Design and Development of a Control Volume Spray Chamber (CVSC) for Fuel Spray Visualization †

Abstract

:1. Introduction

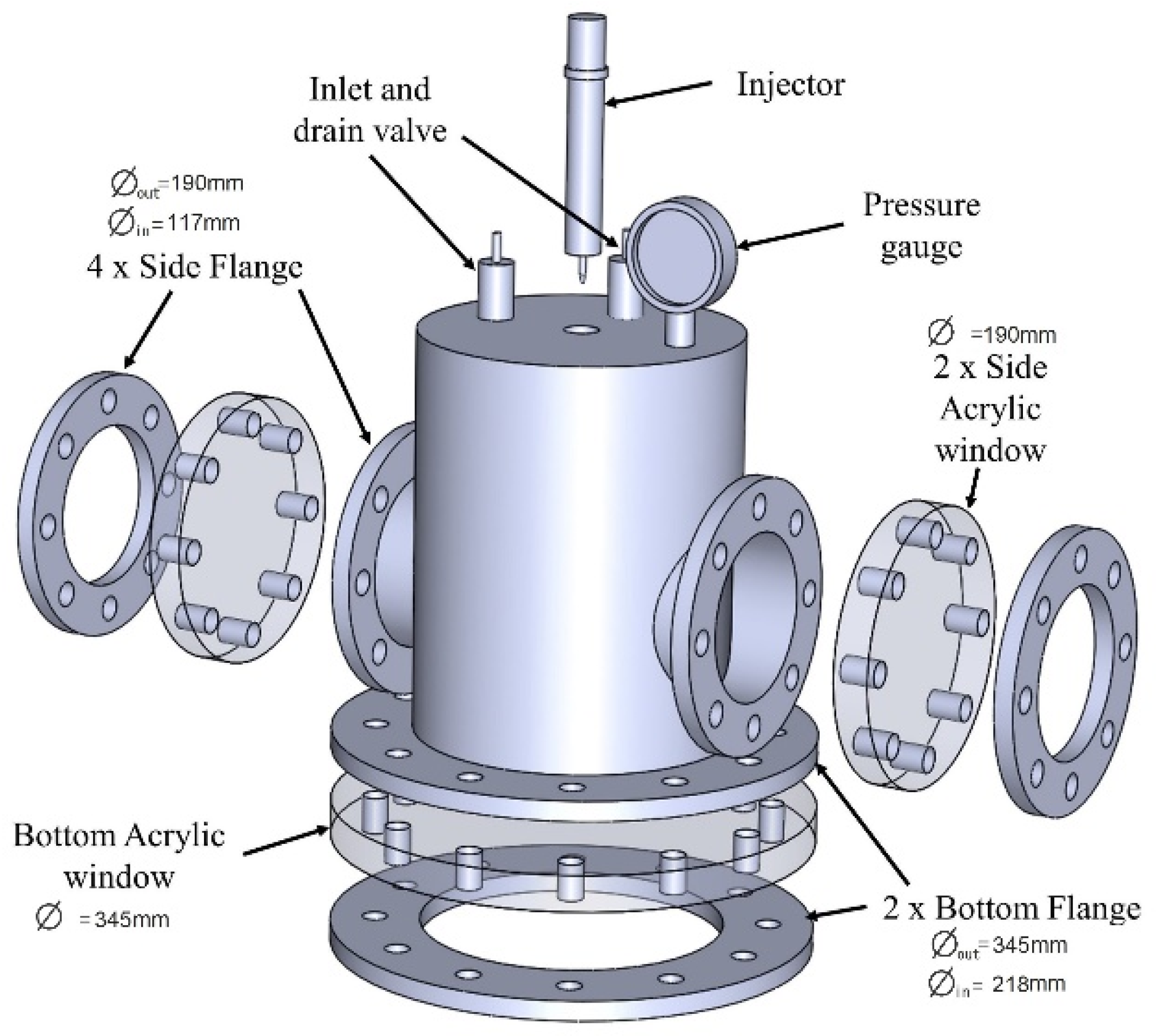

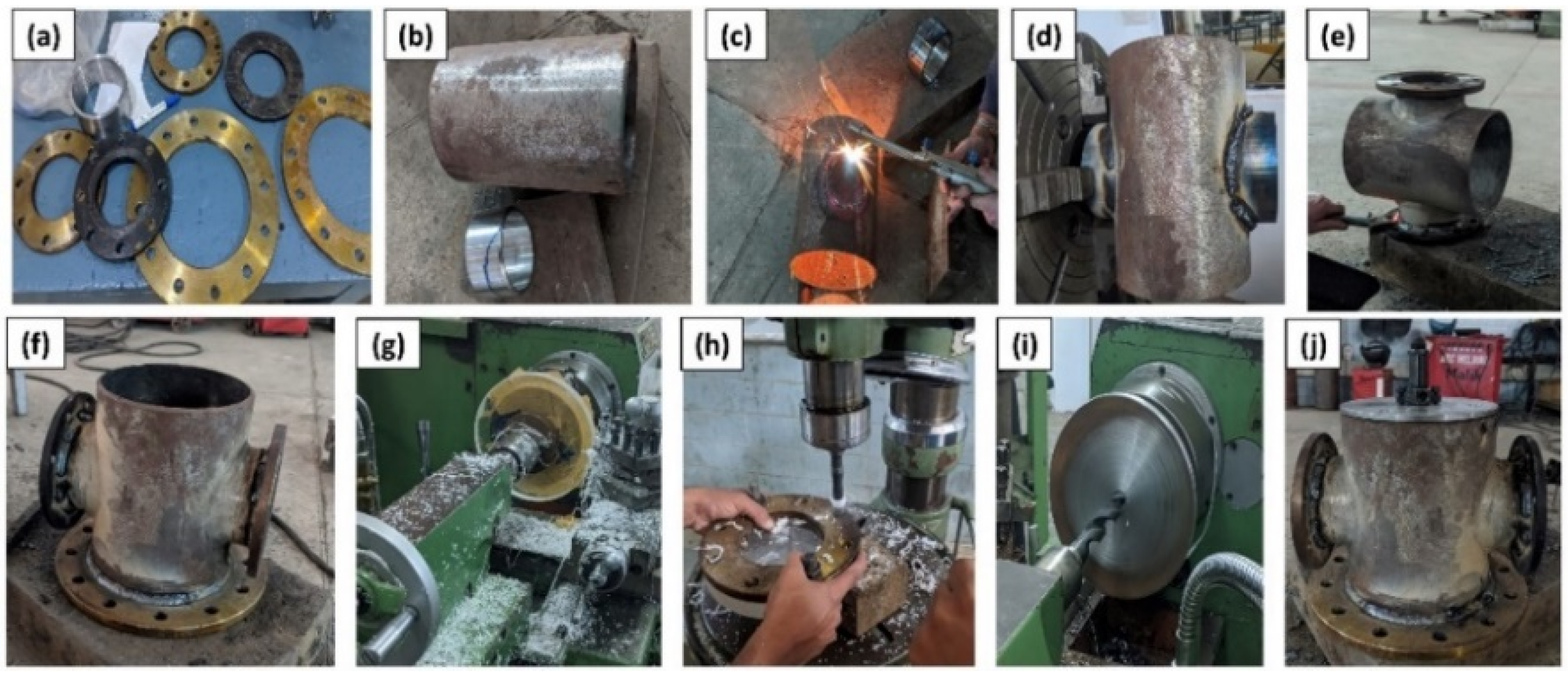

2. Materials and Methods

2.1. Fabrication of Experimental Setup

2.2. Experimental Setup

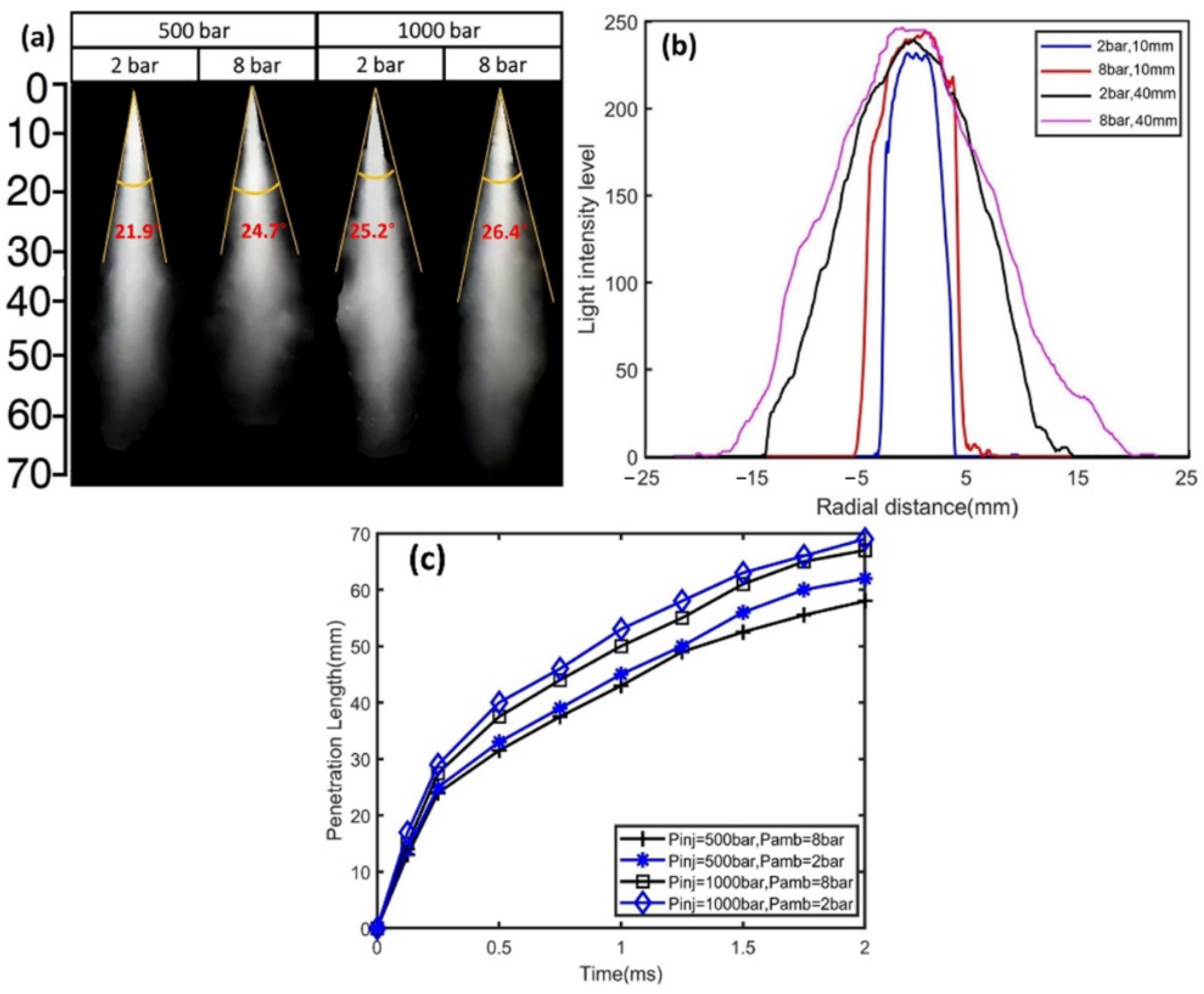

3. Results

Fuel Spray Analysis of Diesel

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McCormick, R.L.; Graboski, M.S.; Alleman, T.L.; Herring, A.M.; Tyson, K.S. Impact of biodiesel source material and chemical structure on emissions of criteria pollutants from a heavy-duty engine. Environ. Sci. Technol. 2001, 359, 1742–1747. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Huang, Z.; Kuti, O.A.; Zhang, W.; Nishida, K. Experimental and analytical study on biodiesel and diesel spray characteristics under ultra-high injection pressure. Int. J. Heat Fluid Flow 2010, 31, 659–666. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Dhar, A.; Gupta, J.G.; Kim, W.I.; Lee, C.S.; Park, S. Effect of fuel injection pressure and injection timing on spray characteristics and particulate size–number distribution in a biodiesel fuelled common rail direct injection diesel engine. Appl. Energy 2014, 130, 212–221. [Google Scholar] [CrossRef]

- Lee, D.; Jho, Y.; Lee, C.S. Effects of soybean and canola oil–based biodiesel blends on spray, combustion, and emission characteristics in a diesel engine. J. Energy Eng. 2014, 140, A4014012. [Google Scholar] [CrossRef]

- Das, M.; Sarkar, M.; Datta, A.; Santra, A.K. Study on viscosity and surface tension properties of biodiesel-diesel blends and their effects on spray parameters for CI engines. Fuel 2018, 220, 769–779. [Google Scholar] [CrossRef]

- Bohl, T.; Tian, G.; Smallbone, A.; Roskilly, A.P. Macroscopic spray characteristics of next-generation bio-derived diesel fuels in comparison to mineral diesel. Appl. Energy 2017, 186, 562–573. [Google Scholar] [CrossRef]

| Parameter | Quantity | Parameter | Quantity |

|---|---|---|---|

| Injection pressure | 500, 1000 bar | Injection duration | 2 ms |

| Injection temperature | 300 K | Chamber diameter | 218 mm |

| Ambient pressure | 2 & 8 bar | Nozzle diameter | 0.290 mm |

| Chamber temperature | 300 K | Diesel density | 837.9 kg/cm3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haq, M.U.; Jafry, A.T.; Ahmad, S.; Muzaffar, A. Design and Development of a Control Volume Spray Chamber (CVSC) for Fuel Spray Visualization. Eng. Proc. 2022, 23, 35. https://doi.org/10.3390/engproc2022023035

Haq MU, Jafry AT, Ahmad S, Muzaffar A. Design and Development of a Control Volume Spray Chamber (CVSC) for Fuel Spray Visualization. Engineering Proceedings. 2022; 23(1):35. https://doi.org/10.3390/engproc2022023035

Chicago/Turabian StyleHaq, Muteeb Ul, Ali Turab Jafry, Saad Ahmad, and Atif Muzaffar. 2022. "Design and Development of a Control Volume Spray Chamber (CVSC) for Fuel Spray Visualization" Engineering Proceedings 23, no. 1: 35. https://doi.org/10.3390/engproc2022023035

APA StyleHaq, M. U., Jafry, A. T., Ahmad, S., & Muzaffar, A. (2022). Design and Development of a Control Volume Spray Chamber (CVSC) for Fuel Spray Visualization. Engineering Proceedings, 23(1), 35. https://doi.org/10.3390/engproc2022023035