1. Introduction

High voltage liquid filled transformers use mineral based oil (MO) for insulation of internal parts and for cooling. However, its future availability is forecasted to be scarce. In addition, it is non-biodegradable and poses serious issues for spillage and aquatic life. As a result, research efforts started in the mid-1990′s to develop fully biodegradable oil due to interest of power utilities. In this context, vegetable-based oils (natural ester oils) were considered as potential replacements for mineral oil. Pakistan is one of the largest rice growing countries in the world [

1]. Quite recently, kitchen grade rice bran oil (RBO) was introduced in the local market. As an alternative to RBO, jatropha seed Oil (JO), which is non-edible, is also grown in Sind and South-Punjab provinces in Pakistan and could be potential choice for this purpose. Recently, great progress was reported in improving the dielectric properties of mineral oils by introducing a small amount of nanoparticles (NPs), thus producing a colloidal solution called nano-fluid (NF) [

2]. However, such colloids were reported to suffer sedimentation and agglomeration. To overcome these problems, researchers have used surfactants or chemical dispersants, but the functionality of these chemicals were reported to produce inconsistent results [

3]. Some researchers have used atmospheric pressure plasma discharge to modify the surface of NPs by imparting desired functionalities and reported success both in nano-fluids as well as nano-polymers [

4,

5].

In this investigation, initially hydrophilic SiO2 NPs of high purity were used to prepare a set of NFs with NP loading varying in a range of 0.03 g/L to 0.15 g/L However, results showed increase in DS, but these too suffered sedimentation/agglomeration with further increase in loading of NPs. To overcome this drawback, the NPs were functionalized under plasma discharge. These efforts also did not yield promising results. It was discovered that the hydrophilic nature of SiO2 NPs was the main hindrance. Therefore, fumed hydrophobic silica NPs grafted with hexa-methyl-disilane (HMDS) were employed instead, either as such or further factionalized under plasma. Results show excellent dispersibility and stability, while the DS of oil samples increased around 50%.

2. Experimental Methods

Three types of oils were investigated and compared. Two of these were ester fluids like JO and RBO, while the third one was transformer mineral oil (MO). RBO was kitchen grade and was acquired from a local supermarket, whereas JO was obtained from local industry. MO was obtained from a local high voltage (HV) power transformer manufacturer. Prior to testing for DS measurements, these oils were filtered through a 16 µm pore size Wattman filter paper and were dried with silica gel pellets. The moisture content of samples was determined by the Karl Fischer titration method according to ASTM-Std-D6304. Two types of NPs (A and B) were used in preparation of NF samples. Type A was a hydrophilic silica obtained from XFnano, China, which had an average particle size of 20 nm; whereas type B was HMDS grafted fumed silica with an average size of 7.0 nm, obtained from Evonik, Germany. Both had purity of more than 99%. Nano-fluids using type A and B nanoparticles were prepared using a two-step method. Breakdown voltage (BDV) of oil samples were measured using HVGrand, China model YY6611 oil tester containing brass mushroom faced electrodes. These were spaced initially at 2.5 mm apart, but the gap was later adjusted to 1.0 mm due to higher breakdown voltage of samples that exceeded the upper limit of this set. The 50 Hz AC voltage was measured as per IEC 60165.

3. Results and Discussion

Table 1 illustrates comparison of properties measured for RBO, JO, and MO, with the values specified for ester fluids for use in transformers as per IEEE Std-C57.147(2018). It was clear that breakdown strength of JO was highest at 48 kV/mm, whereas the RBO depicted a value of 39 kV/mm. Both of these were higher than the MO values, despite that moisture level in both ester fluids were higher than in MO. This exhibits prominent behaviors of RBO and JO, and needs to be further evaluated for essential properties so that these oils prove to be a good replacement of standard MO. Although the moisture content of ≈200 ppm was suitable for applications in transformers operating at ≤69 kV, with a little more purification/chemical treatment, this value can be curtailed to ≈150 ppm so that it becomes suitable for application in an HV apparatus operating at (132–220) kV level. Higher viscosity of RBO at 61cSt sets another problem. This too can be modified to meet the IEEE-Std value set at 50cSt. The dielectric constant of both ester fluids were ≈3.6, which is a good characteristic as the electric field distribution with Kraft paper insulation (

= 4) becomes more favorable for a designer, instead of

= 2.2 for MO.

3.1. Nano-Fluids Prepared with Hydrophilic Silica

The oil samples with SiO

2 NP loadings of 0.03 g/L, 0.05 g/L, 0.075 g/L, 0.15 g/L, and 0.2 g/L were prepared. After stirring and sonication, each sample was placed under vacuum of 0.06 MPa for a duration of 24 h to remove any micro bubbles that might have emerged during the sonication process. These samples were subjected to DS measurements.

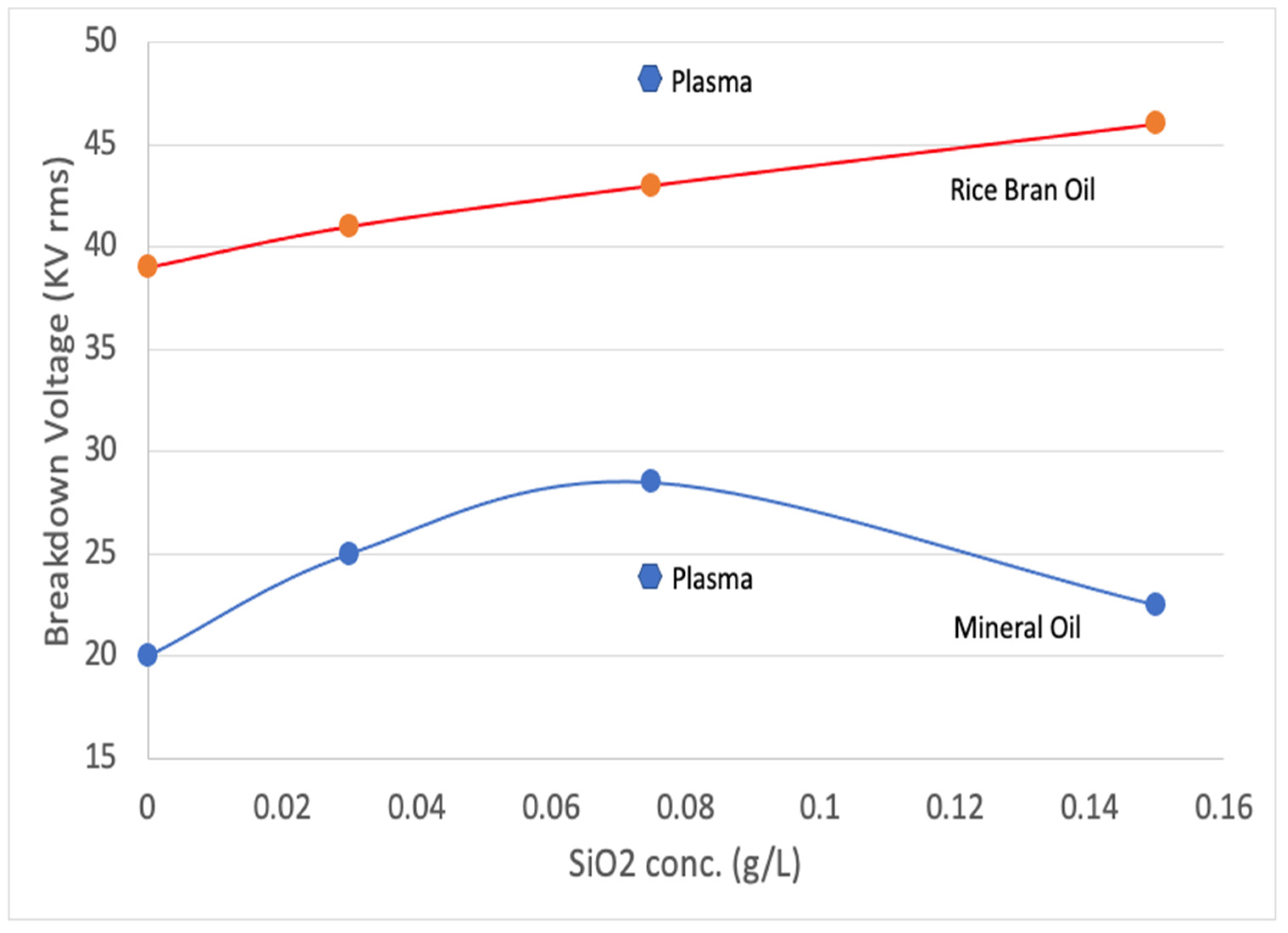

Figure 1 illustrates the variation of breakdown voltage as a function of silica NPs concentration, and are compared with similar NFs prepared with standard MO. NFs of MO that contained SiO

2 in lower loadings such as 0.03–0.075 g/L depicted stability toward sedimentation and agglomeration, but further increase in the loading caused instability as they suffered sedimentation within 24–72 h after formulation. This affect is displayed on dielectric strength values as well. DS increases up to loading of 0.075 g/L, but then sharply declines.

Nano-fluids are associated with enhancement in electrical conductivity, which increases with addition of NPs. The increase is due to formation of electrical double layer (EDL) phenomena and associated repulsive force in NPs. However, with increase of NPs concentration beyond an optimum level, the particles in dispersion may adhere together to form aggregates of increasing size, which may settle out due to gravity.

The stable colloidal solution is controlled by the sum of van der Waals, attractive and EDL repulsive forces that exist between NPs as they approach each other due to Brownian motion they are undergoing. For suspension to be stable, the repulsive force must remain dominant [

6]. At steady state, the sedimentation velocity of aggregates is determined by the Stoke’s law:

= sedimentation velocity; = radius of NP; = density of NP; , = density and viscosity of NP based fluid.

Thus, sedimentation varies according to size of nanoparticle, , and η of fluid. In the present case, the viscosity of RBO (61 cSt) is almost five times higher than that of MO, which results into well retarded sedimentation if any does occur, as compared to that in MO. This is why the DS of RBO monotonically increases with the NP loadings well beyond 0.15 g/L. To overcome the problem of sedimentation in MO due to loading of NPs beyond 0.15 g/L, silica NPs were subjected to plasma treatment to modify their surface chemistry in order to enhance their repulsive forces. However, in MO, this treatment leaves negative impact on the surface of hydrophilic silica NPs. In contrast to MO, the DS of RBO shows almost 16% increase in DS due to treatment of plasma. This is due to difference in the molecular structure of two differing species of oils. Although the moisture content in RBO is much higher, its higher viscosity plays a positive role.

3.2. Nano-Fluids Prepared with HMDS Grafted Fumed Silica

In this case, MO based NFs were prepared using NPs with 0.03 g/L loading of HMDS grafted fumed silica. Two samples were prepared: one with NPs as such and denoted here as MO-N; while the second was prepared with plasma treated NPs kept at the same particle loading. This sample is denoted here as MO-NP.

Table 2 summarizes the average AC breakdown voltage values. There is a remarkable increase of 48% in the breakdown values of nano-fluid (MO-NP), compared to fresh mineral oil. The shelf life of this fluid also increased, as even after 12 weeks of preparation, it did not show any traces of sedimentation.

4. Conclusions

Ester fluids such as RBO and JO which are being cultivated in Pakistan exhibit very favorable dielectric strength, therefore, more research efforts need to be exerted to make them potential replacements of mineral based transformer oil. This experimental study demonstrates that HMDS grafted fumed silica NPs produced stable nano-fluids which exhibited excellent dielectric strength. More advanced investigation continues on this topic at this research center.