Evaluation of Small-Scale Thin Wall AlSi7Mg Alloys LPBF Coupons under Extreme Low Cycle Fatigue Regime †

Abstract

:1. Introduction

2. Materials and Methods

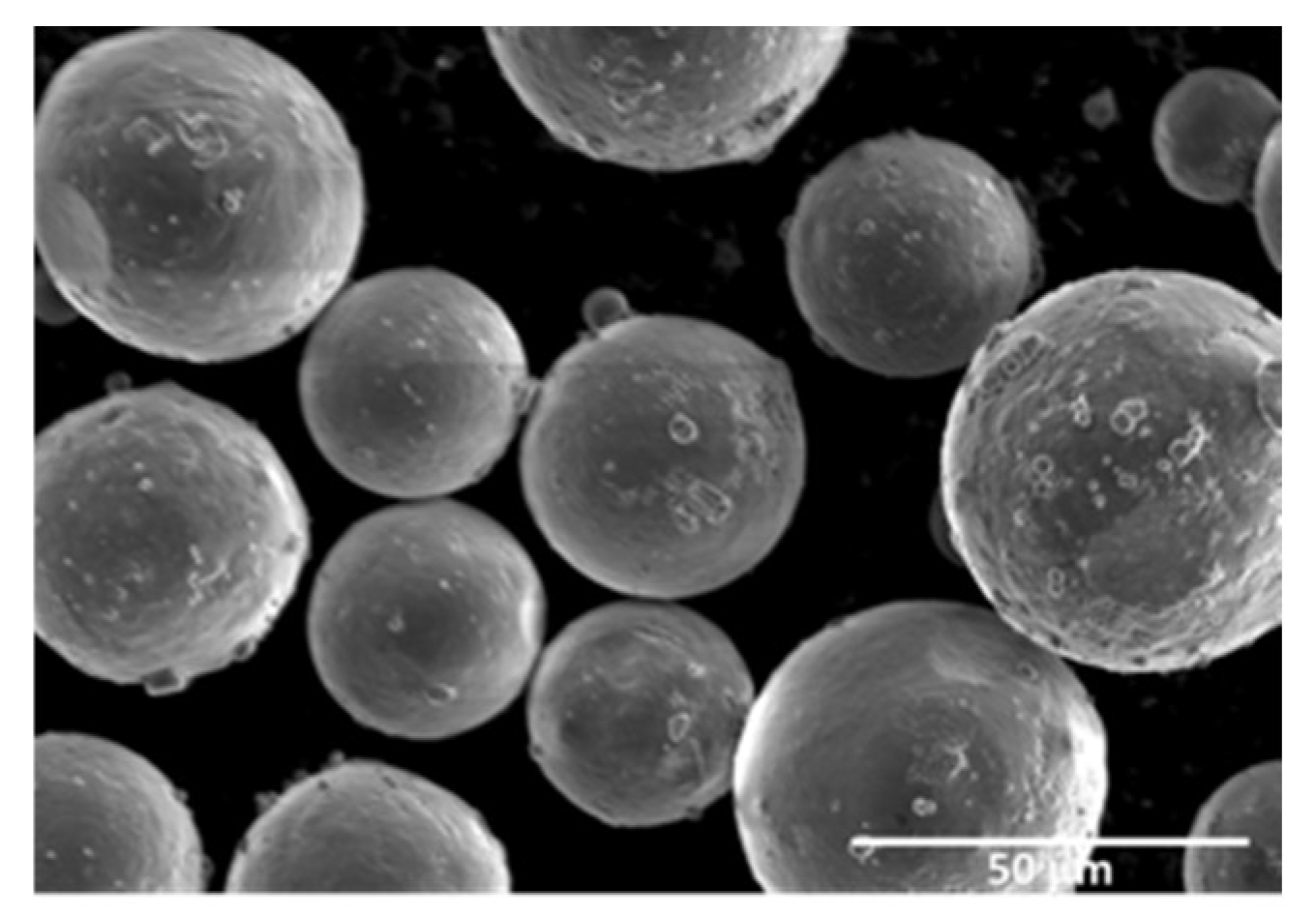

2.1. Powder Selection

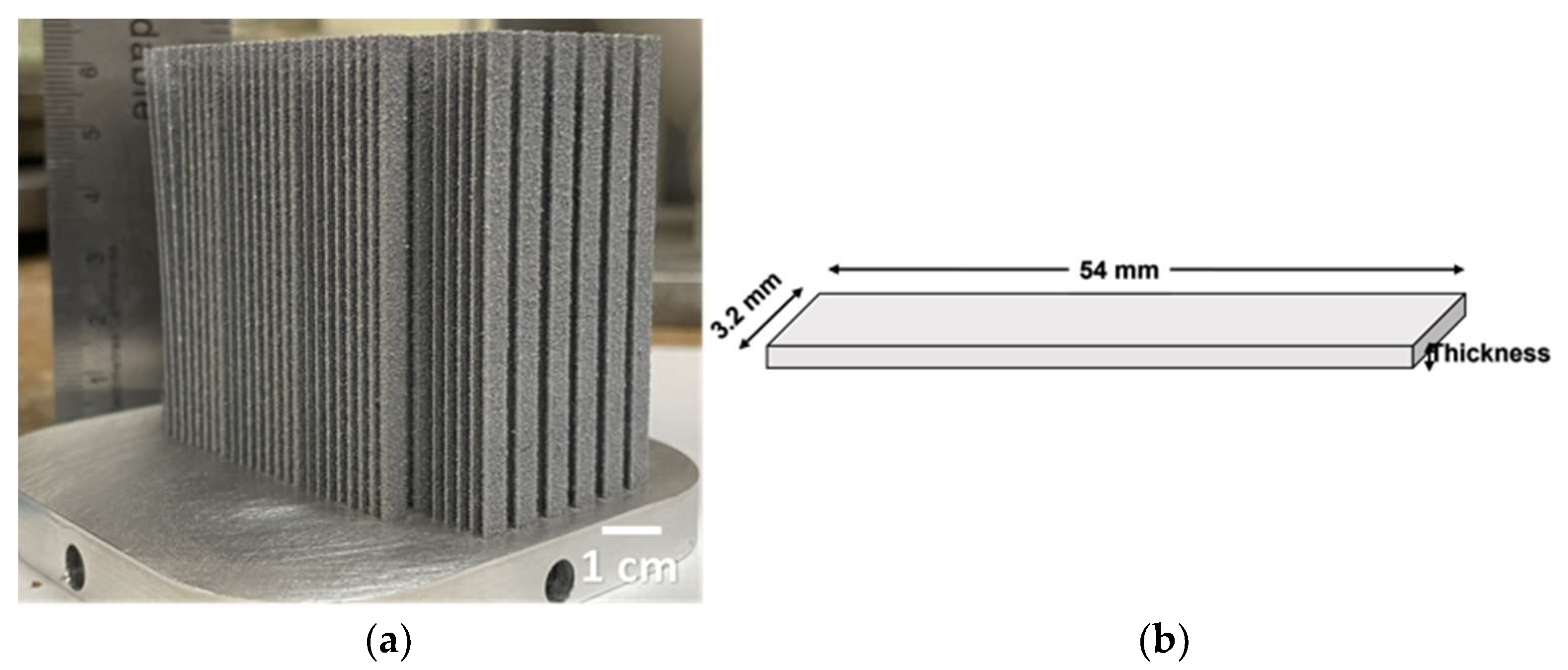

2.2. Sample Fabrication

2.3. Heat Treatment

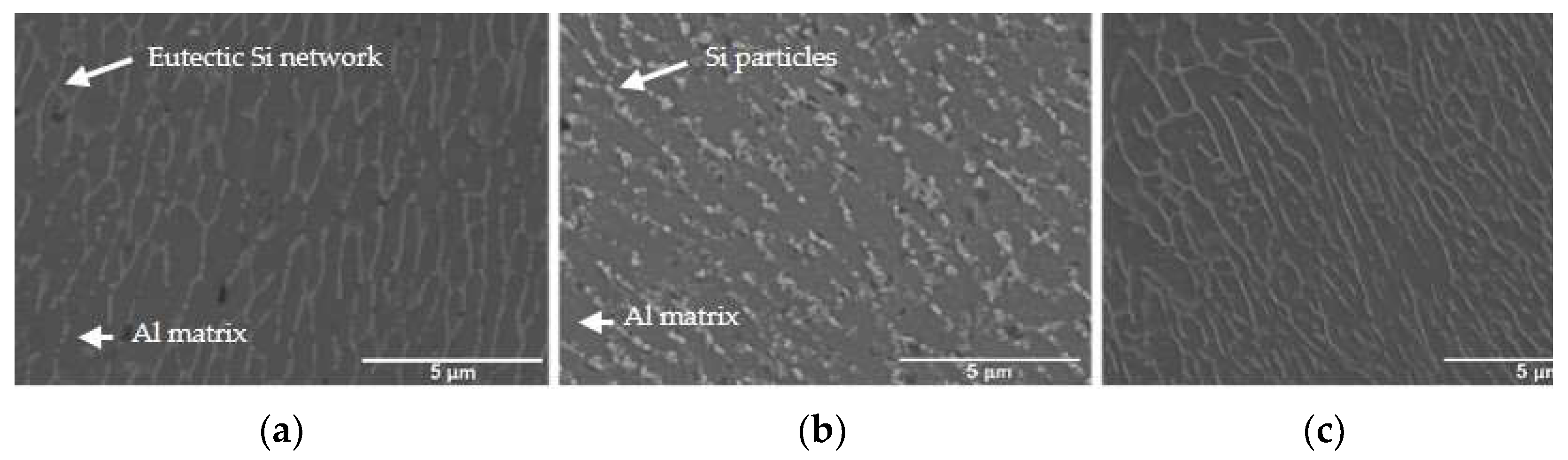

2.4. Microscopy

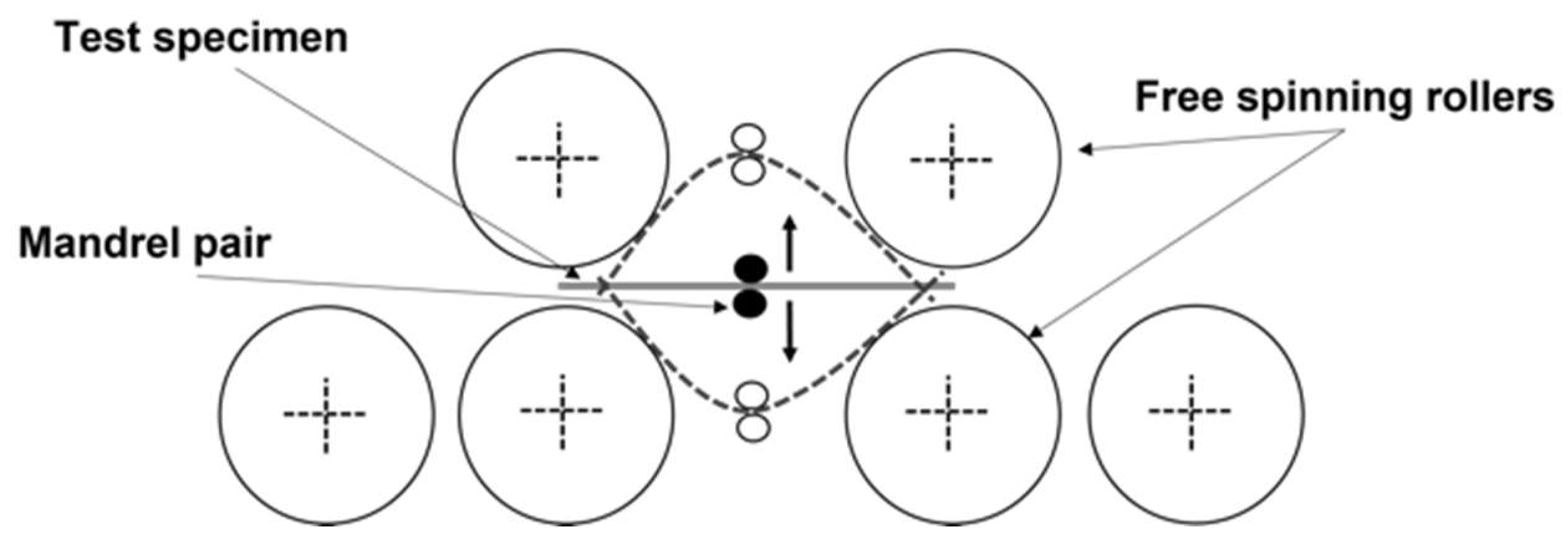

2.5. Alternate Cyclic Bend Fatigue Tester

3. Results & Discussion

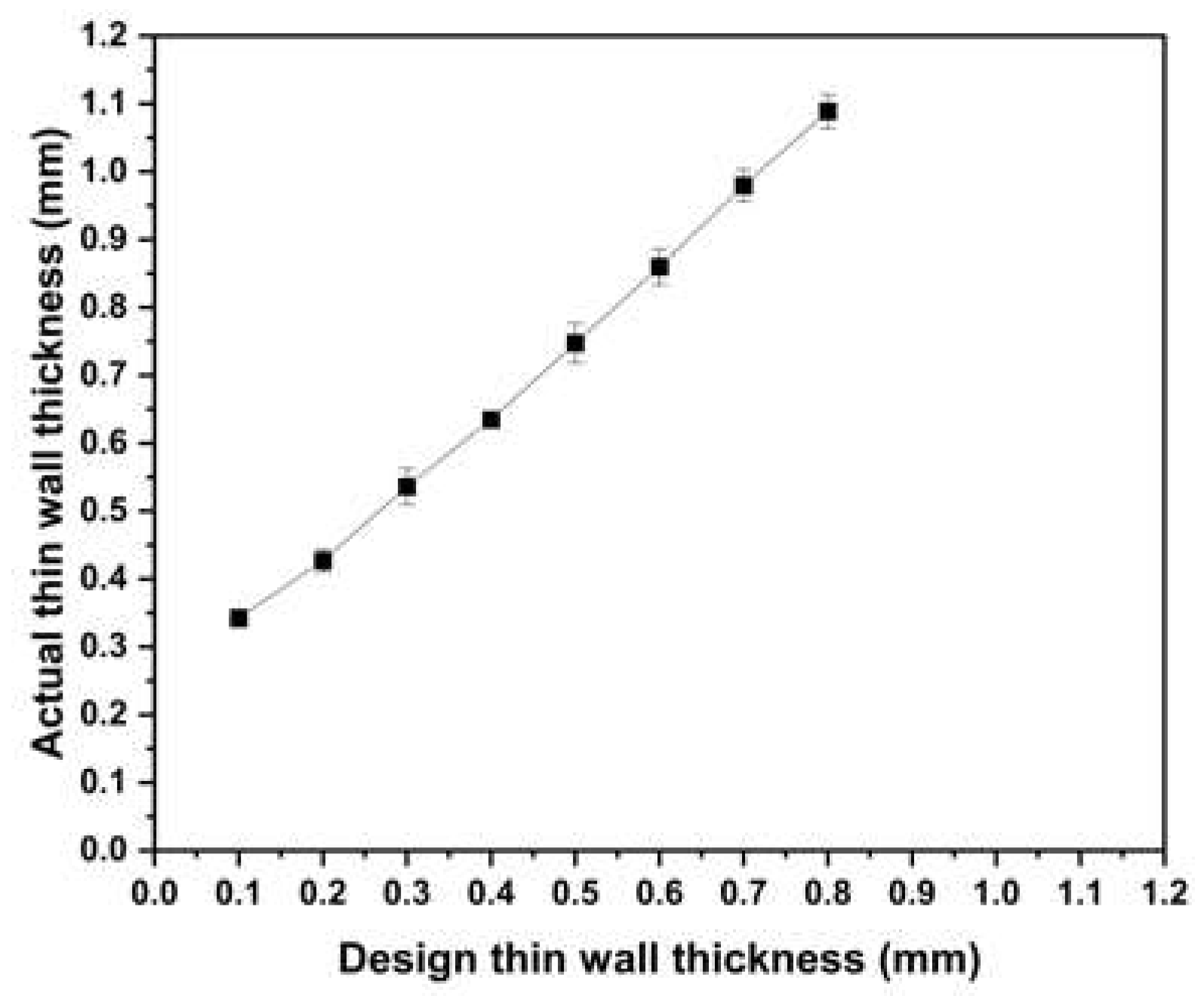

3.1. Thin Wall GD&T

3.2. Optical Density and Microstructure

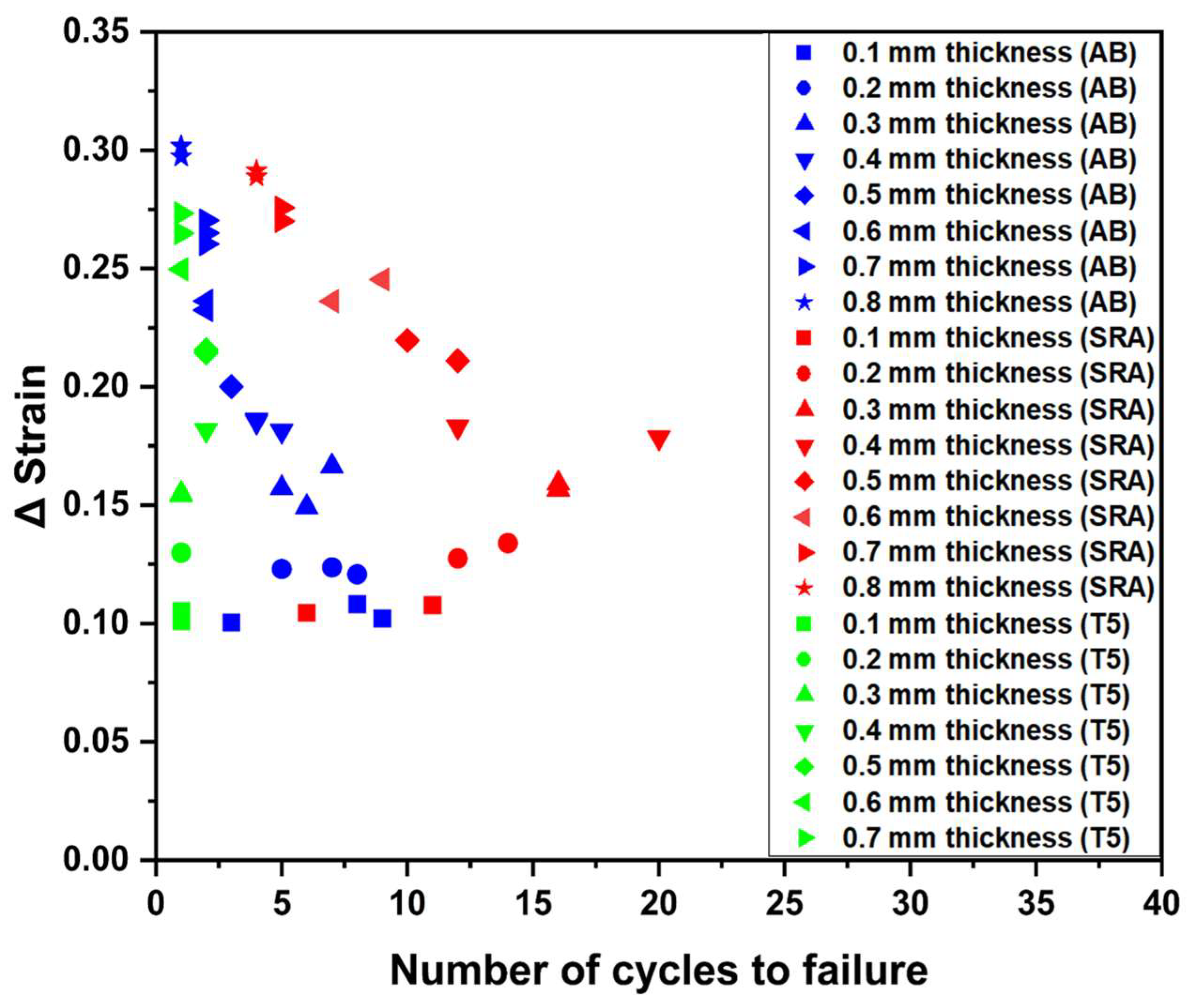

3.3. Alternate Cyclic Bending Fatigue Test in ELCF Regime

4. Conclusions

- The alternate cyclic bend fatigue test for thin wall specimens fabricated from LPBF AlSi7Mg alloy specimens was developed and examined.

- For AB and SRA conditions tested in an alternate cyclic bend fatigue tester, as the delta strain decreases with a decrease in thin wall thickness, the number of cycles to failure increases.

- Thin wall fatigue specimens tested with SRA condition take a greater number of cycles to failure and show better cyclic bending fatigue behavior compared to those in AB and T5 conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Siddique, S.; Imran, M.; Rauer, M.; Kaloudis, M.; Wycisk, E.; Emmelmann, C.; Walther, F. Computed tomography for characterization of fatigue performance of selective laser melted parts. Mater. Des. 2015, 83, 661–669. [Google Scholar] [CrossRef]

- Siddique, S.; Awd, M.; Tenkamp, J.; Walther, F. High and very high cycle fatigue failure mechanisms in selective laser melted aluminum alloys. J. Mater. Res. 2017, 32, 4296–4304. [Google Scholar] [CrossRef]

- Khoda, B.; Ahsan, A.M.M.N.; Shovon, A.N.; Alam, A.I. 3D metal lattice structure manufacturing with continuous rods. Sci. Rep. 2021, 11, 434. [Google Scholar] [CrossRef] [PubMed]

- Alexopoulos, N.D.; Pantelakis, S.G. Quality evaluation of A357 cast aluminum alloy specimens subjected to different artificial aging treatment. Mater. Des. 2004, 25, 419–430. [Google Scholar] [CrossRef]

- Kimura, T.; Nakamoto, T. Microstructures and mechanical properties of A356 (AlSi7Mg0.3) aluminum alloy fabricated by selective laser melting. Mater. Des. 2016, 89, 1294–1301. [Google Scholar] [CrossRef]

- Miranda, G.; Faria, S.; Bartolomeu, F.; Pinto, E.; Alves, N.; Peixinho, N.; Gasik, M.; Silva, F. A study on the production of thin-walled Ti6Al4V parts by selective laser melting. J. Manuf. Process. 2019, 39, 346–355. [Google Scholar] [CrossRef]

- Morciano, M.; Alberghini, M.; Fasano, M.; Almiento, M.; Calignano, F.; Manfredi, D.; Asinari, P.; Chiavazzo, E. 3D printed lattice metal structures for enhanced heat transfer in latent heat storage systems. J. Energy Storage 2023, 65, 107350. [Google Scholar] [CrossRef]

- Zhang, Y.; Majeed, A.; Muzamil, M.; Lv, J.; Peng, T.; Patel, V. Investigation for macro mechanical behavior explicitly for thin-walled parts of AlSi10Mg alloy using selective laser melting technique. J. Manuf. Process. 2021, 66, 269–280. [Google Scholar] [CrossRef]

- Majeed, A.; Muzamil, M.; Khan, M.A.; Malik, E.H.; Huzaifa, M.; Lv, J.; Dar, N.U. Comprehensive Mechanical Behavior of Thin-Walled Additively-Manufactured Parts of AlSi10Mg by SLM in As-Built, Post-Solution, and Aging Treatment Conditions. JOM 2023, 75, 3067–3082. [Google Scholar] [CrossRef]

- Kim, Y.; Hwang, W. High-Cycle, Low-Cycle, Extremely Low-Cycle Fatigue and Monotonic Fracture Behaviors of Low-Carbon Steel and Its Welded Joint. Materials 2019, 12, 4111. [Google Scholar] [CrossRef] [PubMed]

- Kanvinde, A.M.; Deierlein, G.G. Cyclic Void Growth Model to Assess Ductile Fracture initiation in structural steels due to ultra low cycle fatigue. J. Eng. Mech. 2007, 133, 6. [Google Scholar] [CrossRef]

- Yonekura, D.; Arai, Y.; Komotori, J.; Shimizu, M. Fracture Mechanism of Ferritic Ductile Cast Iron in Extremely Low Cycle Fatigue. Trans. Jpn. Soc. Mech. Eng. Ser. A 1999, 65, 821–826. [Google Scholar] [CrossRef]

- Wang, M.; Song, B.; Wei, Q.; Zhang, Y.; Shi, Y. Effects of annealing on the microstructure and mechanical properties of selective laser melted AlSi7Mg alloy. Mater. Sci. Eng. A 2019, 739, 463–472. [Google Scholar] [CrossRef]

- Cheng, C.C.; Li, Z.; Dhillon, J.S.; Hudon, P.; Brochu, M. Influence of powder layer thickness on microstructure and T5 heat treatability of F357 alloy fabricated by laser powder bed fusion process. J. Alloys Compd. 2023, 948, 169633. [Google Scholar] [CrossRef]

- ASTM E796-94; Standard Test Method for Ductility Testing Ofmetallic Foil, (reapproved 2000). ASTM International: West Conshohocken, PA, USA, 2000; pp. 1–4.

- Lam, T.-N.; Lee, A.; Chiu, Y.-R.; Kuo, H.-F.; Kawasaki, T.; Harjo, S.; Jain, J.; Lee, S.Y.; Huang, E.-W. Estimating fine melt pool, coarse melt pool, and heat affected zone effects on the strengths of additive manufactured AlSi10Mg alloys. Mater. Sci. Eng. A 2022, 856, 143961. [Google Scholar] [CrossRef]

- Grimm, T.; Wiora, G.; Witt, G. Characterization of typical surface effects in additive manufacturing with confocal microscopy. Surf. Topogr. Metrol. Prop. 2015, 3, 014001. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, C.C.; Dhillon, J.S.; Kwon, S.Y.; Hudon, P.; Brochu, M. Precipitation behavior of an Al7SiMg alloy processed by laser powder bed fusion during non-isothermal and isothermal heat treatments. Materialia 2023, 28, 101751. [Google Scholar] [CrossRef]

- Alghamdi, F.; Song, X.; Hadadzadeh, A.; Shalchi-Amirkhiz, B.; Mohammadi, M.; Haghshenas, M. Post heat treatment of additive manufactured AlSi10Mg: On silicon morphology, texture and small-scale properties. Mater. Sci. Eng. A 2020, 783, 139296. [Google Scholar] [CrossRef]

| Element | Si | Mg | Fe | Cu | Mn | Ti | Zn | Others | Al |

|---|---|---|---|---|---|---|---|---|---|

| Wt% | 6.7 | 0.5 | 0.06 | <0.001 | 0.006 | 0.1 | 0.01 | <0.0001 | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, M.; Garcia, R.M.; Prasad, S.; Brochu, M. Evaluation of Small-Scale Thin Wall AlSi7Mg Alloys LPBF Coupons under Extreme Low Cycle Fatigue Regime. Eng. Proc. 2023, 43, 41. https://doi.org/10.3390/engproc2023043041

Kumar M, Garcia RM, Prasad S, Brochu M. Evaluation of Small-Scale Thin Wall AlSi7Mg Alloys LPBF Coupons under Extreme Low Cycle Fatigue Regime. Engineering Proceedings. 2023; 43(1):41. https://doi.org/10.3390/engproc2023043041

Chicago/Turabian StyleKumar, Muralidharan, Rafael Mata Garcia, Srikanta Prasad, and Mathieu Brochu. 2023. "Evaluation of Small-Scale Thin Wall AlSi7Mg Alloys LPBF Coupons under Extreme Low Cycle Fatigue Regime" Engineering Proceedings 43, no. 1: 41. https://doi.org/10.3390/engproc2023043041

APA StyleKumar, M., Garcia, R. M., Prasad, S., & Brochu, M. (2023). Evaluation of Small-Scale Thin Wall AlSi7Mg Alloys LPBF Coupons under Extreme Low Cycle Fatigue Regime. Engineering Proceedings, 43(1), 41. https://doi.org/10.3390/engproc2023043041