides: Survey of Methods and Applications. Top. Catal. 2004, 27, 49–66. [Google Scholar] [CrossRef]

- Carlsson, D.O.; Lindh, J.; Nyholm, L.; Stromme, M.; Mihranyan, A.; Strømme, M.; Mihranyan, A. Cooxidant-Free TEMPO-Mediated Oxidation of Highly Crystalline Nanocellulose in Water. RSC Adv. 2014, 4, 52289–52298. [Google Scholar] [CrossRef]

- Parpot, P.; Servat, K.; Bettencourt, A.P.; Huser, H.; Kokoh, K.B. TEMPO Mediated Oxidation of Carbohydrates Using Electrochemical Methods. Cellulose 2010, 17, 815–824. [Google Scholar] [CrossRef]

- Cui, Q.; Zheng, Y.; Lin, Q.; Song, W.; Qiao, K.; Liu, S. Selective Oxidation of Bacterial Cellulose by NO2-HNO3. RSC Adv. 2014, 4, 1630–1639. [Google Scholar] [CrossRef]

- Evans, R.; Wallis, A.F.A. Cellulose Molecular Weights Determined by Viscometry. J. Appl. Polym. Sci. 1989, 37, 2331–2340. [Google Scholar] [CrossRef]

- Tsouko, E.; Kourmentza, C.; Ladakis, D.; Kopsahelis, N.; Mandala, I.; Papanikolaou, S.; Paloukis, F.; Alves, V.; Koutinas, A. Bacterial Cellulose Production from Industrial Waste and By-Product Streams. Int. J. Mol. Sci. 2015, 16, 14832–14849. [Google Scholar] [CrossRef]

- Ryu, D.D.Y.; Lee, S.B.; Tassinari, T.; Macy, C. Effect of Compression Milling on Cellulose Structure and on Enzymatic Hydrolysis Kinetics. Biotechnol. Bioeng. 1982, 24, 1047–1067. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Leitão, A.F.; Silva, J.P.; Dourado, F.; Gama, M. Hemocompatibility Study of a Bacterial Cellulose/Poly(Vinyl Alcohol) Nanocomposite. Colloids Surf. B Biointerfaces 2013, 6, 493–502. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Andrade, F.K.; Alexandre, N.; Amorim, I.; Gartner, F.; Maurício, A.C.; Luís, A.L.; Gama, M. Studies on the Biocompatibility of Bacterial Cellulose. J. Bioact. Compat. Polym. 2013, 28, 97–112. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Z.; Wen, F.; Yuan, K.; Tan, J.; Zhang, Z.; Wang, H. Tubular Structured Bacterial Cellulose-Based Nitrite Sensor: Preparation and Environmental Application. J. Solid State Electrochem. 2017, 21, 3649–3657. [Google Scholar] [CrossRef]

- Zaid, M.H.M.; Abdullah, J.; Yusof, N.A.; Wasoh, H.; Sulaiman, Y.; Noh, M.F.M.; Issa, R. Reduced Graphene Oxide/TEMPO-Nanocellulose Nanohybrid-Based Electrochemical Biosensor for the Determination of Mycobacterium Tuberculosis. J. Sens. 2020, 2020, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Gomes, N.O.; Carrilho, E.; Machado, S.A.S.; Sgobbi, L.F. Bacterial Cellulose-Based Electrochemical Sensing Platform: A Smart Material for Miniaturized Biosensors. Electrochim. Acta 2020, 349, 136341. [Google Scholar] [CrossRef]

- Sezer, U.A.; Sahin, İ.; Aru, B.; Olmez, H.; Demirel, G.Y.; Sezer, S. Cytotoxicity, Bactericidal and Hemostatic Evaluation of Oxidized Cellulose Microparticles: Structure and Oxidation Degree Approach. Carbohydr. Polym. 2019, 219, 87–94. [Google Scholar] [CrossRef]

- Saito, T.; Isogai, A. TEMPO-Mediated Oxidation of Native Cellulose. The Effect of Oxidation Conditions on Chemical and Crystal Structures of the Water-Insoluble Fractions. Biomacromolecules 2004, 5, 1983–1989. [Google Scholar] [CrossRef]

- Hiraoki, R.; Ono, Y.; Saito, T.; Isogai, A. Molecular Mass and Molecular-Mass Distribution of TEMPO-Oxidized Celluloses and TEMPO-Oxidized Cellulose Nanofibrils. Biomacromolecules 2015, 16, 675–681. [Google Scholar] [CrossRef] [PubMed]

- Fukuzumi, H.; Saito, T.; Isogai, A. Influence of TEMPO-Oxidized Cellulose Nanofibril Length on Film Properties. Carbohydr. Polym. 2013, 93, 172–177. [Google Scholar] [CrossRef] [PubMed]

- Neves, R.M.; Lopes, K.S.; Zimmermann, M.G.V.; Poletto, M.; Zattera, A.J. Cellulose Nanowhiskers Extracted from Tempo-Oxidized Curaua Fibers. J. Nat. Fibers 2020, 17, 1355–1365. [Google Scholar] [CrossRef]

- Sang, X.; Qin, C.; Tong, Z.; Kong, S.; Jia, Z.; Wan, G.; Liu, X. Mechanism and Kinetics Studies of Carboxyl Group Formation on the Surface of Cellulose Fiber in a TEMPO-Mediated System. Cellulose 2017, 24, 2415–2425. [Google Scholar] [CrossRef]

- Tang, R.; Yu, Z.; Renneckar, S.; Zhang, Y. Coupling Chitosan and TEMPO-Oxidized Nanofibrilliated Cellulose by Electrostatic Attraction and Chemical Reaction. Carbohydr. Polym. 2018, 202, 84–90. [Google Scholar] [CrossRef]

- Lai, C.; Zhang, S.; Chen, X.; Sheng, L. Nanocomposite Films Based on TEMPO-Mediated Oxidized Bacterial Cellulose and Chitosan. Cellulose 2014, 21, 2757–2772. [Google Scholar] [CrossRef]

- do Nascimento, E.S.; Pereira, A.L.S.; De Oliveira Barros, M.; De Aaraújo Barroso, M.K.; Lima, H.L.S.; De Fátima Borges, M.; De Andrade Feitosa, J.P.; de Azeredo, H.M.C.; De Freitas Rosa, M. TEMPO Oxidation and High-Speed Blending as a Combined Approach to Disassemble Bacterial Cellulose. Cellulose 2019, 26, 2291–2302. [Google Scholar] [CrossRef]

- Luo, H.; Xiong, G.; Hu, D.; Ren, K.; Yao, F.; Zhu, Y.; Gao, C.; Wan, Y. Characterization of TEMPO-Oxidized Bacterial Cellulose Scaffolds for Tissue Engineering Applications. Mater. Chem. Phys. 2013, 143, 373–379. [Google Scholar] [CrossRef]

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A New Family of Nature-Based Materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef]

- Wang, J.; Tavakoli, J.; Tang, Y. Bacterial Cellulose Production, Properties and Applications with Different Culture Methods—A Review. Carbohydr. Polym. 2019, 219, 63–76. [Google Scholar] [CrossRef] [Green Version]

- Numata, Y.; Kono, H.; Mori, A.; Kishimoto, R.; Tajima, K. Structural and Rheological Characterization of Bacterial Cellulose Gels Obtained from Gluconacetobacter Genus. Food Hydrocoll. 2019, 92, 233–239. [Google Scholar] [CrossRef]

- Jun, S.H.; Park, S.G.; Kang, N.G. One-Pot Method of Synthesizing TEMPO-Oxidized Bacterial Cellulose Nanofibers Using Immobilized TEMPO for Skincare Applications. Polymers 2019, 11, 1044. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Horii, F.; Hirai, A.; Yamamoto, H. Microstructural Analysis of Microfibrils of Bacterial Cellulose. Macromol. Symp. 1997, 120, 197–205. [Google Scholar] [CrossRef]

- Vasconcelos, N.F.; Feitosa, J.P.A.; da Gama, F.M.P.; Morais, J.P.S.; Andrade, F.K.; de Souza Filho, M.d.S.M.; De Freitas Rosa, M. Bacterial Cellulose Nanocrystals Produced under Different Hydrolysis Conditions: Properties and Morphological Features. Carbohydr. Polym. 2017, 155, 425–431. [Google Scholar] [CrossRef] [PubMed]

- Vasconcelos, N.F.; Andrade, F.K.; De Araújo Pinto Vieira, L.; Vieira, R.S.; Vaz, J.M.; Chevallier, P.; Mantovani, D.; De Fátima Borges, M.; De Freitas Rosa, M. Oxidized Bacterial Cellulose Membrane as Support for Enzyme Immobilization: Properties and Morphological Features. Cellulose 2020, 27, 3055–3083. [Google Scholar] [CrossRef]

- Kashcheyeva, E.I.; Gladysheva, E.K.; Skiba, E.A.; Budaeva, V.V. A Study of Properties and Enzymatic Hydrolysis of Bacterial Cellulose. Cellulose 2019, 26, 2255–2265. [Google Scholar] [CrossRef]

- Cheng, K.C.; Catchmark, J.M.; Demirci, A. Effect of Different Additives on Bacterial Cellulose Production by Acetobacter Xylinum and Analysis of Material Property. Cellulose 2009, 16, 1033–1045. [Google Scholar] [CrossRef]

- Li, J.; Wan, Y.; Li, L.; Liang, H.; Wang, J. Preparation and Characterization of 2,3-Dialdehyde Bacterial Cellulose for Potential Biodegradable Tissue Engineering Scaffolds. Mater. Sci. Eng. C 2009, 29, 1635–1642. [Google Scholar] [CrossRef]

- Li, H.; Wu, B.; Mu, C.; Lin, W. Concomitant Degradation in Periodate Oxidation of Carboxymethyl Cellulose. Carbohydr. Polym. 2011, 84, 881–886. [Google Scholar] [CrossRef]

- Peng, S.; Zheng, Y.; Wu, J.; Wu, Y.; Ma, Y.; Song, W.; Xi, T. Preparation and Characterization of Degradable Oxidized Bacterial Cellulose Reacted with Nitrogen Dioxide. Polym. Bull. 2012, 68, 415–423. [Google Scholar] [CrossRef]

- Dan Dimitrijevich, S.; Tatarko, M.; Gracy, R.W.; Linsky, C.B.; Olsen, C. Biodegradation of Oxidized Regenerated Cellulose. Carbohydr. Res. 1990, 195, 247–256. [Google Scholar] [CrossRef]

- Wan, Y.; Chen, Y.; Xi, T.; Zheng, Y.; Zhou, L. In Vitro Structural Changes of Nano-Bacterial Cellulose Immersed in Phosphate Buffer Solution In Vitro Structural Changes of Nano-Bacterial Cellulose Immersed in Phosphate Buffer Solution. Artic. J. Biomim. Biomater. Tissue Eng. 2011, 10, 55–66. [Google Scholar] [CrossRef] [Green Version]

- Shi, X.; Cui, Q.; Zheng, Y.; Peng, S.; Wang, G.; Xie, Y. Effect of Selective Oxidation of Bacterial Cellulose on Degradability in Phosphate Buffer Solution and Their Affinity for Epidermal Cell Attachment. RSC Adv. 2014, 4, 60749–60756. [Google Scholar] [CrossRef]

- Andrade, F.K.; Moreira, S.M.G.; Domingues, L.; Gama, F.M.P. Improving the Affinity of Fibroblasts for Bacterial Cellulose Using Carbohydrate-Binding Modules Fused to RGD. J. Biomed. Mater. Res. Part A 2010, 92, 9–17. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sperling, C.; Fischer, M.; Maitz, M.F.; Werner, C. Blood Coagulation on Biomaterials Requires the Combination of Distinct Activation Processes. Biomaterials 2009, 30, 4447–4456. [Google Scholar] [CrossRef] [PubMed]

- Palta, S.; Saroa, R.; Palta, A. Overview of the Coagulation System. Indian J. Anaesth. 2014, 58, 515–523. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Li, J.; Chen, S.; Zhang, X.; Ma, J.; He, J. Oxidized Cellulose-Based Hemostatic Materials. Carbohydr. Polym. 2020, 230, 115585. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Chen, L.; Hong, F.F. A Biodegradable Antibacterial Nanocomposite Based on Oxidized Bacterial Nanocellulose for Rapid Hemostasis and Wound Healing. ACS Appl. Mater. Interfaces 2020, 12, 3382–3392. [Google Scholar] [CrossRef]

- De, L.; Holgado, A.; Leao, A.; Rodrigues, M.; Chaves, M.; Kinoshita, A. Tissue Reaction after Subcutaneous Implantation of a Membrane Composed of Bacterial Cellulose Embedded with Hydroxyapatite. Dent. Oral Craniofac. Res. 2015, 1, 25–30. [Google Scholar] [CrossRef]

- Huang, L.; Du, X.; Fan, S.; Yang, G.; Shao, H.; Li, D.; Cao, C.; Zhu, Y.; Zhu, M.; Zhang, Y. Bacterial Cellulose Nanofibers Promote Stress and Fidelity of 3D-Printed Silk Based Hydrogel Scaffold with Hierarchical Pores. Carbohydr. Polym. 2019, 221, 146–156. [Google Scholar] [CrossRef]

- Kumbhar, J.V.; Jadhav, S.H.; Bodas, D.S.; Barhanpurkar-Naik, A.; Wani, M.R.; Paknikar, K.M.; Rrajwade, J.M. In Vitro and In Vivo Studies of a Novel Bacterial Cellulose-Based Acellular Bilayer Nanocomposite Scaffold for the Repair of Osteochondral Defects. Int. J. Nanomed. 2017, 12, 6437–6459. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Lima, F.M.T.; Pinto, F.C.M.; Andrade-da-Costa, B.L.d.S.; da Silva, J.G.M.; Júnior, O.C.; De Andrade Aguiar, J.L. Biocompatible Bacterial Cellulose Membrane in Dural Defect Repair of Rat. J. Mater. Sci. Mater. Med. 2017, 28, 37. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Lv, X.; Chen, S.; Li, Z.; Sun, X.; Feng, C.; Wang, H.; Xu, Y. In Vitro Biodegradability of Bacterial Cellulose by Cellulase in Simulated Body Fluid and Compatibility in Vivo. Cellulose 2016, 23, 3187–3198. [Google Scholar] [CrossRef]

| Sample | % Oxidation Degree | Duration of Electrolysis (h) |

|---|---|---|

| BNC 400C | 3.68 ± 1.03 | 2.39 ± 0.52 |

| BNC 700C | 6.45 ± 1.13 | 6.07 ± 1.25 |

| BNC 1200C | 14.92 ± 0.31 | 14.5 ± 4.94 |

| Sample | Width of the Fibers (nm) |

|---|---|

| Non-oxidized BNC | 44.3 ± 2.14 |

| BNC 400C | 39.13 ± 2.04 |

| BNC 700C | 38.75 ± 1.15 |

| BNC 1200C | 29.56 ± 1.83 |

| Sample | Crystallite Size (nm) | Crystallinity Index (%) |

|---|---|---|

| Non-oxidized BNC | 7.2 | 91.6 |

| BNC 400C | 6.9 | 89.4 |

| BNC 700C | 6.8 | 89.8 |

| BNC 1200C | 6.5 | 87.8 |

| 3 days | 14 days | 56 days | ||||

|---|---|---|---|---|---|---|

| NO BNC | BNC 700C | NO BNC | BNC 700C | NO BNC | BNC 700C | |

| Polymorphonuclear cells | 4 | 2 | 3 | 2 | 1 | 1 |

| Lymphocytes | 2 | 2 | 2 | 2 | 2 | 2 |

| Plasma cells | 1 | 0 | 1 | 0 | 0 | 0 |

| Macrophages | 2 | 1 | 2 | 2 | 2 | 2 |

| Giant cells | 0 | 0 | 1 | 1 | 1 | 0 |

| Necrosis | 2 | 0 | 0 | 0 | 0 | 0 |

| Neo vascularization | 2 | 0 | 1 | 0 | 0 | 0 |

| Fibrosis | 0 | 0 | 1 | 3 | 3 | 4 |

| Fatty infiltration | 0 | 0 | 0 | 0 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Queirós, E.C.; Pinheiro, S.P.; Pereira, J.E.; Prada, J.; Pires, I.; Dourado, F.; Parpot, P.; Gama, M. Hemostatic Dressings Made of Oxidized Bacterial Nanocellulose Membranes. Polysaccharides 2021, 2, 80-99. https://doi.org/10.3390/polysaccharides2010006

Queirós EC, Pinheiro SP, Pereira JE, Prada J, Pires I, Dourado F, Parpot P, Gama M. Hemostatic Dressings Made of Oxidized Bacterial Nanocellulose Membranes. Polysaccharides. 2021; 2(1):80-99. https://doi.org/10.3390/polysaccharides2010006

Chicago/Turabian StyleQueirós, E. C., S. P. Pinheiro, J. E. Pereira, J. Prada, I. Pires, F. Dourado, P. Parpot, and M. Gama. 2021. "Hemostatic Dressings Made of Oxidized Bacterial Nanocellulose Membranes" Polysaccharides 2, no. 1: 80-99. https://doi.org/10.3390/polysaccharides2010006

APA StyleQueirós, E. C., Pinheiro, S. P., Pereira, J. E., Prada, J., Pires, I., Dourado, F., Parpot, P., & Gama, M. (2021). Hemostatic Dressings Made of Oxidized Bacterial Nanocellulose Membranes. Polysaccharides, 2(1), 80-99. https://doi.org/10.3390/polysaccharides2010006