Investigation of Internal Model for Unmanned Vehicle Control in Case of Its Aggressive Motion along a Spatial Trajectory †

Abstract

1. Introduction

2. Unmanned Vehicle Model Identification

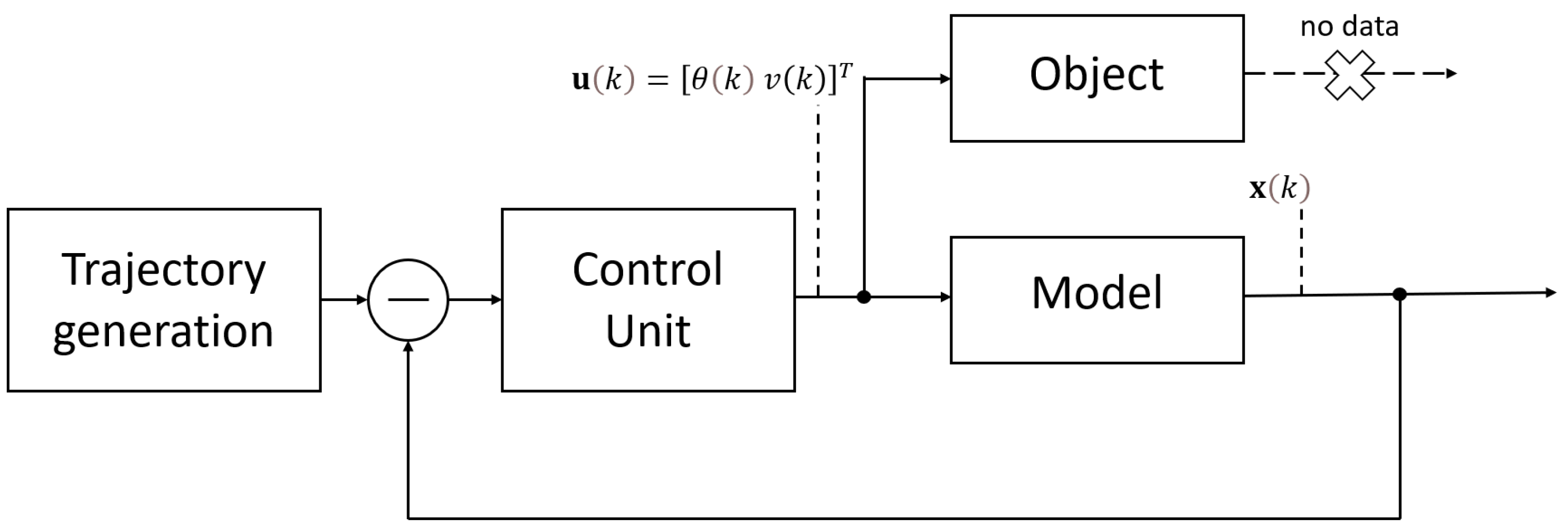

3. Trajectory Tracking Scheme

4. Controllers

4.1. Closed-Loop Control

4.2. Model Prediction Control

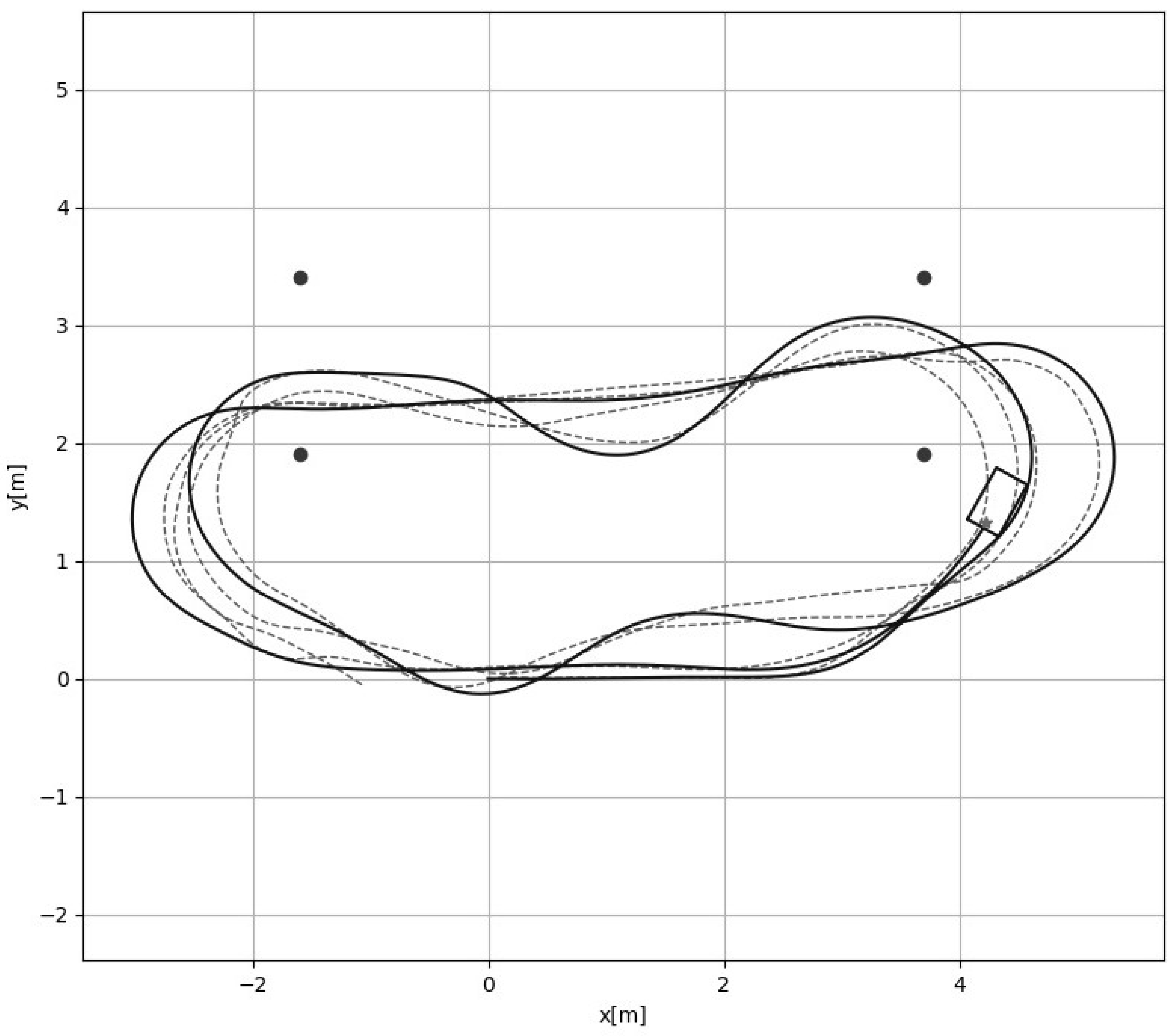

5. Results

- Control based on P-controller is distinguished by the possibility of using relatively simple controllers;

- With both control methods being used at high vehicle speeds, the deviation from the trajectory increases significantly;

- High speeds can be achieved if controller parameters are fine-tuned or in case of applying an intelligent P-controller that adapts to the speeds and curvature of the trajectory;

- High-performance computers are needed for MPC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ljuing, L. System Identification; Prentice Hall PTR: Hoboken, NJ, USA, 1999. [Google Scholar]

- Pupkov, K.A.; Egupov, N.D.; Trofimov, A.I. Statisticheskie Metody Analiza, Sinteza i Identifikacii Nelinejnyh Sistem Avtomaticheskogo Upravleniya; BMSTU: Moscow, Russia, 1998. (In Russian) [Google Scholar]

- Liu, G.P. Nonlinear Identification and Control: A Neural Network Approach; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Paden, B.; Cáp, M.; Yong, S.Z.; Yershov, D.; Frazzoli, E. A Survey of Motion Planning and Control Techniques for Self-driving Urban Vehicles. IEEE Trans. Intell. Veh. 2016, 1, 33–55. [Google Scholar] [CrossRef]

- Mehta, B.R.; Reddy, Y.J. Advanced process control systems. In Industrial Process Automation Systems; Mehta, B.R., Reddy, Y.J., Eds.; Butterworth-Heinemann: Oxford, UK, 2015; pp. 547–557. [Google Scholar] [CrossRef]

- Huang, B.; Kadali, R. Dynamic Modeling, Predictive Control and Performance Monitoring: A Data-Driven Subspace Approach; Springer: Berlin/Heidelberg, Germany, 2008; 241p. [Google Scholar]

- Kingma, D.P.; Ba, J. Adam: A Method for Stochastic Optimization. arXiv 2014, arXiv:1412.6980v8. [Google Scholar]

- Diveev, A.; Sofronova, E. The Synthesis of Optimal Control System by the Network Operator Method. In IFAC Proceedings Volumes; Elsevier: Amsterdam, The Netherlands, 2009; Volume 42, pp. 232–237. [Google Scholar]

| Experiment Number | Speed v, m/s | Deviation When Using P-Controller , m | Deviation When Using MPC , m |

|---|---|---|---|

| 1 | 1.41 | 4.4 | 3.5 |

| 2 | 1.12 | 2.1 | 1.9 |

| 3 | 0.88 | 1.6 | 1.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prokopiev, I.; Sofronova, E.; Moiseenko, V. Investigation of Internal Model for Unmanned Vehicle Control in Case of Its Aggressive Motion along a Spatial Trajectory. Eng. Proc. 2023, 33, 38. https://doi.org/10.3390/engproc2023033038

Prokopiev I, Sofronova E, Moiseenko V. Investigation of Internal Model for Unmanned Vehicle Control in Case of Its Aggressive Motion along a Spatial Trajectory. Engineering Proceedings. 2023; 33(1):38. https://doi.org/10.3390/engproc2023033038

Chicago/Turabian StyleProkopiev, Igor, Elena Sofronova, and Viktoria Moiseenko. 2023. "Investigation of Internal Model for Unmanned Vehicle Control in Case of Its Aggressive Motion along a Spatial Trajectory" Engineering Proceedings 33, no. 1: 38. https://doi.org/10.3390/engproc2023033038

APA StyleProkopiev, I., Sofronova, E., & Moiseenko, V. (2023). Investigation of Internal Model for Unmanned Vehicle Control in Case of Its Aggressive Motion along a Spatial Trajectory. Engineering Proceedings, 33(1), 38. https://doi.org/10.3390/engproc2023033038