Design of an Embedded Broadband Thermoelectric Power Sensor in the InP DHBT Process †

Abstract

:1. Introduction

2. Principle and Modeling

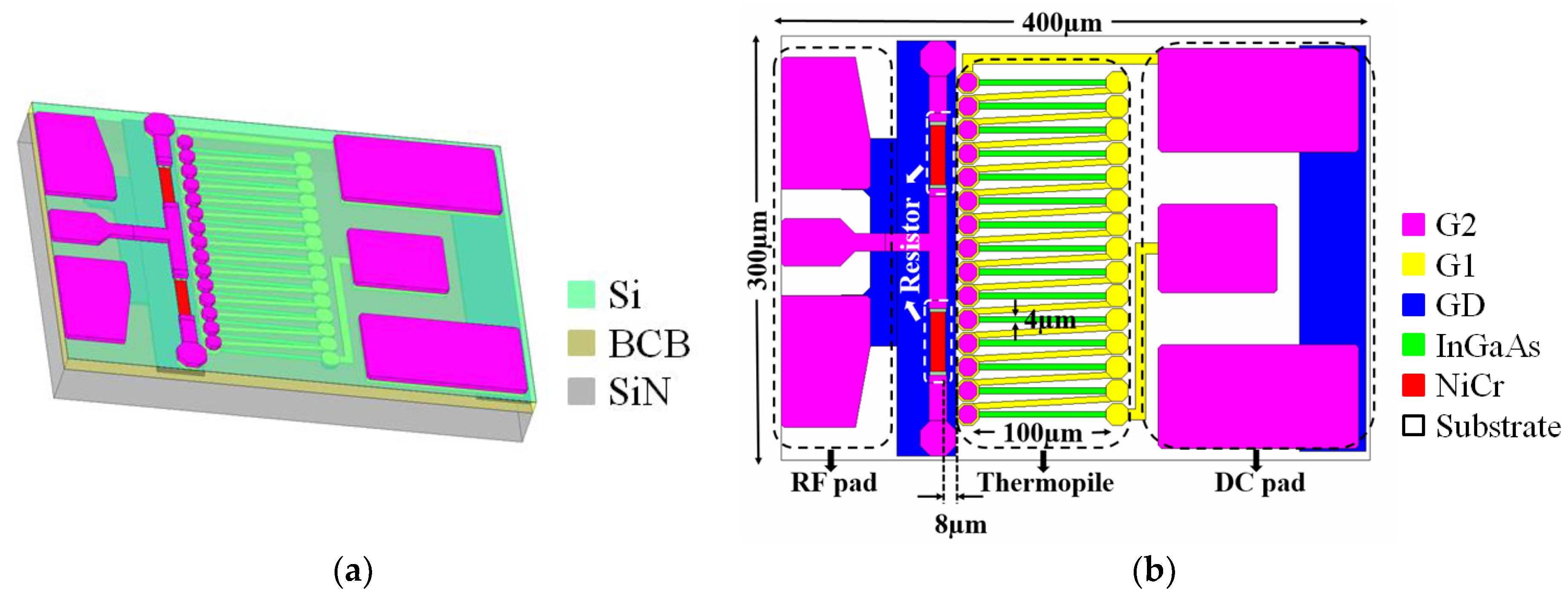

- Three gold metal layers are embedded in BCB, including G1 (1.5 µm), G2 (4.5 µm), and GD (2.5 µm) that serves, respectively, as interconnects, microstrip line, and the ground plane.

- The thickness of nickel-chrome (NiCr) thin-film resistors (TFRs) is 44 nm, with a sheet resistance on 25 Ω/sq [8].

- The 15 thermocouples consist of G1 metal and 30 nm P-In0.53Ga0.47As. The P-In0.53Ga0.47As locates at the B1 layer with a doping level of 5×1019cm-3. The corresponding Seebeck coefficient is calculated based on [9].

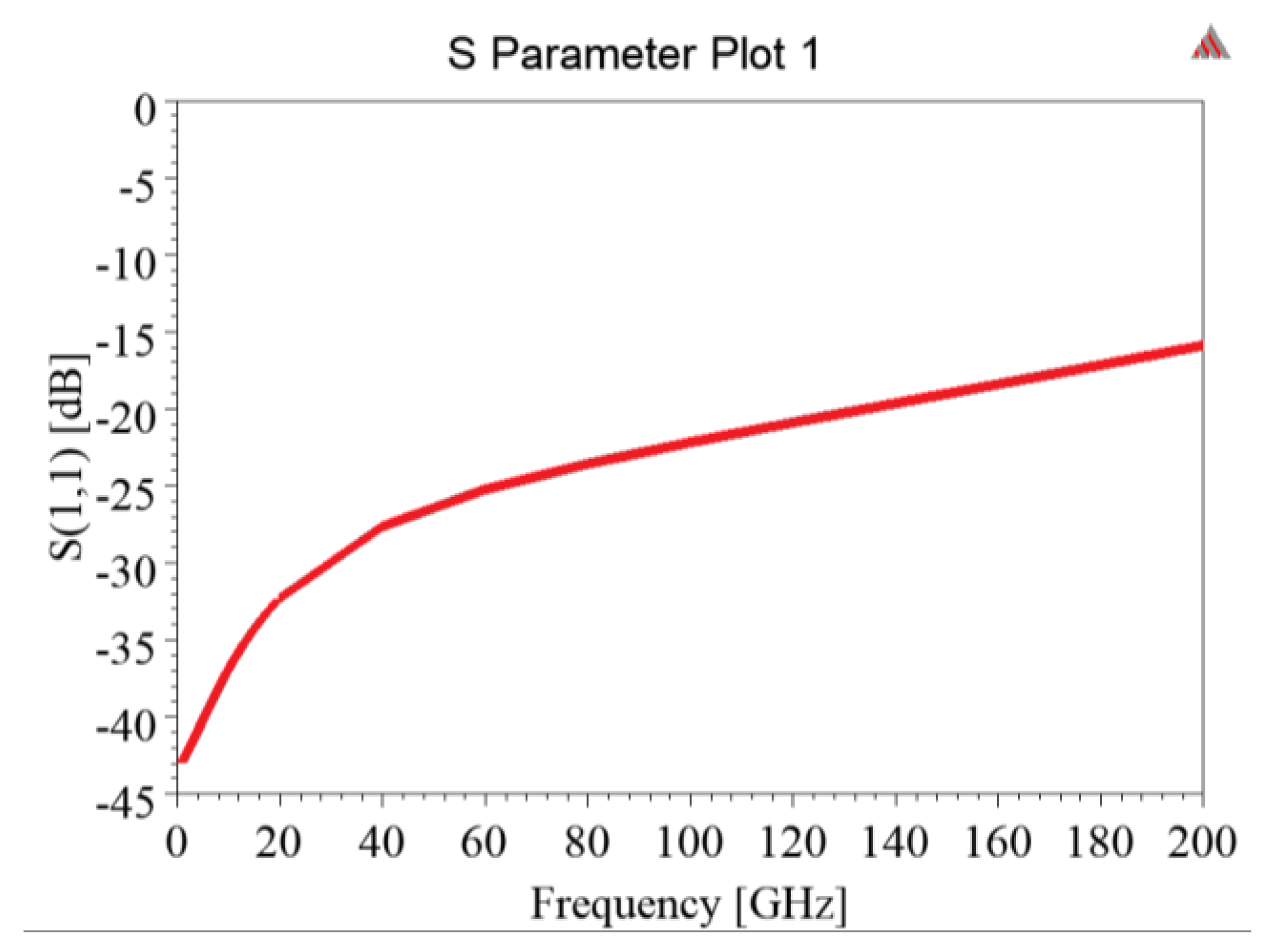

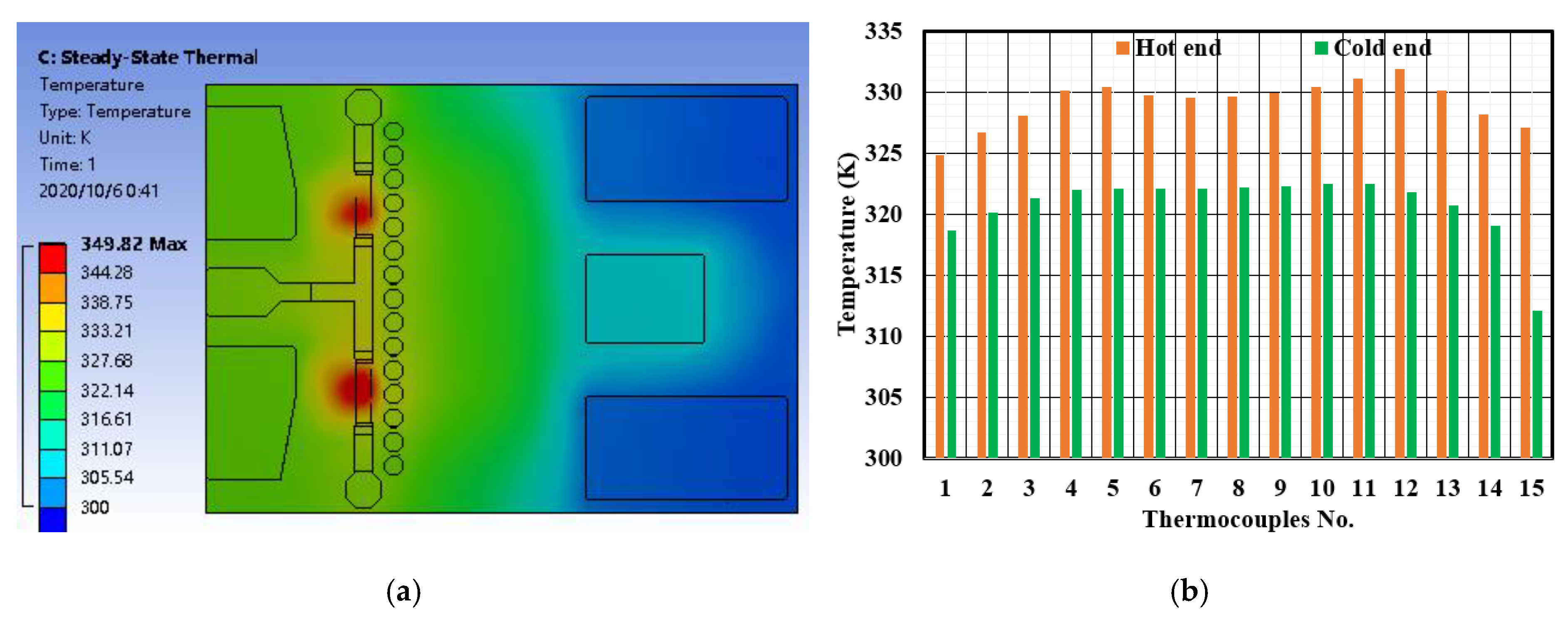

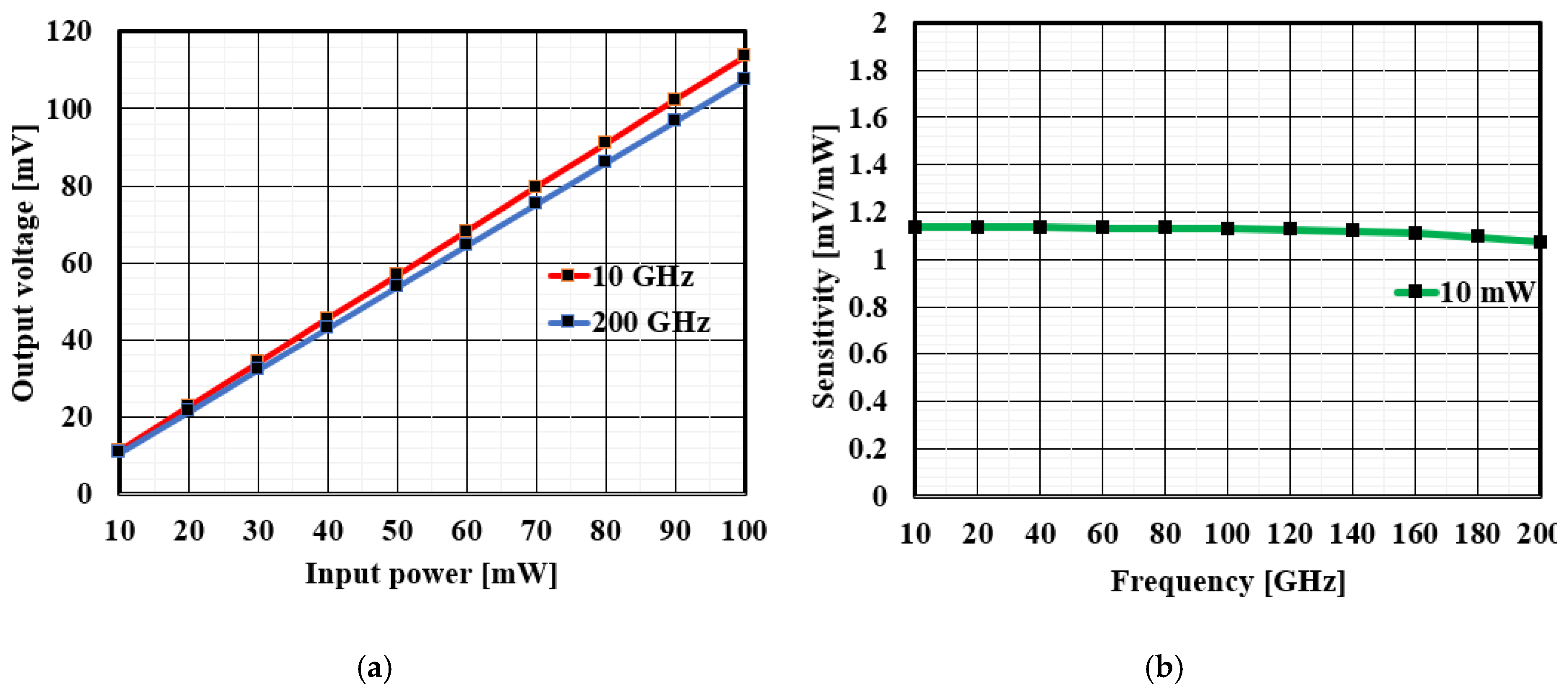

3. Simulation Result

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Yan, J.; Yi, Z.; Liao, X. High dynamic range microwave power sensor with thermopile and curled cantilever beam. Electron. Lett. 2015, 51, 1341–1343. [Google Scholar] [CrossRef]

- Dehe, A.; Fricke-Neuderth, K.; Krozer, V. Broadband Thermoelectric Microwave Power Sensors using GaAs Foundry Process. In Proceedings of the 2002 IEEE MTT-S International Microwave Symposium Digest (Cat. No.02CH37278), Seattle, WA, USA, 2–7 June 2002; Volume 3, pp. 1829–1832. [Google Scholar] [CrossRef]

- Yi, Z.; Liao, X. 3D Model of the Thermoelectric Microwave Power Sensor by MEMS technology. In Proceedings of the 2015 IEEE SENSORS, Busan, Korea, 1–4 November 2015; Volume 1, pp. 1–4. [Google Scholar]

- Zhang, Z.; Guo, Y.; Li, F.; Gong, Y.; Liao, X. A Sandwich-Type Thermoelectric Microwave Power Sensor for GaAs MMIC-Compatible Applications. IEEE Electron Device Lett. 2016, 37, 1639–1641. [Google Scholar] [CrossRef]

- Graf, A.; Arndt, M.; Gerlach, G. Seebeck’s effect in micromachined thermopiles for infrared detection. A review. Est. J. Eng. 2007, 13, 338–353. [Google Scholar]

- Dibra, D.; Stecher, M.; Lindemann, A.; Lutz, J.; Kadow, C. Seebeck difference-temperature sensors integrated into smart power technologies. In Proceedings of the 2008 20th International Symposium on Power Semiconductor Devices and IC’s, Barcelona, Spain, 14–18 June 2009; pp. 216–219. [Google Scholar] [CrossRef]

- Weimann, N.G.; Stoppel, D.; Schukfeh, M.I.; Hossain, M.; Al-Sawaf, T.; Janke, B.; Doerner, R.; Sinha, S.; Schmückle, F.-J.; Krüger, O.; et al. SciFab—A wafer-level heterointegrated InP DHBT/SiGe BiCMOS foundry process for mm-wave applications. Phys. Status Solidi 2016, 213, 909–916. [Google Scholar] [CrossRef]

- Stoppel, D.; Ostermay, I.; Hrobak, M.; Shivan, T.; Hossain, M.; Reiner, M.; Thiele, N.; Nosaeva, K.; Brahem, M.; Krozer, V.; et al. NiCr resistors for terahertz applications in an InP DHBT process. Microelectron. Eng. 2019, 208, 1–6. [Google Scholar] [CrossRef]

- Dehe, A.; Pavlidis, D.; Hong, K.; Hartnagel, H. InGaAs/InP thermoelectric infrared sensor utilizing surface bulk micromachining technology. IEEE Trans. Electron Devices 1997, 44, 1052–1059. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Thermal conductivity (Au) | k) |

| Thermal conductivity (BCB) | k) |

| Thermal conductivity (SiN) | k) |

| Seebeck coefficient (Au) | 1.5 μV/K |

| Seebeck coefficient (In0.53Ga0.47As) | 90 μV/K |

| Ambient temperature | 300 K |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Heinrich, W.; Krozer, V. Design of an Embedded Broadband Thermoelectric Power Sensor in the InP DHBT Process. Eng. Proc. 2020, 2, 10. https://doi.org/10.3390/ecsa-7-08206

Ma S, Heinrich W, Krozer V. Design of an Embedded Broadband Thermoelectric Power Sensor in the InP DHBT Process. Engineering Proceedings. 2020; 2(1):10. https://doi.org/10.3390/ecsa-7-08206

Chicago/Turabian StyleMa, Shiqi, Wolfgang Heinrich, and Viktor Krozer. 2020. "Design of an Embedded Broadband Thermoelectric Power Sensor in the InP DHBT Process" Engineering Proceedings 2, no. 1: 10. https://doi.org/10.3390/ecsa-7-08206

APA StyleMa, S., Heinrich, W., & Krozer, V. (2020). Design of an Embedded Broadband Thermoelectric Power Sensor in the InP DHBT Process. Engineering Proceedings, 2(1), 10. https://doi.org/10.3390/ecsa-7-08206