Chronographic Implementation of Energy Management System in Small-Scale Plastic Industry †

Abstract

:1. Introduction

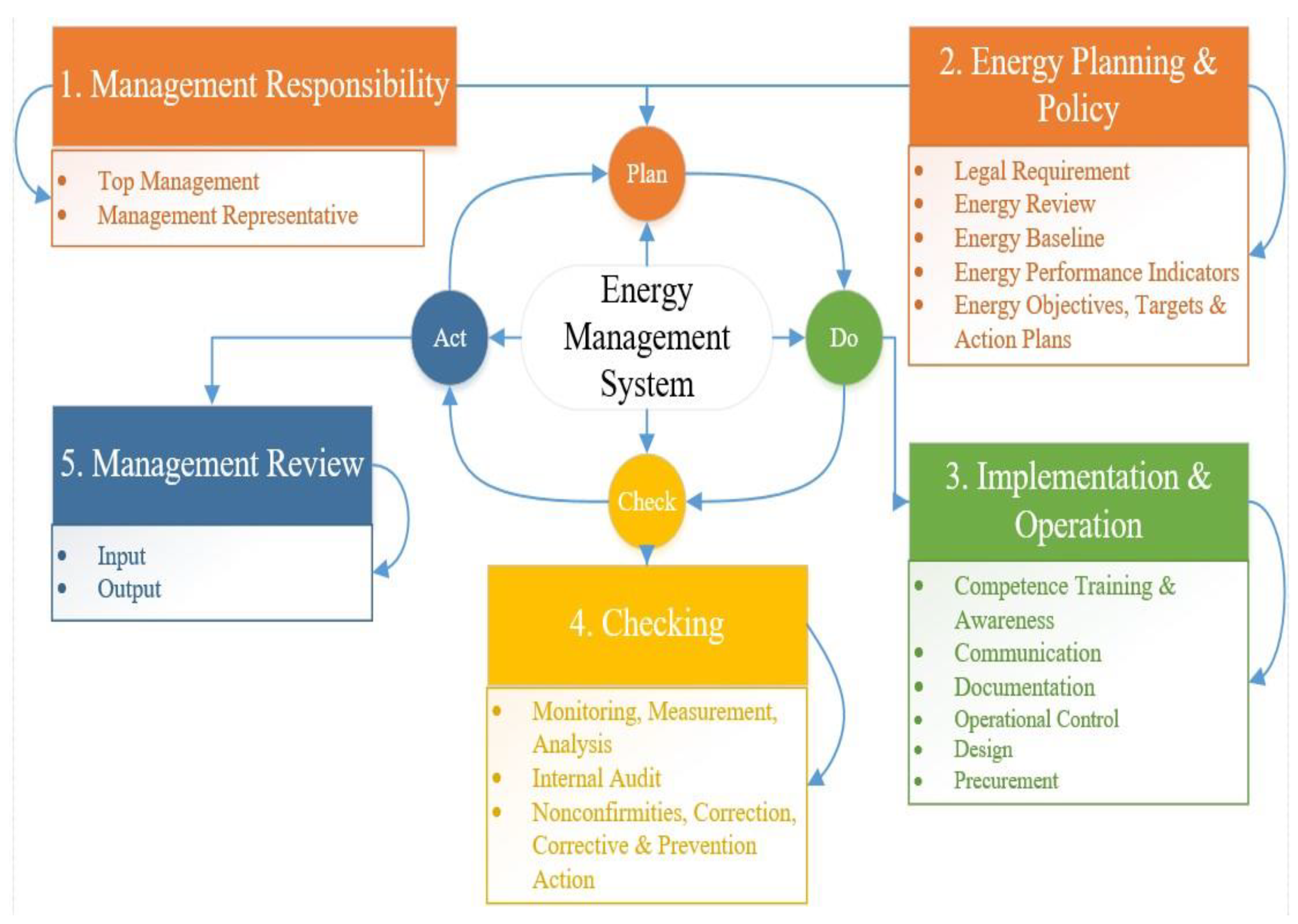

2. Methodology

2.1. Plan

- Analyze the energy resources and their consumption and cost trends by observing their (past and future) electric bills. Then, implement the energy performance indicators (EnPIs).

- Identify the critical operational and maintenance parameters and identify opportunities for their improvement. Then, set objectives, targets and action plans for performance improvement.

2.2. Do

2.3. Check

2.4. Act

- Correcting what is wrong and preventing it from happening in the future.

- Developing new action plans for the future and identifying new opportunities.

3. Result

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Olivares, D.E.; Cañizares, C.A.; Kazerani, M. A centralized energy management system for isolated microgrids. IEEE Trans. Smart Grid 2014, 5, 1864–1875. [Google Scholar] [CrossRef]

- Han, D.M.; Lim, J.H. Smart home energy management system using IEEE 802.15. 4 and zigbee. IEEE Trans. Consum. Electron. 2010, 56, 1403–1410. [Google Scholar] [CrossRef]

- Marimon, F.; Casadesús, M. Reasons to adopt ISO 50001 energy management system. Sustainability 2017, 9, 1740. [Google Scholar] [CrossRef] [Green Version]

- Ozturk, Y.; Senthilkumar, D.; Kumar, S.; Lee, G. An intelligent home energy management system to improve demand response. IEEE Trans. Smart Grid 2013, 4, 694–701. [Google Scholar] [CrossRef]

- Hao, Y.; Wang, W.; Qi, Y. Optimal home energy management with PV system in time of use tariff environment. In Proceedings of the 2017 Chinese Automation Congress (CAC), Jinan, China, 20–22 October 2017; pp. 2693–2697. [Google Scholar]

- Fiedler, T.; Mircea, P.M. Energy management systems according to the ISO 50001 standard—Challenges and benefits. In Proceedings of the 2012 International Conference on Applied and Theoretical Electricity (ICATE), Craiova, Romania, 25–27 October 2012; pp. 1–4. [Google Scholar]

- Apriyanti, D.; Warsito, B.; Prasetyo, T. Creating Green Industry through the Implementation of an Energy Management System: Case Study at PT. X. In Proceedings of the 2018 Conference on Power Engineering and Renewable Energy (ICPERE), Solo, Indonesia, 29–31 October 2018; pp. 1–5. [Google Scholar]

- Kaddari, M.; El Mouden, M.; Hajjaji, A.; Semlali, A. Reducing energy consumption by energy management and energy audits in the pumping stations. In Proceedings of the 2018 Renewable Energies, Power Systems & Green Inclusive Economy (REPS-GIE), Casablanca, Morocco, 23–24 April 2018; pp. 1–6. [Google Scholar]

- Ali, B.; Khan, A.A. Real-time distribution system analysis and load management algorithm for minimizing harmonics. RRST-EE 2021, 66, 237–242. [Google Scholar]

- Lee, P.K.; Lai, L.L.; Chan, S.W. A practical approach of energy efficiency management reporting systems in micro-grid. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–28 July 2011; pp. 1–5. [Google Scholar]

- Bilakanti, N.; Gurung, N.; Chen, H.; Kothandaraman, S.R. Priority-based Management Algorithm in Distributed Energy Resource Management Systems. In Proceedings of the 2021 IEEE Green Technologies Conference (GreenTech), Denver, CO, USA, 7–9 April 2021; pp. 351–356. [Google Scholar]

- Cheddadi, Y.; Gaga, A.; Errahimi, F.; Sbai, N.E. Design of an energy management system for an autonomous hybrid micro-grid based on Labview IDE. In Proceedings of the 2015 3rd International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 10–13 December 2015; pp. 1–6. [Google Scholar]

- Ali, B.; Khan, A.A.; Siddique, I.; Bhutta, J.A.; Israr, M. Fast Track Implementation of Energy Management System 2018 Using Sequential Approach. In Proceedings of the 2020 IEEE 23rd International Multitopic Conference (INMIC), Bahawalpur, Pakistan, 5–7 November 2020; pp. 1–5. [Google Scholar]

- Stamenić, M.; Tanasić, N.; Simonović, T.; Nikolić, A. Energy management system for energy efficiency improvement in the industrial sector of the republic of Serbia. In Proceedings of the 2016 4th International Symposium on Environmental Friendly Energies and Applications (EFEA), Belgrade, Serbia, 14–16 September 2016; pp. 1–4. [Google Scholar]

- Jekabsone, A.; Kamenders, A.; Rosa, M. Implementation of Certified Energy Management System in Municipality. Case Study. Environ. Clim. Technol. 2020, 24, 41–56. [Google Scholar] [CrossRef]

| ENPI | Quantity |

|---|---|

| Motor 18 KW | 2 |

| Motor 15 KW | 1 |

| Ceiling Fan | 3 |

| Bracket Fan | 4 |

| Exhaust Fan | 2 |

| Led | 2 |

| Bulb | 14 |

| Pump Motor | 1 |

| SEU NAME | 18 KW Motor |

|---|---|

| Power | 18,000 |

| Voltage | 380 |

| Current at 0.85 PF | 55.72 |

| Current at 0.9 PF | 52.63 |

| Time duration | 22 h |

| Energy Consumed in 1 day | 396 KWh |

| Energy Consumed in 1 month | 11,880 KWh |

| Energy Consumed in 1 year | 144,540 KWh |

| ENPI | Quantity | Power | Load | Time | Energy |

|---|---|---|---|---|---|

| Motor 18 KW | 2 | 18,000 | 36,000 | 14 | 504 |

| Motor 15 KW | 1 | 15,000 | 15,000 | 14 | 210 |

| Ceiling Fan | 3 | 70 | 210 | 10 | 2.1 |

| Bracket Fan | 4 | 45 | 180 | 8 | 1.44 |

| Exhaust Fan | 2 | 50 | 100 | 6 | 0.6 |

| Led | 2 | 5 | 10 | 5 | 0.05 |

| Bulb | 14 | 10 | 140 | 10 | 1.4 |

| Pump Motor | 1 | 500 | 500 | 3 | 1.5 |

| Machines | 1 | 500 | 500 | 2 | 1 |

| Checklist | Months | Tasks | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |||

| (Phase 1) Management Review | ||||||||||||||

| 1 | Management plan | * | The board plan shows the total responsibility of the top administration for execution. | |||||||||||

| 2 | Energy team selection | * | Energy administration will choose an energy supervisory group for all associate divisions. | |||||||||||

| 3 | Energy review | * | The energy audit ought to be finished by the energy supervisory crew. | |||||||||||

| 4 | Draft energy policy | * | Association’s energy strategy ought to be drafted according to the rules of energy execution guidelines. | |||||||||||

| 5 | Set targets and objectives | * | Destination and targets ought to be set to accomplish full execution. | |||||||||||

| (Phase 2) Plan | ||||||||||||||

| 6 | Record-keeping system | * | * | * | * | The technique should aim to shape an arrangement of record-keeping instruments utilizing programming. | ||||||||

| 7 | Identifying SEU | * | * | After the energy audit, the SEUs ought to be distinguished by the energy supervisory group. | ||||||||||

| 8 | Implementing EnPIs | * | Advancement of EnPI following the energy survey. | |||||||||||

| (Phase 3) Do | ||||||||||||||

| 9 | Documentation | * | * | * | * | * | * | The documentation is sufficiently able to have every one of the records from a solitary stage. | ||||||

| 10 | Gauge conceivable energy decreases on SEUs (critical energy clients) | * | * | * | * | * | * | Specialized heads ought to foster activity intending to decrease energy misfortunes from recognized SEUs. | ||||||

| 11 | Gauge expected decrement in energy utilization (complete association) | Energy groups ought to foster a total intent to limit energy utilization. | ||||||||||||

| 12 | Carry out the plans | * | Energy groups should carry out every one of the plans according to energy strategy rules. | |||||||||||

| (Phase 4) Check | ||||||||||||||

| 13 | Record-keeping system | * | Documenting entire requirements. | |||||||||||

| 14 | EnMS audit | * | Internal audit should include deficiencies and nonconformities list. | |||||||||||

| 15 | Declaring corrective action | * | Rectifying nonconformities. | |||||||||||

| 16 | Declaring action plan | * | Internal audit also suggests avoiding techniques for the upcoming period. | |||||||||||

| 17 | Record controlling | * | * | Energy policy should contain a three-year record. | ||||||||||

| (Phase 5) Act | ||||||||||||||

| 18 | Top management review | * | * | For corrective actions, a management review of 6 months should be tracked. | ||||||||||

| 19 | Management review input | * | * | Internal audit and EnPI must be reviewed, if a revision of suggested objectives/targets is needed. | ||||||||||

| 20 | Output of top management | * | * | The targets set by reviewers should be adopted by the energy team to create required fulfillment of the plan. | ||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, B.; Khan, A.; Asif, A.; Khan, S.; Imtiaz, F. Chronographic Implementation of Energy Management System in Small-Scale Plastic Industry. Eng. Proc. 2022, 20, 3. https://doi.org/10.3390/engproc2022020003

Ali B, Khan A, Asif A, Khan S, Imtiaz F. Chronographic Implementation of Energy Management System in Small-Scale Plastic Industry. Engineering Proceedings. 2022; 20(1):3. https://doi.org/10.3390/engproc2022020003

Chicago/Turabian StyleAli, Basit, Adeel Khan, Abdullah Asif, Shehryar Khan, and Fahad Imtiaz. 2022. "Chronographic Implementation of Energy Management System in Small-Scale Plastic Industry" Engineering Proceedings 20, no. 1: 3. https://doi.org/10.3390/engproc2022020003

APA StyleAli, B., Khan, A., Asif, A., Khan, S., & Imtiaz, F. (2022). Chronographic Implementation of Energy Management System in Small-Scale Plastic Industry. Engineering Proceedings, 20(1), 3. https://doi.org/10.3390/engproc2022020003