Sustainable Engineering of an Outdoor Jacket from Waste in 2030 †

Abstract

:1. Introduction

2. Fibers from Waste

3. Sustainable Finishing

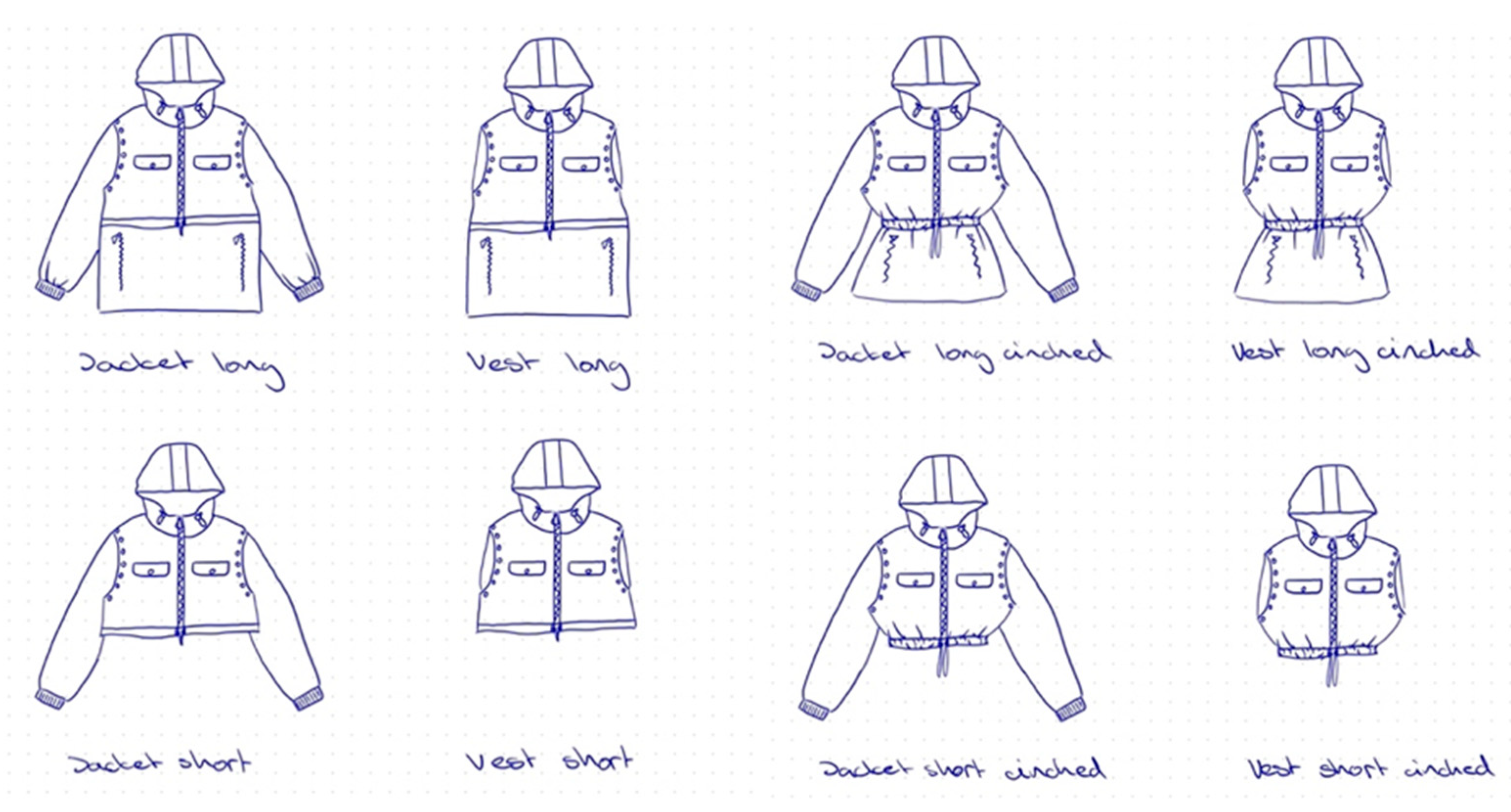

4. Multifunctional Design

5. Modular Transformable Design

6. Zero-Waste Pattern Making

7. Conclusions and Future Outlook

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McKinsey & Company. Scaling Textile Recycling in Europe—Turning Waste into Value. 2022. Available online: https://www.nweurope.eu/media/19019/2207-scaling-textile-recycling-in-europe-turning-waste-into-value.pdf (accessed on 1 March 2023).

- Publications Office of the European Union. © European Union. 2022. Available online: https://www.interregeurope.eu/sites/default/files/2022-05/Textiles_Factsheet_EC.pdf (accessed on 1 March 2023).

- Juanga-Labayen, J.P.; Labayen, I.V.; Yuan, Q. A Review on Textile Recycling Practices and Challenges. Textiles 2022, 2, 174–188. [Google Scholar] [CrossRef]

- European Parliament. The Impact of Textile Production and Waste on the Environment (Infographic), Circular Economy Action Plan. 2022. Available online: https://www.europarl.europa.eu/ (accessed on 14 January 2023).

- Periyasamy, A.P.; Militky, J. Sustainability in Regenerated Textile Fibers. In Sustainability in the Textile and Apparel Industries. Sustainable Textiles: Production, Processing, Manufacturing & Chemistry; Muthu, S.S., Gardetti, M.A., Eds.; Springer: Cham, Switzerland, 2020; pp. 63–95. [Google Scholar] [CrossRef]

- Stenton, M.; Houghton, J.A.; Kapsali, V.; Blackburn, R.S. The Potential for Regenerated Protein Fibres within a Circular Economy: Lessons from the Past Can Inform Sustainable Innovation in the Textiles Industry. Sustainability 2021, 13, 2328. [Google Scholar] [CrossRef]

- Flores-Nieves, M.M.; Castellanos-Espinoza, R.; Estevez, M.; Baldenegro-Pérez, L.A.; García Trejo, J.F.; García, M.E.; Martínez Cano, B.; Soto-Zarazúa, G.M.; España-Sánchez, B.L. Electrospun Casein fibers obtained from revalued milk with mechanical and antibacterial properties. Arab. J. Chem. 2022, 15, 104201. [Google Scholar] [CrossRef]

- Zainol Abidin, N.A.; Kormin, F.; Zainol Abidin, N.A.; Mohamed Anuar, N.A.F.; Abu Bakar, M.F. The Potential of Insects as Alternative Sources of Chitin: An Overview on the Chemical Method of Extraction from Various Sources. Int. J. Mol. Sci. 2020, 21, 4978. [Google Scholar] [CrossRef] [PubMed]

- Shahid-Ul-Islam, B.B.S. Recent advances in chitosan polysaccharide and its derivatives in antimicrobial modification of textile materials. Int. J. Biol. Macromol. 2019, 121, 905–912. [Google Scholar] [CrossRef] [PubMed]

- Svensson, S.E.; Ferreira, J.A.; Hakkarainen, M.; Adolfsson, K.H.; Zamani, A. Fungal textiles: Wet spinning of fungal microfibers to produce monofilament yarns. Sustain. Mater. Technol. 2021, 28, e00256. [Google Scholar] [CrossRef]

- Shirvan, A.R.; Shakeri, M.; Bashari, A. Recent advances in application of chitosan and its derivatives in functional finishing of textiles. In The Textile Institute Book Series, The Impact and Prospects of Green Chemistry for Textile Technology; Shahid-ul-Islam, B.S.B., Ed.; Woodhead Publishing: Sawston, UK, 2019; pp. 107–133. [Google Scholar] [CrossRef]

- Collet, C. Chapter 8—Biotextiles: Making Textiles in a Context of Climate and Biodiversity Emergency; Pedgley, O., Rognoli, V., Karana, E., Eds.; Materials Experience 2; Butterworth-Heinemann: Oxford, UK, 2021; pp. 207–226. [Google Scholar] [CrossRef]

- van Nes, N.; Cramer, J. Product lifetime optimization: A challenging strategy towards more sustainable consumption patterns. J. Clean. Prod. 2006, 14, 1307–1318. [Google Scholar] [CrossRef]

- Koo, H.S.; Dunne, L.; Bye, E. Design functions in transformable garments for sustainability. J. Fash. Des. Technol. Educ. 2013, 7, 10–20. [Google Scholar] [CrossRef]

- Hethorn, J.U. Sustainable Fashion: Why now? A Conversation Exploring Issues, Practices, and Possibilities; Fairchild Books: New York, NY, USA, 2008. [Google Scholar]

- McQuillan, H. Zero-Waste Design Practice: Strategies and Risk Taking for Gament Design; Earthscan: London, UK, 2011. [Google Scholar]

- Valenzuela-Fernández, L.; Escobar-Farfán, M. Zero-Waste Management and Sustainable Consumption: A Comprehensive Bibliometric Mapping Analysis. Sustainability 2022, 14, 16269. [Google Scholar] [CrossRef]

- Ramkalaon, S.; Sayem, A.S.M. Zero-Waste Pattern Cutting (ZWPC) to tackle over sixty billion square metres of fabric wastage during mass production of apparel. J. Text. Inst. 2021, 112, 809–819. [Google Scholar] [CrossRef]

- Carrico, M.; Dragoo, S.L.; McKinney, E.; Stannard, C.; Moretz, C.; Rougeaux-Burnes, A. An Inquiry into Gradable Zero-Waste Apparel Design. Sustainability 2022, 14, 452. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marterer, L.; Torst, N.; Haddar, O.A.; Sabantina, L. Sustainable Engineering of an Outdoor Jacket from Waste in 2030. Eng. Proc. 2023, 37, 66. https://doi.org/10.3390/ECP2023-14715

Marterer L, Torst N, Haddar OA, Sabantina L. Sustainable Engineering of an Outdoor Jacket from Waste in 2030. Engineering Proceedings. 2023; 37(1):66. https://doi.org/10.3390/ECP2023-14715

Chicago/Turabian StyleMarterer, Laura, Nora Torst, Oussema Ahmed Haddar, and Lilia Sabantina. 2023. "Sustainable Engineering of an Outdoor Jacket from Waste in 2030" Engineering Proceedings 37, no. 1: 66. https://doi.org/10.3390/ECP2023-14715