Electrochemical Determination of Catechol Using a Disposable Printed Electrode with Conductive Ink Based on Graphite and Carbon Black

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Obtaining Working Electrodes

2.2.1. Carbon Paste Electrode (CPE)

2.2.2. Screen-Printed Carbon Electrode (SPEC)

2.3. Instrumentation

3. Results

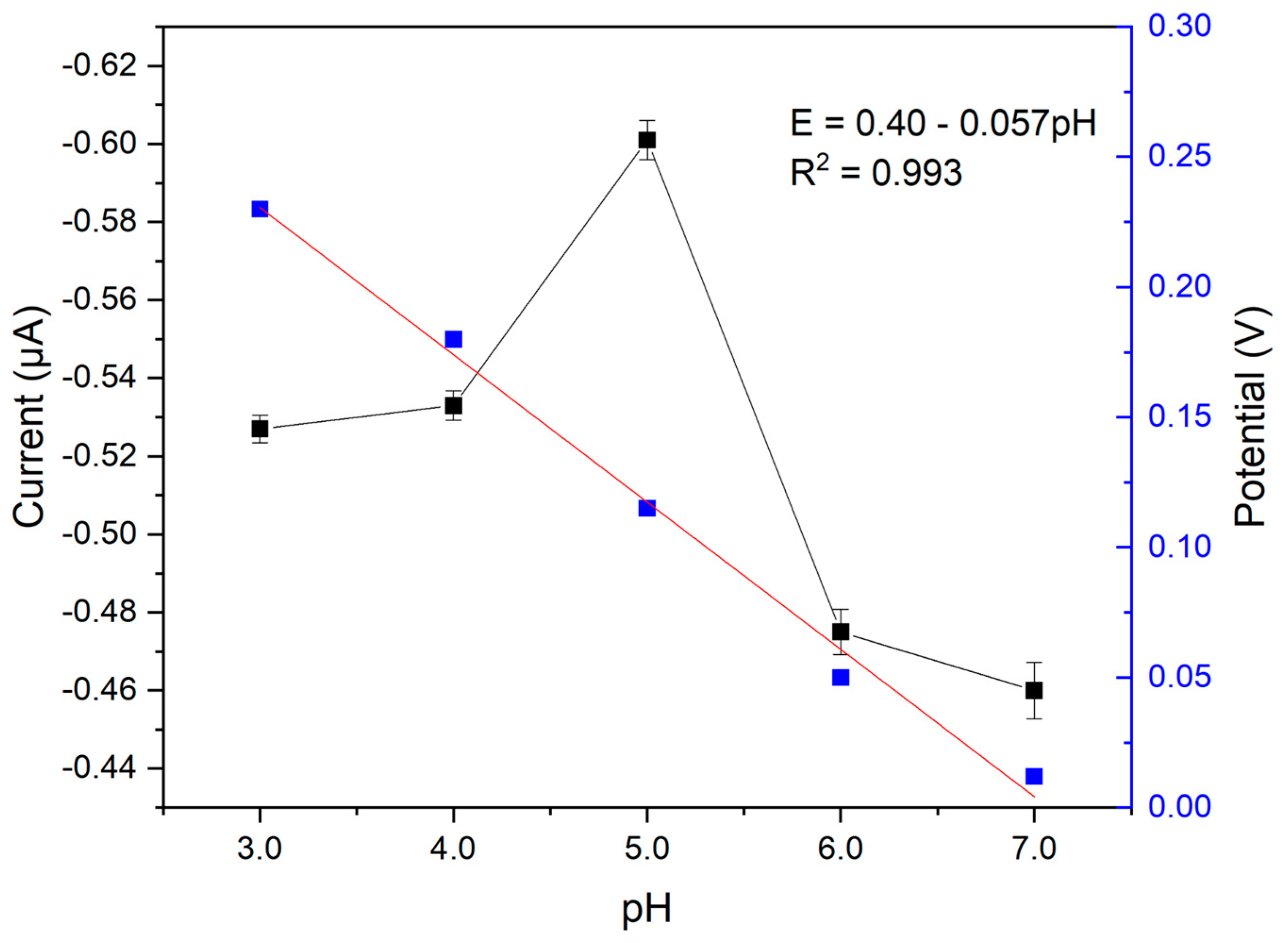

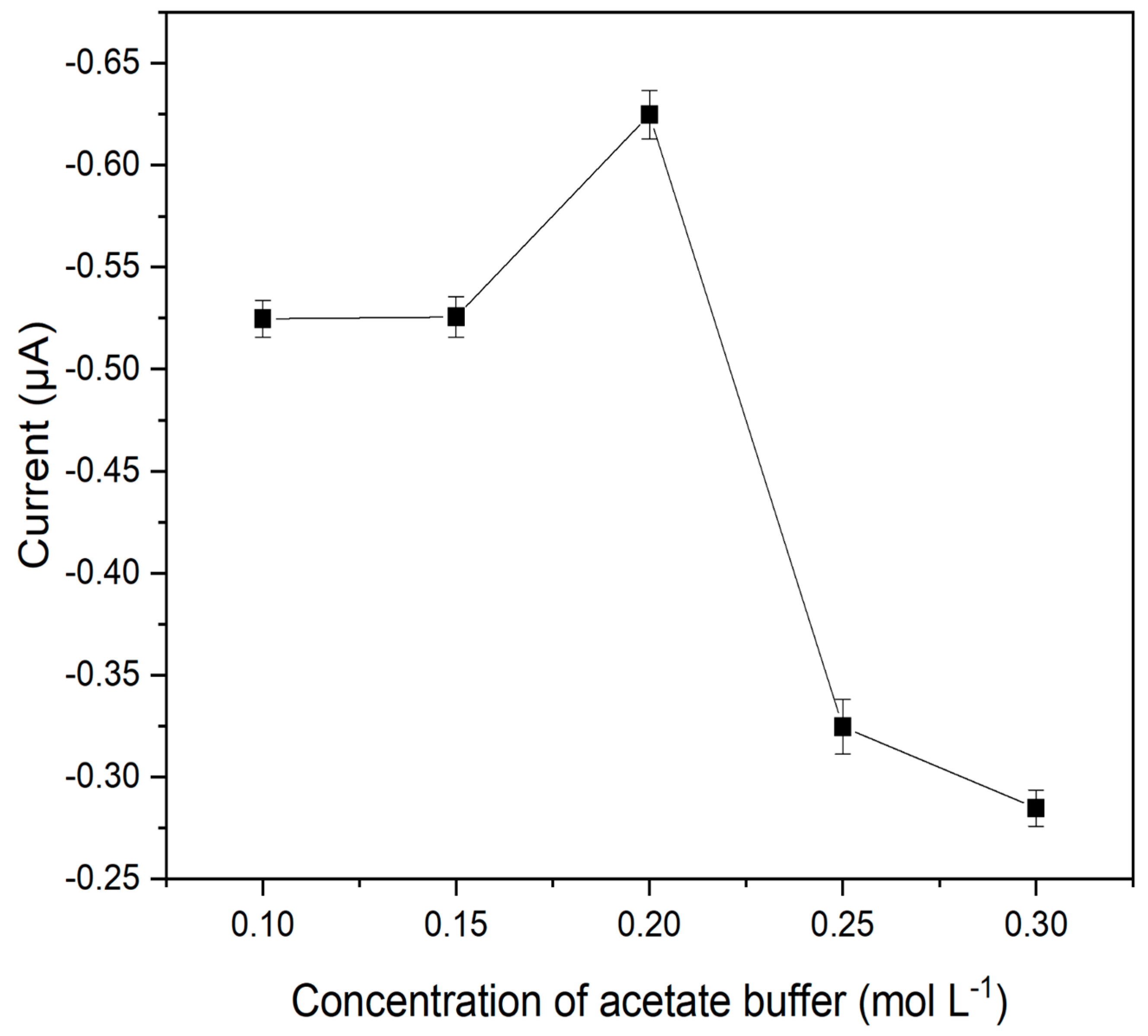

3.1. Electrochemical Performance as a Function of pH and Buffer Solution Concentration

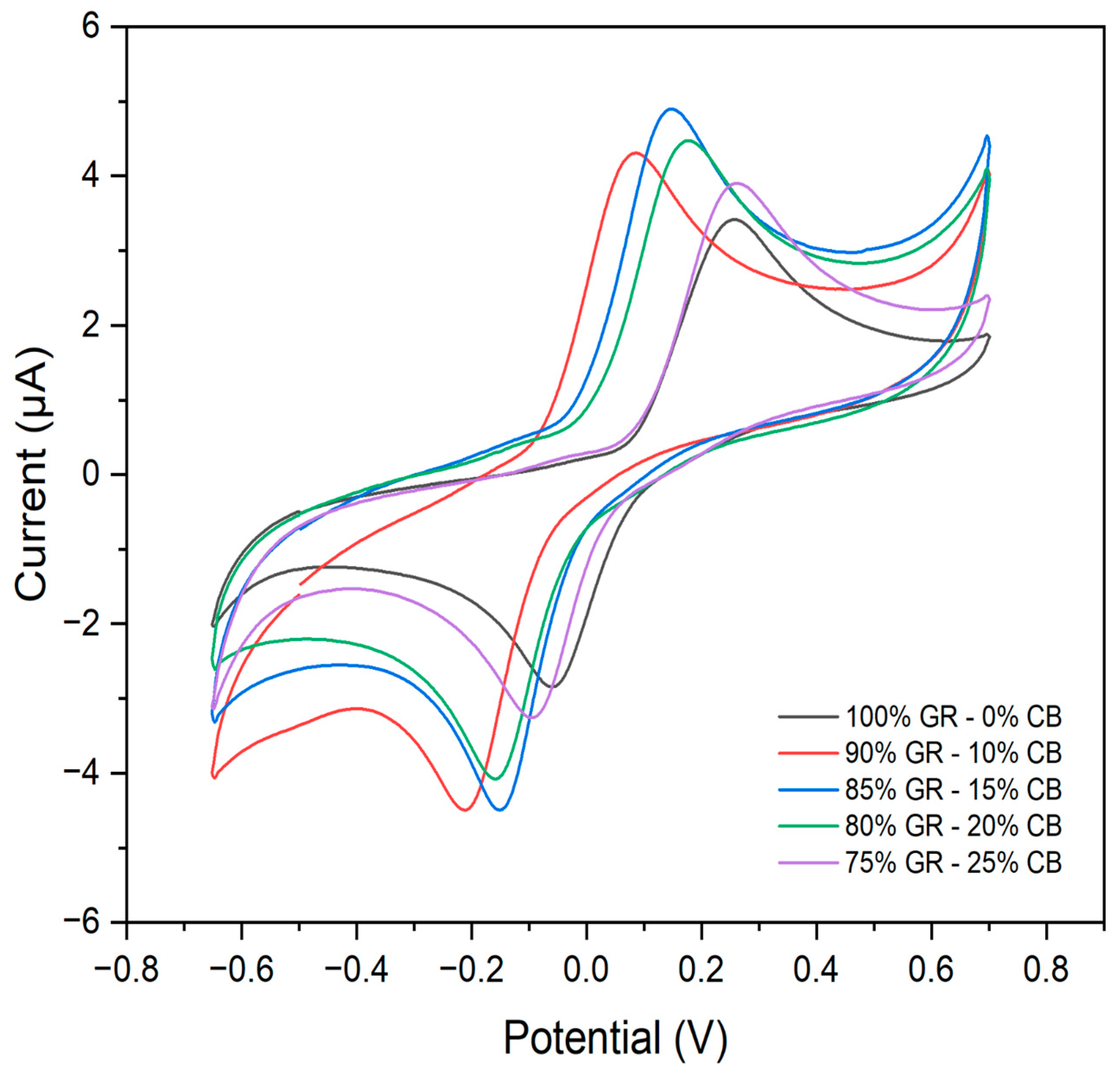

3.2. Conductive Ink Optimization

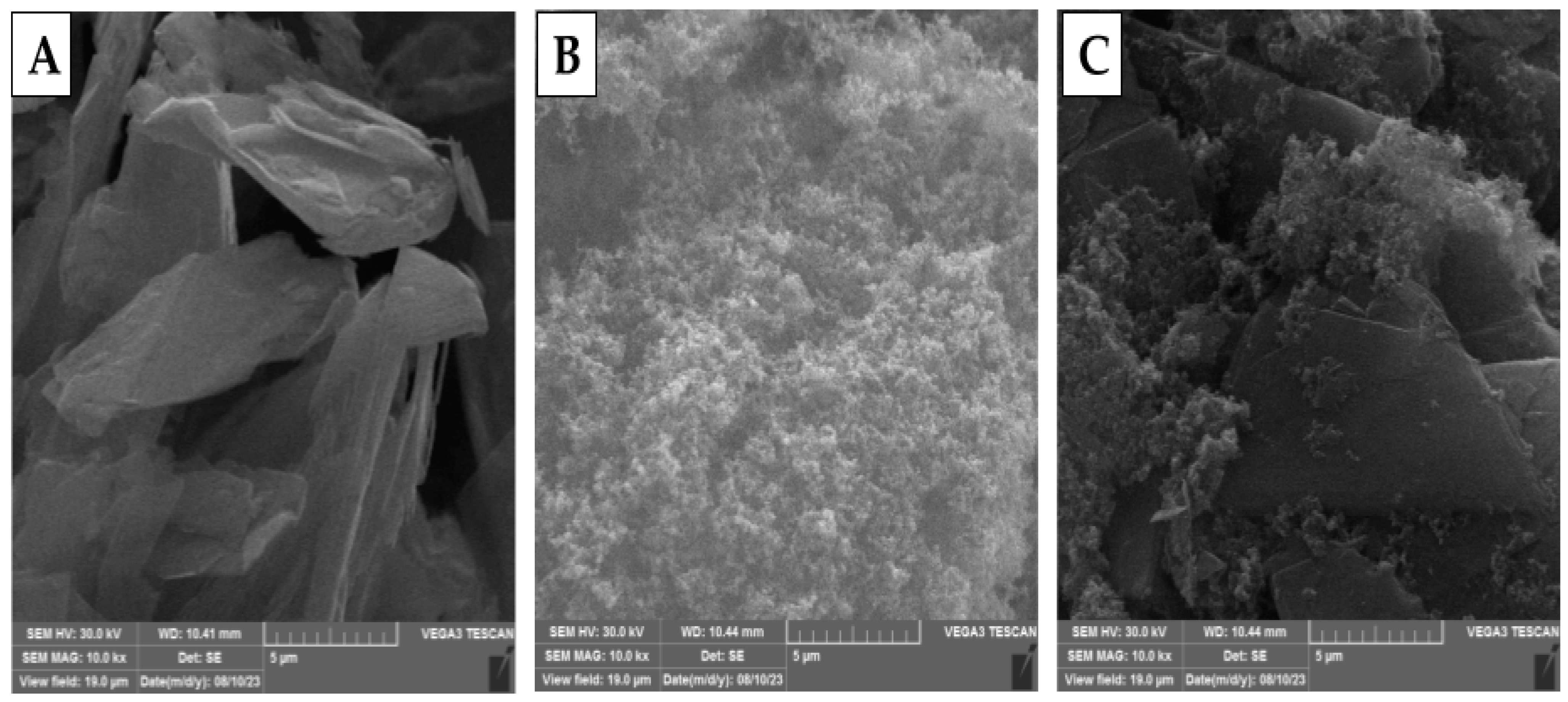

3.3. Scanning Electron Microscopy (SEM)

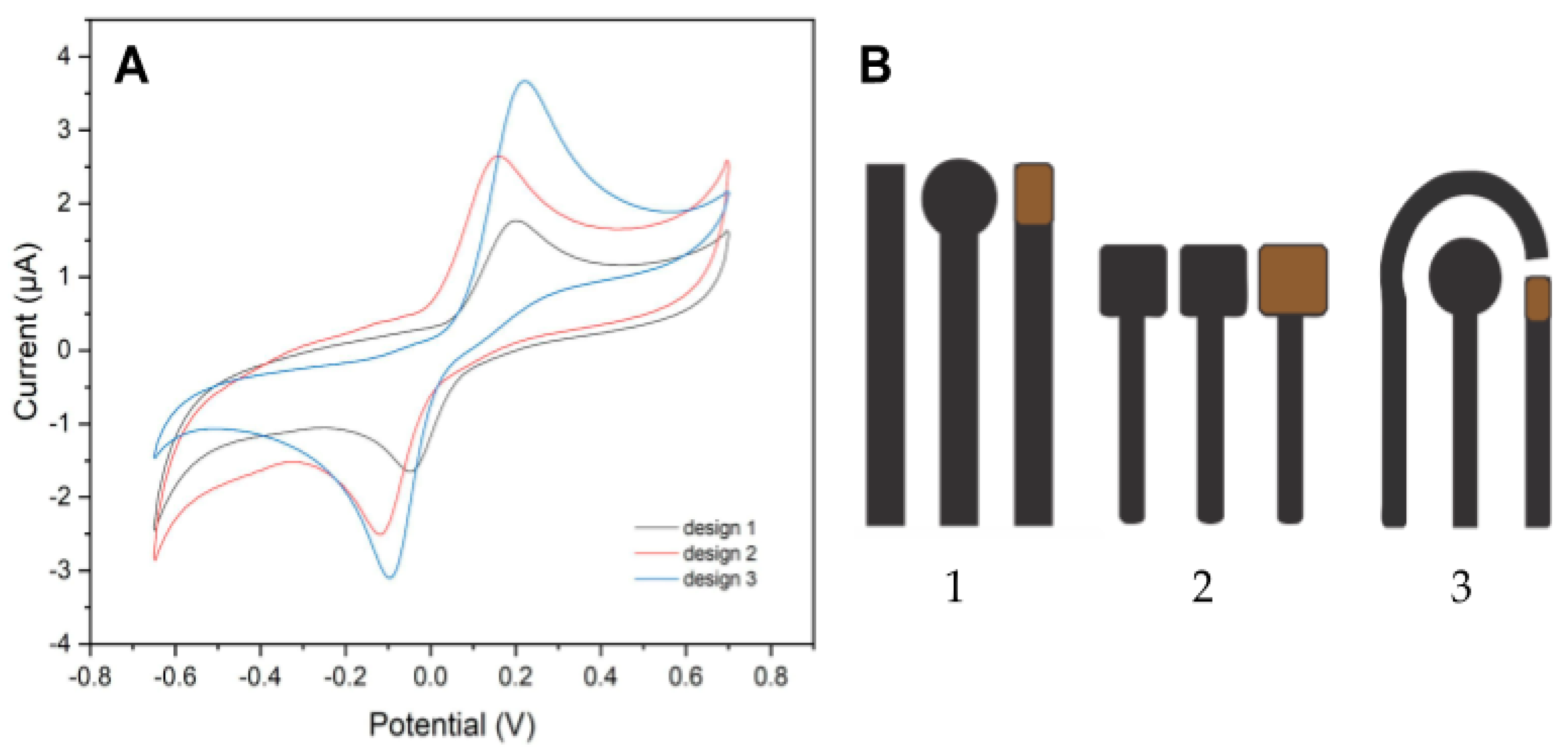

3.4. Sensor Design Optimization

3.5. Choice of Technique and Optimization of Operating Parameters

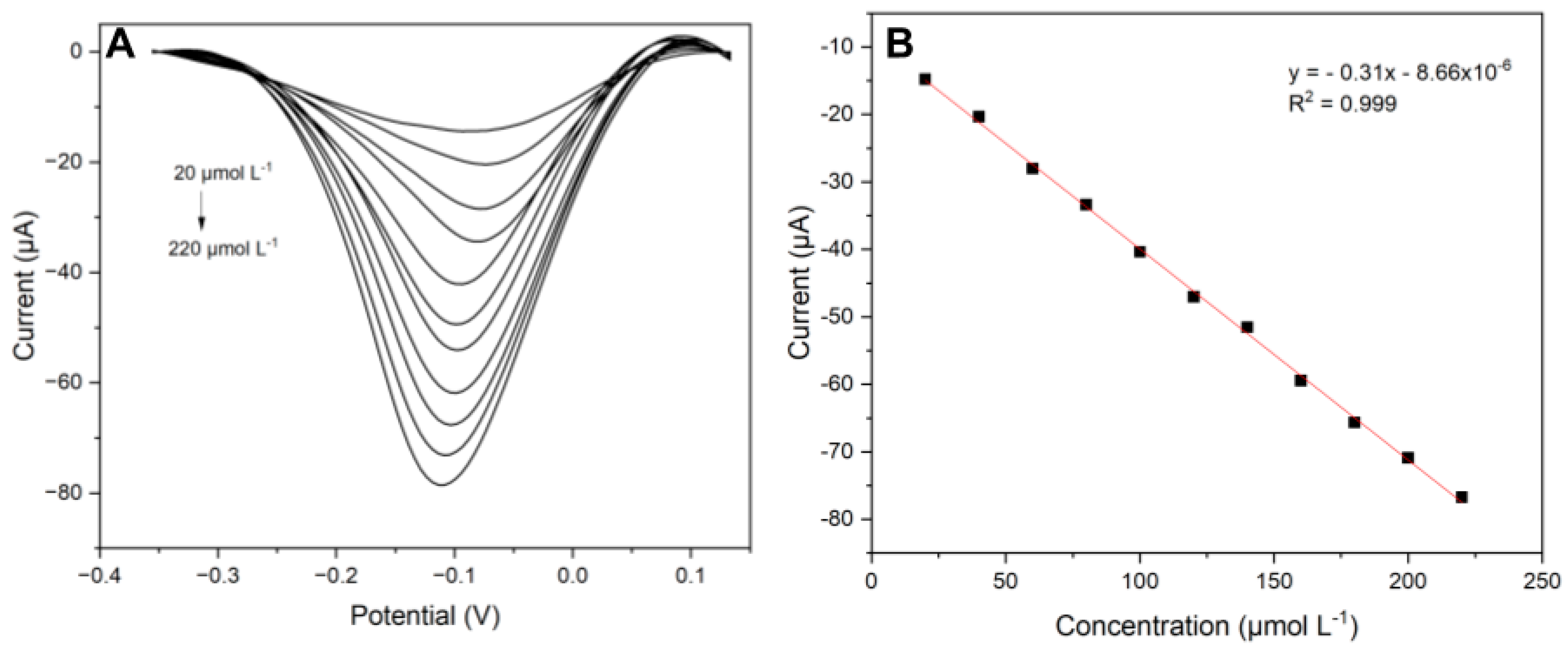

3.6. Construction of the Analytical Curve

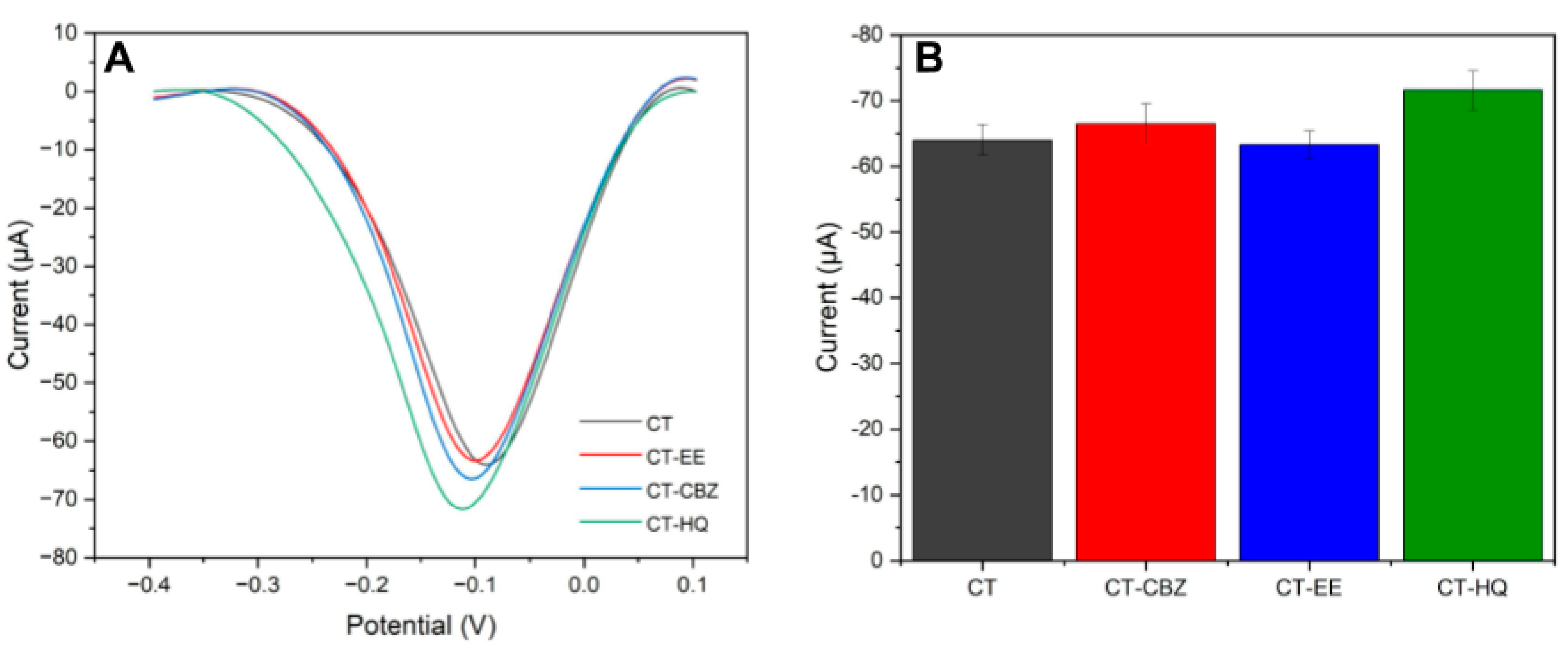

3.7. Assessment of Sensor Performance against Possible Interfering Species

3.8. Application of the Method

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nikhil, S.; Karthika, A.; Suresh, P.; Suganthi, A.; Rajarajan, M. A selective and sensitive electrochemical determination of catechol based on reduced graphene oxide decorated β-cyclodextrin nanosheet modified glassy carbon electrode. Adv. Powder Technol. 2021, 32, 2148–2159. [Google Scholar] [CrossRef]

- Harshitha, B.T.; Manjunatha, J.G.; Pushpanjali, P.A.; Karthik, C.S.; Sandeep, S.; Mallu, P.; D’Souza, E.; Sreeharsha, N.; Asdaq, S.M.B.; Anwer, M.K. Efficient Electrochemical Determination of Catechol with Hydroquinone at Poly (L-Serine) Layered Carbon Paste Electrode. Chem. Sel. 2021, 6, 6764. [Google Scholar] [CrossRef]

- Suvina, V.; Kokulnathan, T.; Wang, T.J.; Geetha Balakrishna, R. Lanthanum cobaltite supported in graphene nanosheets for non-enzymatic electrochemical determination of catechol. Microchim Acta 2020, 187, 189. [Google Scholar] [CrossRef] [PubMed]

- Sumanth, G.S.; Swamy, B.K.; Chetankumar, K. Poly DY 11/Zn/CuO modified electrochemical sensor for the detection of catechol and hydroquinone: A voltammetric study. Mater. Chem. Phys. 2023, 296, 127349. [Google Scholar] [CrossRef]

- Meskher, H.; Achi, F.; Zouaoui, A.; Ha, S.; Peacock, M.; Belkhalfa, H. Simultaneous and selective electrochemical determination of catechol and hydroquinone on a platinum electrode modified with nickel oxide (NiO) and reduced graphene oxide (rGO). Anal. Lett. 2022, 55, 1466–1481. [Google Scholar] [CrossRef]

- Mashhadizadeh, M.H.; Kalantarian, S.M.; Azhdeh, A. A Novel Electrochemical Sensor for Simultaneous Determination of Hydroquinone, Catechol, and Resorcinol Using a Zn-MOF Modified Carbon Paste Electrode, Nitrogen-Doped Graphite and AuNPs. Electroanalysis 2021, 33, 160. [Google Scholar] [CrossRef]

- Lupetti, K.O.; Rocha, F.R.P.; Fatibello-Filho, O. An improved flow system for phenols determination exploiting multi commutation and long path length spectrophotometry. Talanta 2004, 62, 463–467. [Google Scholar] [CrossRef]

- Ogrizek, M.; Kroflič, A.; Šala, M. Determination of trace concentrations of simple phenols in ambient PM samples. Chemosphere 2022, 303, 135313. [Google Scholar] [CrossRef]

- Yao, C.; Zhang, H.; Wang, Z.; Liu, G. Determination of catechol in tea based on the inhibition of CS@Cd composites electrochemiluminescence. Microchem. J. 2024, 198, 110200. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Gao, S.; Zheng, Y.; Tang, M.; Chen, B. A solid-state electrochemiluminescence sensing platform for detection of catechol based on novel luminescent composite nanofibers. Talanta 2013, 107, 127–132. [Google Scholar] [CrossRef]

- Bagheri, H.; Mohammadi, A.; Salemi, A. On-line trace enrichment of phenolic compounds from water using a pyrrole-based polymer as the solid-phase extraction sorbent coupled with high-performance liquid chromatography. Anal. Chim. Acta 2004, 513, 445–449. [Google Scholar] [CrossRef]

- Karim, M.N.; Lee, J.E.; Lee, H.J. Amperometric detection of catechol using tyrosinase modified electrodes enhanced by the layer-by-layer assembly of gold nanocubes and polyelectrolytes. Biosens. Bioelectron. 2014, 61, 147–151. [Google Scholar] [CrossRef] [PubMed]

- Boopathy, G.; Keerthi, M.; Chen, S.M.; Umapathy, M.J.; Kumar, B.N. Highly porous nickel molybdate@ graphene oxide nanocomposite for the ultrasensitive electrochemical detection of environmental toxic pollutant catechol. Mater. Chem. Phys. 2020, 239, 121982. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, S.; Xie, J.; Yang, Z.; Pang, P.; Gao, Y. Simultaneous electrochemical determination of catechol and hydroquinone based on graphene–TiO2 nanocomposite modified glassy carbon electrode. Sens. Actuators B Chem. 2014, 204, 102–108. [Google Scholar] [CrossRef]

- Dos Santos, S.M.V.; Oliveira, P.R.; Oliveira, M.C.; Bergamini, M.F.; Marcolino, L.H., Jr. Screen-Printed Electrodes Constructed Using Carbon Black as Conductive Material. Virtual J. Chem. 2017, 9, 626–640. [Google Scholar] [CrossRef]

- Lawes, S.; Riese, A.; Sun, Q.; Cheng, N.; Sun, X. Printing Nanostructured Carbon for Energy Storage and Conversion Applications. Carbon 2015, 92, 150–176. [Google Scholar] [CrossRef]

- Oliveira, A.E.F.; Pereira, A.C. Development of a Simple and Cheap Conductive Graphite Ink. J. Electrochem. Soc. 2021, 168, 087508. [Google Scholar] [CrossRef]

- Oliveira, A.E.F.; Pereira, A.C.; Ferreira, L.F. Fabrication of Low-cost Screen-printed Electrode in Paper Using Conductive Inks of Graphite and Silver/Silver Chloride. Electroanalysis 2023, 35, e202200093. [Google Scholar] [CrossRef]

- Fonseca, W.T.; Castro, K.R.; Oliveira, T.R.; Faria, R.C. Disposable and Flexible Electrochemical Paper-based Analytical Devices Using Low-cost Conductive Ink. Electroanalysis 2021, 33, 1520–1527. [Google Scholar] [CrossRef]

- Oliveira, A.E.F.; Pereira, A.C.; Resende, M.A.C.; Ferreira, L.F. Fabrication of a Simple and Cheap Screen-printed Silver/Silver Chloride (Ag/AgCl) Quasi-reference Electrode. Electroanalysis 2022, 34, 809–819. [Google Scholar] [CrossRef]

- Cândido, T.C.O.; Pereira, A.C.; Silva, D.N. Development and Characterization of Conductive Ink Composed of Graphite and Carbon Black for Application in Printed Electrodes. Analytica 2023, 4, 513–526. [Google Scholar] [CrossRef]

- Das Neves, M.F.F.; Damasceno, J.P.V.; Junior, O.D.L.; Zarbin, A.J.G.; Roman, L.S. Conductive ink based on PEDOT nanoparticles dispersed in water without organic solvents, passivant agents or metallic residues. Synth. Met. 2021, 272, 116657. [Google Scholar] [CrossRef]

- Wiklund, J.; Karakoç, A.; Palko, T.; Yiğitler, H.; Ruttik, K.; Jäntti, R.; Paltakari, J. A Review on Printed Electronics: Fabrication Methods, Inks, Substrates, Applications and Environmental Impacts. J. Manuf. Mater. Process. 2021, 5, 89. [Google Scholar] [CrossRef]

- Pérez-Fernández, B.; Costa-García, A.; Muñiz, A.D.L.E. Electrochemical (bio) sensors for pesticides detection using screen-printed electrodes. Biosensors 2020, 10, 32. [Google Scholar] [CrossRef] [PubMed]

- De Freitas, R.C.; Fonseca, W.T.; Azzi, D.C.; Raymundo-Pereira, P.A.; Oliveira, O.N.; Janegitz, B.C. Flexible electrochemical sensor printed with conductive ink made with craft glue and graphite to detect drugs and neurotransmitters. Microchem. J. 2023, 191, 108823. [Google Scholar] [CrossRef]

- Orzari, L.O.; Silva, L.R.G.e.; de Freitas, R.C.; Brazaca, L.C.; Janegitz, B.C. Lab-made disposable screen-printed electrochemical sensors and immunosensors modified with Pd nanoparticles for Parkinson’s disease diagnostics. Microchim. Acta 2024, 191, 189. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Mullick, G.; He, S.; Nag, A.; Deng, S.; Afsarimanesh, N.; Gao, J. Graphene allotropes-based electrochemical sensors to detect catechol molecules. Sens. Actuators A Phys. 2024, 368, 115088. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Li, D.; Wei, Q. A laccase based biosensor on AuNPs-MoS2 modified glassy carbon electrode for catechol detection. Colloids Surf. B Biointerfaces 2020, 186, 110683. [Google Scholar] [CrossRef] [PubMed]

- Saha, R.; Mukhopadhyay, M. Electrochemical analysis of Catechol polymerization in presence of Trametes versicolor laccase and the mediator ABTS. Enzym. Microb. Technol. 2021, 152, 109934. [Google Scholar] [CrossRef]

- Yasa, M.; Deniz, A.; Forough, M.; Yildirim, E.; Persil Cetinkol, O.; Udum, Y.A.; Toppare, L. Construction of amperometric biosensor modified with conducting polymer/carbon dots for the analysis of catechol. J. Polym. Sci. 2020, 58, 3336–3348. [Google Scholar] [CrossRef]

- Malinowski, S.; Wardak, C.; Jaroszyńska-Wolińska, J.; Herbert, P.A.F.; Pietrzak, K. New electrochemical laccase-based biosensor for dihydroxybenzene isomers determination in real water samples. J. Water Process Eng. 2020, 34, 101150. [Google Scholar] [CrossRef]

- Romero, A.; Lavin-Lopez, M.P.; Sanchez-Silva, L.; Valverde, J.L.; Paton-Carrero, A. Comparative study of different scalable routes to synthesize graphene oxide and reduced graphene oxide. Mater. Chem. Phys. 2018, 203, 284–292. [Google Scholar] [CrossRef]

- Pinto, S.D.S.; Rezende, M.C. Application of poly(o-methoxyaniline) and its carbon black composites in microwave absorbers. Polímeros 2012, 22, 325–331. [Google Scholar] [CrossRef]

- Montês, V. Development and Optimization of Printed Electrochemical Sensors. Master’s Thesis, Department of Chemistry and Biochemistry, University of Porto, Porto, Portugal, 2015. [Google Scholar]

- Souza, D.; Machado, S.A.S.; Avaca, L.A. Square wave voltammetry. Part I: Theoretical aspects. Quim. Nova 2003, 26, 81–89. [Google Scholar] [CrossRef]

- Manoj, D.; Gnanasekaran, L.; Rajendran, S.; Jalil, A.A.; Siddiqui, M.N.; Gracia, F.; Soto-Moscoso, M. A mechanothermal approach for the synthesis of Fe3O4 nanoparticles as dopant on mesoporous TiO2 for electrochemical determination of catechol. Environ. Res. 2023, 222, 115358. [Google Scholar] [CrossRef] [PubMed]

- Gil, E.S.; Muller, L.; Santiago, M.F.; Garcia, T.A. Biosensor based on crude laccase extract (Pycnoporus sanguineus) for environmental analysis of phenolic compounds. J. Port. Soc. Electrochem. 2009, 27, 215–225. [Google Scholar] [CrossRef]

- Gao, Z.-Y.; Gao, Y.-L.; Wang, E.; Xu, S.; Chen, W. Electrochemical determination of catechol based on cadmium telluride quantum dots/graphene composite film modified electrode. J. Electrochem. Soc. 2016, 163, H528–H533. [Google Scholar] [CrossRef]

- Orzari, L.O.; Andreotti, I.A.d.A.; Bergamini, M.F.; Junior, L.H.M.; Janegitz, B.C. Disposable electrode obtained by pencil drawing on corrugated fiberboard substrate. Sens. Actuators B Chem. 2018, 264, 20–26. [Google Scholar] [CrossRef]

| Technique | DPV | SWV | ||

|---|---|---|---|---|

| Evaluated Parameters | Evaluated Range | Optimized Value | Evaluated Range | Optimized Value |

| scan rate (mV/s) | 4–30 | 10 | - | - |

| amplitude (mV) | 5–120 | 80 | 5–120 | 100 |

| frequency (Hz) | - | - | 5–60 | 40 |

| sensitivity (μA L μmol−1) | 0.13 | 0.31 | ||

| Proposed Sensor | Technique | Linear Range (μmol L−1) | LOD (μmol L−1) | Reference |

|---|---|---|---|---|

| Fe3O4–TiO2/GC a | CV | 100–500 | 45.00 | [36] |

| PCL b | DPV | 20–700 | 4.50 | [37] |

| CdTe QDs/GR/GCE c | DPV | 30–1000 | 18.28 | [38] |

| disposable electrode PD-CFB d | LSV e | 50–1100 | 10.00 | [39] |

| SPEC | SWV | 20–220 | 5.96 | This work |

| Added Concentration (μmol L−1) | Concentration Detected (μmol L−1) | Recovery (%) |

|---|---|---|

| 0.00 | 0.00 | - |

| 70.00 | 68.00 | 97.95 |

| 150.00 | 150.30 | 100.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Oliveira, S.P.; de Oliveira Cândido, T.C.; Pereira, A.C.; da Silva, D.N. Electrochemical Determination of Catechol Using a Disposable Printed Electrode with Conductive Ink Based on Graphite and Carbon Black. Analytica 2024, 5, 250-262. https://doi.org/10.3390/analytica5020016

de Oliveira SP, de Oliveira Cândido TC, Pereira AC, da Silva DN. Electrochemical Determination of Catechol Using a Disposable Printed Electrode with Conductive Ink Based on Graphite and Carbon Black. Analytica. 2024; 5(2):250-262. https://doi.org/10.3390/analytica5020016

Chicago/Turabian Stylede Oliveira, Sthephane Pereira, Thaís Cristina de Oliveira Cândido, Arnaldo César Pereira, and Daniela Nunes da Silva. 2024. "Electrochemical Determination of Catechol Using a Disposable Printed Electrode with Conductive Ink Based on Graphite and Carbon Black" Analytica 5, no. 2: 250-262. https://doi.org/10.3390/analytica5020016