Hydroforming of High-Strength Aluminum Tubes with Thermo-Mechanical Manufacturing Processes †

Abstract

:1. Introduction

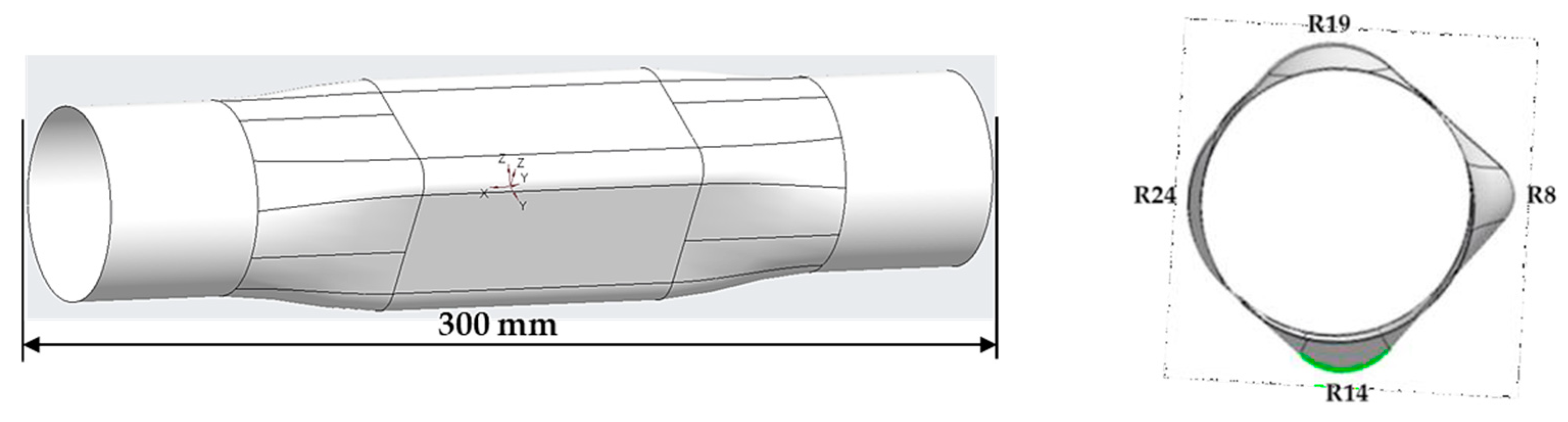

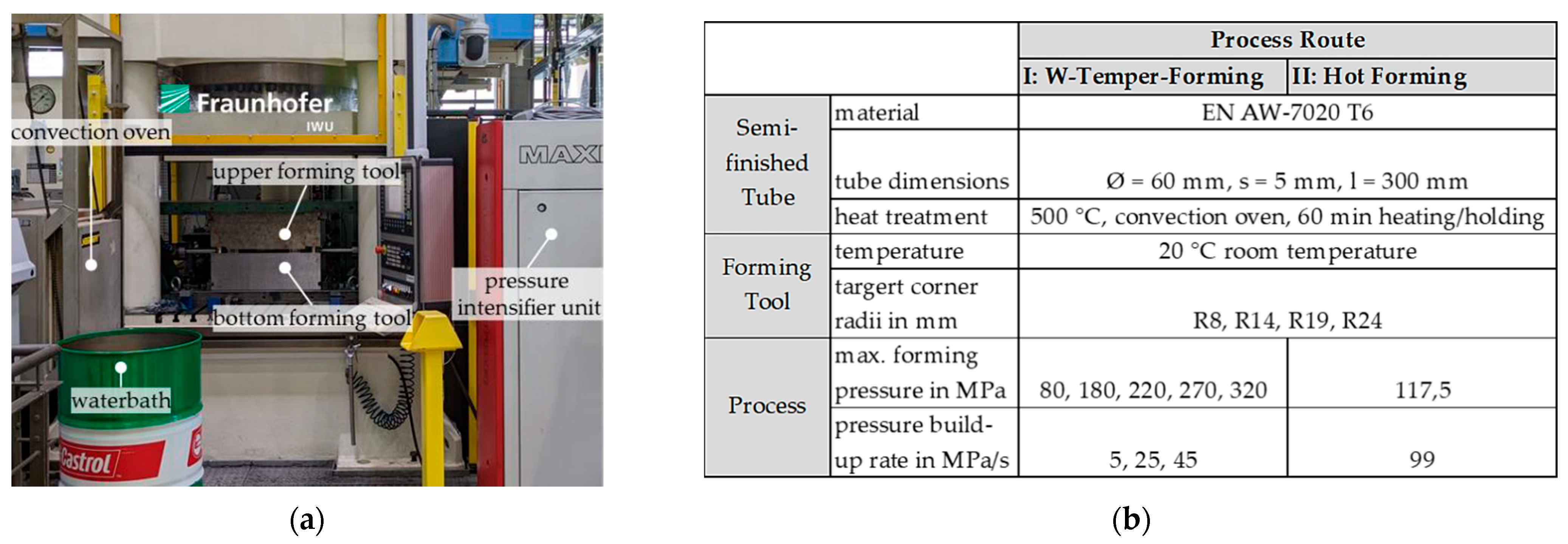

2. Materials and Methods

2.1. Specimen Preparation and Experimental Setup for Tensile Tests

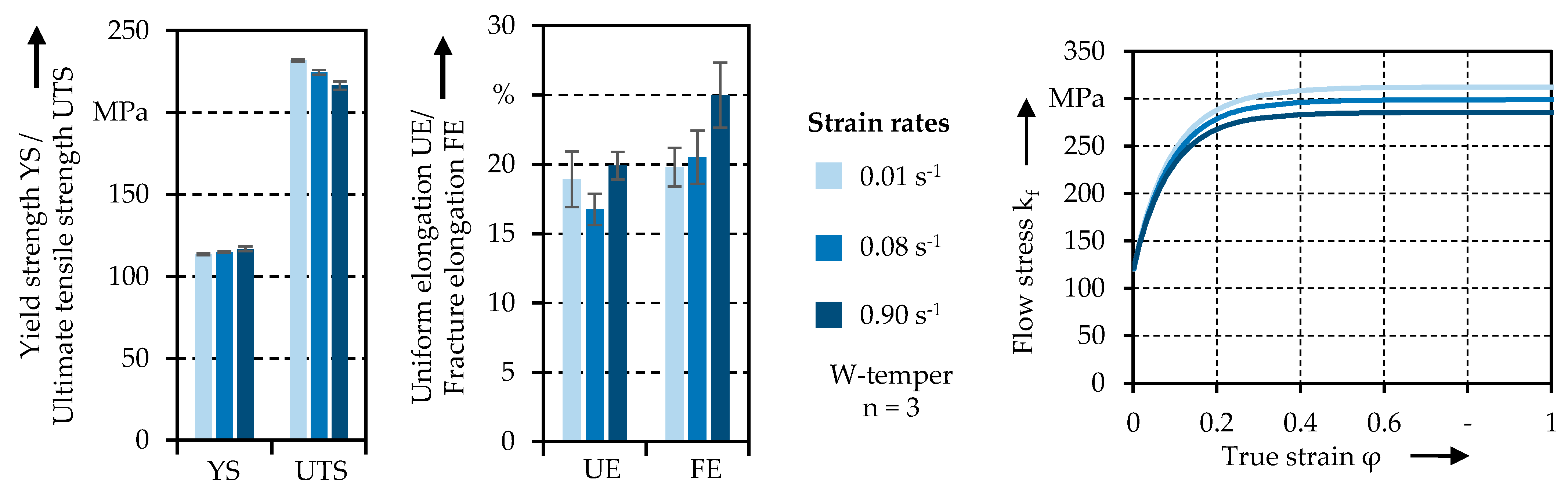

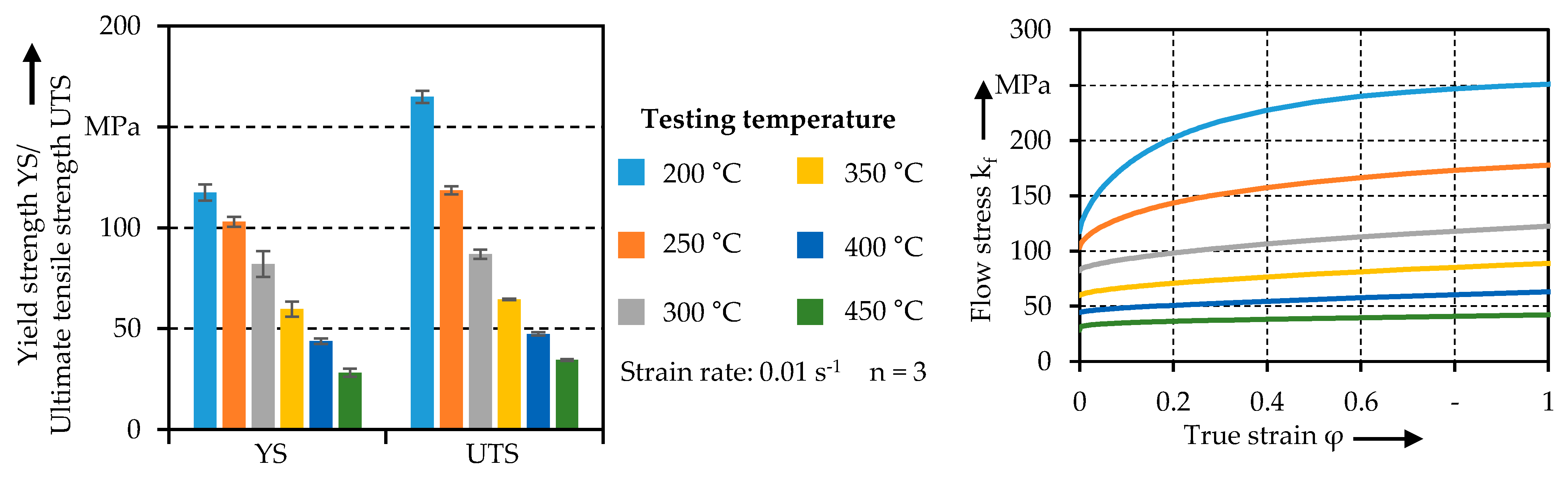

2.2. Material Properties in W-Temper and Hot Forming Condition

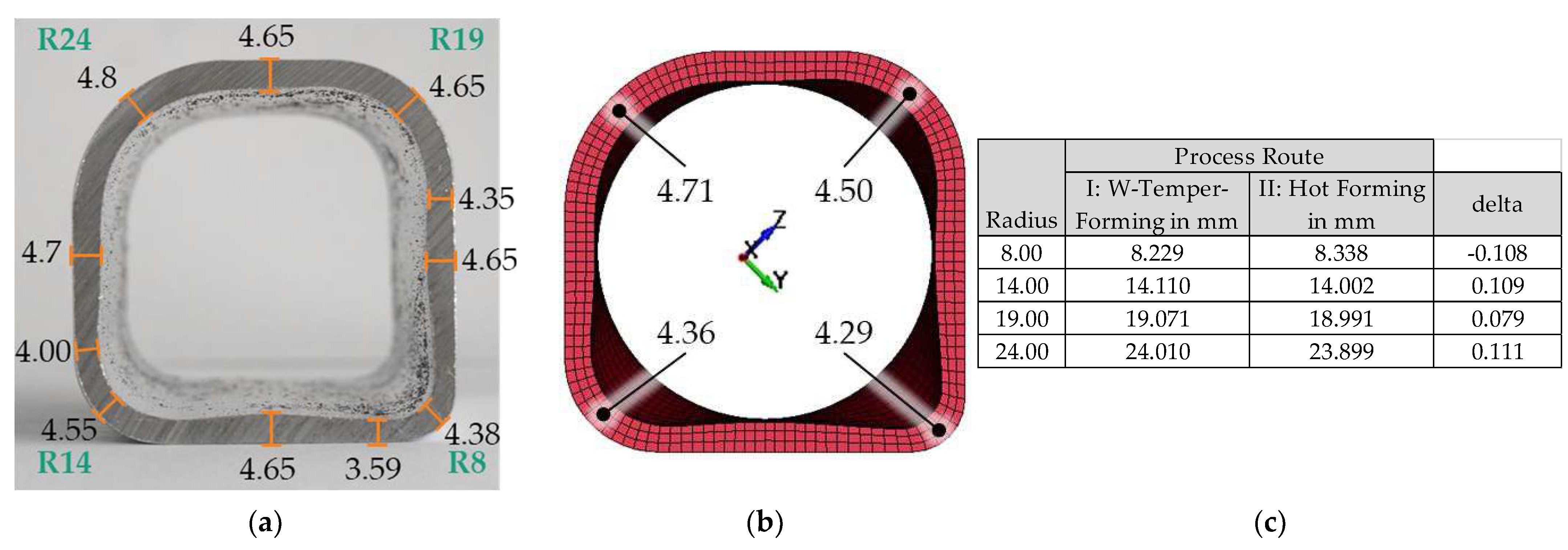

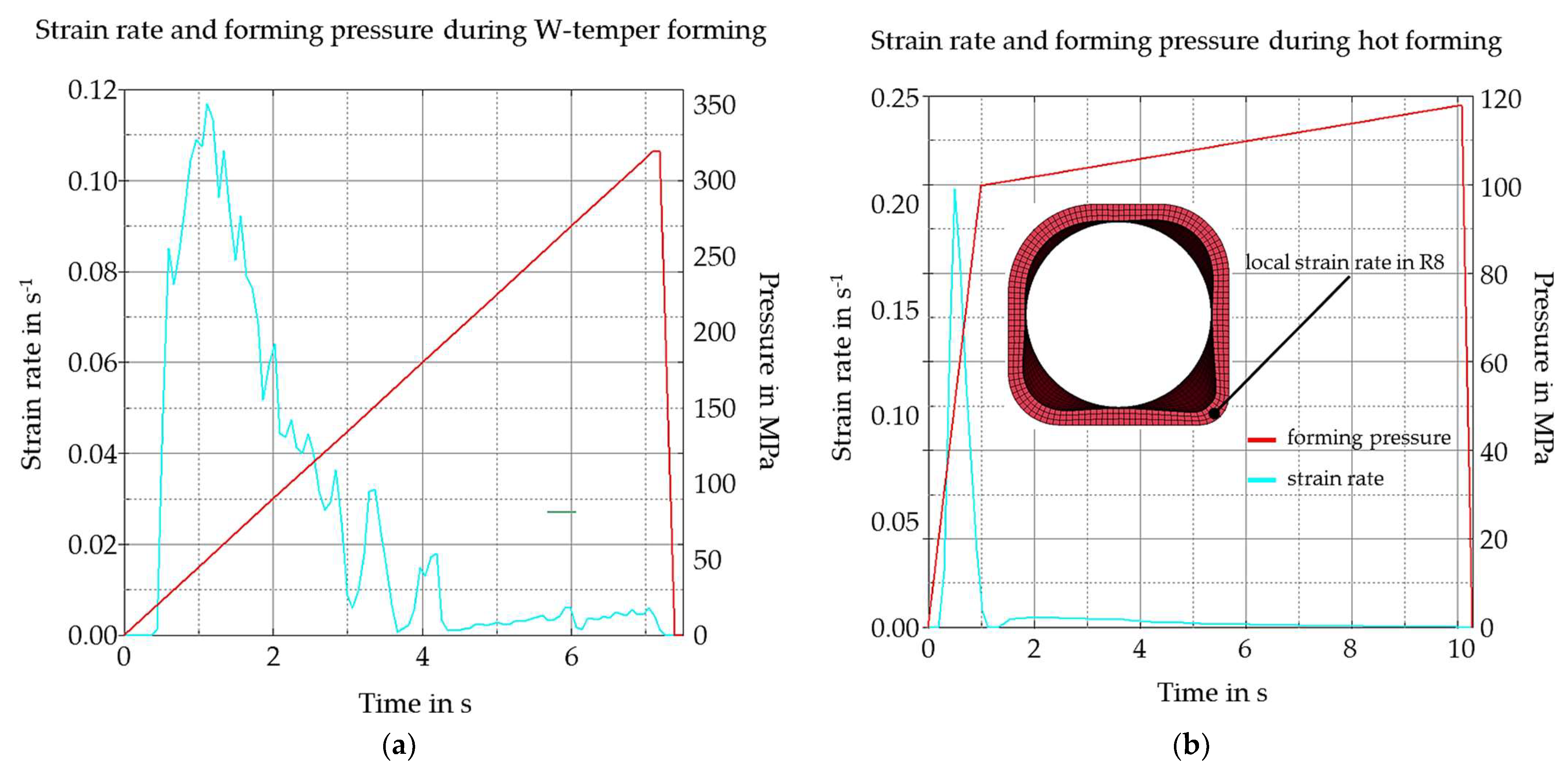

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bell, C.; Corney, J.; Zuelli, N.; Savings, D. A state of the art review of hydroforming technology. Int. J. Mater. Form. 2020, 13, 789–828. [Google Scholar] [CrossRef] [Green Version]

- Neugebauer, R. Hydro-Umformung, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 978-3-540-49013-5. [Google Scholar]

- Trân, R.; Reuther, F.; Winter, S.; Psyk, V. Process Development for a Superplastic Hot Tube Gas Forming Process of Titanium (Ti-3Al-2.5V) Hollow Profiles. Metals 2020, 10, 1150. [Google Scholar] [CrossRef]

- Paul, A.; Werner, M.; Trân, R.; Landgrebe, D. Hot metal gas forming of titanium grade 2 bent tubes. In AIP Conference Proceedings, Proceedings of the 20th International ESAFORM Conference on Material Forming: ESAFORM 2017, Dublin, Ireland, 26–28 April 2017; Brabazon, D., Naher, S., Ahad, I.U., Eds.; AIP Publishing: Melville, NY, USA, 2017; ISBN 978-0-7354-1580-5. [Google Scholar]

- Bach, M.; Degenkolb, L.; Reuther, F.; Psyk, V.; Demuth, R.; Werner, M. Conductive Heating during Press Hardening by Hot Metal Gas Forming for Curved Complex Part Geometries. Metals 2020, 10, 1104. [Google Scholar] [CrossRef]

- Landgrebe, D.; Albert, A.; Reuther, F.; Paul, A. Press Hardening of Tubes by Hot Metal. Gas. Forming. In Proceedings of the 2nd Sino-German Workshop, Dresden, Germany, 17–21 July 2018; Available online: https://publica.fraunhofer.de/handle/publica/400983 (accessed on 28 July 2022).

- Zheng, K.; Zheng, J.-H.; He, Z.; Liu, G.; Politis, D.J.; Wang, L. Fundamentals, processes and equipment for hot medium pressure forming of light material tubular components. Int. J. Lightweight Mater. Manuf. 2020, 3, 1–19. [Google Scholar] [CrossRef]

- Lee, M.-Y.; Sohn, S.-M.; Kang, C.-Y.; Suh, D.-W.; Lee, S.-Y. Effects of pre-treatment conditions on warm hydroformability of 7075 aluminum tubes. J. Mater. Processing Technol. 2004, 155–156, 1337–1343. [Google Scholar] [CrossRef]

- Hartl, C. Research and advances in fundamentals and industrial applications of hydroforming. J. Mater. Process. Technol. 2005, 167, 383–392. [Google Scholar] [CrossRef]

- Zheng, K.; Politis, D.J.; Wang, L.; Lin, J. A review on forming techniques for manufacturing lightweight complex—Shaped aluminium panel components. Int. J. Lightweight Mater. Manuf. 2018, 1, 55–80. [Google Scholar] [CrossRef]

- Foster, A.; Dean, T.A.; Lin, J. Process for Forming Aluminium Alloy Sheet Components. WO2010032002A1, 16 September 2009. [Google Scholar]

- de Argandoña, E.S.; Galdos, L.; Ortubay, R.; Mendiguren, J.; Agirretxe, X. Room Temperature Forming of AA7075 Aluminum Alloys: W-Temper Process. KEM 2015, 651–653, 199–204. [Google Scholar] [CrossRef]

- DIN EN ISO 6892-1:2020-06; Metallische Werkstoffe-Zugversuch-Teil 1: Prüfverfahren bei Raumtemperatur. ISO: Geneva, Switzerland, 2020.

- Reblitz, J.; Reuther, F.; Trân, R.; Kräusel, V.; Merklein, M. Numerical and Experimental Investigations on the Mechanical Properties of Milled Specimens from an AA7020 Tube. KEM 2022, 926, 1949–1958. [Google Scholar] [CrossRef]

- Paul, A.; Reuther, F.; Neumann, S.; Albert, A.; Landgrebe, D. Process simulation and experimental validation of Hot Metal Gas Forming with new press hardening steels. J. Phys. Conf. Ser. 2017, 896, 12051. [Google Scholar] [CrossRef]

- Shapiro, A.B. Using LS-Dyna for Hot Stamping. In Proceedings of the 7th European LS-DYNA Conference, Salzburg, Austria, 14–15 May 2009. [Google Scholar]

| Equation for the Flow Curve Approximation: kf = b − (b − a) · e −cφd | ||||

|---|---|---|---|---|

| Flow Curve | a in MPa | b in MPa | c | d |

| W-temper 0.01 s−1 | 113.66 | 298.49 | 11.8749 | 0.9858 |

| W-temper 0.08 s−1 | 114.90 | 290.31 | 12.6919 | 1.0171 |

| W-temper 0.90 s−1 | 116.85 | 280.71 | 11.4966 | 0.9896 |

| Hot forming 200 °C | 117.50 | 258.926 | 3.0588 | 0.7329 |

| Hot forming 250 °C | 103.04 | 213.59 | 1.6019 | 0.6342 |

| Hot forming 300 °C | 82.17 | 1471.82 | 0.5279 | 0.6987 |

| Hot forming 350 °C | 59.73 | 5624.20 | 0.0509 | 0.6153 |

| Hot forming 400 °C | 43.81 | 8538.09 | 0.0638 | 0.6778 |

| Hot forming 450 °C | 28.35 | 79866.21 | 0.0003 | 0.3474 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trân, R.; Reblitz, J.; Haase, R.; Psyk, V.; Kräusel, V.; Merklein, M. Hydroforming of High-Strength Aluminum Tubes with Thermo-Mechanical Manufacturing Processes. Eng. Proc. 2022, 26, 13. https://doi.org/10.3390/engproc2022026013

Trân R, Reblitz J, Haase R, Psyk V, Kräusel V, Merklein M. Hydroforming of High-Strength Aluminum Tubes with Thermo-Mechanical Manufacturing Processes. Engineering Proceedings. 2022; 26(1):13. https://doi.org/10.3390/engproc2022026013

Chicago/Turabian StyleTrân, Ricardo, Jonas Reblitz, Rico Haase, Verena Psyk, Verena Kräusel, and Marion Merklein. 2022. "Hydroforming of High-Strength Aluminum Tubes with Thermo-Mechanical Manufacturing Processes" Engineering Proceedings 26, no. 1: 13. https://doi.org/10.3390/engproc2022026013

APA StyleTrân, R., Reblitz, J., Haase, R., Psyk, V., Kräusel, V., & Merklein, M. (2022). Hydroforming of High-Strength Aluminum Tubes with Thermo-Mechanical Manufacturing Processes. Engineering Proceedings, 26(1), 13. https://doi.org/10.3390/engproc2022026013