An Intelligent Optimization Algorithm for Scheduling the Required SIL Using Neural Network †

Abstract

:1. Introduction

- ✓

- artificial neural networks that rely on recognition system based on machine learning/deep learning to perform learning from observational data and discover their solutions [6].

2. Artificial Neural Networks

- They learn from experience rather than by programming;

- They have the ability to generalize from given training data to unseen data;

- They are fast and can be implemented in real-time;

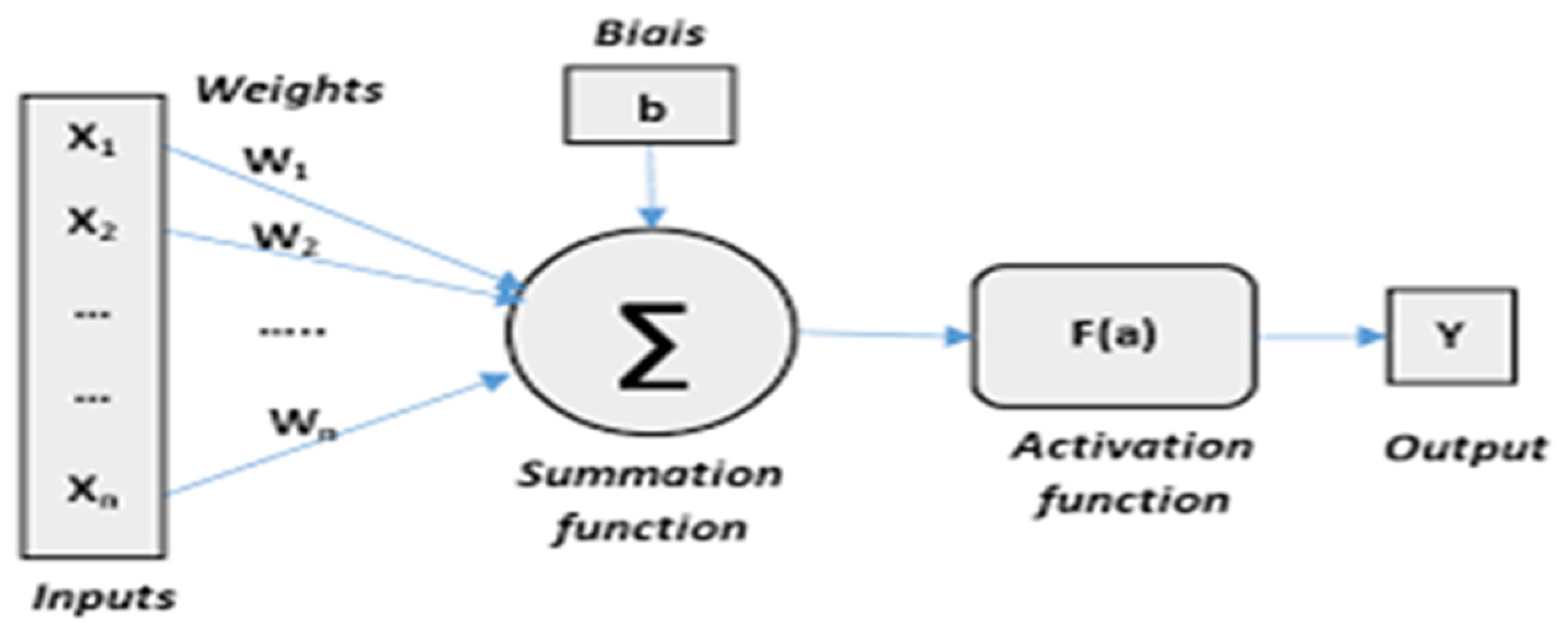

2.1. The Formal Neuron

2.2. Multi-Layer Networks

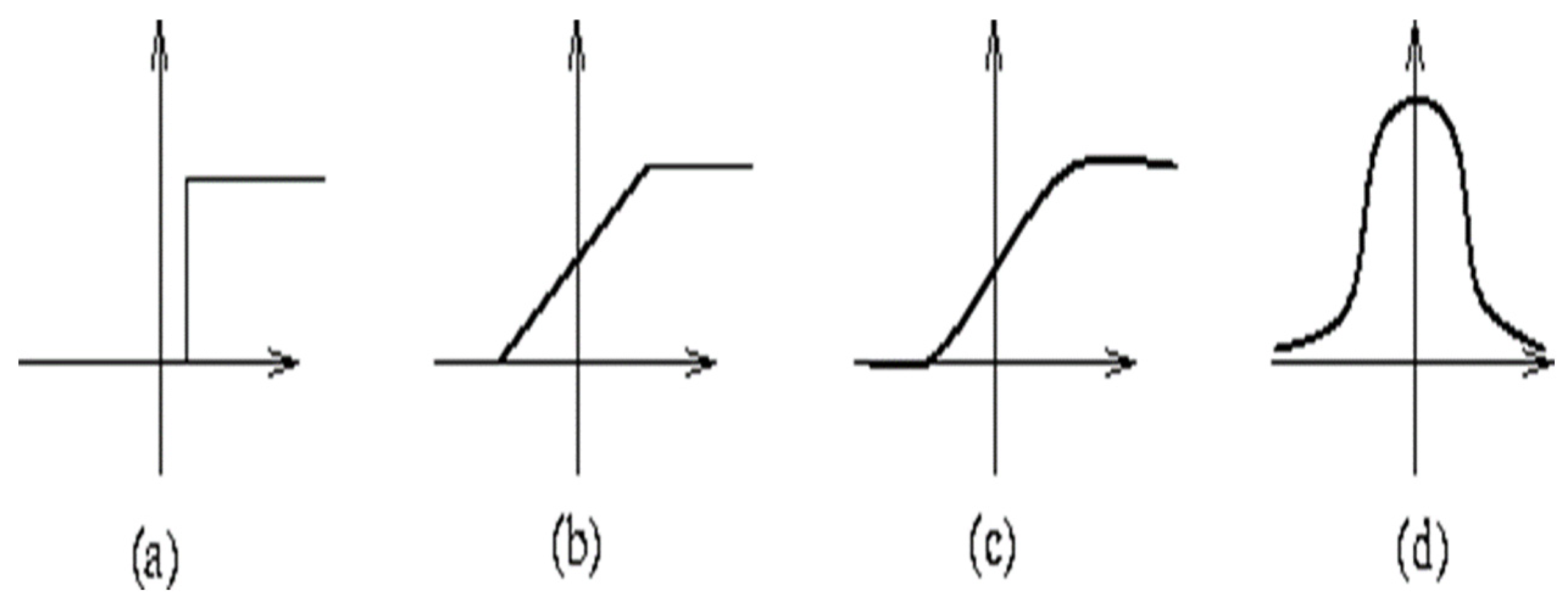

2.3. Activation Function

2.4. Neural Networks Learning

- Unsupervised learning: the algorithm must operate from unannotated examples. Indeed, in this case, machine learning is entirely independent. Data is then entered into the machine without being provided with examples of results. This mode of learning is also called competitive learning—letting the network self-organize by the local laws that govern the evolution of synaptic weights [16,17].

- Supervised learning: this is the most popular learning paradigm in machine learning and deep learning. As the name suggests, this consists of supervising the learning of the machine by showing it examples (data) of the task it must perform. The applications are numerous: Speech recognition, computer vision, regressions, classifications, etc. The vast majority of machine learning and deep learning problems use supervised learning [16,18].

3. Safety Integrity Level (SIL)

- Quantitative methods, such as fault tree analysis (FTA) and Markov graphs;

- Semi-qualitative methods, such as safety layer matrix, calibrated risk graph, and layers of protection analysis (LOPA);

- Qualitative methods, such as risk graph and hazardous event severity matrix.

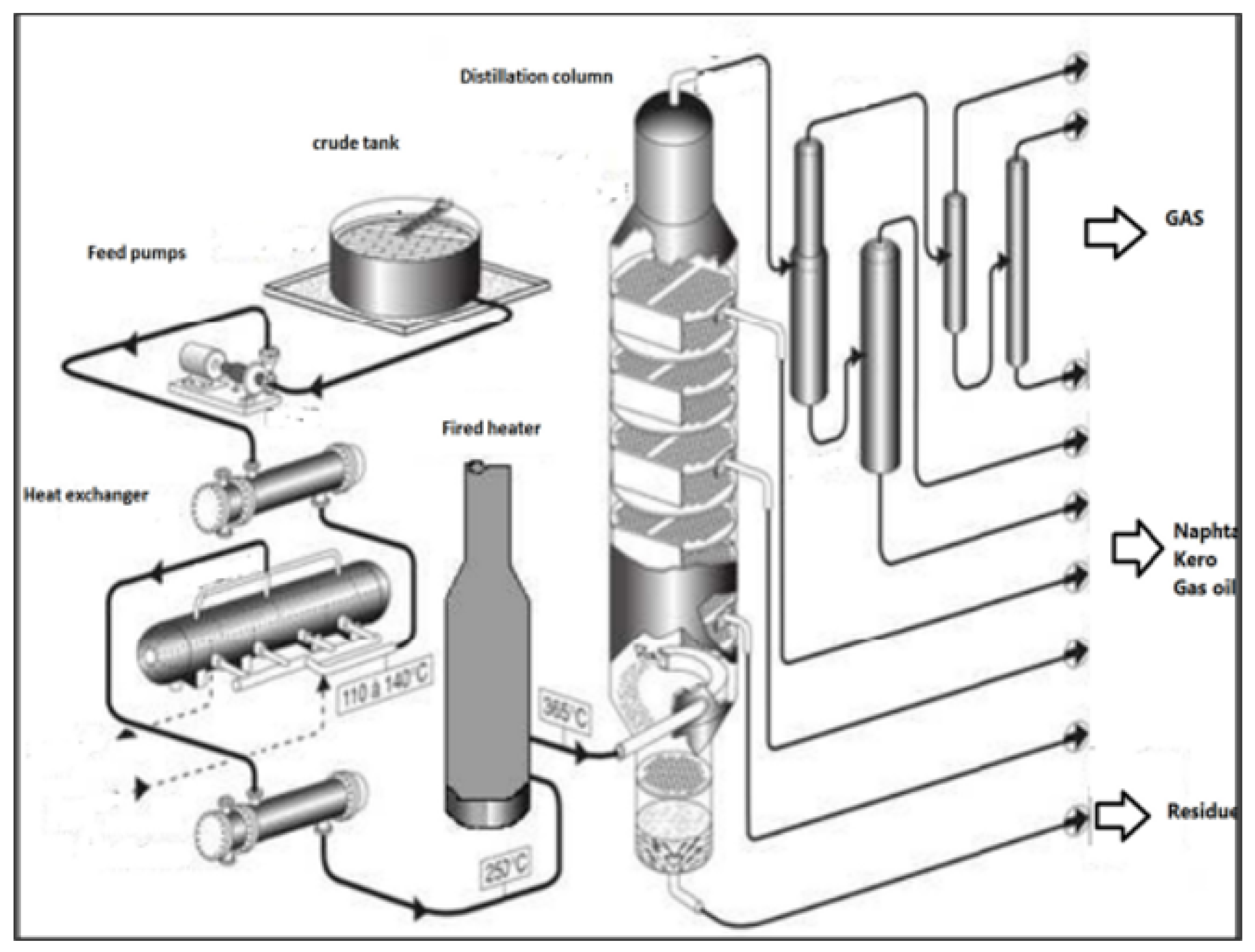

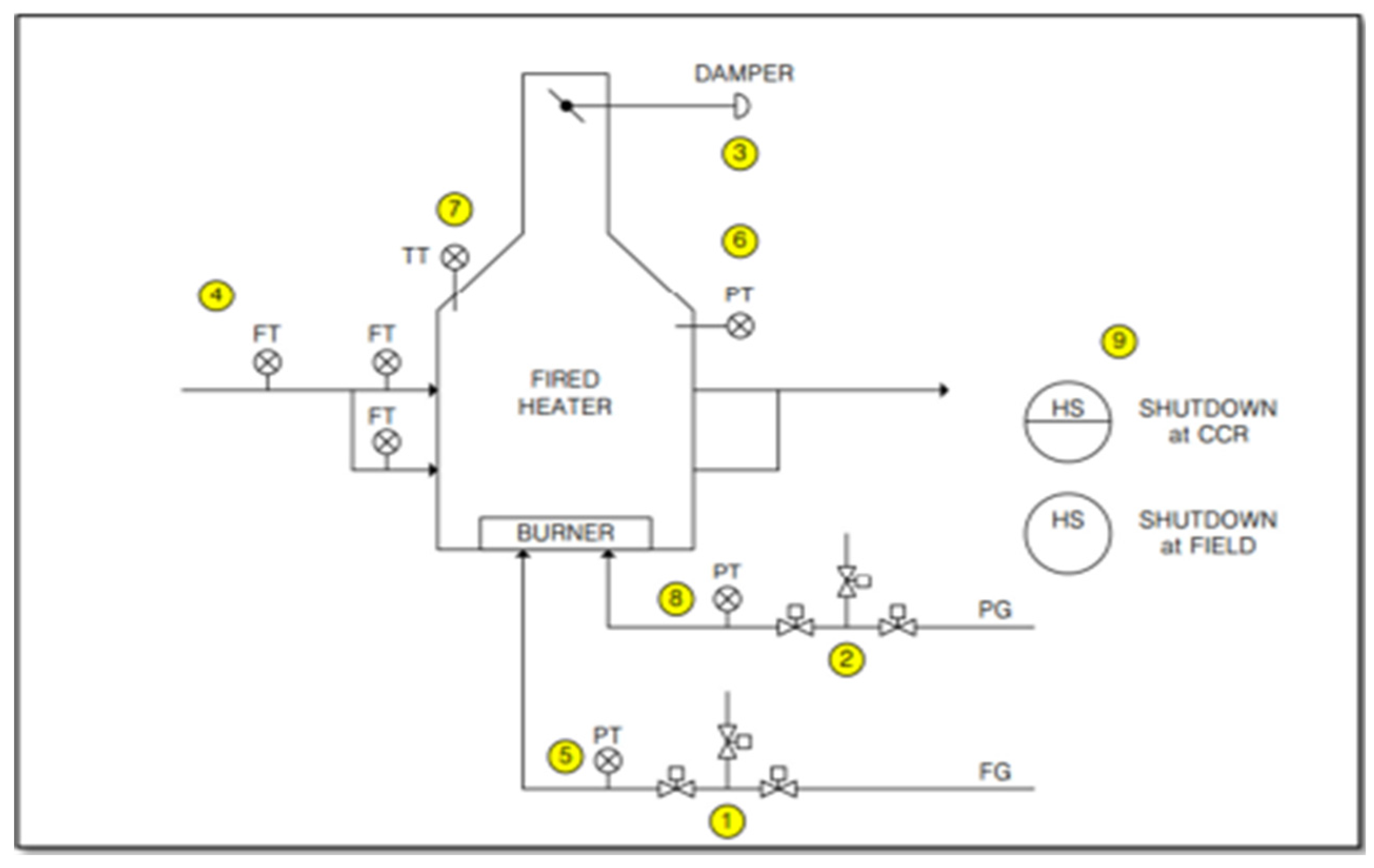

4. Application

- The product flow on each heater pass (in our case the heater has two passes). Some heaters employ a combination of the flow in each pass and the skin temperature of the corresponding tubes to regulate the flow in the tube.

- The internal temperature of the tubes and the product. By using a cascade type controller, which regulates output temperature by pressure of fuel gas in the burners, it is possible to control the temperature of the product so that the set point is 365 c.

- The pressure: the pressure of the fuel gas in the burner’s and the pilot’s gas lines, as well as the pressure inside.

5. Results and Discussion

Author Contributions

Funding

Conflicts of Interest

Appendix A

| SIF | Definition | Type | Scenario |

|---|---|---|---|

| PS 11203 | Low/low pressure in the fuel gas and pilot gas lines. | existing | Burner can extinguish low fuel gas pressure and possible flammable material accumulation |

| TAHH 1 | Temperature High/High in tube | New | High/High temperature in the tube may lead to tube failure and explosion in case where the tube is damaged (pressure of hydrocarbons with fire). The existing protection is the low pressure vapour to extinguish the inside the heater. |

| FS11204 FS11205 | Low/low flow of the crude in each pass | Existing | Low /low flow of the product in each pass will lead to increase the skin temperature of the corresponding heater tube which will lead to tube damage. Fire and explosion is expected. |

| PAHH 2 | High/high alarm in the pressure of both fuel gas and pilot lines | New | Burner can extinguish at high/high fuel gas pressure as a result of gas blowing, and possible flammable material accumulation inside the heater. There is a possibility of explosion during heater restart-up. |

| TS 11207 | High/high temperature in the heater box | Existing | Prolonged exposure to high temperature may cause tube failure which will lead to explosion and unit shutdown. High temperature of the crude may lead to perturbation of distillation column operation, and it may cause harm for the column internal in future. |

| PAHH 3 | High/high pressure in the heater box | New | Increasing the pressure inside the heater box may lead to explosion. The existing physical protection is the explosion windows. |

| Categories | Consequences |

|---|---|

| S0 | No injury or health effect |

| S1 | Slight injury or health effect |

| S2 | Minor injury or health effect |

| S3 | Major injury or health effect |

| S4 | One to three fatalities |

| S5 | Multiple fatalities |

| Categories | Consequences |

|---|---|

| E0 | No effect |

| E1 | Slight effect |

| E2 | Minor effect |

| E3 | Local effect |

| E4 | Major effect |

| E5 | Massive effect |

| Categories | Consequences |

|---|---|

| L0 | No loss |

| L1 | Slight loss < 10 K USD |

| L2 | Minor loss 10–100 K USD |

| L3 | Local loss 0.1–1 M USD |

| L4 | Major loss 1–10 M USD |

| L5 | Extensive loss > 10 M USD |

References

- You, M.; Li, S.; Li, D.; Xu, S. Applications of Artificial Intelligence for Coal Mine Gas Risk Assessment. Saf. Sci. 2021, 143, 105420. [Google Scholar] [CrossRef]

- Rahmanifard, H.; Plaksina, T. Application of Artificial Intelligence Techniques in the Petroleum Industry: A Review. Artif. Intell. Rev. 2019, 52, 2295–2318. [Google Scholar] [CrossRef]

- Wittwehr, C.; Blomstedt, P.; Gosling, J.P.; Peltola, T.; Raffael, B.; Richarz, A.-N.; Sienkiewicz, M.; Whaley, P.; Worth, A.; Whelan, M. Artificial Intelligence for Chemical Risk Assessment. Comput. Toxicol. 2020, 13, 100114. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.-J. Imitating the Brain with Neurocomputer a “New” Way towards Artificial General Intelligence. Int. J. Autom. Comput. 2017, 14, 520–531. [Google Scholar] [CrossRef] [Green Version]

- Abiodun, O.I.; Jantan, A.; Omolara, A.E.; Dada, K.V.; Mohamed, N.A.; Arshad, H. State-of-the-Art in Artificial Neural Network Applications: A Survey. Heliyon 2018, 4, e00938. [Google Scholar] [CrossRef] [Green Version]

- Cheng, J.; Li, Q.S.; Xiao, R. A New Artificial Neural Network-Based Response Surface Method for Structural Reliability Analysis. Probab. Eng. Mech. 2008, 23, 51–63. [Google Scholar] [CrossRef]

- Nabian, M.A.; Meidani, H. Deep Learning for Accelerated Reliability Analysis of Infrastructure Networks. Comput.-Aided Civ. Infrastruct. Eng. 2018, 33, 443–458. [Google Scholar] [CrossRef] [Green Version]

- Paltrinieri, N.; Comfort, L.; Reniers, G. Learning about Risk: Machine Learning for Risk Assessment. Saf. Sci. 2019, 118, 475–486. [Google Scholar] [CrossRef]

- Adler, R.; Akram, M.N.; Bauer, P.; Feth, P.; Gerber, P.; Jedlitschka, A.; Jöckel, L.; Kläs, M.; Schneider, D. Hardening of Artificial Neural Networks for Use in Safety-Critical Applications—A Mapping Study. arXiv 2019, arXiv:1909.03036. [Google Scholar]

- Goh, Y.M.; Chua, D. Neural Network Analysis of Construction Safety Management Systems: A Case Study in Singapore. Constr. Manag. Econ. 2013, 31, 460–470. [Google Scholar] [CrossRef]

- Anastasi, S.; Madonna, M.; Monica, L. Implications of Embedded Artificial Intelligence-Machine Learning on Safety of Machinery. Procedia Comput. Sci. 2021, 180, 338–343. [Google Scholar] [CrossRef]

- Davoudi Kakhki, F.; Freeman, S.A.; Mosher, G.A. Use of Neural Networks to Identify Safety Prevention Priorities in Agro-Manufacturing Operations within Commercial Grain Elevators. Appl. Sci. 2019, 9, 4690. [Google Scholar] [CrossRef] [Green Version]

- Albawi, S.; Mohammed, T.A.; Al-Zawi, S. Understanding of a Convolutional Neural Network. In Proceedings of the 2017 International Conference on Engineering and Technology (ICET), Antalya, Turkey, 21–23 August 2017; pp. 1–6. [Google Scholar]

- Bengio, Y. Learning Deep Architectures for AI. Found. Trends® Mach. Learn. 2009, 2, 1–127. [Google Scholar] [CrossRef]

- Kumar, M.; Jindal, M.K.; Sharma, R.K. Weka-Based Classification Techniques for Offline Handwritten Gurmukhi Character Recognition. In Proceedings of the Second International Conference on Soft Computing for Problem Solving (SocProS 2012), 28–30 December 2012; Babu, B.V., Nagar, A., Deep, K., Pant, M., Bansal, J.C., Ray, K., Gupta, U., Eds.; Springer: New Delhi, India, 2014; pp. 711–720. [Google Scholar]

- Hertz, J.A. Introduction To The Theory Of Neural Computation; CRC Press: Boca Raton, FL, USA, 2019; ISBN 978-0-429-49966-1. [Google Scholar]

- Fern´ndez, A.S.; Delgado-Mata, C.; Velazquez, R. Training a Single-Layer Perceptron for an Approximate Edge Detection on a Digital Image. In Proceedings of the 2011 International Conference on Technologies and Applications of Artificial Intelligence, Washington, DC, USA, 11–13 November 2011; pp. 189–193. [Google Scholar]

- Carpenter, G.A.; Grossberg, S. A Self-Organizing Neural Network for Supervised Learning, Recognition, and Prediction. IEEE Commun. Mag. 1992, 30, 38–49. [Google Scholar] [CrossRef]

- Fae, E.; Marcel, F. Standard Devices vs IEC 61508 SIL Safety Devices Integration in Process Industry. Annu. Electr. Autom. Knowl. Shar. Event 2018, 15, 199–207. [Google Scholar]

- Bendib, R.; Zennir, Y.; Mechhoud, E.-A.; Bouziane, S. Risk Assessment for a Steam Generator (1050 G1) Skikda Refinery Algeria, Using HAZOP and RQA Methods. In Proceedings of the 2019 International Conference on Advanced Systems and Emergent Technologies (IC_ASET), Hammamet, Tunisia, 19–22 March 2019; pp. 262–267. [Google Scholar]

- Nait-Said, R.; Zidani, F.; Ouzraoui, N. Fuzzy Risk Graph Model for Determining Safety Integrity Level. Int. J. Qual. Stat. Reliab. 2008, 2008, 263895. [Google Scholar] [CrossRef] [Green Version]

- Cruz-Campa, H.J.; Cruz-Gómez, M.J. Determine SIS and SIL Using HAZOPS. Process Saf. Prog. 2010, 29, 22–31. [Google Scholar] [CrossRef]

- Gabriel, A.; Ozansoy, C.; Shi, J. Developments in SIL Determination and Calculation. Reliab. Eng. Syst. Saf. 2018, 177, 148–161. [Google Scholar] [CrossRef]

- Torres-Echeverria, A.C. On the Use of LOPA and Risk Graphs for SIL Determination. J. Loss Prev. Process Ind. 2016, 41, 333–343. [Google Scholar] [CrossRef]

- Riad, B.; Hamid, B.; Hind, R.; Youcef, Z. Design Of an Integration Frame HAZOP-SIL for Safety Optimization of a Fired Heater. In Proceedings of the 2018 International Conference on Electrical Sciences and Technologies in Maghreb (CISTEM), Algiers, Algeria, 29–31 October 2018; pp. 1–6. [Google Scholar]

- Bendib, R.; Mechhoud, E.; Bendjama, H.; Boulksibat, H. Risk Assessment of a Gas Plant (Unit 30 Skikda Refinery) Using Hazop &Bowtie Methods, Simulation of Dangerous Scenarios Using ALOHA Software. Alger. J. Signals Syst. 2020, 5, 25–32. [Google Scholar] [CrossRef]

- Ahn, J.; Chang, D. Fuzzy-Based HAZOP Study for Process Industry. J. Hazard. Mater. 2016, 317, 303–311. [Google Scholar] [CrossRef] [PubMed]

| SIL | Rang of Average PFD | Range of RRF |

|---|---|---|

| 1 | [10−2, 10−1] | [10, 100] |

| 2 | [10−3, 10−2] | [100, 1000] |

| 3 | [10−4, 10−3] | [1000, 10,000] |

| 4 | [10−5, 10−4] | [10,000, 100,000] |

| Consequence Category | Demand Rate Category | ||||||

|---|---|---|---|---|---|---|---|

| Health and Safety (S) | Environmental (E) | Economic (L) | D0 | D1 | D2 | D3 | D4 |

| S0 | E0 | L0 | - | - | - | - | - |

| S1 | E1 | L1 | - | - | A1 | A2 | A2 |

| S2 | E2 | L2 | - | A1 | A2 | 1 | 2 |

| S3 | E3 | L3 | - | A2 | 1 | 2 | 3 |

| S4 | E4 | L4 | - | 1 | 2 | 3 | 4(x) |

| S5 | E5 | L5 | - | 2 | 3 | 4(x) | x |

| SIF 1/PS11203 | ||

| Economic Risk SIL | Environment Risk SIL | Personnel health SIL |

| 2 | (-) no safety requirement | (-) no safety requirement |

| SIF 2/TAHH1 | ||

| Economic Risk SIL | Environment Risk SIL | Personnel health SIL |

| 3 | (-) no safety requirement | 2 |

| SIF 3/FS11204, FS11205 | ||

| Economic Risk SIL | Environment Risk SIL | Personnel health SIL |

| 3 | (-) no safety requirement | 2 |

| SIF 4/PAHH2 | ||

| Economic Risk SIL | Environment Risk SIL | Personnel health SIL |

| 2 | (-) no safety requirement | (-) no safety requirement |

| SIF 5/TS11207 | ||

| Economic Risk SIL | Environment Risk SIL | Personnel health SIL |

| 2 | (-) no safety requirement | 1 |

| SIF 6/PAHH3 | ||

| Economic Risk SIL | Environment Risk SIL | Personnel health SIL |

| 3 | (-) no safety requirement | 2 |

| Input Layer | Hidden Layer | Output Layer |

|---|---|---|

| x1: SIL-risk; x2: economic SIL; | Y1: output of first layer; x3: environment SIL | Y: SIL overall F = |

| SIF | SILoverall |

|---|---|

| PS 11203 | SIL2 |

| TAHH 1 | SIL3 |

| FS11204 FS11205 | SIL3 |

| PAHH 2 | SIL2 |

| TS 11207 | SIL2 |

| PAHH 3 | SIL3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Batout, N.; Bendib, R.; Zennir, Y. An Intelligent Optimization Algorithm for Scheduling the Required SIL Using Neural Network. Eng. Proc. 2023, 29, 5. https://doi.org/10.3390/engproc2023029005

Batout N, Bendib R, Zennir Y. An Intelligent Optimization Algorithm for Scheduling the Required SIL Using Neural Network. Engineering Proceedings. 2023; 29(1):5. https://doi.org/10.3390/engproc2023029005

Chicago/Turabian StyleBatout, Naoual, Riad Bendib, and Youcef Zennir. 2023. "An Intelligent Optimization Algorithm for Scheduling the Required SIL Using Neural Network" Engineering Proceedings 29, no. 1: 5. https://doi.org/10.3390/engproc2023029005

APA StyleBatout, N., Bendib, R., & Zennir, Y. (2023). An Intelligent Optimization Algorithm for Scheduling the Required SIL Using Neural Network. Engineering Proceedings, 29(1), 5. https://doi.org/10.3390/engproc2023029005