Energy Efficiency Ratio Analysis of Half Cycle Air-Conditioners Using Liquified Petroleum Gas †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Methodology and Setup Design

2.2. Description of Evaporators

3. Design of Experiments

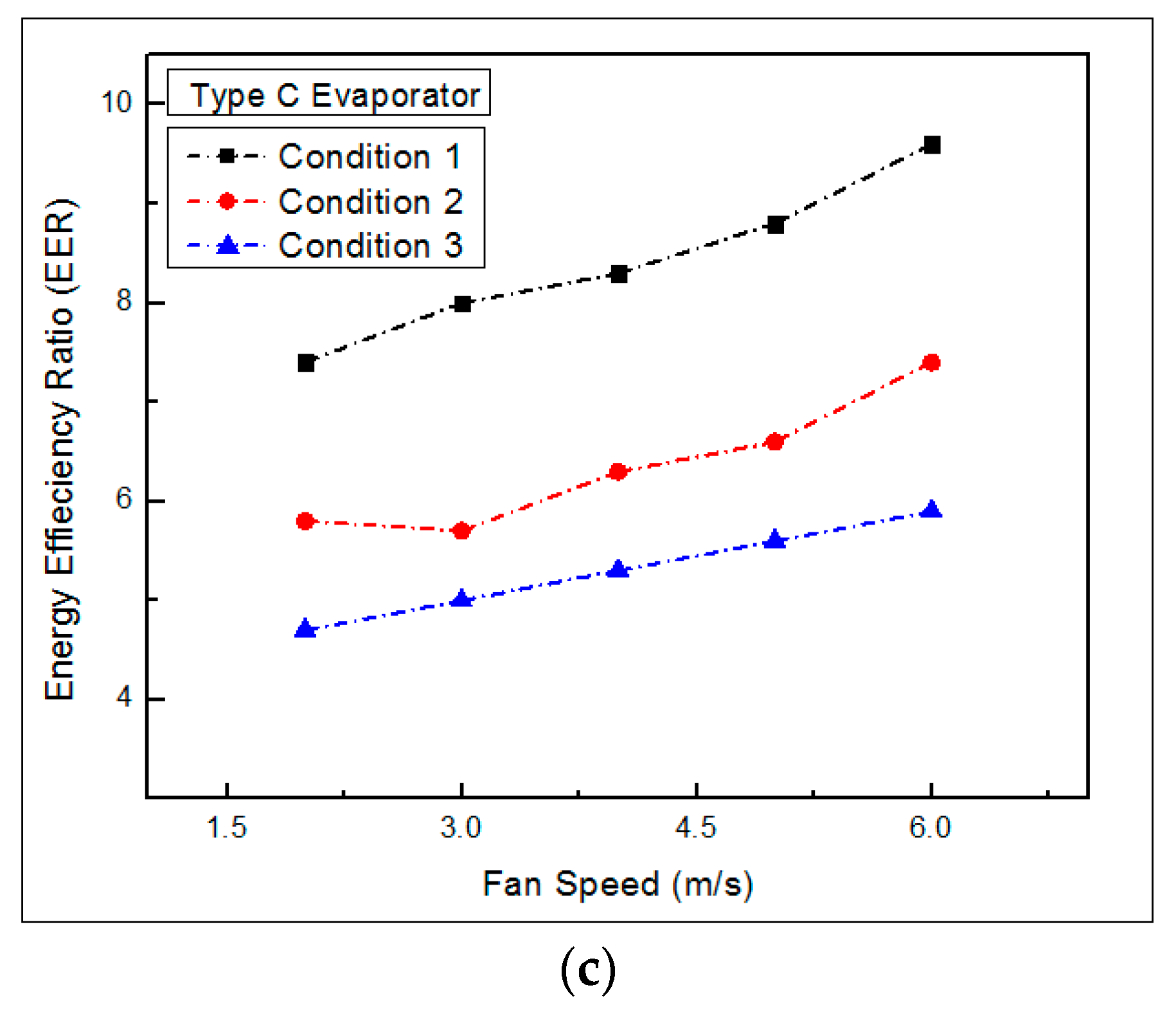

4. Results and Discussion

5. Conclusions

Conflicts of Interest

References

- Setiyo, M.; Soeparman, S.; Hamidi, N.; Wahyudi, S. Cooling effect characteristics of a ½ cycle refrigeration system on an LPG fuel system. Int. J. Refrig. 2017, 82, 227–237. [Google Scholar] [CrossRef]

- Werpy, M.R.; Burnham, A.; Bertram, K. Propane Vehicles: Status, Challenges, and Opportunities; Center for Transportation Research, Energy Systems Division, Argonne National Laboratory: Lemont, IL, USA, 2010. [Google Scholar]

- Razus, D.; Brinzea, V.; Mitu, M.; Oancea, D. Burning Velocity of Liquified Petroleum Gas (LPG)−Air Mixtures in the Presence of Exhaust Gas. Energy Fuels 2010, 24, 1487–1494. [Google Scholar] [CrossRef]

- Setiyo, M.; Soeparman, S.; Wahyudi, S.; Hamidi, N. A simulation for predicting potential cooling effect on LPG-fuelled vehicles. AIP Conf. Proceedingsvol. 2016, 1717, 30002. [Google Scholar]

- Muzaffar, A.; Cheema, T.A.; Abbas, A.; Tayyab, M.; Ilyas, M.; Park, C.W. Performance analysis of liquified petroleum gas (LPG) driven half-cycle air conditioning system. Heat Mass Transf. 2020, 56, 3177–3197. [Google Scholar] [CrossRef]

- El-Morsi, M. Energy and exergy analysis of LPG (Liquified petroleum gas) as a drop in replacement for R134a in domestic refrigerators. Energy 2015, 86, 344–353. [Google Scholar] [CrossRef]

| Type of Evaporator | Type A | Type B | Type C |

|---|---|---|---|

| Tubes positioning | In-line | Staggered | In-line |

| Tube/fin materials | Cu/Cu | Cu/mild steel | Cu/G. iron |

| Tube (Outer diameter, Inner diameter and length; unit: mm) | 8, 6, and 120 | 8, 6, and 120 | 27, 24, and 220 |

| ; unit: mm) | 96 | 96 | 150 |

| No and space between fins | 122, 0.7 mm | 122, 0.7 mm | 23, 9 mm |

| Longitudinal–Transverse pitch ratio | 1 | 1 | 1 |

| Diagonal pitch | - | 26.83 mm | - |

| Numbers of rows and tubes/rows | 2 and 4 | 2 and 4 | 2 and 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muzaffar, A.; Tayyab, M.; Abbas, A.; Cheema, T.A. Energy Efficiency Ratio Analysis of Half Cycle Air-Conditioners Using Liquified Petroleum Gas. Eng. Proc. 2021, 12, 5. https://doi.org/10.3390/engproc2021012005

Muzaffar A, Tayyab M, Abbas A, Cheema TA. Energy Efficiency Ratio Analysis of Half Cycle Air-Conditioners Using Liquified Petroleum Gas. Engineering Proceedings. 2021; 12(1):5. https://doi.org/10.3390/engproc2021012005

Chicago/Turabian StyleMuzaffar, Atif, Muhammad Tayyab, Ahmad Abbas, and Taqi Ahmad Cheema. 2021. "Energy Efficiency Ratio Analysis of Half Cycle Air-Conditioners Using Liquified Petroleum Gas" Engineering Proceedings 12, no. 1: 5. https://doi.org/10.3390/engproc2021012005