Surface Roughness Evaluation of the Inner Surface of Automobile Engine Bores by RANSAC and the Least Squares Method †

Abstract

:1. Introduction

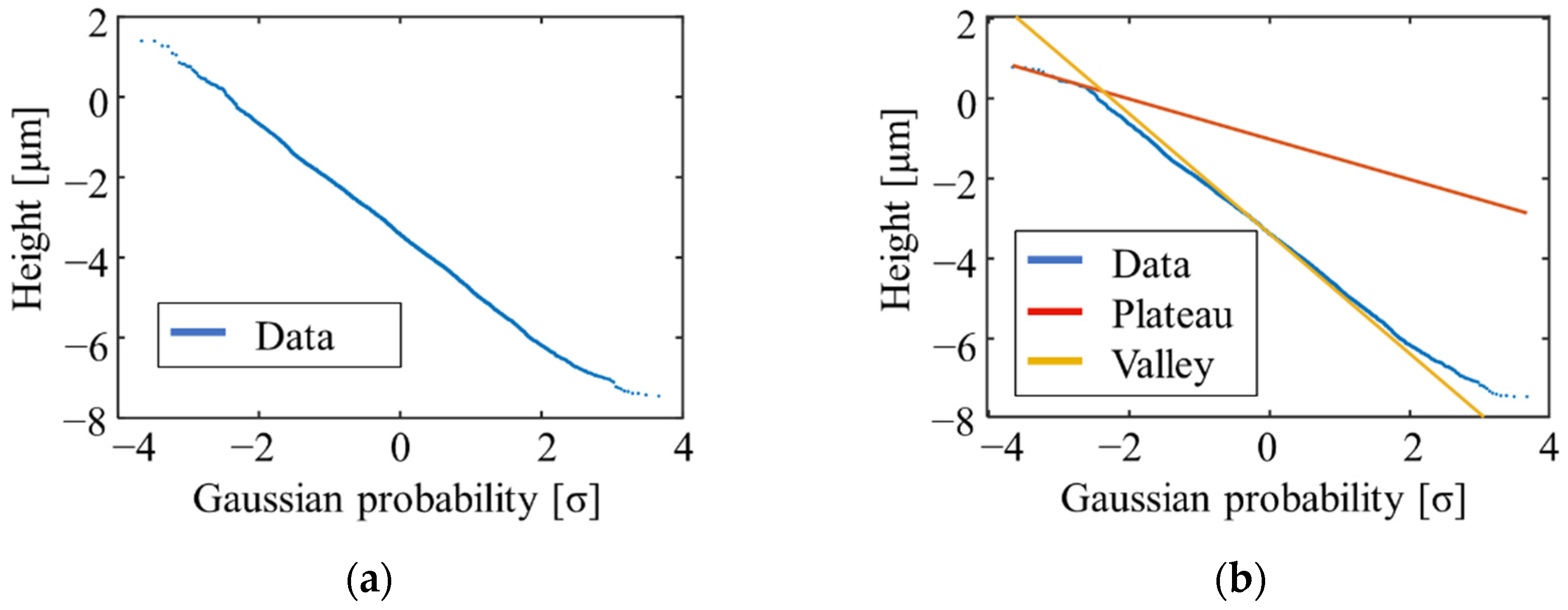

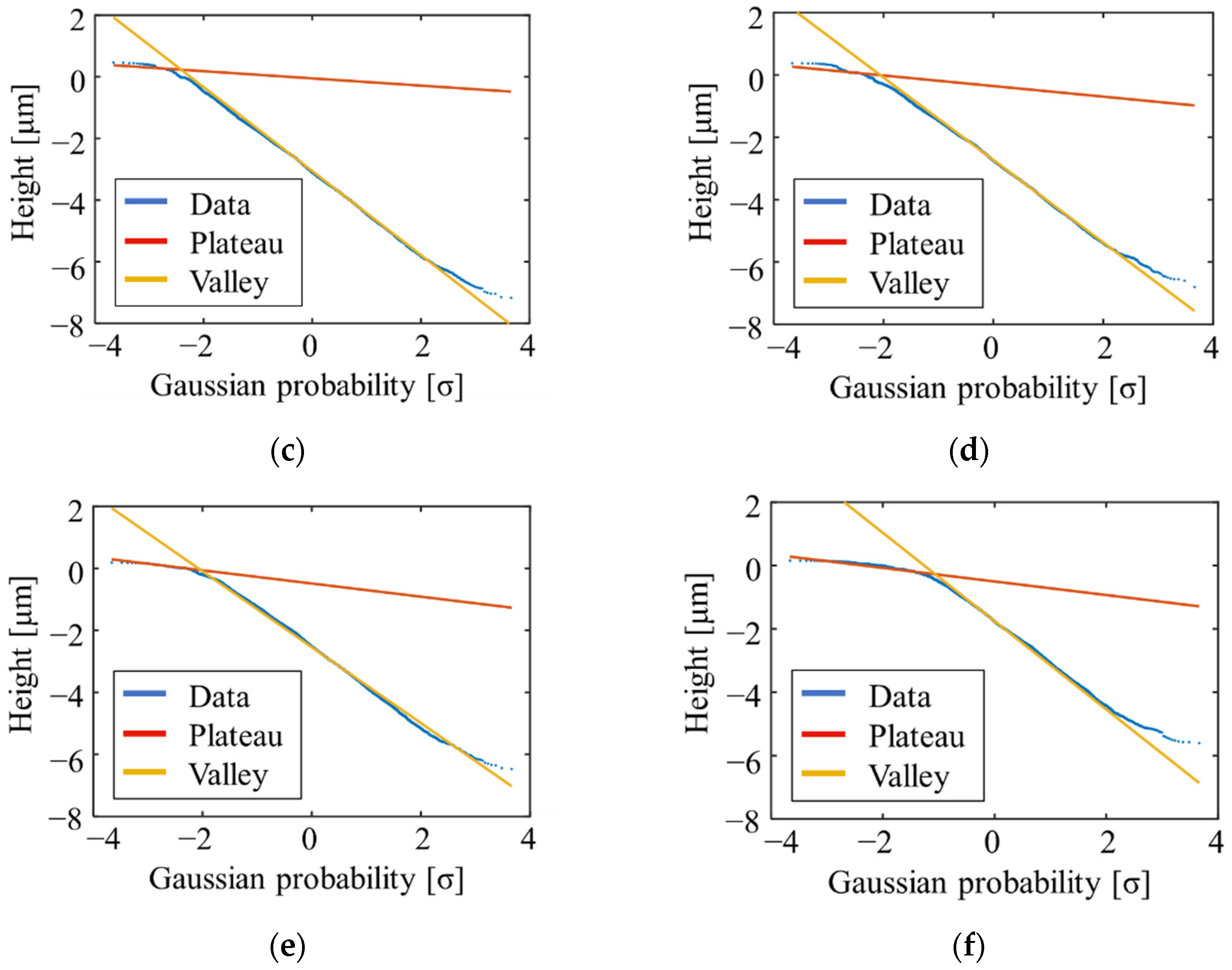

2. Proposed Method Applying RANSAC and the Least Squares Method

- Two points are randomly extracted from the material probability curve, and the model line is calculated from the two randomly extracted points.

- The number of data points within the tolerance (inliers) from the model line is counted.

- The best model is the one in which the number of inliers is greater than the specified value and the total error between the acceptable data and the model line is the smallest.

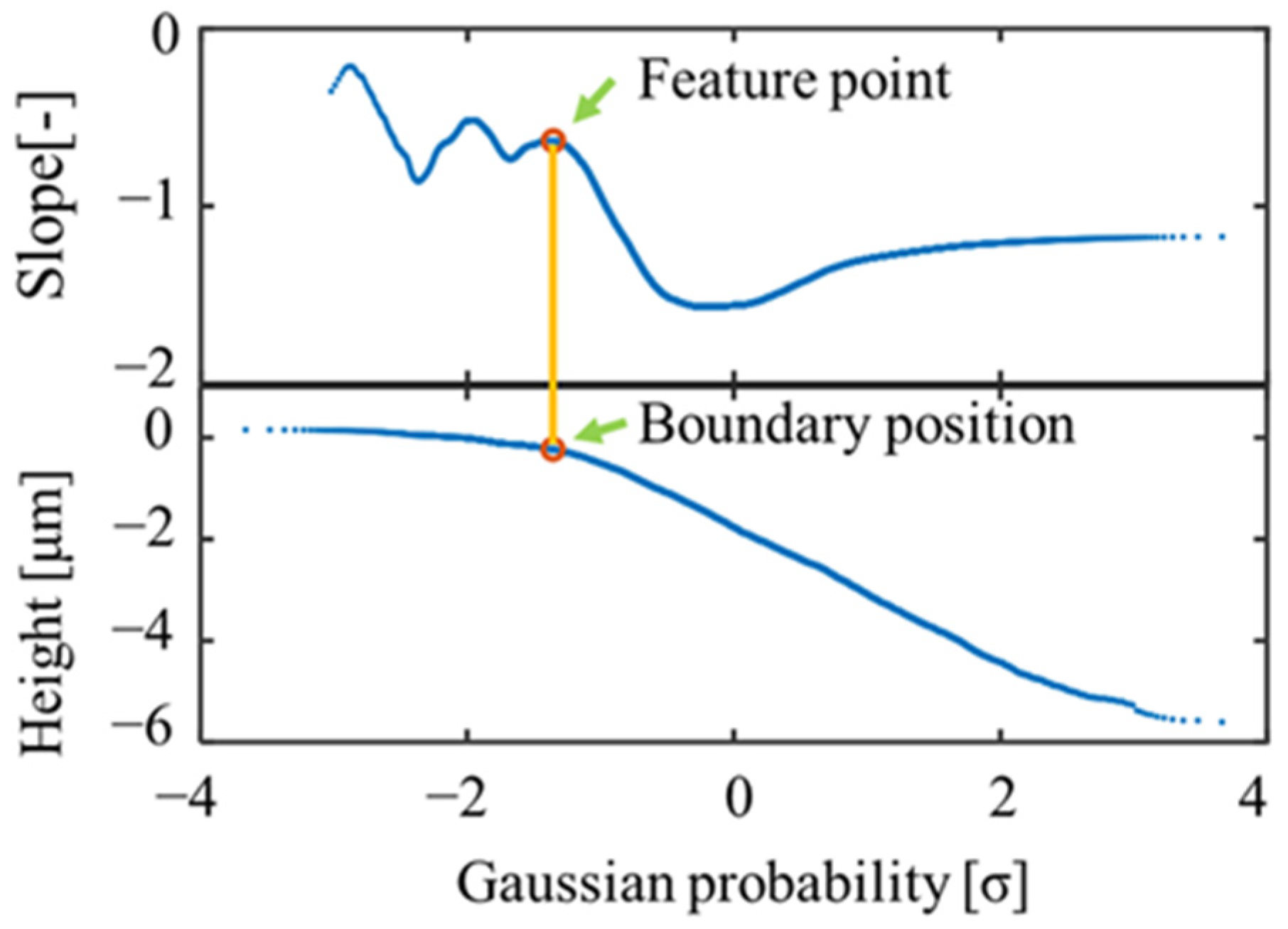

2.1. Determination of Boundary Position Using the Least Squares Method

- The material probability curve is scanned one point at a time from the edge, and the straight line that is fitted to each range is calculated using the least squares method.

- The change in the slope of the line produces an extreme value.

- The local maximum point with the largest difference from the neighboring local minimum point, among several detected extremes, is set as a feature point.

- The point on the material probability curve corresponding to the feature point is determined to be the boundary position.

2.2. Automization of Setting of Tolerances and Number of Inliers

3. Experiment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yoshida, I.; Tsukada, T.; Arai, Y. Characterization of three-stratum surface textures. Jpn. J. Tribol. 2008, 53, 99–111. Available online: https://www.researchgate.net/publication/297936036_Characterization_of_three-stratum_surface_textures (accessed on 1 September 2021).

- ISO 13565-3:1998 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method; Surfaces Having Stratified Functional Properties-Part 3: Height Characterization Using the Material Probability Curve. Available online: https://www.iso.org/obp/ui/#iso:std:iso:13565:-3:ed-1:v1:en (accessed on 25 November 2021).

- ISO 21920-2:2021 Geometrical product specifications (GPS)—Surface Texture: Profile-Part 2: Terms, Definitions, and Surface Texture Parameters. Available online: https://www.iso.org/standard/72226.html (accessed on 25 November 2021).

- Yoshida, I.; Kondo, Y.; Wakatsuki, G.; Numada, M. Study of a Plateau Surface Evaluation Method Using a Fast M-Estimation Type Hough Transform, International Journal of Automation Technology. Int. J. Autom. Technol. 2019, 13, 118–123. [Google Scholar] [CrossRef]

- Sakakibara, R.; Yoshida, I.; Kondo, Y.; Numada, M.; Yamashita, K. A Proposal of Hyperbolic Fitting Method by Applying the Properties of Functions for Plateau Surface Analysis in ISO13565-3. Nanomanufacturing Metrol. 2020, 3, 1–11. [Google Scholar]

- Sakakibara, R.; Yoshida, I.; Nagai, S.; Kondo, Y.; Yamashita, K. Surface roughness evaluation method based on roughness parameters in ISO 13565-3 using the least-squares method for running-in wear process analysis of plateau surface. Tribol. Int. 2021, 163, 1–9. [Google Scholar] [CrossRef]

- Nagai, S.; Yoshida, I.; Machida, H.; Kondo, Y.; Sakakibara, R.; Yamashita, K. Study on Surface Roughness Evaluation Method of Inner Surface of Engine Bore Using RANSAC Method and Least Squares Method. In Proceedings of the Abrasive Technology Conference 2021, Hokkaido, Japan, 30 November–3 December 2021; ABTEC-U-C44. p. 215. [Google Scholar]

- Nagai, S.; Yoshida, I.; Sakakibara, R. Study on Surface Roughness Evaluation Method for Engine Bore Surface Using RANSAC and Least Square Method. In Proceedings of the 6th STI-Gigaku 2021, Nagaoka, Japan, 20–22 October 2021. STI-9-19. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagai, S.; Yoshida, I.; Sakakibara, R. Surface Roughness Evaluation of the Inner Surface of Automobile Engine Bores by RANSAC and the Least Squares Method. Eng. Proc. 2021, 11, 23. https://doi.org/10.3390/ASEC2021-11169

Nagai S, Yoshida I, Sakakibara R. Surface Roughness Evaluation of the Inner Surface of Automobile Engine Bores by RANSAC and the Least Squares Method. Engineering Proceedings. 2021; 11(1):23. https://doi.org/10.3390/ASEC2021-11169

Chicago/Turabian StyleNagai, Sho, Ichiro Yoshida, and Ryo Sakakibara. 2021. "Surface Roughness Evaluation of the Inner Surface of Automobile Engine Bores by RANSAC and the Least Squares Method" Engineering Proceedings 11, no. 1: 23. https://doi.org/10.3390/ASEC2021-11169

APA StyleNagai, S., Yoshida, I., & Sakakibara, R. (2021). Surface Roughness Evaluation of the Inner Surface of Automobile Engine Bores by RANSAC and the Least Squares Method. Engineering Proceedings, 11(1), 23. https://doi.org/10.3390/ASEC2021-11169