Deep Rolling of Bores Using Centrifugal Force †

Abstract

:1. Introduction

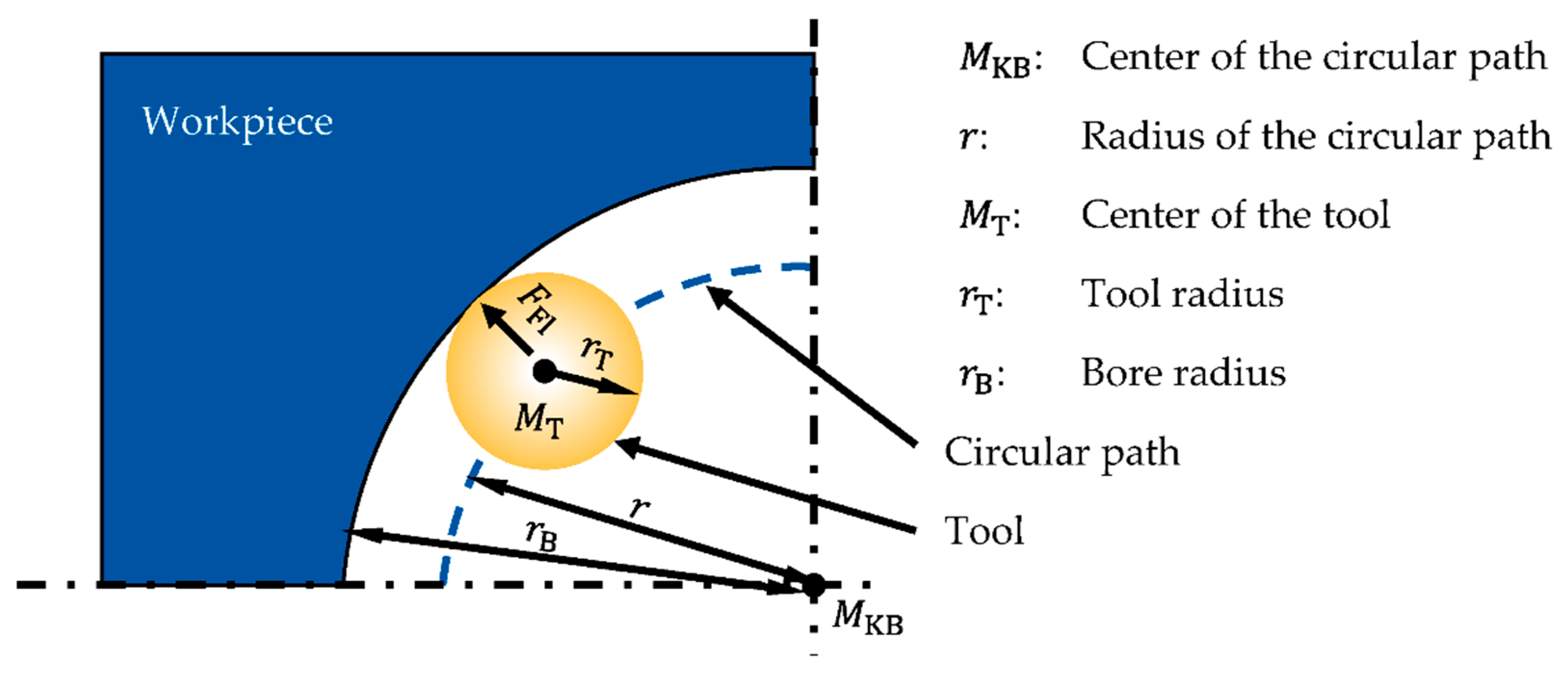

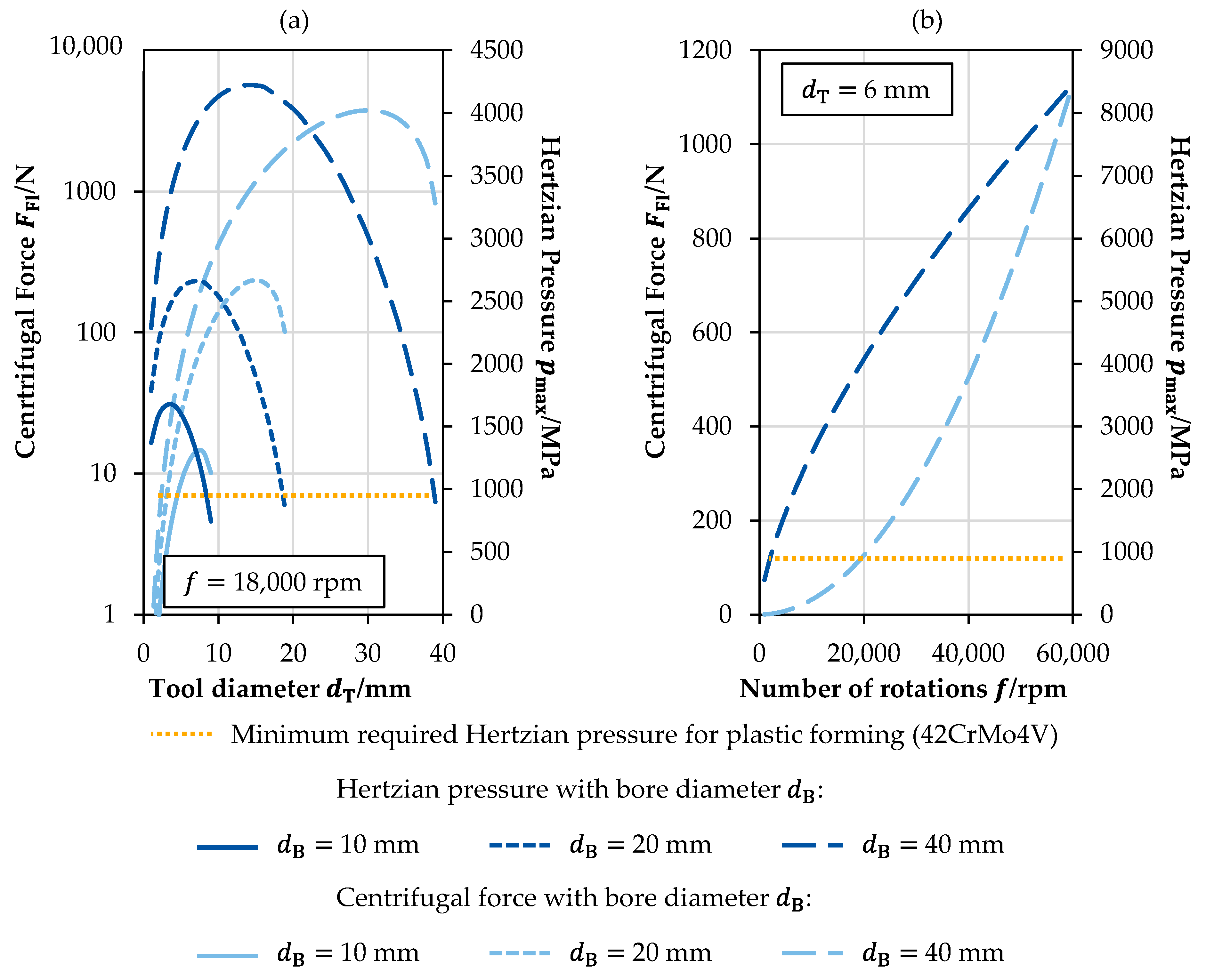

2. Process Force and Hertzian Pressure

3. Materials and Methods

3.1. Prototype of Centrifugal Deep Rolling Tool and Experimental Setup

3.2. Experimental Design

3.3. Measurement Methods and Objectives

4. Results and Discussion

4.1. Visual Evaluation

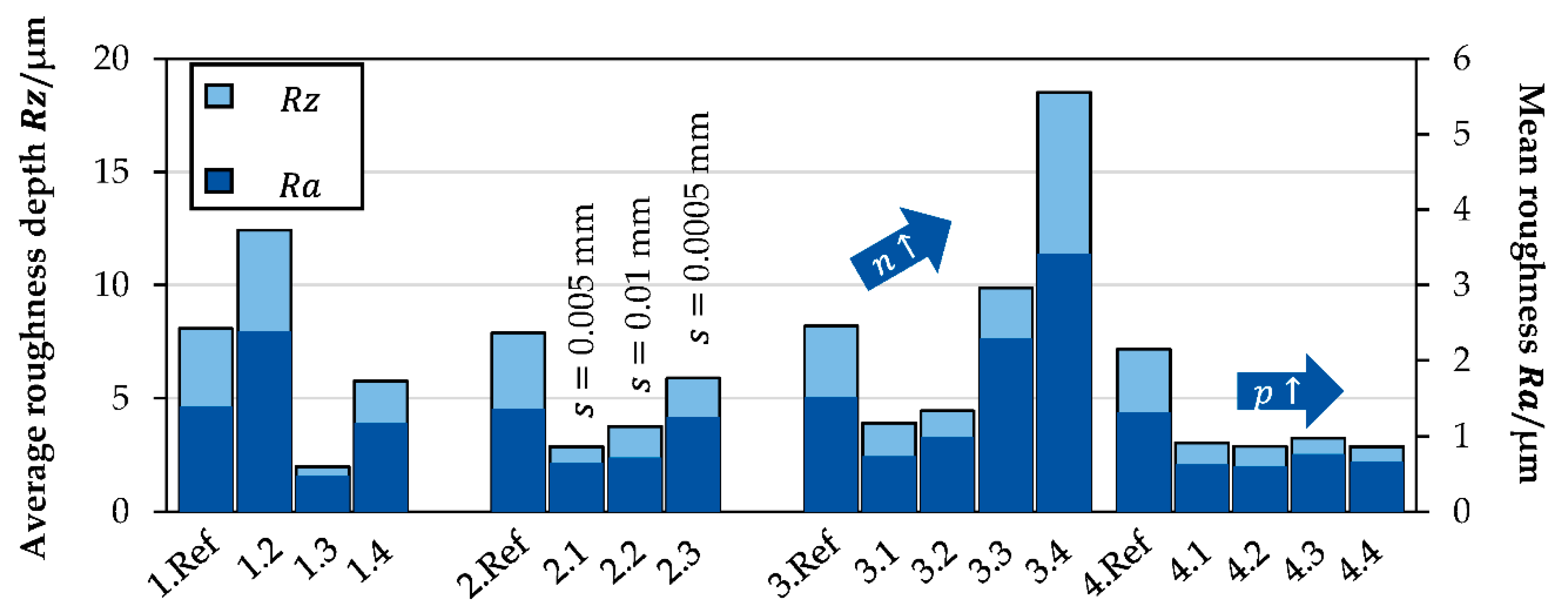

4.2. Roughness Measurements

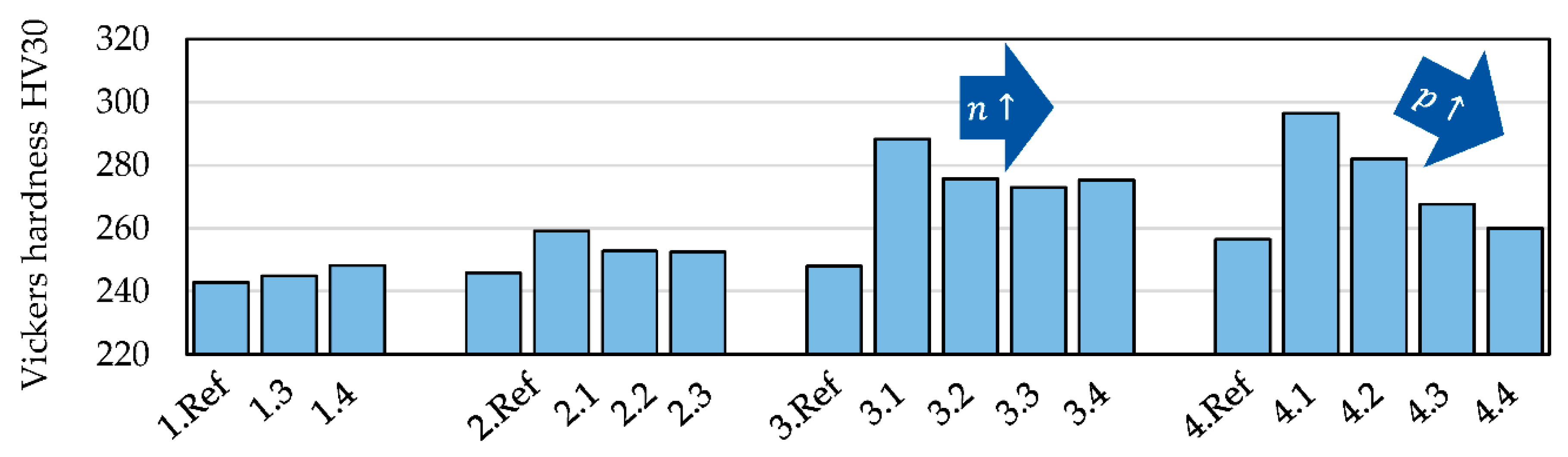

4.3. Hardness Tests

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lyubenova, N. Comprehensive Characterisation and Modelling of the Surface Integrity by Deep Rolling on Flat Surface. Ph.D. Thesis, Saarland University, Saarbrücken, Germany, 2020. [Google Scholar]

- Akkurt, A. Comparison of Roller Burnishing Method with Other Hole Surface Finishing Processes Applied on AISI 304 Austenitic Stainless Steel. J. Mater. Eng. Perform. 2011, 20, 960–968. [Google Scholar] [CrossRef]

- Schubnell, J.; Farajian, M. Fatigue improvement of aluminium welds by means of deep rolling and diamond burnishing. Weld. World 2021, 66, 699–708. [Google Scholar] [CrossRef]

- Muñoz-Cubillos, J.; Coronado, J.J.; Rodríguez, S.A. Deep rolling effect on fatigue behavior of austenitic stainless steels. Int. J. Fatigue 2017, 95, 120–131. [Google Scholar] [CrossRef]

- Ecoroll, A.G. Accessories for HG Tools: HGP Hydraulic Power Units. Available online: https://www.ecoroll.de/en/products/hydrostatic-tools/hgp-hydraulic-power-units.html (accessed on 11 July 2022).

- Types of Input and Output. Available online: https://mapal.com/en-us/products-and-solutions/actuating/types-of-input-and-output (accessed on 1 July 2022).

- Benenson, W. (Ed.) Handbook of Physics, 3rd ed.; Springer: New York, NY, USA; Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Kirchner, E. Leistungsübertragung in Fahrzeuggetrieben: Grundlagen der Auslegung, Entwicklung und Validierung von Fahrzeuggetrieben und deren Komponenten; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

| Property | Unit | Value |

|---|---|---|

| Density of the tool material ρT | g/cm3 | 14.9 |

| Elastic modulus of the tool ET | MPa | 630,000 |

| Poission ratio of the tool νT | - | 0.22 |

| Elastic modulus of the workpiece EW | MPa | 210,000 |

| Poission ratio of the workpiece νW | - | 0.3 |

| Test Number | Bore Type | Length of Test Field | Step-Over Distance s/mm | Feed fT/mm/min | Internal Lubricant Pressure p/bar | Rotational Speed n/1/min |

|---|---|---|---|---|---|---|

| 1.1 | Blind | 0 | 0 | 0 | 45 | 0–10,000 |

| 1.2 | Blind | 0 | 0 | 0 | 15 | 5000 |

| 1.3 | Blind | 6 | 0.001 | 5 | 15 | 5000 |

| 1.4 | Blind | 8 | 0.001 | 10 | 15 | 10,000 |

| 2.1 | Blind | 6 | 0.005 | 37.5 | 0 ** | 7500 |

| 2.2 | Blind | 6 | 0.01 | 75 | 0 ** | 7500 |

| 2.3 | Blind | 6 | 0.0005 | 3.75 | 0 ** | 7500 |

| 3.1 | Through | 6 | 0.001 | 5 | 0 ** | 5000 |

| 3.2 | Through | 6 | 0.001 | 7.5 | 0 ** | 7500 |

| 3.3 | Through | 6 | 0.001 | 10 | 0 ** | 10,000 |

| 3.4 | Through | 6 | 0.001 | 12.5 | 0 ** | 12,500 |

| 4.1 | Through | 6 | 0.001 | 7.5 | 15 | 7500 |

| 4.2 | Through | 6 | 0.001 | 7.5 | 30 | 7500 |

| 4.3 | Through | 6 | 0.001 | 7.5 | 45 | 7500 |

| 4.4 | Through | 6 | 0.001 | 7.5 | 60 | 7500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uhlmann, L.; Weiser, I.F.; Herrig, T.; Bergs, T. Deep Rolling of Bores Using Centrifugal Force. Eng. Proc. 2022, 26, 20. https://doi.org/10.3390/engproc2022026020

Uhlmann L, Weiser IF, Herrig T, Bergs T. Deep Rolling of Bores Using Centrifugal Force. Engineering Proceedings. 2022; 26(1):20. https://doi.org/10.3390/engproc2022026020

Chicago/Turabian StyleUhlmann, Lars, Ingo Felix Weiser, Tim Herrig, and Thomas Bergs. 2022. "Deep Rolling of Bores Using Centrifugal Force" Engineering Proceedings 26, no. 1: 20. https://doi.org/10.3390/engproc2022026020