Abstract

Robotics is undoubtedly one of the most influential fields of modern technology in changing the very nature of our society. Parallel Delta robots have for a long time been mainly focused on a niche market; however, compared to serial anthropomorphic robots they present several simplicity and improved dynamics features. Additive manufacturing (AM) and 3D-printing technologies are enabling rapid changes in robotic engineering as we classically know it, allowing for greater creativity and freedom in mechatronics design and innovation. The effective benefits of far-reaching design freedom in terms of geometry, materials, and manufacturing accessibility are now starting to become apparent, answering many complex technical questions and scientific uncertainties that go beyond basic design and functional knowledge and that require engineering skills and scientific analysis. The Delta robot, as one of the most significant industrialized parallel robots due to its simplicity, is considered in this work, which provides an overview of the multidisciplinary aspects of the new Smile.Tech’s 3D-printed and low-cost Delta robot, the Óscar family. We provide a concise analysis of the current state of the art and use of Delta robots, as well as a discussion of the Delta architecture, interface software, and virtual operation environments. The article concludes with a market analysis, a summary of the major manufacturers and currently available Delta models as well as a benchmarking study of their major operating and technical features.

1. Introduction

Recent advancements in artificial intelligence and 5G telecommunications services have resulted in robotic technology influencing an increasing number of aspects of our lives at work and at home. As a result of easy access to robots and the more interesting interactions between humans and robots, our daily routines and work practices are being changed and automated in a safe way, which is encouraging research and the spread of cutting-edge robotic technology and collaborative work environments.

It is well known that, in robotics, there are essentially two kinds of kinematics—serial and parallel—and a combination thereof. Serial robots typically consist of a sequence of linkage arms sequentially connected through their joints until the moving tool carrier, whereas parallel robots take effect on the moving tool carrier directly with several simultaneously actuated linkage arms, the archetypal serial and parallel robots being the anthropomorphic arm and the 3D spatial moving platform used in ludic and professional motion simulators.

In contrast to serial kinematics, in parallel kinematics, not all joints carry drive engines, which are usually located on the base platform and, therefore, the moving mass is smaller and high-dynamic tasks can be more easily addressed. The resulting low moving masses of parallel kinematics enable both high-dynamics and very precise mechanics.

It is widely claimed that parallel robots are intrinsically more accurate than serial robots because their errors are averaged instead of added cumulatively, an assertion that has been somewhat confirmed [1]. Engineering experience and scientific reasoning agree on the strengths and weaknesses of serial and parallel architectures: small footprint, large workspace, simple modeling, but large movable masses, for serial manipulators; low movable masses, high dynamic capabilities, but large footprint and small workspaces, for parallel manipulators [2]. These enhanced mechanical features make parallel robots better suited for handling and assembly tasks.

The so-called Delta robot is a type of parallel robot whose fundamental concept is based on parallelograms (Figure 1). A parallelogram enables a fixed orientation of an output link relative to an input link. By employing three such parallelograms, the orientation of the mobile platform is completely constrained, leaving only three purely translational degrees of freedom. The three parallelograms’ input links are mounted on rotating levers via revolute joints, which can be actuated in two ways: by rotational servomotors motors (DC or AC) or by linear actuators—the former being the most frequent.

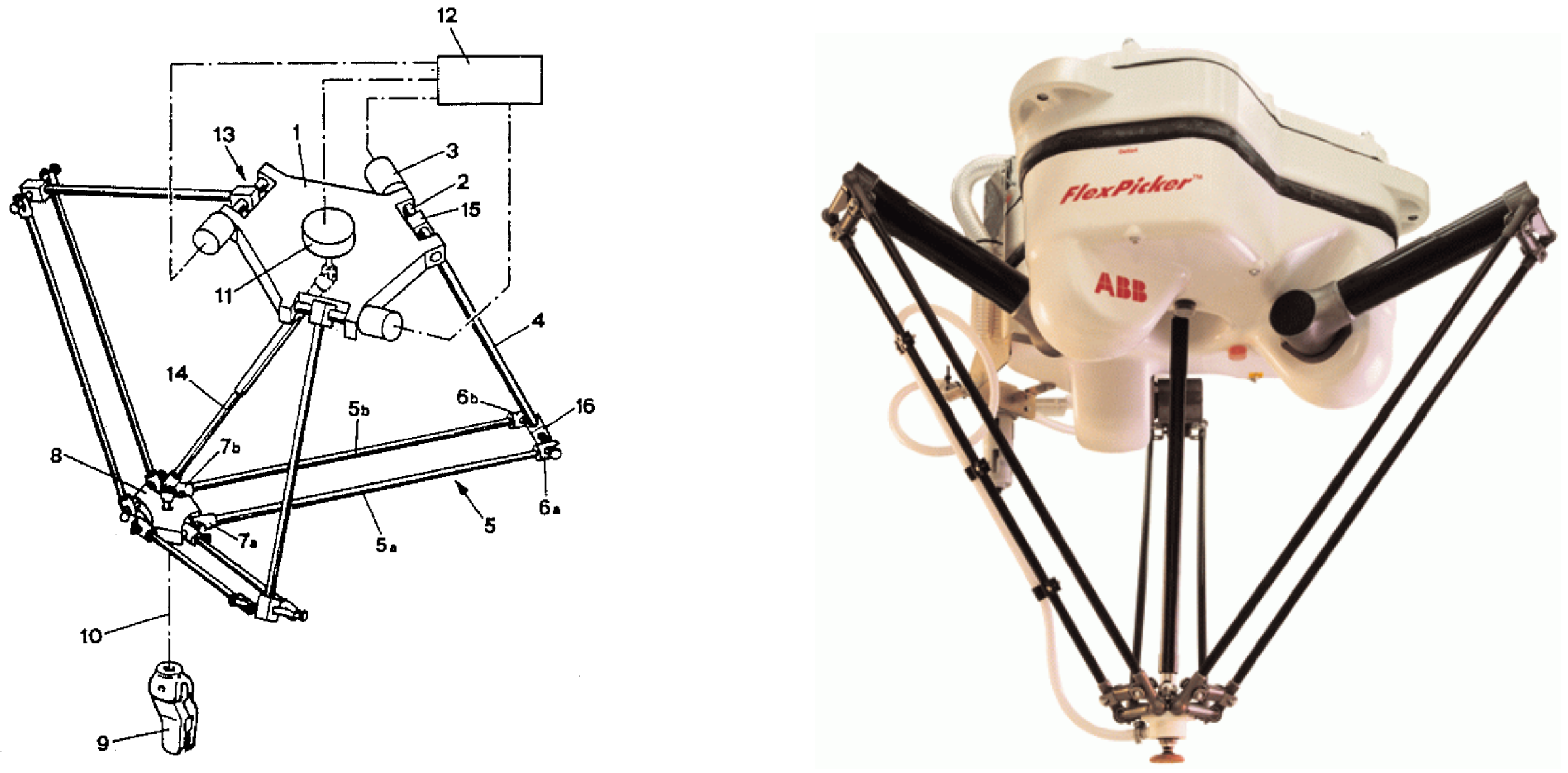

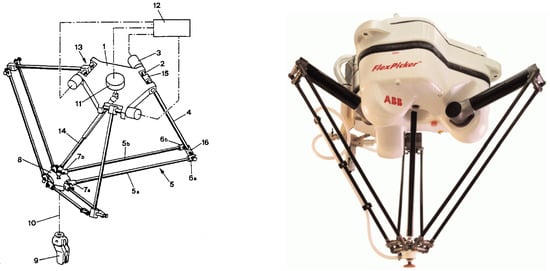

Figure 1.

Schematic of the original Clavel’s Delta robot patented in 1990 [3] and the first ABB Flexible Automation’s Delta robot IRB 340 FlexPicker launched in 1999. Source: ABB Robotics.

The Delta robot, as one of the most significant industrialized parallel robots due to its simplicity, is considered in this work, which provides an overview of the multidisciplinary aspects of the new Smile.Tech’s 3D-printed and low-cost Delta robot, the Óscar family. It addresses a concise and overview analysis of the current state of the art and use of Delta robots, as well as discussion of the Delta architecture, interface software, and virtual operation environments. The article concludes with a market analysis, a summary of the major manufacturers and currently available Delta models, and a benchmarking study of their major technical and operating features.

2. State of the Art and Use of Delta-like Robots

The Delta robot is a type of parallel robot that has established itself as one of the most successful parallel robot designs, certainly with over several hundred thousand active robots worldwide today [4,5]. It was first invented by Clavel in the 1980s [3,6,7] at École Polytechnique Fédérale de Lausanne (EPFL) in Switzerland with the objective to develop an industrial robot for automating a monotonous manual packaging process involving the manipulation of very light chocolates (of a few grams) at a very high speed (a few transfers per second).

Based on a patent license, ABB launched in 1999 the very successful and well-known commercial Delta robot IRB 340 FlexPicker (Figure 1). Originally developed with 3 translational degrees of freedom (DoF), it is typically constituted by three control arms driven by servomotors, which are mounted to a base plate; an optional telescopic drive shaft is used to transmit rotary motion from the base to an end-effector mounted on the mobile platform adding one additional rotational DoF.

The key design feature is the use of parallelograms in the arms, which maintains the orientation of the end-effector (moving tool carrier) and therefore ensures parallel motion, by contrast to the well-know Stewart platform that can change the orientation of its end-effector [8]. Allowing three spatial translations, the manipulator utilizes its symmetry and rigidity to create a simplistic system that can perform pick-and-place on small objects and assembly operations at high speeds with accuracy.

Alternatively, the Delta robot can also be driven by linear actuators, instead of rotary ones, in a Delta design often referred to as Linapod or linear Delta [9,10]; while in theory there is this design possibility, rotary actuation is probably the most interesting one implemented into commercial products and applications; for further details on linear Deltas, the reader is referred to [11,12].

Assembly and pick-and-place applications usually require at least one additional rotational DoF, mostly around the axis perpendicular to the mobile platform plane. Such motions, with three translational and one rotational DoF, are generally called Schoenflies (or SCARA) motions [13], resembling the kinematics of the well known SCARA robots that have been around for decades. Delta robots, in comparison to these, are generally considered to be faster (i.e., with a shorter transfer time) and with a lower maximum payload. In this vein, the so-called hybrid Delta robots comprise an additional orientation mechanism with one, two, or three DoF, mounted in series to the three DoF position mechanism, forming a hybrid parallel-serial manipulator, or mounted in parallel, forming a cooperating machine [14]. The basic idea behind a hybrid manipulator is to split the task of manipulation into two parts: position and orientation. The position mechanism controls the end effector’s position and the orientation mechanism controls its orientation.

Regarding conventional hybrid manipulators, FANUC created an holder assembly resembling a wrist having three additional rotational DoF, mounted in series to the parallel 3 DoF Delta position mechanism, to which a tool is attached and orientated [15]. Coordinating the motions of the position and orientation mechanisms enables for example 6-axis machining of a workpiece. This strategy has a number of significant advantages. To begin, the parallel construction enables the realization of a high stiffness, low inertia, and high speed machine tool. Secondly, its direct and inverse kinematic solutions are available in closed-form, which simplifies control and path planning problems significantly. Thirdly, in comparison to fully parallel platform manipulators, it has a relatively large workspace. Fourthly, its position and orientation kinematics are completely decoupled. Lastly, it makes extensive use of revolute joints, which can be precisely manufactured at a low cost. Overcoming the shortcomings of expensive and imprecise spherical joints as used within six-limbed 6 DoF Stewart platform architectures, and introducing a new generation of hybrid manipulators comprising independent position and orientation mechanisms, each with three complementary DoF, hybrid manipulators were also developed at the University of Maryland [14,16,17,18] employing only revolute joints.

Thus, a possible solution to implement additional orientation DoF is the already mentioned mechanism rotationally actuated by a motor that is usually fixed on the base platform and connected through an intermediary telescopic drive shaft and universal joints to a mechanism pivotally mounted on the end-effector (element 14 in the left-hand side of Figure 1); other variants may consider the end-effector manipulated by a flexible cable, a small motor mounted directly or the pull of a cable wound on a drum with a torsion spring. Other designs, as the one created by FANUC, utilize the basic Delta structure in conjunction with a three DoF rotating head or serial robotic wrist positioned on the end-effector powered by three independent motors mounted on the frame.

Based on Delta technology, Pierrot [19] suggested a new distinctive family of four DoF parallel Delta robots considering an articulated (and not rigid) movable platform with embedded joints—the H4-family—with four independent kinematic chains with an H-shaped end-effector, with the hope that such designs would improve the maximum range of motion in rotation. The most frequent mechanism in this family is the H4 robot where, in contrast to the original Delta robot concept, four kinematic chains connected to the traveling plate through revolute joints are operated by four angular motors. The gripper may rotate due to an extra gear-based amplification mechanism. Extensive research and testing of this and likewise model I4 have shown that none of these designs is optimum for extremely rapid pick-and-place operations and that problems may arise from greatly varying Jacobian condition number, risk of singular configurations, self-collisions, and short service-life of prismatic joints for the I4.

Later, these designs were reviewed and improved, and a prototype was developed with a superior actuator arrangement and only revolute joints on its articulated traveling plate—the Par4 [2]. The first commercially available version of the high-speed pick-and-place parallel manipulator employing the Par4 architecture (Adept Quattro), was free of any singular postures within its workspace and the preliminary prototype succeeded in achieving high speeds (more than 4 m/s) and high accelerations (more than 15 g).

Serial-parallel hybrid and fully-parallel designs with Schoenflies motion are discussed more in detail in [2,12]. Regarding further research and development activities, during the last decades, extensive research on dimensional synthesis, workspace and singular configurations, kinematics, dynamics, control, vibrations, position accuracy, calibration, stiffness, optimization, gravity compensation, and mechanical design of Delta robots has been conducted. Refer, for example to [20,21,22,23,24,25,26] for an overview of the main contributions.

As mentioned, Delta robots are typically used in applications where the robot picks up products in groups and arranges them in a container or assembly pattern. Deltas can now distinguish and select from a variety of size, color, and shape options, as well as pick and place objects based on a programmed pattern. The packaging industry, as well as the medical and pharmaceutical industries, benefit from Delta robots’ high speed. It is also used in surgery due to its stiffness. Additionally, high-precision assembly operations in a clean room for electronic components are possible. A Delta robot’s structure can also be used to create haptic controllers and, recently, the technology was adapted for use with 3D printers. These printers are faster, can be built for less than $200, and perform well in comparison to traditional Cartesian printers [27]. 3D printing challenges and the analysis of the contribution of key process parameters in printing results and quality is discussed in [28,29]; there are a wide variety of uses for 3D printing, ranging from mechanical components and human implants to musical instruments and personal protection equipment, such as COVID-19 protection [30,31,32,33,34]. Numerous other broader application areas for Delta robots include micro robotics, visual control, dynamic balancing, medical haptic devices, and redundancy [4,5,22,35,36]. These are merely a handful of the many possible application scenarios with many more in development.

3. The Óscar Delta Robot Family Development

Automated systems have become increasingly prevalent in recent years in smaller and smaller businesses, offices, schools, and households, owing to the advent of mass production, 3D printing, and open source robotic solutions. It is relatively easy to find examples of this in any field. Automated software completion, scheduled reminders on our agenda, automated data collection, self-driving vehicles, automated access control, and even automated vacuum cleaning and kitchen robots are all possible these days. While the statements above are accurate, despite their exponential growth in industrial settings, non-cartesian robotic manipulators have not yet been widely adopted. Our assessment indicates that there are three significant obstacles maintaining the existing state of affairs:

- A good match between arm length and payload results in a high moment of inertia, which makes direct drive actuators extremely heavy and economically inefficient. With the addition of a reduction system to the output shaft, smaller actuators may be used and, in this case, any backlash results in a significant positioning error; although backlash-free reducers are commercially available, they are quite expensive.

- Safety! Long arms necessitate the use of powerful actuators. When these machines are operating in close proximity to humans, they must protect the latter in the event of contact. As a result, it is necessary to distinguish between the torques required to maneuver a payload and the torques generated by a collision, which is not always easy to do with proven guaranteed success.

- Difficulty of use; the programming and commissioning of robotic systems is more complex than it appears at first sight, namely with regard to safety.

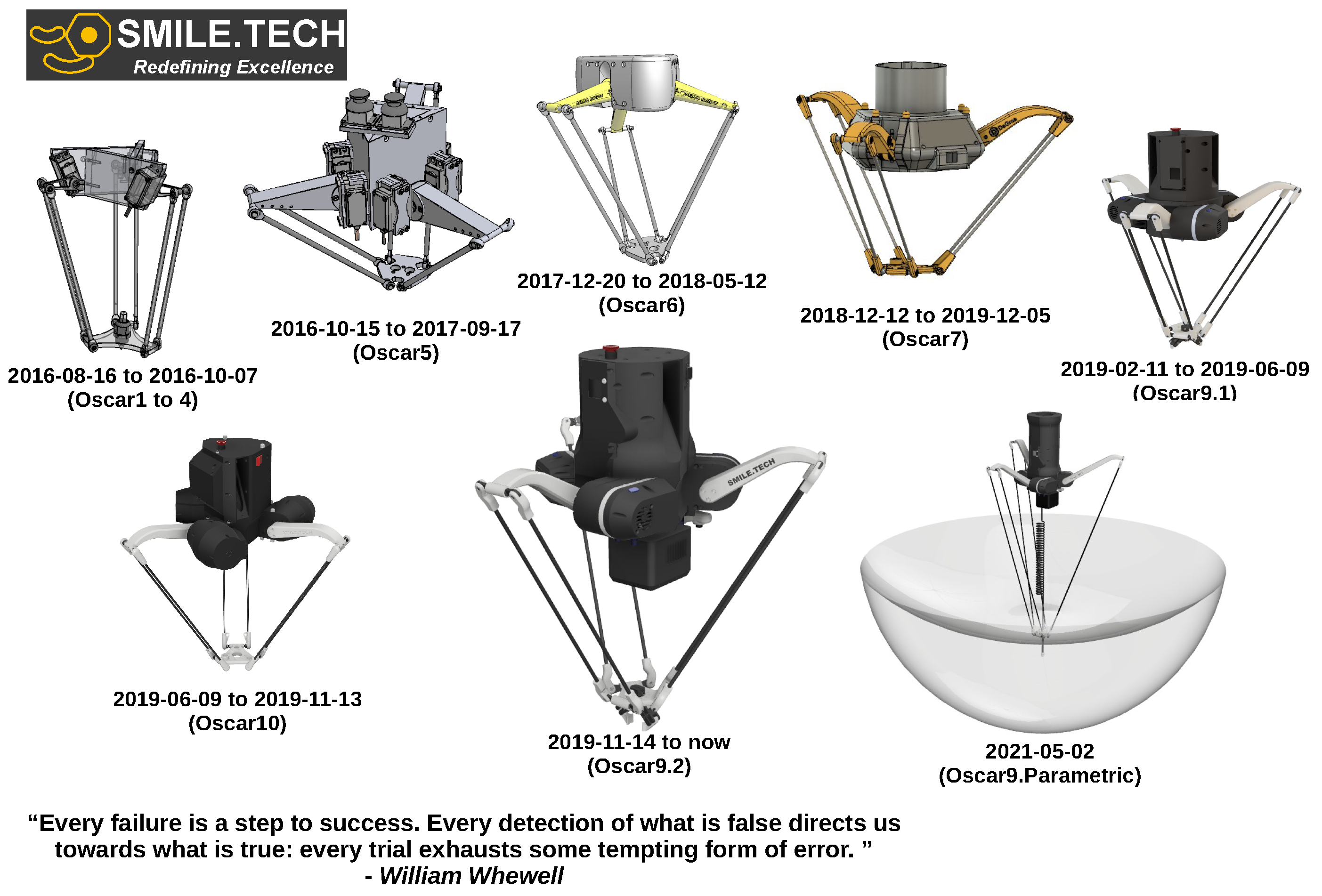

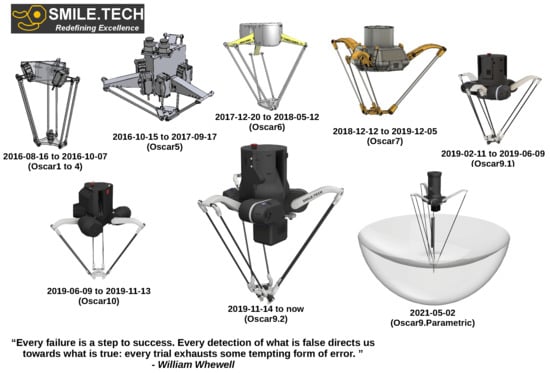

With the above in mind, the iterative design procedure for the Óscar Delta robot included many stages and a long time since its first version was set back in 2016 (see Figure 2). The market for collaborative robotics applications is widely perceived to be developing to satisfy the demands of consumers or clients across a variety of sectors and applications with varying specifications. This was also discovered through market research and the company’s expertise identifying the demands of future consumers, indicating that expanding into a library of off-the-shelf integrating parts and family of Delta solutions was the way to go.

Figure 2.

History of the iterative design, successive Delta robot model versions and Óscar family.

The first step in developing the design was to ascertain the true nature of the problem, which was accomplished through analysis. This is a critical stage because incorrectly defining the problem can result in time being wasted on designs that do not meet the requirements. Following the analysis, it was possible to create and document a specification of the requirements, with some of the primary requirements being an excellent cost-performance ratio and safety suitability for collaborative and effective broad-scope use. Various concepts were developed throughout the conceptual stage, followed by preliminary engineering analyses of the most promising solutions, as illustrated in Figure 2.

Outline solutions were developed and detailed enough to indicate the methods for achieving each of the required functions, e.g., approximate sizes, shapes, materials, costs, and performance (whether by test or analysis). Additionally, this entails determining what has been done previously to address similar issues; there is no point in reinventing the wheel and subsequent versions have been built upon previous knowledge about the former versions. The various solutions were weighed, and the most appropriate ones were chosen. Oftentimes, evaluation involved modeling the system and then simulating it to determine how it might react to various inputs and selecting the most suitable solution. The details of the chosen design have now been worked out, including the creation of prototypes or mock-ups based on 3D printing of selected components in order to ascertain the optimal design details. The chosen designs were then translated into working drawings, circuit diagrams, and so on, so that the items can be promptly manufactured and dispatched as part of a continuous technology improvement process and market entrance.

4. The Smile.Tech’s SMLT Robótica Platform

The Smile.Tech’s SMLT Robótica Platform (STRP) is an in-house dedicated cost-effective robotic platform that outperforms competitors in terms of efficiency, accuracy, reliability, and safety. It makes use of stepper motors due to their simplicity of position control and, more significantly, their simplicity of velocity restriction. These motors are connected to low-backlash mechanical reducers that incorporate absolute position feedback on the output shaft. The torque created by this assembly can be simply computed from its elastic deformation, allowing the system to calculate the magnitude and direction of force at all times.

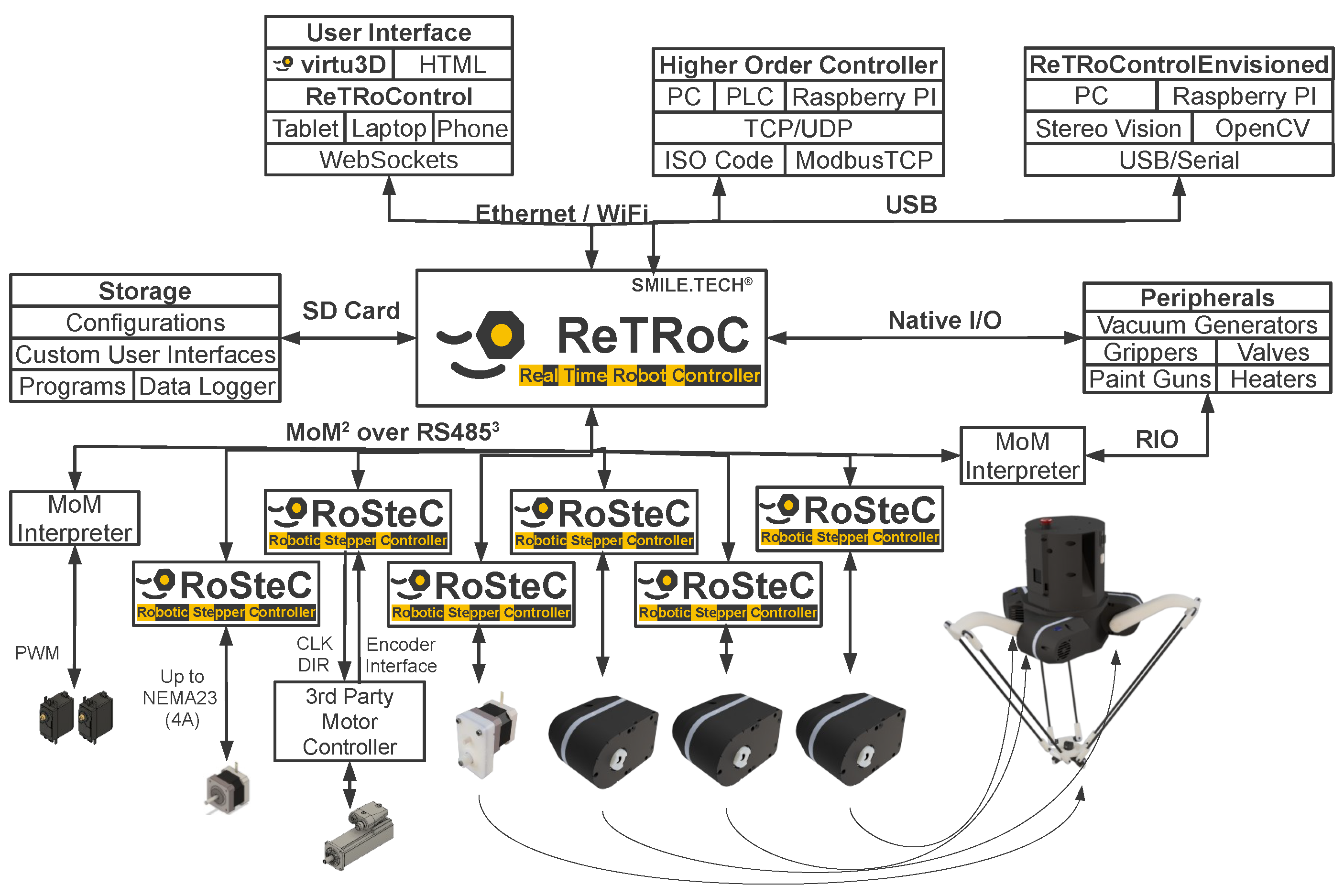

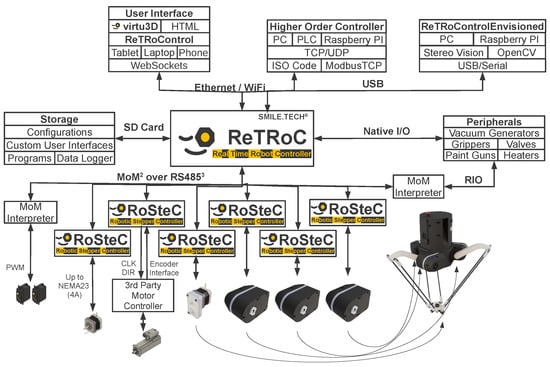

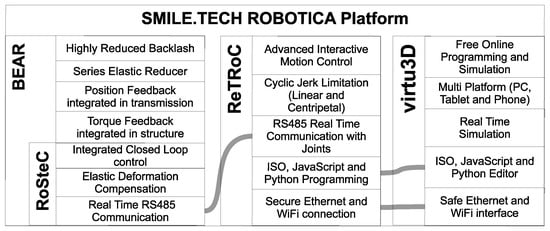

As depicted in Figure 3, the platform is composed of multiple components connected in a variety of ways. The PDR-20 (Óscar 9.2 model version) is a Delta robot that is built upon the STRP and comprises four major key components, where these key components can be arranged to build any kind of manipulation robot kinematics:

Figure 3.

Overview of the Smile.Tech’s SMLT Robótica Platform (STRP) and product breakdown structure.

- The programming and simulation software (Virtu3D, ReTRoControl and ReTroControlEnvisioned);

- The Real Time Robot Controller (ReTRoC);

- The Robotic Stepper Controller (RoSteC);

- The Belt Elastic Actuator for Robotics (BEAR).

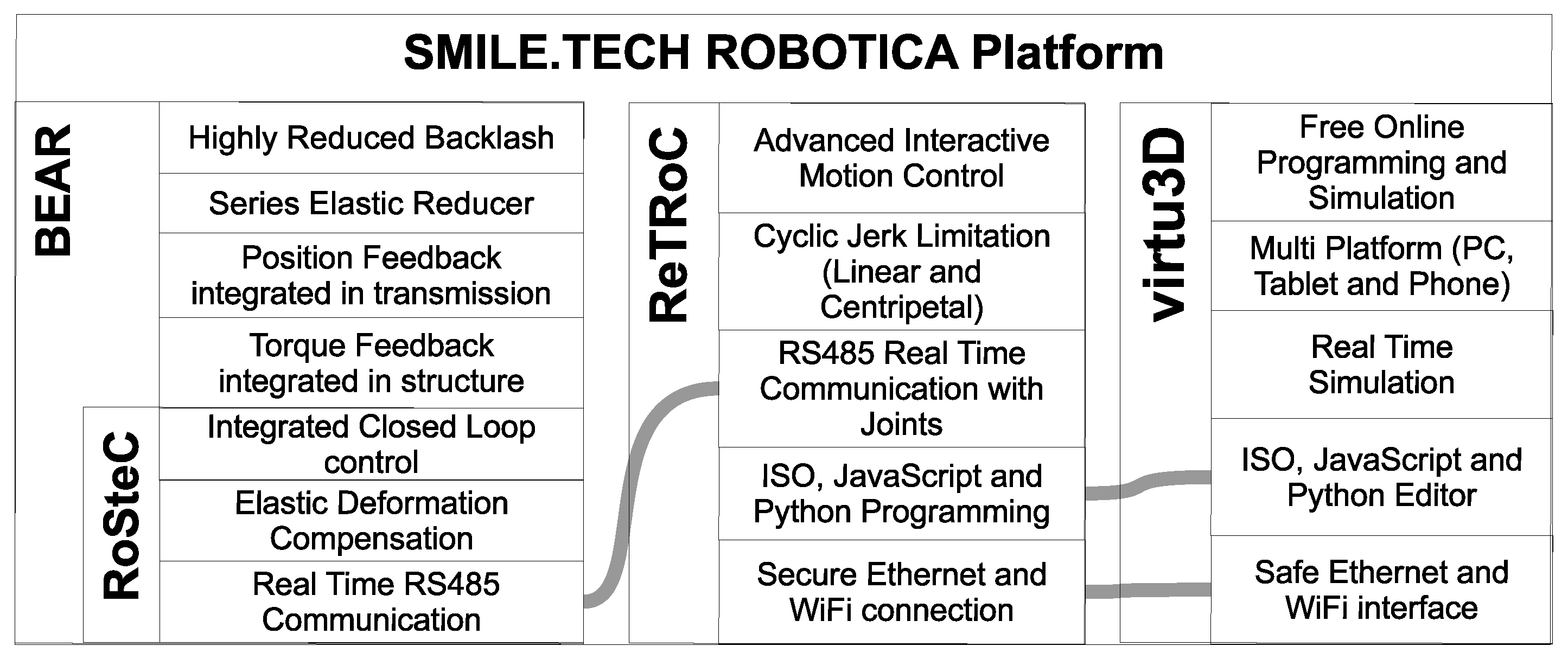

The STRP is a comprehensive system built on three interconnected pillars: the BEAR, the ReTRoC and the Virtu3D (Figure 4). By substituting elasticity for backlash in the transmission, the BEAR eliminates positioning uncertainty and provides mechanical compliance. It is a low-cost actuator based on the popular NEMA 17 stepper motor series. It includes instrumentation and a controller called RoSteC, which calculates torque based on transmission deformation and is capable of compensating for, or virtually increasing compliance.

Figure 4.

Pillars of the Smile.Tech’s SMLT Robótica Platform (STRP) and features diagram.

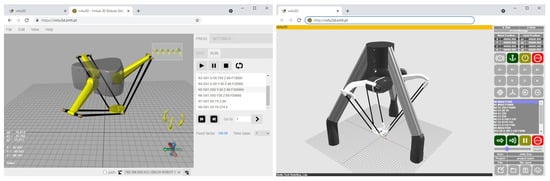

All robotic actuators (BEARs) are connected via an RS485 communication network and are managed by the ReTRoC. This controller is capable of interpreting commands sent by higher-order controllers or pre-programmed sequences stored on an SD card. Additionally, it manages motion and trajectory, converts coordinates, and calculates forces and their directions using data from the actuators’ torque sensors. Lastly, Virtu3D is an online tool that works on any computer, tablet, or smart-phone, that can be used to program and simulate robotic systems and that is capable of connecting to the robot controller via Ethernet or WiFi (Figure 5).

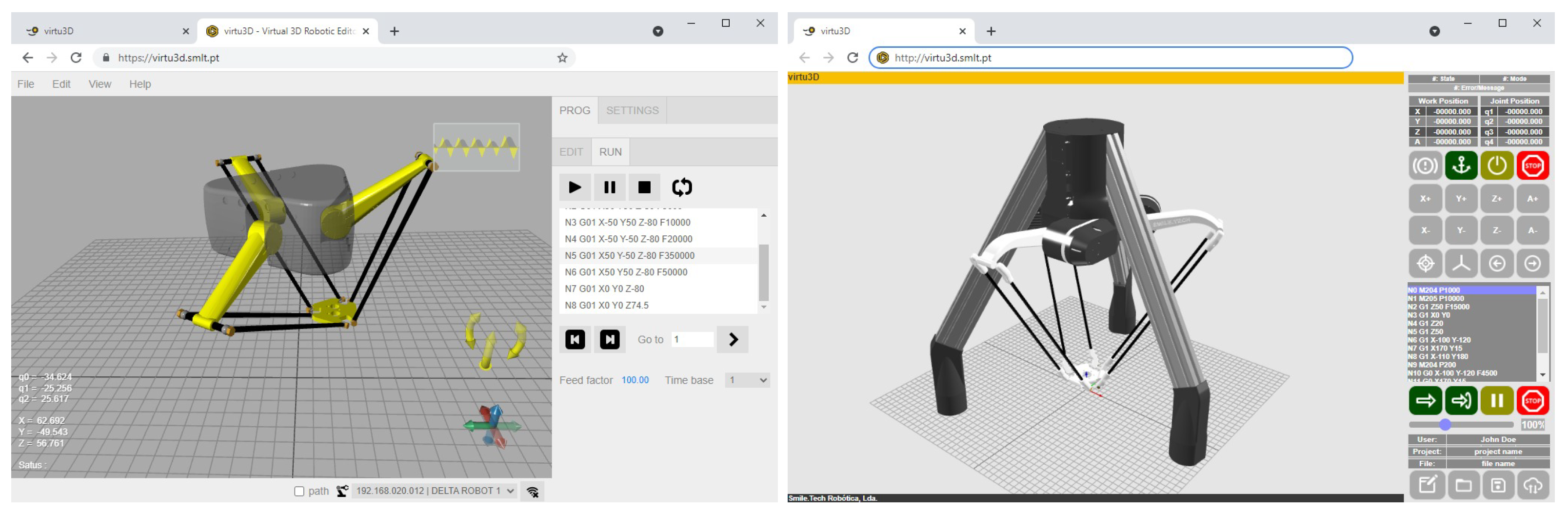

Figure 5.

Virtu3D, a web-based application that can be used on any computer, tablet, or smartphone to program and simulate robotic systems and is capable of connecting to the robot controller via Ethernet or WiFi. On-line kinematics simulator available at https://virtu3d.smlt.pt; current (left, accessed on 11 March 2022) and future (right) versions.

5. Market, Manufacturers, and Benchmarking

Currently, the robotics industry mainly serves two distinct markets—industrial and professional services—commonly lumped together. The emergence of new service robots has been noticed by many organizations throughout the world, and steps have been taken to support the new developments [37]. However, industrial robots and professional service robots have different operational requirements and different costs and have recently been shown to have very different market growth rates [38].

Industrial robots have been around since the 1970s—the archetypal industrial robot being a mechanical anthropomorphic arm with varying number of DoF, found in factories around the world. In the manufacturing industry, the biggest users of industrial robots by descending order are, in general, the automotive, electrical/electronics, metal and machinery, plastics and chemicals, and food and beverage sectors. In contrast to industrial robots, professional service robots are more recent, taking off within the last decade, and are typically used outside of manufacturing lines to assist humans rather than replace them. They can have wheels to make them mobile, some are anthropomorphic, but they are not intended for the kinds of heavy tasks that most industrial robots tackle.

Thus far, professional service robots have been most popular in the retail, hospitality, health care, and logistics (in warehouse or fulfillment settings) industries, although some have also started to be used in space and defense, agriculture, and demolition. In addition to the industrial and professional service robots used by enterprises, there are two other large and quickly growing consumer robot markets—consumer service and entertainment robots; the former designed for tasks, such as vacuuming, mowing the lawn, and washing windows and the latter consisting mainly of toys, some of which are fairly sophisticated and mainly made in Asia.

The foregoing analysis was detailed in a recent market study [39] that indicated that nearly 1 million robots were expected to be sold for enterprise use in 2020, and over half of them were expected to be professional service robots, generating more than $16 billion in revenue, 30% more than in 2019. The market for professional service robots is growing much faster than that for industrial robots, where professional service robots are on the verge of passing industrial robots in terms of units and revenue.

On the other hand, although 97% of all of the robots sold in 2019 were consumer service and toy robots, they represent only 14% of robotics industry revenue, where industrial robots lead with 49% of revenues; but the growth drivers of 5G, artificial intelligence chips, and affordability of robotic technology are also likely to have a strong influence on consumer robots growth in the future and certainly contribute to a rapid market change.

Regarding collaborative robots, another study [40] suggested that the market size is expected to reach a value of $1.09 billion at a compound annual growth rate (CAGR) of 16.08% with accelerating momentum during 2021–2025; 34% of the growth will originate from the Asia-Pacific region and key countries are presently US, China, and Germany. Refer also to [41] for a recent tracing of the evolution of service robotics.

For the Delta’s, still another market study [42] predicted that the global Delta robots market size will grow by $242 million during 2019–2023 with a CAGR of almost 9%, also accelerating, with 50% coming from the Asia-Pacific region; the market is fairly fragmented, where one of the key trends for the period is the development of vision-integrated Delta robots, bringing up new application possibilities.

Delta robots are reported to have been typically designed and optimized to meet the requirements of extremely fast product handling, low cost, and easy disassembly for cleaning in the food (e.g., dough cutting or pancake stacking) and packaging industries (e.g., top-loading, feed placement, and assortment placement). Additionally, the medical field, the electronics industry, pick-and-place tasks for cells and wafers in the photovoltaic industry, laser cutting, high-speed milling, drilling, wood tooling, and use as a 3D haptic device with force feedback in the gaming industry are possible application highlights. Additionally, agricultural applications have been reported to include a Delta-based prototype for manipulating soft vegetables, an autonomous field robot platform equipped with a Delta robot for treating individual plants, and a non-chemical vegetable weed controller. See also [4,12] and the references therein for further details on Delta applications and an overview of the historical developments of the Delta robot on the market and academia.

According to [5,12], the license for the Delta robot was purchased in 1987 from EPFL to a Swiss company, Demaurex, which started the industrial development process and began manufacturing Delta robots for the packaging industry at that time. In 1996, Demaurex bought the license and merged with Sigpack Systems to increase competitiveness and internationalization to sell in the world market. The IRB340 FlexPicker Delta robot was also launched in 1999 by ABB Flexible Automation that purchased also a license. Later, in 2004, the merged Demaurex and Sigpack Systems were incorporated by the Bosch Packaging Technology division. Since then, and fostered also by the expiration of the Clavel’s original patent, parallel robots with Delta-like architecture have attracted the interest by industry and researchers all over the world. The global Delta robot market has become moderately fragmented since then also due to the expiraton of the original Clavel’s patent and progressively others, with various manufacturers located all over the world. However, several top-rated companies, such as ABB (Swedish–Swiss), FANUC (Japan), Kawasaki Heavy Industries (Japan), Adept/Omrom (USA/Japan), Yaskawa Electric (Japan), Codian Robotics (Netherlands), Penta Robotics (Netherlands), Estun Automation (China), and Bosch (Germany), are apparently leading the way.

As such, Delta robots have nowadays popular usage in picking and packaging in factories because they can be quite fast, some executing up to 300 picks per minute. For its stiffness it is also used for surgery and other applications include high precision assembly operations in a clean room for electronic components. The structure of a Delta robot can also be used to create haptic controllers [43,44,45]. Agriculture apps [46] and others used in mechanical machining processes [47,48]. Surveys on parallel robots with Delta-like architecture can be found e.g., in [5,12].

A list of commercially available Delta-robots along with their main features is presented in Table 1. As a benchmarking study, the features of the Óscar 9 SMLT Delta robot PDR-20 are also presented. The criteria for the benchmarking analysis was to select consolidated manufacturers and Delta models with a payload in the same range of the SMLT PRD-20, i.e., <5 kg, and with a comparable architecture and number of DoF. As can be seen, the prices and weight differ significantly at the cost of sacrificing speed, for equivalent (or, at least, not significant for the majority of applications) position accuracy. The top two models represent two consolidated and high-performance models from ABB and FANUC; the middle model is an unusually featured model from Festo; and the fourth model is the most comparable model from Igus, targeted at a similar clientele as the SMLT PDR-20.

Table 1.

Benchmarking of technical specifications of selected Delta robots in the same class of the PDR-20 of Smile.Tech’s Óscar family.

Together, they provide a streamlined overview of the market and competing products, allowing an accurate and concise benchmarking for Delta robots selection. The SMLT PDR-20 (Óscar 9.2 model version) Delta robot, whose features were mainly determined by analysis of design and engineering judgment, is shown to be the most affordable one and to cover a range of operating requirements and cost-benefit trade-off not yet fully covered by the most well-known models available on the market.

6. Conclusions

Almost 40 years after the original ideas, Delta robots continue to serve a niche market for high-speed pick-and-place applications, and a huge number of new additional applications are anticipated and currently under development. During the past decade, the patents that have expired and the surge of new areas of application have resulted in an increase in research and development. Also, the growing scientific emphasis on extended architectures with more rotational DoF has resulted in a variety of serial-parallel hybrid and completely parallel systems able to respond to commercial demands for new and more sophisticated handling jobs requiring also increased payload capacity and non-contaminating designs.

This article describes the process and major technical developments and features of a platform for developing safe, easy-to-use, precise, and reliable robotic manipulators that are also affordable for general public use—the Smile.Tech’s SMLT Robótica Platform (STRP) and the SMLT Delta Robot Óscar family. The STRP project aims to leverage technologies that, despite their longevity, are not yet widely adopted. Two examples include additive manufacturing and substituting transmission elasticity by transmission backlash. Another significant feature of the STRP is that its success is determined not only by the achievement of the proposed technical features but also by the acceptance and satisfaction of its derived products by customers. Thus, during the design and integration processes performed by Smile.Tech, several aspects of parallel robots were covered, ranging from modeling (geometric, kinematic, dynamic, elasticity, etc.) to control, while taking into account singularity analysis, repetition accuracy, calibration, design optimization, durability, and a variety of other scientific and technology development issues. In this vein, the article presents a focused analysis of the current state of the art and use of Delta robots as well as a discussion of the Delta architecture, interface software, virtual operation environments, and the technologies involved. Moreover, the article presents a market analysis, a summary of the major manufacturers and currently available Delta models, and a benchmarking study of their major operating and technical features.

Overall, this work is expected to contribute to and enable a sustained selection and identification of the primary technical characteristics of leading Delta robots in the same class, as well as the advantages of the Smile.Tech’s Delta robot model SMLT PDR-20 and its success in being an appellation to the collaborative robot market due to its affordable price, high level of safety, and exceptional cost–benefit ratio.

Author Contributions

Conceptualization, C.M.A.V. and F.A.V.F.; methodology, C.M.A.V. and F.A.V.F.; software, F.A.V.F.; formal analysis, C.M.A.V. and F.A.V.F.; investigation, C.M.A.V.; resources, F.A.V.F.; data curation, F.A.V.F.; writing—original draft preparation, C.M.A.V. and F.A.V.F.; writing—review and editing, C.M.A.V.; funding acquisition, C.M.A.V. and F.A.V.F. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully acknowledge the support provided by the Foundation for Science and Technology (FCT) of Portugal, within the scope of the project of the Research Unit on Materials, Energy and Environment for Sustainability (proMetheus), Ref. UID/05975/2020, financed by national funds through the FCT/MCTES.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Briot, S.; Bonev, I.A. Are parallel robots more accurate than serial robots? Trans. Can. Soc. Mech. Eng. 2007, 31, 445–455. [Google Scholar] [CrossRef]

- Pierrot, F.; Nabat, V.; Company, O.; Krut, S.; Poignet, P. Optimal design of a 4-DOF parallel manipulator: From academia to industry. IEEE Trans. Robot. 2009, 25, 213–224. [Google Scholar] [CrossRef]

- Clavel, R. Device for the Movement and Positioning of an Element in Space. U.S. Patent 4,976,582, 11 December 1990. [Google Scholar]

- Bonev, I. Delta Parallel Robot—The Story of Success. 2001. Available online: http://www.parallemic.org/Reviews/Review002.html (accessed on 13 July 2021).

- Poppeova, V.; Uricek, J.; Bulej, V.; Sindler, P. Delta robots—Robots for high speed manipulation. Teh.-Vjesn.-Tech. Gaz. 2011, 18, 435–445. [Google Scholar]

- Clavel, R. DELTA: A fast robot with parallel geometry. In Proceedings of the 18th International Symposium on Industrial Robots, Sydney, Australia, 26–28 April 1988; pp. 91–100. [Google Scholar]

- Clavel, R. Conception d’un Robot Parallle Rapide à 4 Degrés de Liberté. Ph.D. Thesis, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 1991. [Google Scholar] [CrossRef]

- Stewart, D. A Platform with six degrees of freedom. Proc. Inst. Mech. Eng. 1965, 180, 371–386. [Google Scholar] [CrossRef]

- Wurst, K.H. LINAPOD—Machine Tools as Parallel Link Systems Based on a Modular Design. In Parallel Kinematic Machines; Boër, C.R., Molinari-Tosatti, L., Smith, K.S., Eds.; Springer: London, UK, 1999; pp. 377–394. [Google Scholar] [CrossRef]

- Merlet, J.P. Parallel Robots, 2nd ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2006. [Google Scholar]

- Bouri, M.; Clavel, R. The Linear Delta: Developments and applications. In Proceedings of the 41st International Symposium on Robotics (ISR 2010) and 6th German Conference on Robotics (ROBOTIK 2010), Munich, Germany, 7–9 June 2010; p. 8. [Google Scholar]

- Brinker, J.; Corves, B. A survey on parallel robots with Delta-like architecture. In Proceedings of the 14th IFToMM World Congress, Taipei, Taiwan, 25–30 October 2015; pp. 407–414. [Google Scholar] [CrossRef]

- Company, O.; Pierrot, F.; Nabat, V.; de la O Rodriguez, M. Schoenflies motion generator: A new non redundant parallel manipulator with unlimited rotation capability. In Proceedings of the 2005 IEEE International Conference on Robotics and Automation, Barcelona, Spain, 18–22 April 2005; pp. 3250–3255. [Google Scholar] [CrossRef]

- Tsai, L.W. Multi-Degree-of-Freedom Mechanisms for Machine Tools and the Like. U.S. Patent 5,656,905, 12 August 1997. [Google Scholar]

- Kinoshita, S.; Yamashiro, H. Parallel Robot Provided with Wrist Section Having Three Degrees of Freedom. U.S. Patent 8,893,578 B2, 25 November 2014. [Google Scholar]

- Tsai, L.W.; Joshi, S. Kinematic analysis of 3-DOF position mechanisms for use in hybrid kinematic machines. J. Mech. Des. 2002, 124, 245–253. [Google Scholar] [CrossRef]

- Tsai, L.W.; Stamper, R. A parallel manipulator with only translational degrees of freedom. In Proceedings of the Volume 2B: 24th Biennial Mechanisms Conference; American Society of Mechanical Engineers: New York, NY, USA, 1996. [Google Scholar] [CrossRef]

- Tsai, L.W.; Walsh, G.; Stamper, R. Kinematics of a novel three DOF translational platform. In Proceedings of the IEEE International Conference on Robotics and Automation, Minneapolis, MN, USA, 22–28 April 1996; Volume 4, pp. 3446–3451. [Google Scholar] [CrossRef]

- Pierrot, F.; Company, O. H4: A new family of 4-DOF parallel robots. In Proceedings of the 1999 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Atlanta, GA, USA, 19–23 September 1999; pp. 508–513. [Google Scholar] [CrossRef]

- Gogu, G. Structural Synthesis of Parallel Robots, Part 2: Translational Topologies with Two and Three Degrees of Freedom; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar] [CrossRef]

- Zhao, Y. Singularity, isotropy, and velocity transmission evaluation of a three translational degrees-of-freedom parallel robot. Robotica 2012, 31, 193–202. [Google Scholar] [CrossRef]

- Brinker, J.; Corves, B.; Wahle, M. A comparative study of inverse dynamics based on Clavel’s Delta robot. In Proceedings of the 14th World Congress in Mechanism and Machine Science, Taipei, Taiwan, 25–30 October 2015; pp. 89–98. [Google Scholar] [CrossRef]

- Patil, M.J.; Deshmukh, M.P. A review paper on introduction of parallel manipulator and control system. Int. J. Eng. Res. Technol. 2015, 4, 959–963. [Google Scholar]

- Brinker, J.; Funk, N.; Ingenlath, P.; Takeda, Y.; Corves, B. Comparative study of serial-parallel Delta robots with full orientation capabilities. IEEE Robot. Autom. Lett. 2017, 2, 920–926. [Google Scholar] [CrossRef]

- Brinker, J.; Corves, B.; Takeda, Y. On the motion/force transmissibility and constrainability of Delta parallel robots. In Computational Kinematics; Mechanisms and Machine Science; Springer: Berlin/Heidelberg, Germany, 2018; pp. 340–348. [Google Scholar] [CrossRef]

- Brinker, J.; Schmitz, M.; Takeda, Y.; Corves, B. Dynamic modeling of functionally extended Delta-like parallel robots with virtual tree structures. In ROMANSY 22—Robot Design, Dynamics and Control; CISM International Centre for Mechanical Sciences; Springer: Berlin/Heidelberg, Germany, 2019; pp. 171–179. [Google Scholar] [CrossRef]

- Wikipedia. Delta Robot—Wikipedia, The Free Encyclopedia. 2021. Available online: http://en.wikipedia.org/w/index.php?title=Delta%20robot&oldid=1030986049 (accessed on 6 September 2021).

- Kantaros, A.; Piromalis, D. Employing a low-cost desktop 3D printer: Challenges, and how to overcome them by tuning key process parameters. Int. J. Mech. Appl. 2021, 10, 11–19. [Google Scholar] [CrossRef]

- Vasques, C.M.A.; Resende, P.M.; Cavadas, A.M.; Abrantes, J.C. Quality analysis of a demonstration 3D-printed maraging steel part. In Proceedings of the 2nd International Electronic Conference on Applied Sciences, Online, 15–31 October 2021. [Google Scholar] [CrossRef]

- Kantaros, A.; Diegel, O. 3D printing technology in musical instrument research: Reviewing the potential. Rapid Prototyp. J. 2018, 24, 1511–1523. [Google Scholar] [CrossRef]

- Coimbra, M.R.C.; Barbosa, T.P.; Vasques, C.M.A. Preliminary design and validation of a 3D-printed continuously variable transmission for an electric vehicle prototype. Eng. Proc. 2021, 11, 11. [Google Scholar] [CrossRef]

- Kantaros, A.; Laskaris, N.; Piromalis, D.; Ganetsos, T. Manufacturing zero-waste COVID-19 personal protection equipment: A case study of utilizing 3D printing while employing waste material recycling. Circ. Econ. Sustain. 2021, 1, 851–869. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Piromalis, D. Fabricating lattice structures via 3D printing: The case of porous bio-engineered scaffolds. Appl. Mech. 2021, 2, 289–302. [Google Scholar] [CrossRef]

- Vasques, C.M.A.; Gonçalves, F.C.; Cavadas, A.M. Manufacturing and testing of 3D-printed polymer isogrid lattice cylindrical shell structures. In Proceedings of the 2nd International Electronic Conference on Applied Sciences, Online, 15–31 October 2021. [Google Scholar] [CrossRef]

- Bloss, R. Review of new robot designs and the rise of remote programming in manufacturing technology. Ind. Robot. Int. J. 2013, 40, 213–217. [Google Scholar] [CrossRef]

- Singh, B.; Sellappan, N.; Kumaradhas, P. Evolution of industrial robots and their applications. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 763–768. [Google Scholar]

- Virk, G.S.; Moon, S.; Gelin, R. ISO Standards for Service Robots. In Proceedings of the Eleventh International Conference on Climbing and Walking Robots and the Support Technologies for Mobile Machines, Coimbra, Portugal, 8–10 September 2008; World Scientific Press: Singapore; pp. 133–138. [Google Scholar] [CrossRef]

- Global Delta Robots Market. Market.us. Available online: https://market.us/report/delta-robots-market (accessed on 13 July 2021).

- Stewart, D.; Wigginton, C.; Casey, M. Robots on the move: Professional service robots set for double-digit growth. In Deloitte Insights—Technology, Media, and Telecommunications Predictions 2020; Deloitte Development LLC: Hermitage, TN, USA, 2019; pp. 18–29. [Google Scholar]

- Collaborative Robots Market by Application and Geography—Forecast and Analysis 2021–2025. Technavio. Available online: https://www.technavio.com/report/collaborative-robots-market-industry-analysis (accessed on 17 July 2021).

- Ott, I.; Savin, I.; Konop, C. Tracing the evolution of service robotics: Insights from a topic modeling approach. In Kiel Working Paper No. 2180; Kiel Institute for the World Economy (IfW): Kiel, Germany, 2021; 47p. [Google Scholar]

- Global Delta Robots Market 2019–2023. Technavio. Available online: https://www.technavio.com/report/global-delta-robots-market-industry-analysis (accessed on 17 July 2021).

- Grange, S.; Conti, F.; Helmer, P.; Rouiller, P.; Baur, C. Delta haptic device as a nanomanipulator. In Microrobotics and Microassembly III; Nelson, B.J., Breguet, J.M., Eds.; SPIE: Bellingham, WA, USA, 2001. [Google Scholar] [CrossRef] [Green Version]

- Mitsantisuk, C.; Ohishi, K. Haptic human-robot collaboration system based on Delta robot with gravity compensation. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016. [Google Scholar] [CrossRef]

- Liu, G.; Chen, Y.; Xie, Z.; Geng, X. GA\SQP optimization for the dimensional synthesis of a Delta mechanism based haptic device design. Robot.-Comput.-Integr. Manuf. 2018, 51, 73–84. [Google Scholar] [CrossRef]

- Hussmann, S.; Knoll, F.J.; Meissner, A.; Holtorf, T. Development and evaluation of a low-cost Delta robot system for weed control applications in organic farming. In Proceedings of the 2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Auckland, New Zealand, 20–23 May 2019. [Google Scholar] [CrossRef]

- Ayyıldız, E.A.; Ayyildiz, M. Development of a 3-axis Parallel Kinematic Machine for Milling Wood Material—Part 1: Design. Bioresources 2017, 12, 9326–9337. [Google Scholar]

- Ayyıldız, E.A.; Ayyıldız, M.; Kara, F. Optimization of surface roughness in drilling medium-density fiberboard with a parallel robot. Adv. Mater. Sci. Eng. 2021, 2021, 6658968. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).