Linear and Non-Linear Regression Analysis on the Prediction of Compressive Strength of Sodium Hydroxide Pre-Treated Crumb Rubber Concrete †

Abstract

:1. Introduction

2. Research Procedure

2.1. Dataset Development

2.2. Error Evaluation

3. Results

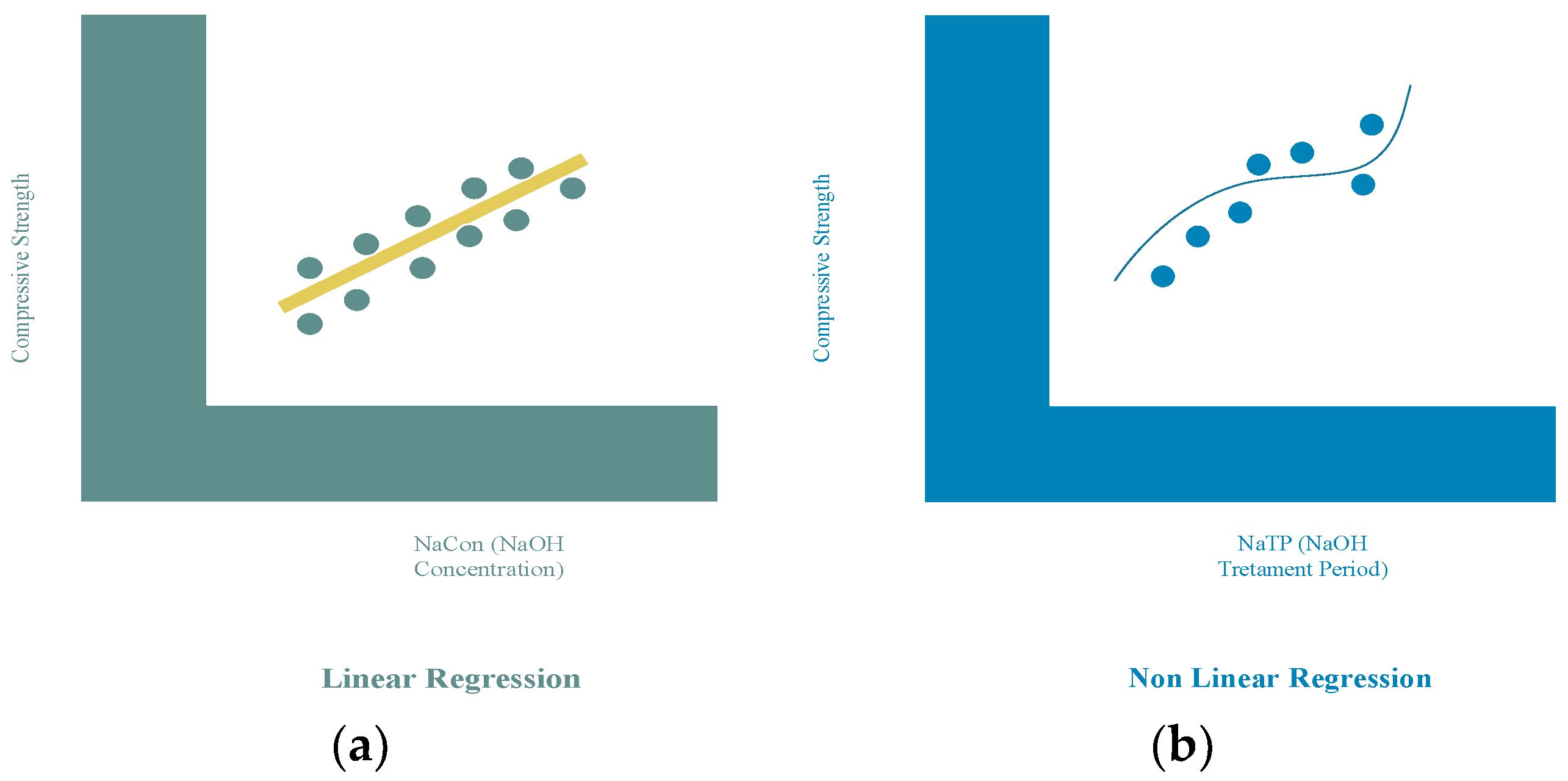

3.1. MLR Model

3.2. MNLR Model

4. Conclusions

- Several evaluation criteria are used for checking the accuracy of the models, including R2, MAE, and RMSE. The MNLR performs the best compared to MLR;

- MLNR obtains the value of 0.8791, 4.642, and 6.15 for R2, MAE, and RMSE, respectively;

- The determined sequence with respect to accuracy in this research is MNLR > MLR;

- Using a comprehensive set of variables for concrete mixture design, including alternative waste materials, was found to be feasible for predicting the strength of sustainable concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; De-Prado-Gil, J.; Qaidi, S.M.A.; Brahmia, A. RETRACTED ARTICLE: Effects of waste glass and waste marble on mechanical and durability performance of concrete. Sci. Rep. 2021, 11, 21525. [Google Scholar] [CrossRef] [PubMed]

- Kirthika, S.K.; Singh, S.; Chourasia, A. Alternative fine aggregates in production of sustainable concrete—A review. J. Clean. Prod. 2020, 268, 122089. [Google Scholar] [CrossRef]

- Ren, F.; Mo, J.; Wang, Q.; Ho, J.C.M. Crumb rubber as partial replacement for fine aggregate in concrete: An overview. Constr. Build. Mater. 2022, 343, 128049. [Google Scholar] [CrossRef]

- Qaidi, S.; Al-Kamaki, Y.S.S.; Al-Mahaidi, R.; Mohammed, A.S.; Ahmed, H.U.; Zaid, O.; Althoey, F.; Ahmad, J.; Isleem, H.F.; Bennetts, I. Investigation of the effectiveness of CFRP strengthening of concrete made with recycled waste PET fine plastic aggregate. PLoS ONE 2022, 17, 0269664. [Google Scholar] [CrossRef] [PubMed]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Ho, H.-J.; Iizuka, A.; Shibata, E. Chemical recycling and use of various types of concrete waste: A review. J. Clean. Prod. 2021, 284, 124785. [Google Scholar] [CrossRef]

- Sankar, B.; Ramadoss, P. Modelling the compressive strength of high-performance concrete containing metakaolin using distinctive statistical techniques. Results Control. Optim. 2023, 12, 100241. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Abdalla, A.A.; Mohammed, A.S.; Mohammed, A.A.; Mosavi, A. Statistical Methods for Modeling the Compressive Strength of Geopolymer Mortar. Materials 2022, 15, 1868. [Google Scholar] [CrossRef] [PubMed]

- Saloni; Parveen; Pham, T.M.; Lim, Y.Y.; Malekzadeh, M. Effect of pre-treatment methods of crumb rubber on strength, permeability and acid attack resistance of rubberised geopolymer concrete. J. Build. Eng. 2021, 41, 102448. [Google Scholar] [CrossRef]

- Jokar, F.; Khorram, M.; Karimi, G.; Hataf, N. Experimental investigation of mechanical properties of crumbed rubber concrete containing natural zeolite. Constr. Build. Mater. 2019, 208, 651–658. [Google Scholar] [CrossRef]

- Awan, H.H.; Javed, M.F.; Yousaf, A.; Aslam, F.; Alabduljabbar, H.; Mosavi, A. Experimental Evaluation of Untreated and Pretreated Crumb Rubber Used in Concrete. Crystals 2021, 11, 558. [Google Scholar] [CrossRef]

- Mohammadi, I.; Khabbaz, H.; Vessalas, K. Enhancing mechanical performance of rubberised concrete pavements with sodium hydroxide treatment. Mater. Struct. 2016, 49, 813–827. [Google Scholar] [CrossRef]

- Safan, M.; Eid, F.M.; Awad, M. Enhanced properties of crumb rubber and its application in rubberized concrete. Int. J. Curr. Eng. Technol. 2017, 7, 1784–1790. [Google Scholar]

- Youssf, O.; Mills, J.E.; Hassanli, R. Assessment of the mechanical performance of crumb rubber concrete. Constr. Build. Mater. 2016, 125, 175–183. [Google Scholar] [CrossRef]

- Youssf, O.; ElGawady, M.A.; Mills, J.E.; Ma, X. An experimental investigation of crumb rubber concrete confined by fibre reinforced polymer tubes. Constr. Build. Mater. 2014, 53, 522–532. [Google Scholar] [CrossRef]

- Li, D.; Zhuge, Y.; Gravina, R.; Benn, T.; Mills, J.E. Creep and drying shrinkage behaviour of crumb rubber concrete (CRC). Aust. J. Civ. Eng. 2020, 18, 187–204. [Google Scholar] [CrossRef]

- Youssf, O.; Mills, J.E.; Benn, T.; Zhuge, Y.; Ma, X.; Roychand, R.; Gravina, R. Development of Crumb Rubber Concrete for Practical Application in the Residential Construction Sector—Design and Processing. Constr. Build. Mater. 2020, 260, 119813. [Google Scholar] [CrossRef]

| Parameters | NaTP | NaCon | %CR | w/c | Cement | Water | Sand | Gravel | CS |

|---|---|---|---|---|---|---|---|---|---|

| Mean | 7.40 | 8.07 | 10.00 | 0.45 | 377.55 | 173.92 | 699.46 | 607.81 | 36.41 |

| Standard Error | 1.01 | 0.81 | 0.75 | 0.01 | 8.59 | 4.45 | 20.94 | 36.28 | 1.21 |

| Median | 0.50 | 10.00 | 10.00 | 0.48 | 396.00 | 175.00 | 685.00 | 416.00 | 36.72 |

| Mode | 0.00 | 10.00 | 0.00 | 0.50 | 400.00 | 175.00 | 990.00 | 311.00 | 35.00 |

| Standard Deviation | 10.81 | 8.64 | 8.08 | 0.06 | 92.11 | 47.74 | 224.58 | 389.09 | 12.96 |

| Sample Variance | 116.85 | 74.59 | 65.25 | 0.00 | 8483.41 | 2279.06 | 50,437.86 | 151,393.70 | 167.99 |

| Kurtosis | −1.20 | 4.85 | −0.84 | −0.25 | 8.03 | 5.01 | 2.42 | −1.52 | −0.18 |

| Skewness | 0.90 | 1.77 | 0.27 | −0.36 | −2.35 | −1.23 | −0.24 | 0.15 | −0.29 |

| Range | 24.00 | 50.00 | 30.00 | 0.25 | 481.20 | 284.60 | 1333.20 | 1257.00 | 61.30 |

| Minimum | 0.00 | 0.00 | 0.00 | 0.35 | 18.80 | 9.20 | 41.80 | 0.00 | 1.70 |

| Maximum | 24.00 | 50.00 | 30.00 | 0.60 | 500.00 | 293.80 | 1375.00 | 1257.00 | 63.00 |

| Sum | 851.34 | 928.00 | 1150.00 | 52.29 | 43,418.00 | 20,001.09 | 80,438.20 | 69,898.40 | 4187.19 |

| Count | 115.00 | 115.00 | 115.00 | 115.00 | 115.00 | 115.00 | 115.00 | 115.00 | 115.00 |

| Model | R2 | MAE | RMSE |

|---|---|---|---|

| MLR | 0.8177 | 5.855 | 7.43 |

| MNLR | 0.8791 | 4.642 | 6.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aamir, H.; Aamir, K.; Javed, M.F. Linear and Non-Linear Regression Analysis on the Prediction of Compressive Strength of Sodium Hydroxide Pre-Treated Crumb Rubber Concrete. Eng. Proc. 2023, 44, 5. https://doi.org/10.3390/engproc2023044005

Aamir H, Aamir K, Javed MF. Linear and Non-Linear Regression Analysis on the Prediction of Compressive Strength of Sodium Hydroxide Pre-Treated Crumb Rubber Concrete. Engineering Proceedings. 2023; 44(1):5. https://doi.org/10.3390/engproc2023044005

Chicago/Turabian StyleAamir, Hamza, Kinza Aamir, and Muhammad Faisal Javed. 2023. "Linear and Non-Linear Regression Analysis on the Prediction of Compressive Strength of Sodium Hydroxide Pre-Treated Crumb Rubber Concrete" Engineering Proceedings 44, no. 1: 5. https://doi.org/10.3390/engproc2023044005

APA StyleAamir, H., Aamir, K., & Javed, M. F. (2023). Linear and Non-Linear Regression Analysis on the Prediction of Compressive Strength of Sodium Hydroxide Pre-Treated Crumb Rubber Concrete. Engineering Proceedings, 44(1), 5. https://doi.org/10.3390/engproc2023044005