Motion Planning of a Triple-Link Robotic System †

Abstract

:1. Introduction

2. Related Work

- -

- Such systems can contribute to research investigating problems of movement for disabled or injured individuals, who do not have full use of their arms or legs [13].

- -

- If such systems could be effectively controlled through the exploitation of the dynamic properties within them, machines could be developed that are more energy efficient and move more smoothly in line with natural moving systems [14] Other studies previously conducted have examined how stability can be achieved in multiple-link robotic systems using a swing mechanism through examining various types of controllers, including Linear–quadratic regulator (LQR) [15], proportional–integral–derivative controller (PID) [16], fuzzy proportional–derivative controller FPD [17], and Fuzzy proportional–integral–derivative controller (FLQR) [18].

3. System Description and Setup

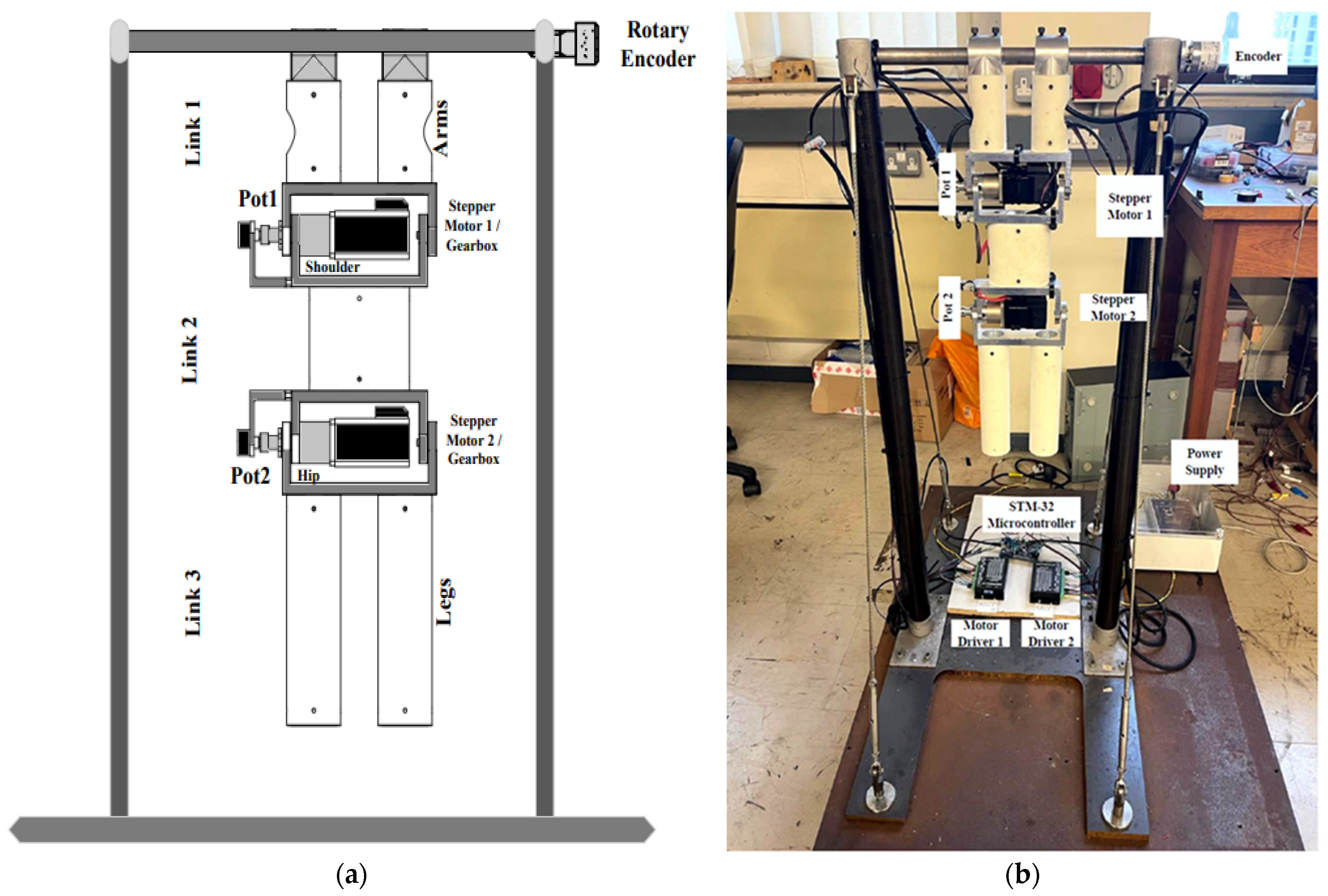

3.1. System Description

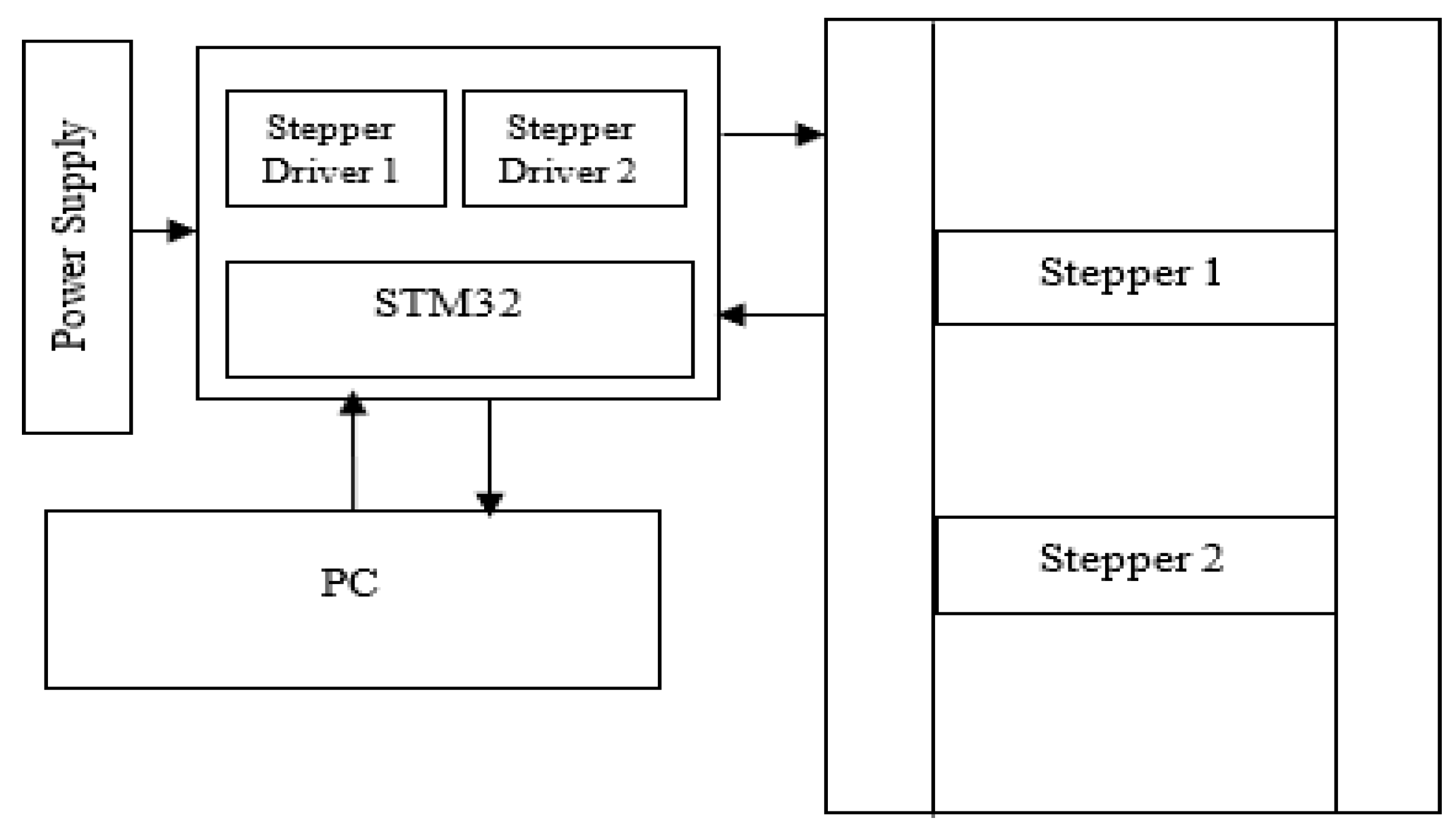

3.2. System Setup

4. Results

Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ismail, H.; Eldhukhri, E.; Packianather, M.S. Invasive weed optimization of swing-up control parameters for robot gymnast. In Proceedings of the 2014 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Besacon, France, 8–11 July 2014. [Google Scholar]

- Lai, X.; Wu, M.; She, J.; Zhang, A. Motion control of underactuated three-link gymnast robot based on combination of energy and posture. IET Control Theory Appl. 2011, 5, 1484–1493. [Google Scholar] [CrossRef]

- Muskinja, N.; Tovornik, B. Swinging up and stabilization of a real inverted pendulum. IEEE Trans. Ind. Electron. 2006, 53, 631–639. [Google Scholar] [CrossRef]

- Spong, M. The swing up control problem for the Acrobot. IEEE Control Syst. 1995, 15, 49–55. [Google Scholar]

- Medrano-Cerda, G.A.; Eldukhri, E.E.; Cetin, M. Balancing and Attitude Control of Double and Triple Inverted Pendulums. Trans. Inst. Meas. Control 1995, 17, 143–154. [Google Scholar] [CrossRef]

- Lakshmi, K. Design of Robust Energy Control for Cart-Inverted Pendulum. Int. J. Eng. Technol. 2007, 4, 66–76. [Google Scholar]

- Brown, S.; Passino, K.M.K. Intelligent Control for an Acrobat. J. Intell. Robot. Syst. Theory Appl. 1997, 18, 209–247. [Google Scholar] [CrossRef]

- Eldukhri, E.; Pham, D.T. Autonomous Swing-Up Control of a Three-Link Robot Gymnast. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2010, 224, 825–832. [Google Scholar] [CrossRef]

- Kamil, H.; Eldukhri, E.; Packianather, M. Balancing Control of Robot Gymnast Based on Discrete-Time Linear Quadratic Regulator Technique. In Proceedings of the 2014 2nd International Conference on Artificial Intelligence, Modelling and Simulation, Madrid, Spain, 18–20 November 2014. [Google Scholar]

- Eldukhri, E.E.; Kamil, H.G. Optimisation of swing-up control parameters for a robot gymnast using the Bees Algorithm. J. Intell. Manuf. 2013, 26, 1039–1047. [Google Scholar] [CrossRef]

- Ismail, H.A.; Packianather, M.S.; Grosvenor, R.I. Multi-objective invasive weed optimization of the LQR controller. Int. J. Autom. Comput. 2017, 14, 321–339. [Google Scholar] [CrossRef]

- Mohamed, M.; Samad, B.A.; Anayi, F.; Packianather, M. Analysing Various Control Technics for Manipulator Robotic System (Robogymnast). Comput. Mater. Contin. 2023, in press. [Google Scholar]

- Ismail, H.A. Intelligent Model-Based Control of Complex Multi-Link Mechanisms. Ph.D. Thesis, Cardiff University, Cardiff, UK, December 2016. [Google Scholar]

- Kamil, H.G. Intelligent Model-Based Control of Complex Three-Link Mechanisms. Ph.D. Thesis, Cardiff University, Cardiff, UK, April 2015. [Google Scholar]

- Samad, B.A.; Anayi, F.; Melikhov, Y.; Mohamed, M.; Altayef, E. Modelling of LQR and Fuzzy-LQR Controllers for Stabilisation of Multi-link Robotic System (Robogymnast). In Proceedings of the 2022 8th International Conference on Automation, Robotics and Applications (ICARA), Prague, Czech Republic, 18–20 February 2022. [Google Scholar]

- Mohamed, M.; Anayi, F.; Packianather, M.; Samad, B.A.; Yahya, K. Simulating LQR and PID controllers to stabilise a three-link robotic system. In Proceedings of the 2022 2nd International Conference on Advance Computing and Innovative Technologies in Engineering (ICACITE), Greater Noida, India, 28–29 April 2022. [Google Scholar]

- Samad, B.A.; Mohamed, M.; Anayi, F.; Melikhov, Y. A hybrid Fuzzy approach of different controllers to stabilize a 3-link swinging robotic (Robogymnast). In Proceedings of the 2022 2nd International Conference on Advance Computing and Innovative Technologies in Engineering (ICACITE), Greater Noida, India, 28–29 April 2022. [Google Scholar]

- Samad, B.A.; Mohamed, M.; Anayi, F.; Melikhov, Y. An Investigation of Various Controller Designs for Multi-Link Robotic System (Robogymnast). Knowledge 2022, 2, 465–486. [Google Scholar] [CrossRef]

| Symbol | Parameters | Mean Value |

|---|---|---|

| L1 | Length of 1st link | 0.16 m |

| L2 | Length of the middle link (link 2) | 0.18 m |

| L3 | Length of lower link (link 3) | 0.24 m |

| m1 | Weight of link 1 | 1.2 kg |

| m2 | Weight of link 2 | 1.2 kg |

| m3 | Weight of lower link 3 | 0.5 kg |

| q1, q2, q3 | Angles’ initial values | 0 (rad) |

| g | Gravity | 9.81 m/s2 |

| Symbol | Parameters | Average (Degrees)° | Max Point (Degrees)° |

|---|---|---|---|

| θ1 | Link 1 (free rotate) upper | (−5) to 25 | (−45) to 80 |

| θ2 | Link 2 (Motor 1) middle | (−5) to 15 | (−45) to 25 |

| θ3 | Link 3 (Motor 3) lower | (−10) to 10 | (−35) to 35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdul Samad, B.; Mohamed, M.; Anayi, F. Motion Planning of a Triple-Link Robotic System. Eng. Proc. 2023, 31, 48. https://doi.org/10.3390/ASEC2022-13774

Abdul Samad B, Mohamed M, Anayi F. Motion Planning of a Triple-Link Robotic System. Engineering Proceedings. 2023; 31(1):48. https://doi.org/10.3390/ASEC2022-13774

Chicago/Turabian StyleAbdul Samad, Bdereddin, Mahmoud Mohamed, and Fatih Anayi. 2023. "Motion Planning of a Triple-Link Robotic System" Engineering Proceedings 31, no. 1: 48. https://doi.org/10.3390/ASEC2022-13774

APA StyleAbdul Samad, B., Mohamed, M., & Anayi, F. (2023). Motion Planning of a Triple-Link Robotic System. Engineering Proceedings, 31(1), 48. https://doi.org/10.3390/ASEC2022-13774