Development of an Electrowetting-on-Dielectric Cellulose-Based Conductive Sensor Using Direct Inkjet Printed Silver Nanoparticles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

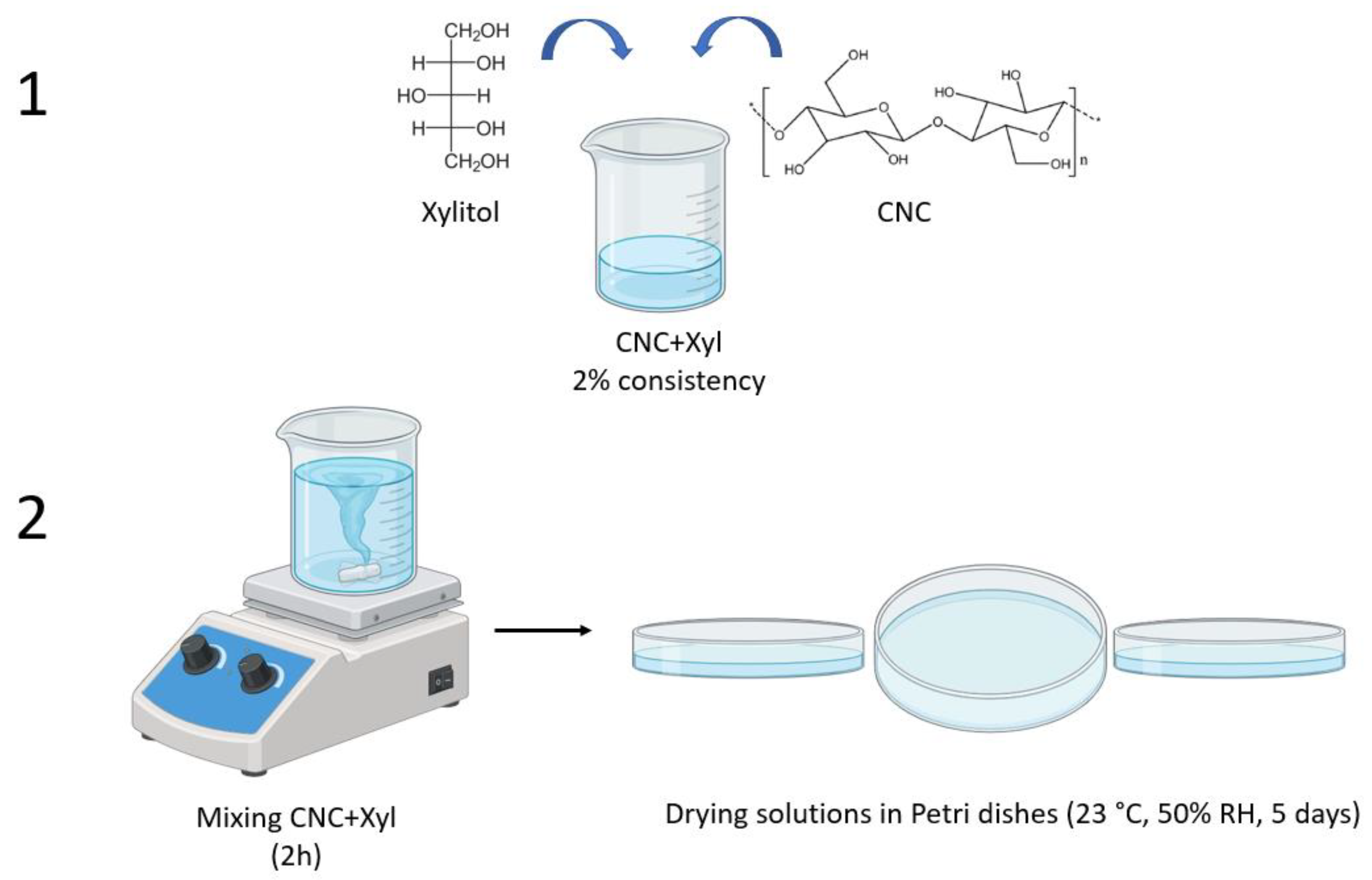

2.2. Formation of CNC Films with Xylitol

2.3. Preliminary Conductivity Testing on CNC Films

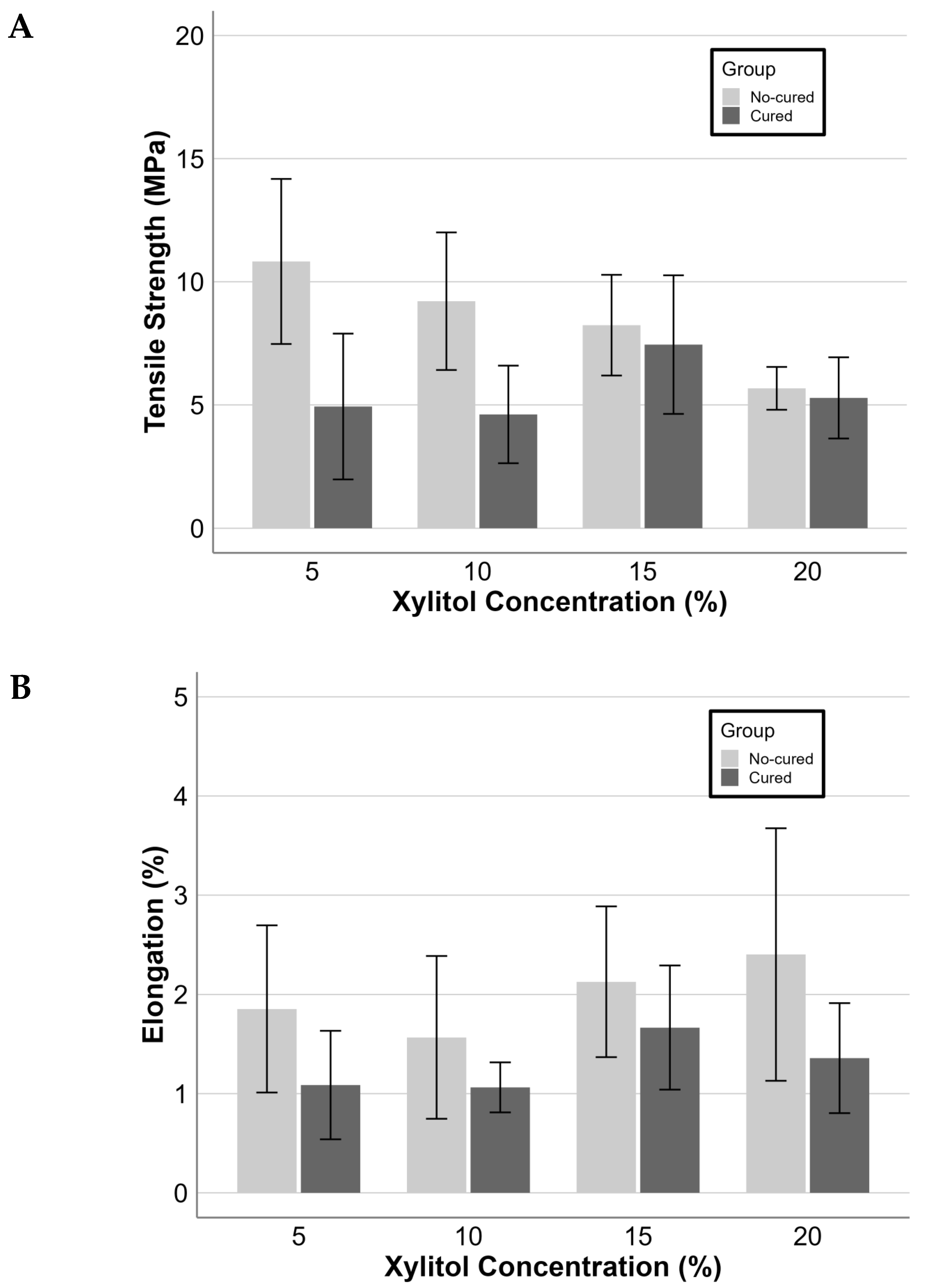

2.4. Mechanical Property Evaluation

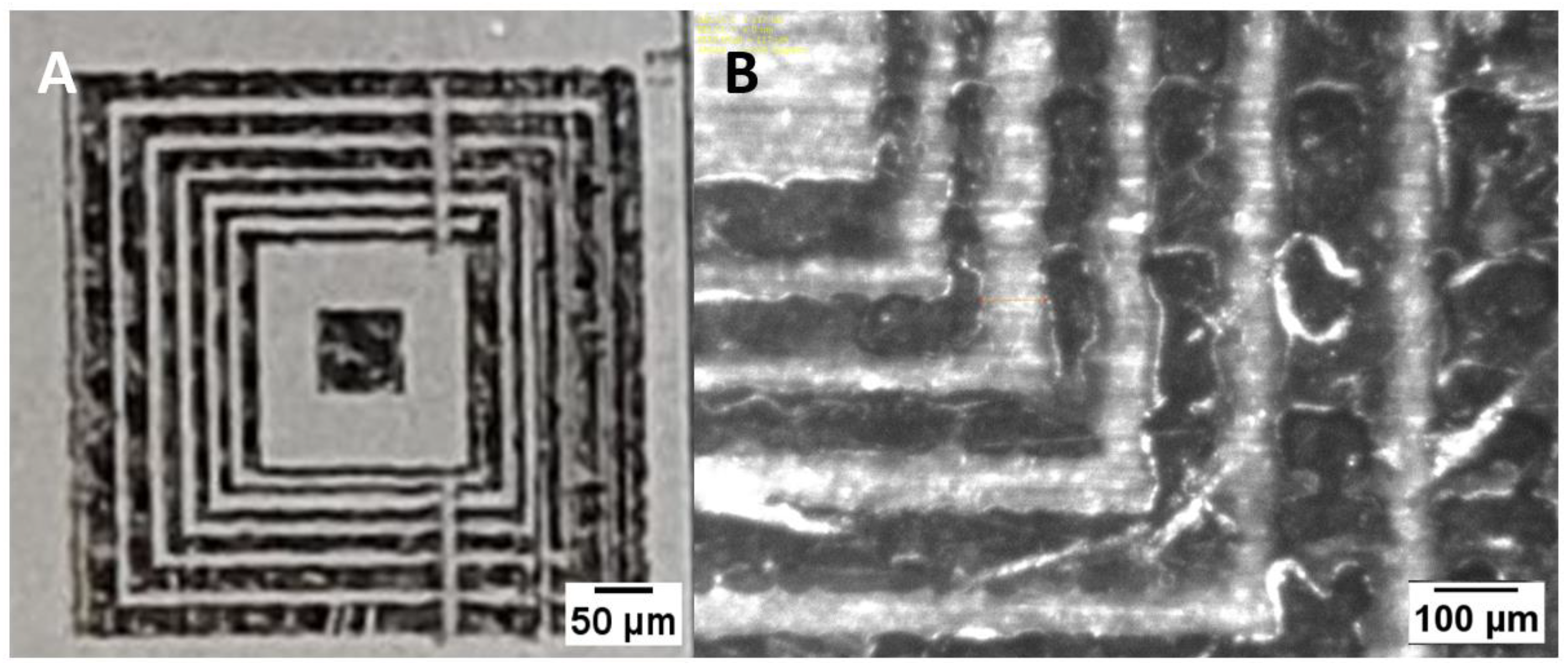

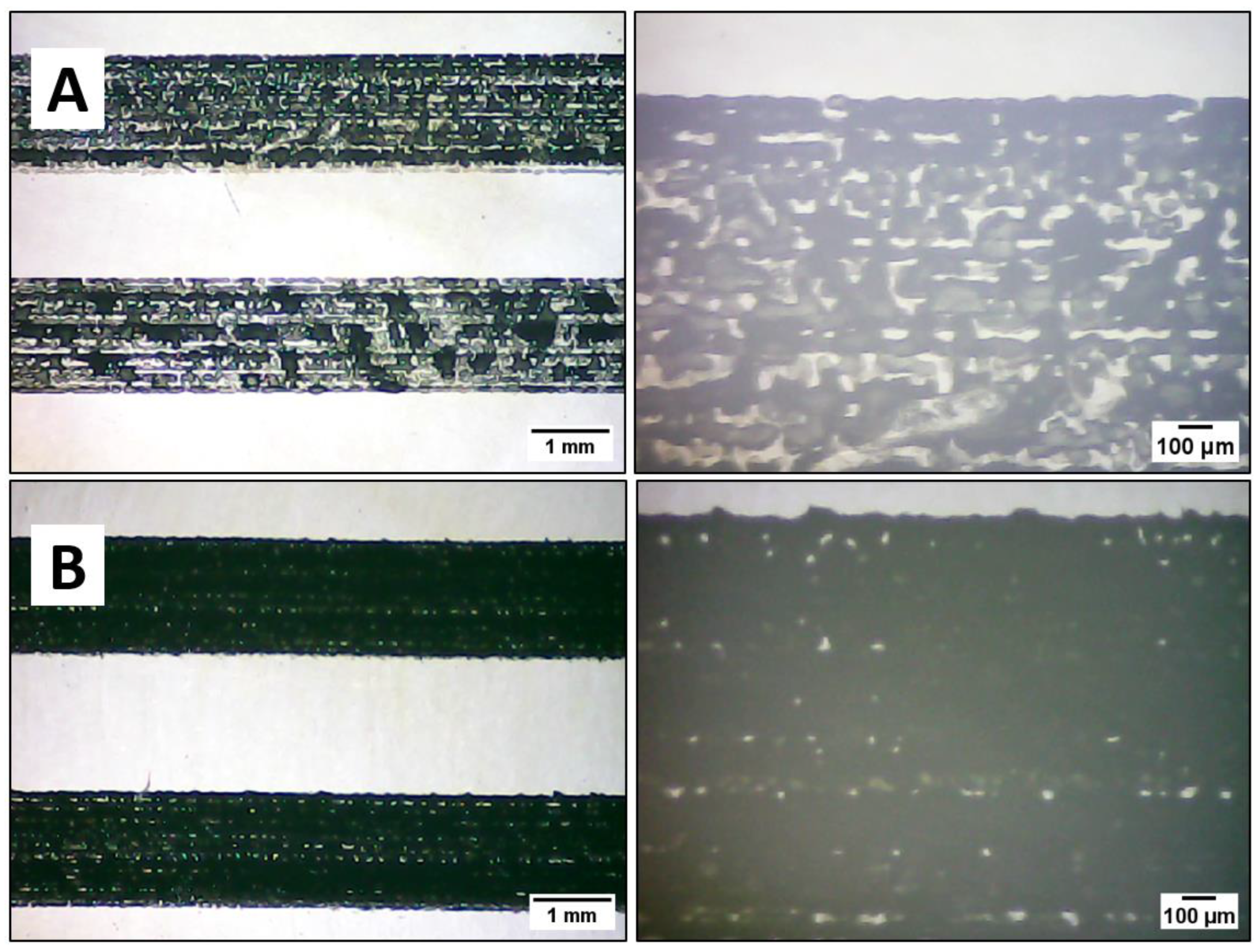

2.5. Preliminary Electrode Printing Tests

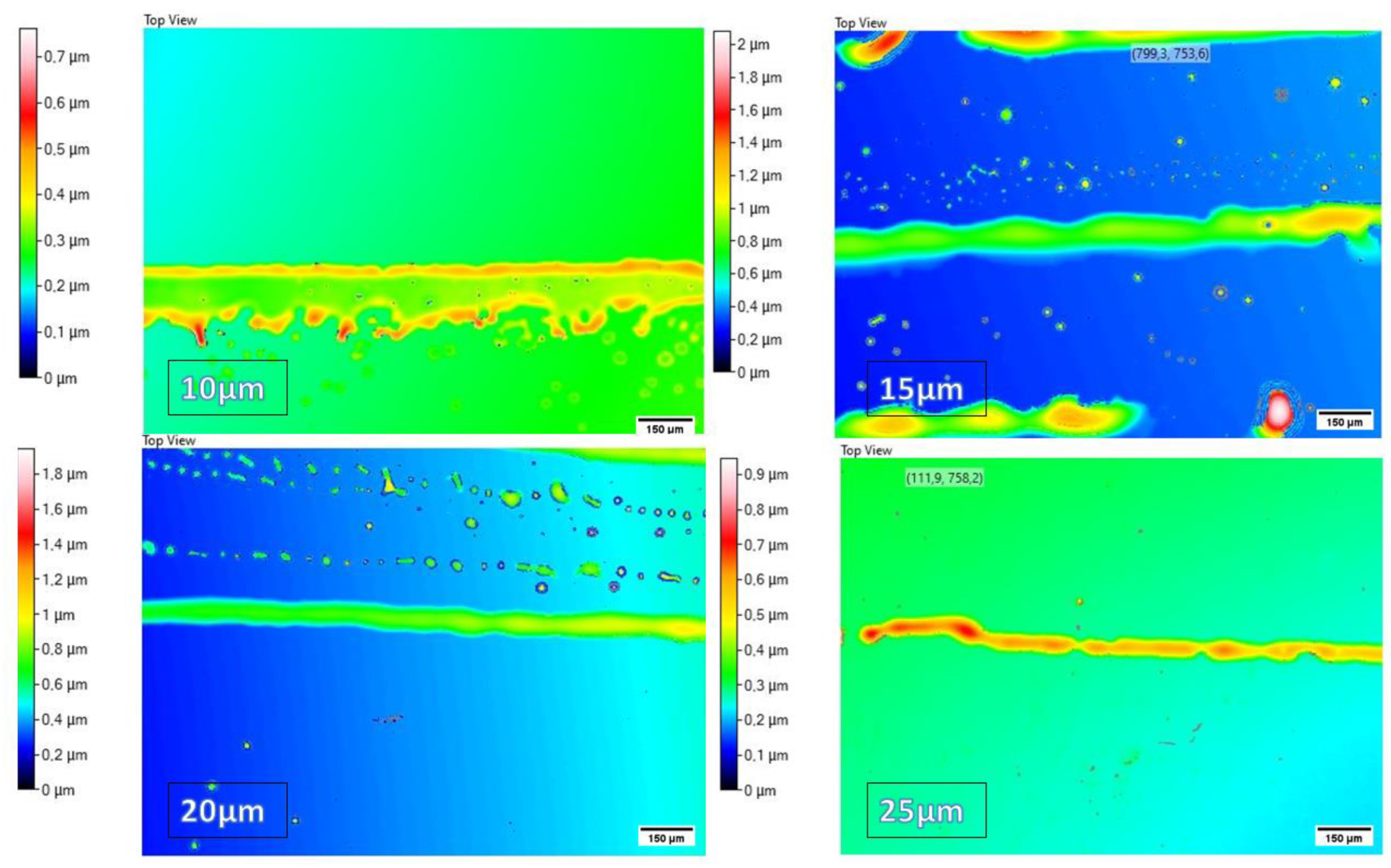

2.6. Electrode Printing on CNC+Xyl Films

2.7. Implementation of Dielectric and Hydrophobic Layers

2.8. Optical Evaluation of Printed Layers

2.9. Thickness and Roughness Measurements

2.10. Statistical Analysis

3. Results and Discussion

3.1. Mechanical Properties of the Films

3.2. Results of npAg Ink Printing

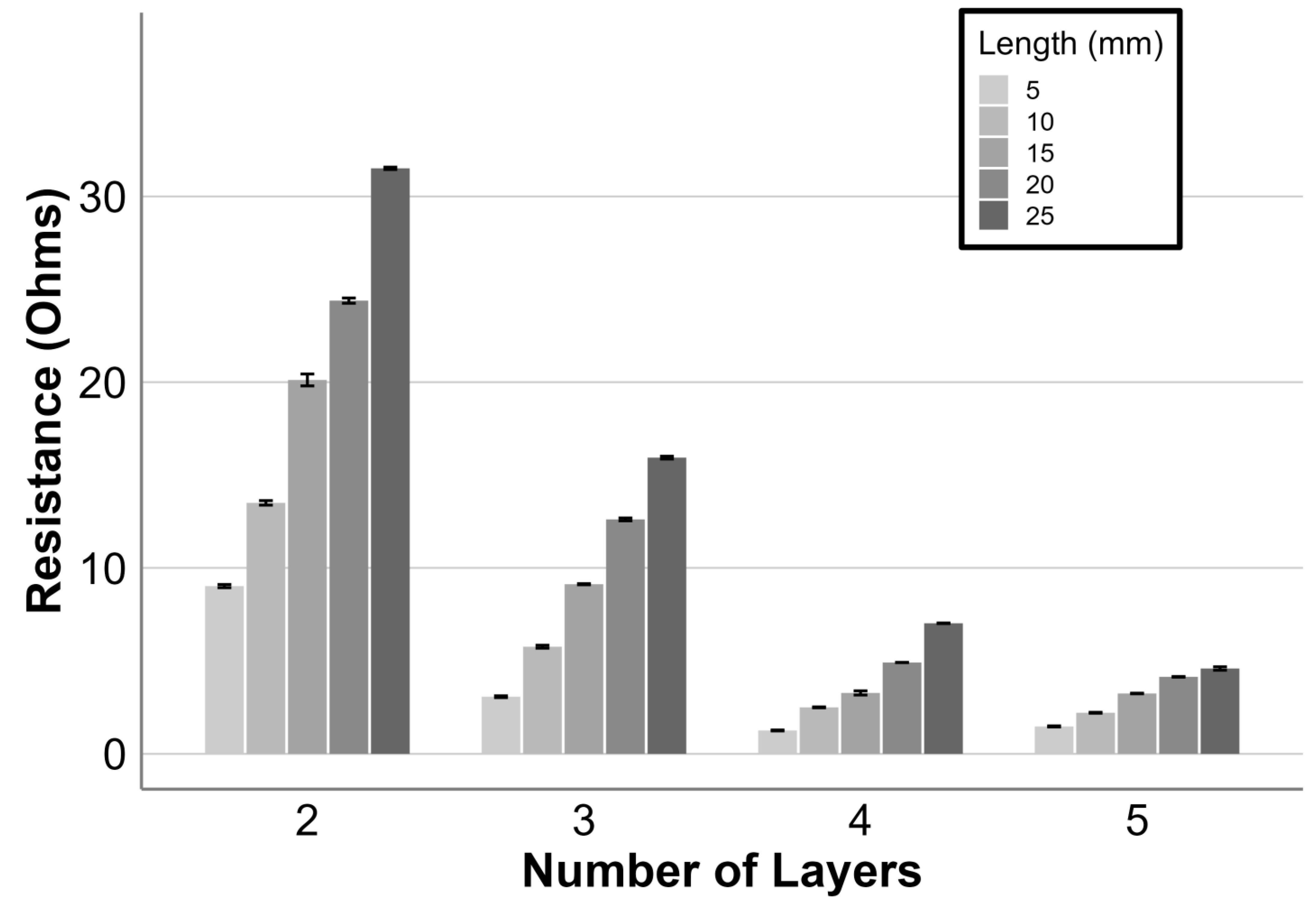

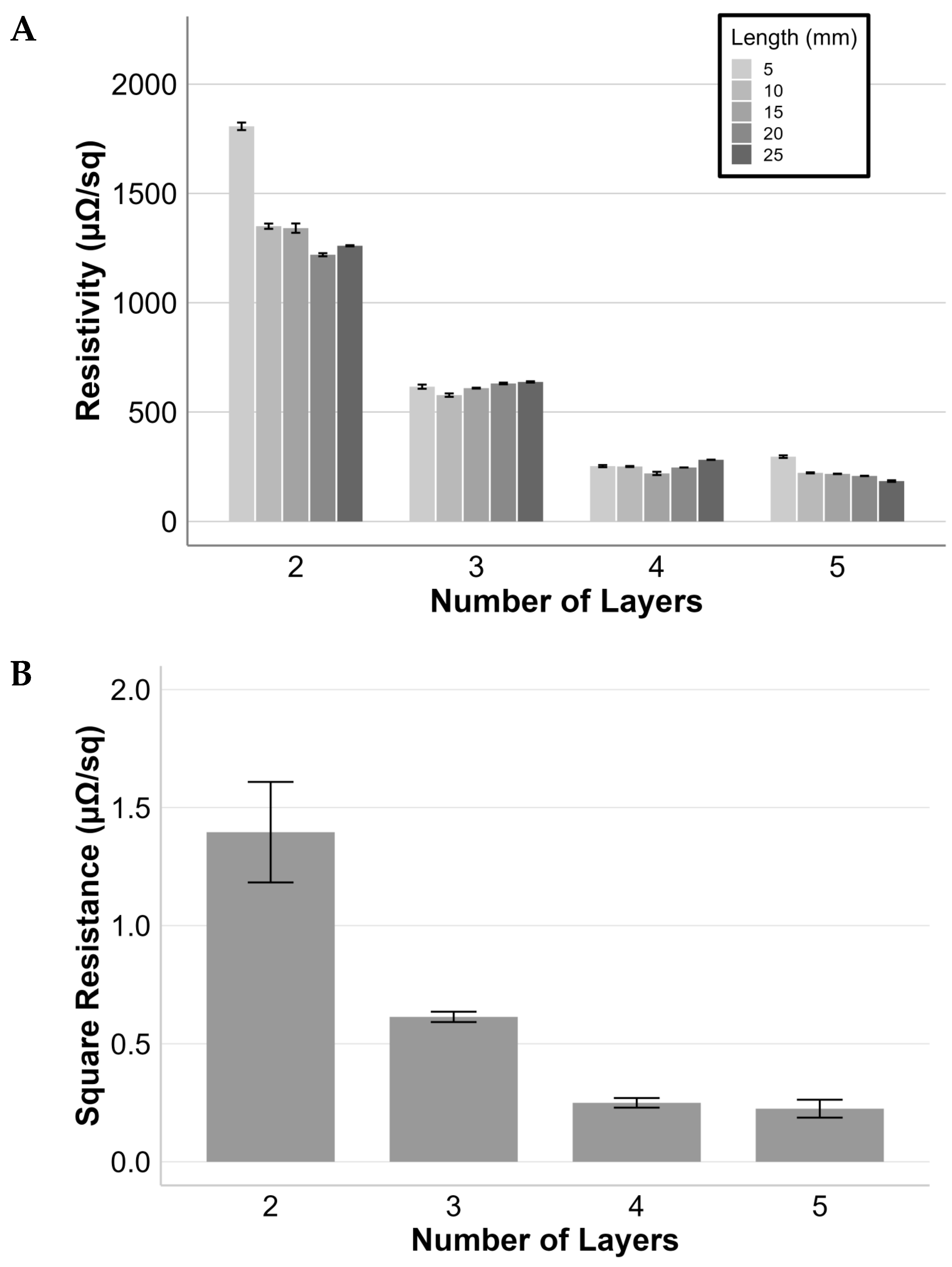

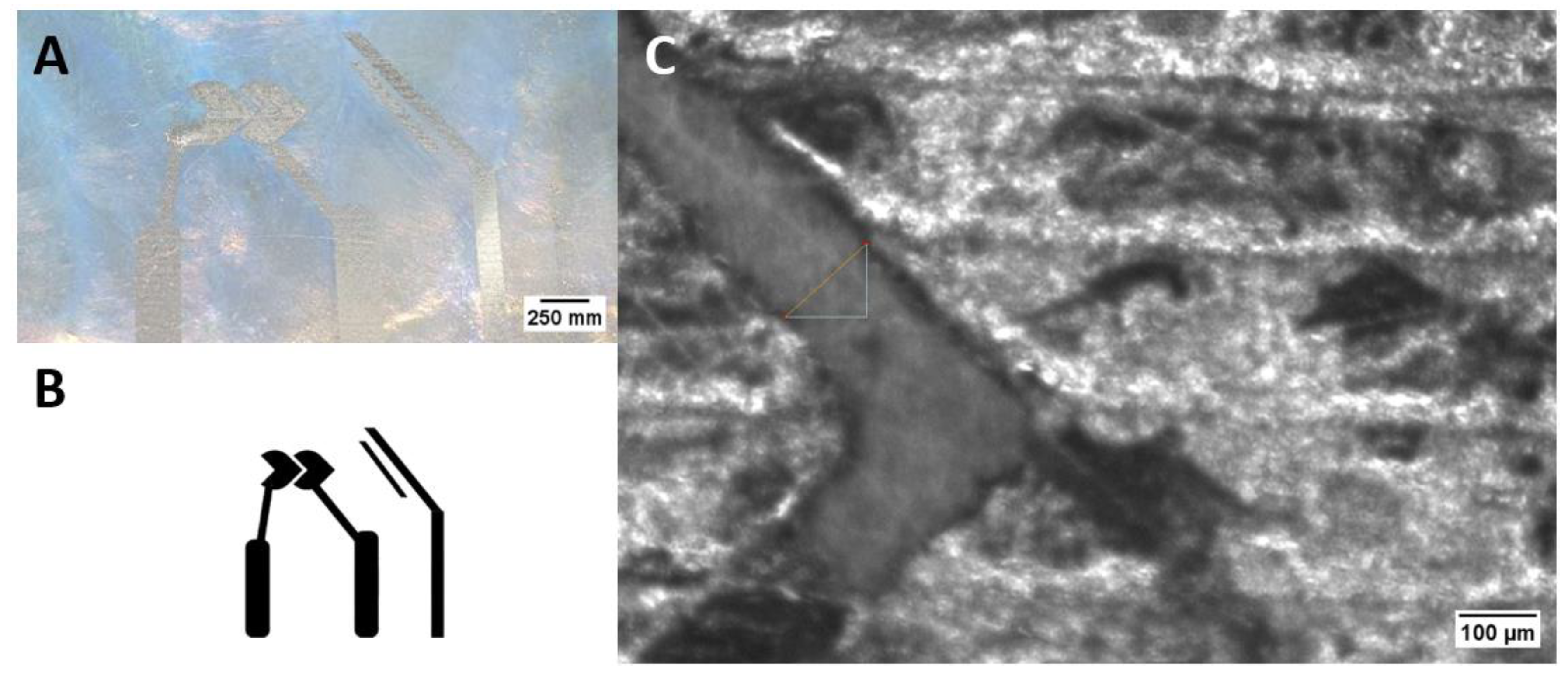

3.3. Layer Device Characterization

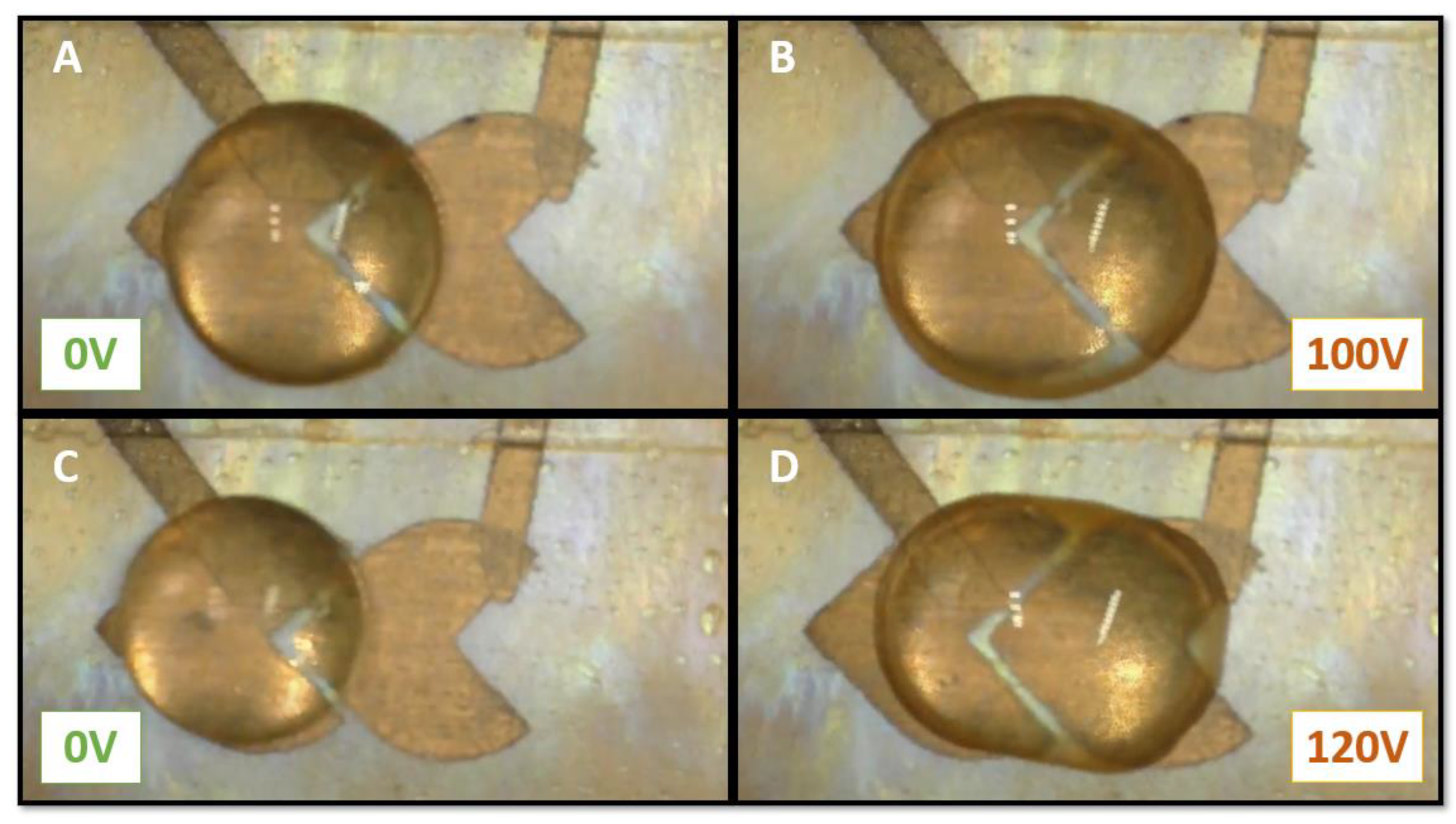

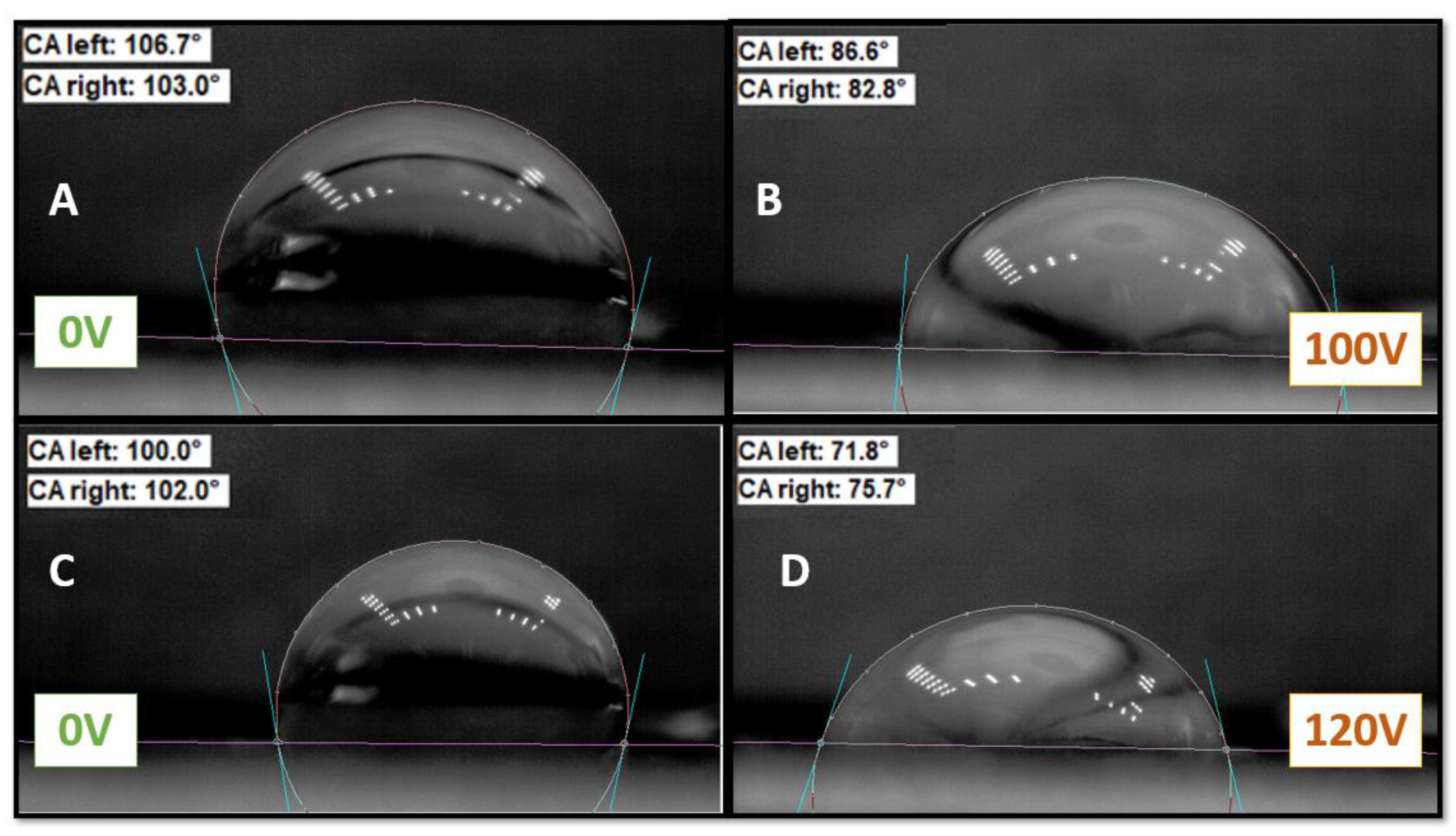

3.4. Device Actuation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Li, L.; Han, L.; Hu, H.; Zhang, R. A review on polymers and their composites for flexible electronics. Mater. Adv. 2023, 4, 726–746. [Google Scholar] [CrossRef]

- Aftab, S.; Hegazy, H.H.; Kabir, F. Emerging trends in 2D flexible electronics. Adv. Mater. Technol. 2023, 8, 2201897. [Google Scholar] [CrossRef]

- Boumegnane, A.; Douhi, S.; Batine, A.; Dormois, T.; Cochrane, C.; Nadi, A.; Cherkaoui, O.; Tahiri, M. Rheological Properties and Inkjet Printability of a Green Silver-Based Conductive Ink for Wearable Flexible Textile Antennas. Sensors 2024, 24, 2938. [Google Scholar] [CrossRef] [PubMed]

- Mu, B.; Xu, Y.; Xu, J.; Nikitina, M.A.; Zafari, U.; Xiao, X. Inkjet direct printing approach for flexible electronic. Results Eng. 2022, 14, 100466. [Google Scholar] [CrossRef]

- Wang, S.; Wu, X.; Lu, J.; Luo, Z.; Xie, H.; Zhang, X.; Lin, K.; Wang, Y. Inkjet-printed silver nanowire ink for flexible transparent conductive film applications. Nanomaterials 2022, 12, 842. [Google Scholar] [CrossRef]

- Pang, B.; Jiang, G.; Zhou, J.; Zhu, Y.; Cheng, W.; Zhao, D.; Wang, K.; Xu, G.; Yu, H. Molecular-scale design of cellulose-based functional materials for flexible electronic devices. Adv. Electron. Mater. 2021, 7, 2000944. [Google Scholar] [CrossRef]

- Nie, S.; Hao, N.; Zhang, K.; Xing, C.; Wang, S. Cellulose nanofibrils-based thermally conductive composites for flexible electronics: A mini review. Cellulose 2020, 27, 4173–4187. [Google Scholar] [CrossRef]

- Zhang, C.; Cha, R.; Li, R.; Tang, L.; Long, K.; Zhang, Z.; Zhang, L.; Jiang, X. Cellophane or nanopaper: Which is better for the substrates of flexible electronic devices? ACS Sustain. Chem. Eng. 2020, 8, 7774–7784. [Google Scholar] [CrossRef]

- Zhao, D.; Zhu, Y.; Cheng, W.; Chen, W.; Wu, Y.; Yu, H. Cellulose-based flexible functional materials for emerging intelligent electronics. Adv. Mater. 2021, 33, 2000619. [Google Scholar] [CrossRef]

- Martins, P.; Pereira, N.; Lima, A.; Garcia, A.; Mendes-Filipe, C.; Policia, R.; Correia, V.; Lanceros-Mendez, S. Advances in printing and electronics: From engagement to commitment. Adv. Funct. Mater. 2023, 33, 2213744. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, Q.; Payne, G.F.; Sun, R.; Wang, X. A highly conductive, pliable and foldable Cu/cellulose paper electrode enabled by controlled deposition of copper nanoparticles. Nanoscale 2019, 11, 725–732. [Google Scholar] [CrossRef] [PubMed]

- Hsieh, M.-C.; Kim, C.; Nogi, M.; Suganuma, K. Electrically conductive lines on cellulose nanopaper for flexible electrical devices. Nanoscale 2013, 5, 9289–9295. [Google Scholar] [CrossRef] [PubMed]

- Khondoker, M.A.H.; Yang, S.Y.; Mun, S.C.; Kim, J. Flexible and conductive ITO electrode made on cellulose film by spin-coating. Synth. Met. 2012, 162, 1972–1976. [Google Scholar] [CrossRef]

- Liana, D.D.; Raguse, B.; Gooding, J.J.; Chow, E. Recent advances in paper-based sensors. Sensors 2012, 12, 11505–11526. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Zheng, G.; Yao, J.; Liu, N.; Weil, B.; Eskilsson, M.; Karabulut, E.; Ruan, Z.; Fan, S.; Bloking, J.T.; et al. Transparent and conductive paper from nanocellulose fibers. Energy Environ. Sci. 2013, 6, 513–518. [Google Scholar] [CrossRef]

- Siegel, A.C.; Phillips, S.T.; Dickey, M.D.; Lu, N.; Suo, Z.; Whitesides, G.M. Foldable printed circuit boards on paper substrates. Adv. Funct. Mater. 2010, 20, 28–35. [Google Scholar] [CrossRef]

- Asadpoordarvish, A.; Sandström, A.; Larsen, C.; Bollström, R.; Toivakka, M.; Österbacka, R.; Edman, L. Light-emitting paper. Adv. Funct. Mater. 2015, 25, 3238–3245. [Google Scholar] [CrossRef]

- Yang, L.; Rida, A.; Vyas, R.; Tentzeris, M.M. RFID tag and RF structures on a paper substrate using inkjet-printing technology. IEEE Trans. Microw. Theory Tech. 2007, 55, 2894–2901. [Google Scholar] [CrossRef]

- Alimenti, F.; Mariotti, C.; Palazzi, V.; Virili, M.; Orecchini, G.; Mezzanotte, P.; Roselli, L. Communication and sensing circuits on cellulose. J. Low Power Electron. Appl. 2015, 5, 151–164. [Google Scholar] [CrossRef]

- Timofeev, O.; Torvinen, K.; Sievänen, J.; Kaljunen, T.; Kouko, J.; Ketoja, J.A. Drying of pigment-cellulose nanofibril substrates. Materials 2014, 7, 6893–6907. [Google Scholar] [CrossRef]

- Mraović, M.; Muck, T.; Pivar, M.; Trontelj, J.; Pleteršek, A. Humidity sensors printed on recycled paper and cardboard. Sensors 2014, 14, 13628–13643. [Google Scholar] [CrossRef] [PubMed]

- Corzo, D.; Tostado-Blázquez, G.; Baran, D. Flexible electronics: Status, challenges and opportunities. Front. Electron. 2020, 1, 594003. [Google Scholar] [CrossRef]

- Ahmad, S.; Rahman, K.; Shakeel, M.; Qasuria, T.A.K.; Cheema, T.A.; Khan, A. A low-cost printed humidity sensor on cellulose substrate by EHD printing. J. Mater. Res. 2021, 36, 3667–3678. [Google Scholar] [CrossRef]

- Jaiswal, A.K.; Kumar, V.; Jansson, E.; Huttunen, O.-H.; Yamamoto, A.; Vikman, M.; Khakalo, A.; Hiltunen, J.; Behfar, M.H. Biodegradable cellulose nanocomposite substrate for recyclable flexible printed electronics. Adv. Electron. Mater. 2023, 9, 2201094. [Google Scholar] [CrossRef]

- Corletto, A.; Hosseinmardi, A.; Annamalai, P.K.; Martin, D.J.; Shapter, J.G. High-resolution R2R-compatible printing of carbon nanotube conductive patterns enabled by cellulose nanocrystals. ACS Appl. Nano Mater. 2022, 5, 1574–1587. [Google Scholar] [CrossRef]

- Wibowo, A.F.; Han, J.W.; Kim, J.H.; Prameswati, A.; Entifar, S.A.N.; Park, J.; Lee, J.; Kim, S.; Lim, D.C.; Eom, Y.; et al. Universal Stretchable Conductive Cellulose/PEDOT: PSS Hybrid Films for Low Hysteresis Multifunctional Stretchable Electronics. ACS Appl. Mater. Interfaces 2023, 15, 18134–18143. [Google Scholar] [CrossRef]

- Moya, A.; Ortega-Ribera, M.; Guimerà, X.; Sowade, E.; Zea, M.; Illa, X.; Ramon, E.; Villa, R.; Gracia-Sancho, J.; Gabriel, G. Online oxygen monitoring using integrated inkjet-printed sensors in a liver-on-a-chip system. Lab. Chip 2018, 18, 2023–2035. [Google Scholar] [CrossRef] [PubMed]

- Sowade, E.; Göthel, F.; Zichner, R.; Baumann, R.R. Inkjet printing of UHF antennas on corrugated cardboards for packaging applications. Appl. Surf. Sci. 2015, 332, 500–506. [Google Scholar] [CrossRef]

- Gong, M.M.; Sinton, D. Turning the page: Advancing paper-based microfluidics for broad diagnostic application. Chem. Rev. 2017, 117, 8447–8480. [Google Scholar] [CrossRef]

- Fernández-Santos, J.; Valls, C.; Cusola, O.; Roncero, M.B. Improving filmogenic and barrier properties of nanocellulose films by addition of biodegradable plasticizers. ACS Sustain. Chem. Eng. 2021, 9, 9647–9660. [Google Scholar] [CrossRef]

- Tomar, B.S.; Shahin, A.; Tirumkudulu, M. Stress Evolution and Cracking in Drying Polymer Films. In Proceedings of the 2020 Virtual AIChE Annual Meeting, 16–20 November 2020; AIChE: New York, NY, USA, 2020. [Google Scholar]

- Scheepers, F.; Stähler, A.; Stähler, M.; Carmo, M.; Lehnert, W.; Stolten, D. Steering and in situ monitoring of drying phenomena during film fabrication. J. Coat. Technol. Res. 2019, 16, 1213–1221. [Google Scholar] [CrossRef]

- Razali, N.M.; Wah, Y.B. Power comparisons of shapiro-wilk, kolmogorov-smirnov, lilliefors and anderson-darling tests. J. Stat. Model. Anal. 2011, 2, 21–33. [Google Scholar]

- Shapiro, S.S.; Wilk, M.B. An analysis of variance test for normality (complete samples). Biometrika 1965, 52, 591–611. [Google Scholar] [CrossRef]

- Ostertagova, E.; Ostertag, O.; Kováč, J. Methodology and application of the Kruskal-Wallis test. Appl. Mech. Mater. 2014, 611, 115–120. [Google Scholar] [CrossRef]

- Abdi, H.; Williams, L.J. Newman-Keuls test and Tukey test. Encycl. Res. Des. 2010, 2, 897–902. [Google Scholar]

- Szpiłyk, M.; Lubczak, R.; Walczak, M.; Lubczak, J. Polyol and polyurethane foam from cellulose hydrolysate. J. Chem. Technol. Biotechnol. 2021, 96, 881–889. [Google Scholar] [CrossRef]

- Kong, X.; Zhao, L.; Curtis, J.M. Polyurethane nanocomposites incorporating biobased polyols and reinforced with a low fraction of cellulose nanocrystals. Carbohydr. Polym. 2016, 152, 487–495. [Google Scholar] [CrossRef]

- Cao, Y.; Chen, X.; Li, Y.; Wang, Y.; Yu, H.; Li, Z.; Zhou, Y. Regulating and controlling the microstructure of nanocellulose aerogels by varying the intensity of hydrogen bonds. ACS Sustain. Chem. Eng. 2023, 11, 1581–1590. [Google Scholar] [CrossRef]

- Spoljaric, S.; Salminen, A.; Luong, N.D.; Seppälä, J. Ductile nanocellulose-based films with high stretchability and tear resistance. Eur. Polym. J. 2015, 69, 328–340. [Google Scholar] [CrossRef]

- Wu, G.; Panahi-Sarmad, M.; Van Vlierberghe, S.; Xu, R.; Hou, X.; Cui, Z.; Xiao, X. Multi-stimuli responsive shape memory behavior of dual-switch TPU/CB/CNC hybrid nanocomposites as triggered by heat, water, ethanol, and pH. Chem. Eng. J. 2022, 450, 138253. [Google Scholar] [CrossRef]

- Herrera, M.A.; Mathew, A.P.; Oksman, K. Barrier and mechanical properties of plasticized and cross-linked nanocellulose coatings for paper packaging applications. Cellulose 2017, 24, 3969–3980. [Google Scholar] [CrossRef]

- Nasiri, N.; Cainglet, H.E.; Garnier, G.; Batchelor, W. Transparent maltitol-cellulose nanocrystal film for high performance barrier. Cellulose 2024, 31, 7421–7436. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.; Zuhri, M. Mechanical, physical and thermal properties of sugar palm nanocellulose reinforced thermoplastic starch (TPS)/poly (lactic acid)(PLA) blend bionanocomposites. Polymers 2020, 12, 2216. [Google Scholar] [CrossRef] [PubMed]

- Niskanen, I.; Zhang, K.; Karzarjeddi, M.; Liimatainen, H.; Shibata, S.; Hagen, N.; Heikkilä, R.; Yoda, H.; Otani, Y. Optical properties of cellulose nanofibre films at high temperatures. J. Polym. Res. 2022, 29, 187. [Google Scholar] [CrossRef]

- Ornaghi, H.L., Jr.; Faccio, M.; Soares, M.R.F. Thermal degradation kinetics of natural fibers: Determination of the kinetic triplet and lifetime prediction. Polysaccharides 2024, 5, 169–183. [Google Scholar] [CrossRef]

- Hernández-Flores, J.A.; Morales-Cepeda, A.B.; Castro-Guerrero, C.F.; Delgado-Arroyo, F.; Díaz-Guillén, M.R.; de la Cruz-Soto, J.; Magallón-Cacho, L.; León-Silva, U. Morphological and electrical properties of nanocellulose compounds and its application on capacitor assembly. Int. J. Polym. Sci. 2020, 2020, 1891064. [Google Scholar] [CrossRef]

- Hoeng, F.; Denneulin, A.; Bras, J. Use of nanocellulose in printed electronics: A review. Nanoscale 2016, 8, 13131–13154. [Google Scholar] [CrossRef]

- Das, D.; Das, S.; Biswas, K. Effect of electrode geometry on voltage reduction in EWOD based devices. In Proceedings of the 2010 International Conference on Systems in Medicine and Biology, Kharagpur, India, 16–18 December 2010; IEEE: New York, NY, USA, 2010; pp. 371–375. [Google Scholar]

- Nelson, W.C.; Kim, C.-J. ‘CJ’ Droplet actuation by electrowetting-on-dielectric (EWOD): A review. J. Adhes. Sci. Technol. 2012, 26, 1747–1771. [Google Scholar] [CrossRef]

- Ohira, S.; Mizumura, D.; Hanasaki, I. Inkjet drawing dynamics of conductive polymer droplets on cellulose nanopapers. AIP Adv. 2020, 10, 045122. [Google Scholar] [CrossRef]

- Wiklund, J.; Miettinen, A.; Parkkonen, J.; Mela, L.; Karakoç, A.; Paltakari, J. A detailed investigation of acetylated cellulose nanofiber films as a substrate for printed electronics. Mater. Des. 2024, 245, 113230. [Google Scholar] [CrossRef]

- Fang, Z.; Hou, G.; Chen, C.; Hu, L. Nanocellulose-based films and their emerging applications. Curr. Opin. Solid State Mater. Sci. 2019, 23, 100764. [Google Scholar] [CrossRef]

- Walker, S.W.; Shapiro, B. Modeling the fluid dynamics of electrowetting on dielectric (EWOD). J. Microelectromech. Syst. 2006, 15, 986–1000. [Google Scholar] [CrossRef]

- Reichert, M.D.; Walker, L.M. Interfacial tension dynamics, interfacial mechanics, and response to rapid dilution of bulk surfactant of a model oil–water-dispersant system. Langmuir 2013, 29, 1857–1867. [Google Scholar] [CrossRef]

- Shah, P.; Driscoll, M.M. Drop impact dynamics of complex fluids: A review. Soft Matter 2024, 20, 4839–4858. [Google Scholar] [CrossRef] [PubMed]

- Patel, C.V. Investigation of Polyaniline (PANi) and SU-8 Composite Conductive Polymer: Pattern Ability and Electrical Characteristics. Ph.D. Thesis, San Diego State University, San Diego, CA, USA, 2012. [Google Scholar]

- Agate, S.; Joyce, M.; Lucia, L.; Pal, L. Cellulose and nanocellulose-based flexible-hybrid printed electronics and conductive composites–A review. Carbohydr. Polym. 2018, 198, 249–260. [Google Scholar] [CrossRef]

- Li, W.; Wang, S.; Fan, Z.; Li, S.; Bernussi, A.; Newman, N. Functionalized bacterial cellulose as a separator to address polysulfides shuttling in lithium–sulfur batteries. Mater. Today Energy 2021, 21, 100813. [Google Scholar] [CrossRef]

- Wang, W.; Rui, X.; Sheng, W.; Wang, Q.; Wang, Q.; Zhang, K.; Riaud, A.; Zhou, J. An asymmetric electrode for directional droplet motion on digital microfluidic platforms. Sens. Actuators B Chem. 2020, 324, 128763. [Google Scholar] [CrossRef]

- Jain, V.; Devarasetty, V.; Patrikar, R. Effect of electrode geometry on droplet velocity in open EWOD based device for digital microfluidics applications. J. Electrost. 2017, 87, 11–18. [Google Scholar] [CrossRef]

- Naseri, E.; Van Beek, A.; Ahmadi, A. Application of electrowetting on dielectric (EWOD) in drug release control and release-on-demand. Colloids Surf. Physicochem. Eng. Asp. 2022, 654, 130131. [Google Scholar] [CrossRef]

- Jiang, H.; Qian, R.; Yang, T.; Guo, Y.; Yuan, D.; Tang, B.; Zhou, R.; Li, H.; Zhou, G. Inkjet-Printed Dielectric Layer for the Enhancement of Electrowetting Display Devices. Nanomaterials 2024, 14, 347. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yin, Y.; Zhang, J.; Liu, S.; Li, Y.; Wang, C. Design and preparation of the composite film of SiO2 inlaying RGO and its enhanced electro-wetting performance. Eur. Phys. J. Plus 2020, 135, 52. [Google Scholar] [CrossRef]

- Kim, J.-H.; Lee, J.-H.; Mirzaei, A.; Kim, H.W.; Tan, B.T.; Wu, P.; Kim, S.S. Electrowetting-on-dielectric characteristics of ZnO nanorods. Sci. Rep. 2020, 10, 14194. [Google Scholar] [CrossRef]

- Högnadóttir, S.; Kristinsson, K.; Thormar, H.G.; Leosson, K. Increased droplet coalescence using electrowetting on dielectric (EWOD). Appl. Phys. Lett. 2020, 116, 073702. [Google Scholar] [CrossRef]

- Cao, J.; Zeng, X.; Shen, S.; Feng, H.; Qin, X.; Jin, M.; Liu, Z.; Yan, Z.; Shui, L. Replaceable Dielectric Film for Low-Voltage and High-Performance Electrowetting-Based Digital Microfluidics. Langmuir 2023, 39, 10189–10198. [Google Scholar] [CrossRef] [PubMed]

- Sohail, S.; Das, D.; Das, S.; Biswas, K. Study of PDMS as dielectric layer in electrowetting devices. In Physics of Semiconductor Devices, Proceedings of the 17th International Workshop on the Physics of Semiconductor Devices 2013, Noida, India, 10–13 December; Springer: Berlin/Heidelberg, Germany, 2014; pp. 487–490. [Google Scholar]

- Zhang, Y.; Karasu, F.; Rocco, C.; van der Ven, L.; van Benthem, R.; Allonas, X.; Croutxé-Barghorn, C.; Esteves, A.; de With, G. PDMS-based self-replenishing coatings. Polymer 2016, 107, 249–262. [Google Scholar] [CrossRef]

- Fendinger, N.J. Polydimethylsiloxane (PDMS): Environmental fate and effects. In Organosilicon Chemistry IV: From Molecules to Materials; Auner, N., Weis, J., Eds.; Wiley: Hoboken, NJ, USA, 2005; pp. 626–638. [Google Scholar]

- Caputo, D.; de Cesare, G.; Vecchio, N.L.; Nascetti, A.; Parisi, E.; Scipinotti, R. Polydimethylsiloxane material as hydrophobic and insulating layer in electrowetting-on-dielectric systems. Microelectron. J. 2014, 45, 1684–1690. [Google Scholar] [CrossRef]

| Layer Numbers | Resistance (Ω) | Sheet Resistance (µΩ/sq) | ||

|---|---|---|---|---|

| Mean | SD | Mean | SD | |

| 2 | 19.7 | 7.97 | 1400 | 213 |

| 3 | 9.31 | 4.63 | 614 | 21.9 |

| 4 | 3.8 | 2.02 | 250 | 20.4 |

| 5 | 3.14 | 1.17 | 225 | 37.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caro-Pérez, O.; Roncero, M.B.; Casals-Terré, J. Development of an Electrowetting-on-Dielectric Cellulose-Based Conductive Sensor Using Direct Inkjet Printed Silver Nanoparticles. Polysaccharides 2024, 5, 761-782. https://doi.org/10.3390/polysaccharides5040048

Caro-Pérez O, Roncero MB, Casals-Terré J. Development of an Electrowetting-on-Dielectric Cellulose-Based Conductive Sensor Using Direct Inkjet Printed Silver Nanoparticles. Polysaccharides. 2024; 5(4):761-782. https://doi.org/10.3390/polysaccharides5040048

Chicago/Turabian StyleCaro-Pérez, Oriol, Maria Blanca Roncero, and Jasmina Casals-Terré. 2024. "Development of an Electrowetting-on-Dielectric Cellulose-Based Conductive Sensor Using Direct Inkjet Printed Silver Nanoparticles" Polysaccharides 5, no. 4: 761-782. https://doi.org/10.3390/polysaccharides5040048

APA StyleCaro-Pérez, O., Roncero, M. B., & Casals-Terré, J. (2024). Development of an Electrowetting-on-Dielectric Cellulose-Based Conductive Sensor Using Direct Inkjet Printed Silver Nanoparticles. Polysaccharides, 5(4), 761-782. https://doi.org/10.3390/polysaccharides5040048