Abstract

Freshwater scarcity is a growing concern worldwide due to increasing demand and climate change. A promising method that could provide fresh water is seawater desalination. Presently, both thermal- and membrane-based desalination technologies consume a high amount of specific energy (measured in kWh/m3), which limits the use of seawater for drinking purposes. The development of hybrid desalination technologies has the potential to significantly reduce the energy consumption and cost of desalination, making it a more viable solution to address freshwater scarcity. By integrating the advantages of several desalination techniques and eliminating their drawbacks, hybridization can improve system performance. In the current study, a hybrid desalination system was developed by integrating the vacuum membrane distillation (VMD) output into the multi-effect distillation (MED) input. The results indicated a drop in specific thermal energy consumption (STEC) at various feed flow rates and a decrease in STEC in hybrid mode compared to stand-alone VMD.

1. Introduction

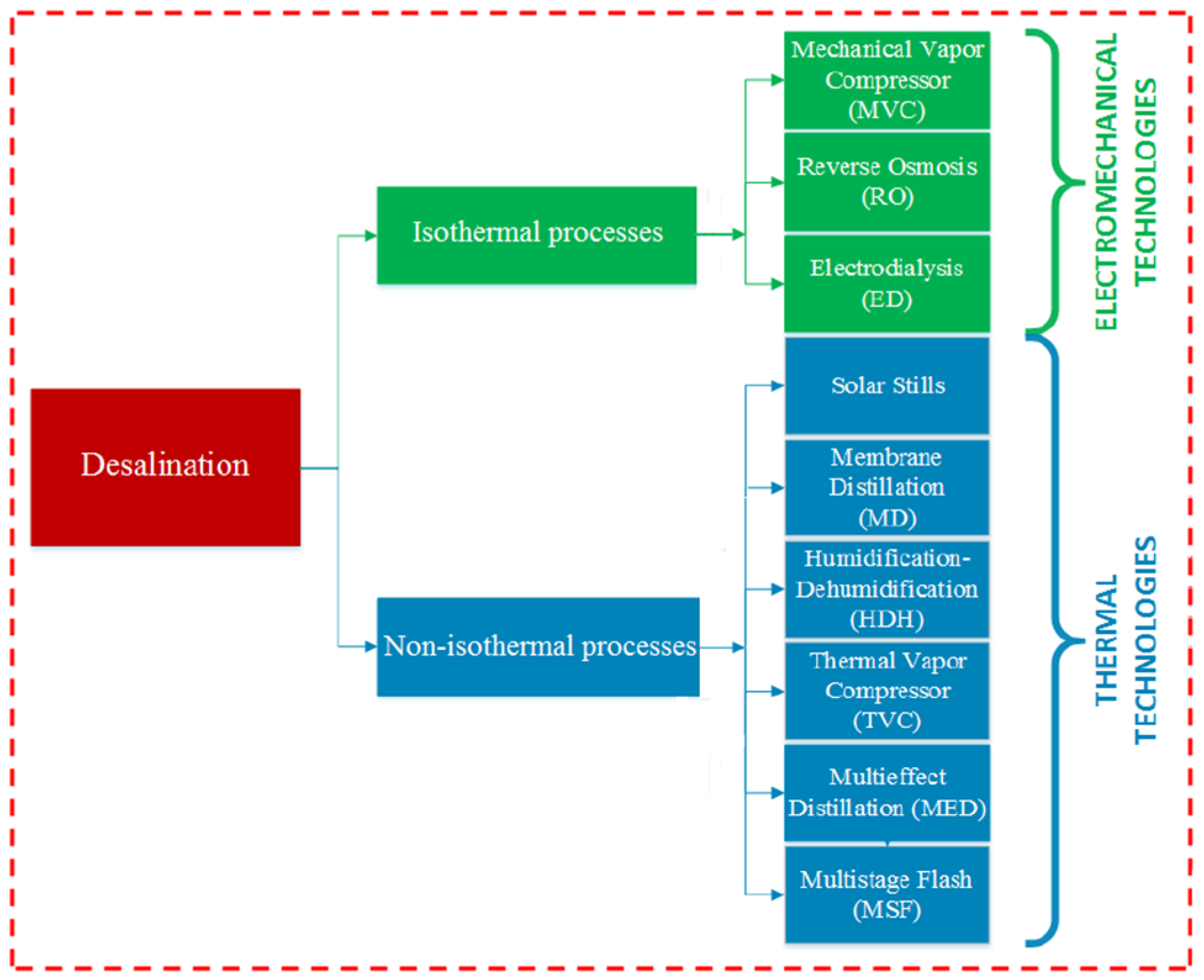

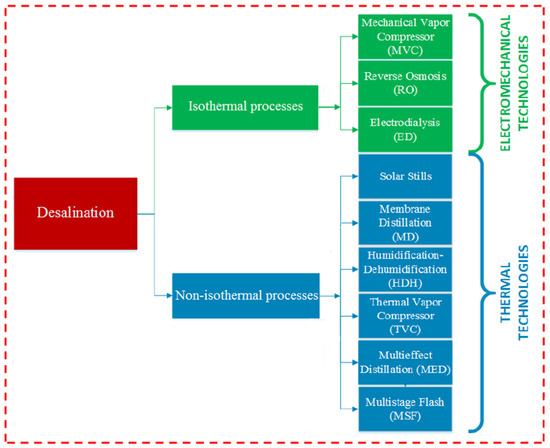

Heat transfer is typically involved in distillation, a thermal process based on natural distillation processes. The major thermal technologies for water desalination are multi-effect distillation (MED) and multi-stage flash (MSF), while membrane processes rely on electricity and membrane filtration. This process-based classification of water desalination is shown in Figure 1 [1]. Each desalination technology offers distinct benefits and drawbacks. Vacuum membrane distillation (VMD) is notable for its operation at lower inlet feed temperatures and smaller hydrostatic pressure [2], allowing it to utilize low-grade waste heat sources like geothermal energy, solar energy, and waste heat from power plants. This attribute gives VMD an advantage over other techniques. Additionally, VMD exhibits relatively higher permeate flux compared to other membrane distillation (MD) technologies, which is attributed to its superior thermal efficiency, making it highly suitable for various MD applications [3]. Despite these advantages, VMD faces challenges, particularly in terms of high specific heat consumption (SHC), which significantly affects its commercialization [4].

Figure 1.

Classification of water desalination based on the type of process.

To address these challenges, researchers have begun exploring hybrid systems to enhance system performance and overcome these drawbacks. Due to the numerous benefits of hybrid systems, they have gained significant attention as a potential solution to current challenges in sustainable desalination. By combining the advantages of multiple desalination techniques while mitigating their drawbacks, hybridization holds the potential to enhance system performance. The literature demonstrates a promising future, with various reports highlighting the use of different hybrid desalination systems [5]. Conventional hybrid plants that integrate thermal technologies, such as multi-stage flash (MSF) or multi-effect evaporation (MEE) with reverse osmosis (RO), have already been implemented and are widely adopted. However, upon studying the existing literature on hybrid systems, it becomes apparent that no research has specifically examined the hybridization of VMD and MED systems, particularly regarding the specific thermal energy consumption for VMD/MED (without heat recovery) and VMD-HR/MED (with heat recovery) systems at different inlet feed temperatures. The impact of inlet feed temperature was investigated at a practical range of operation (60–70 °C), as mentioned in the majority of the literature.

Thus, the main objective of this research work is to present a novel hybrid distillation model and to study the specific energy consumption of these hybrid systems. By integrating VMD with MED, there has been a significant reduction in specific thermal energy consumption. The findings of this research contribute to a deeper understanding of hybrid systems and their potential for energy efficiency improvements.

2. Modelling Procedure

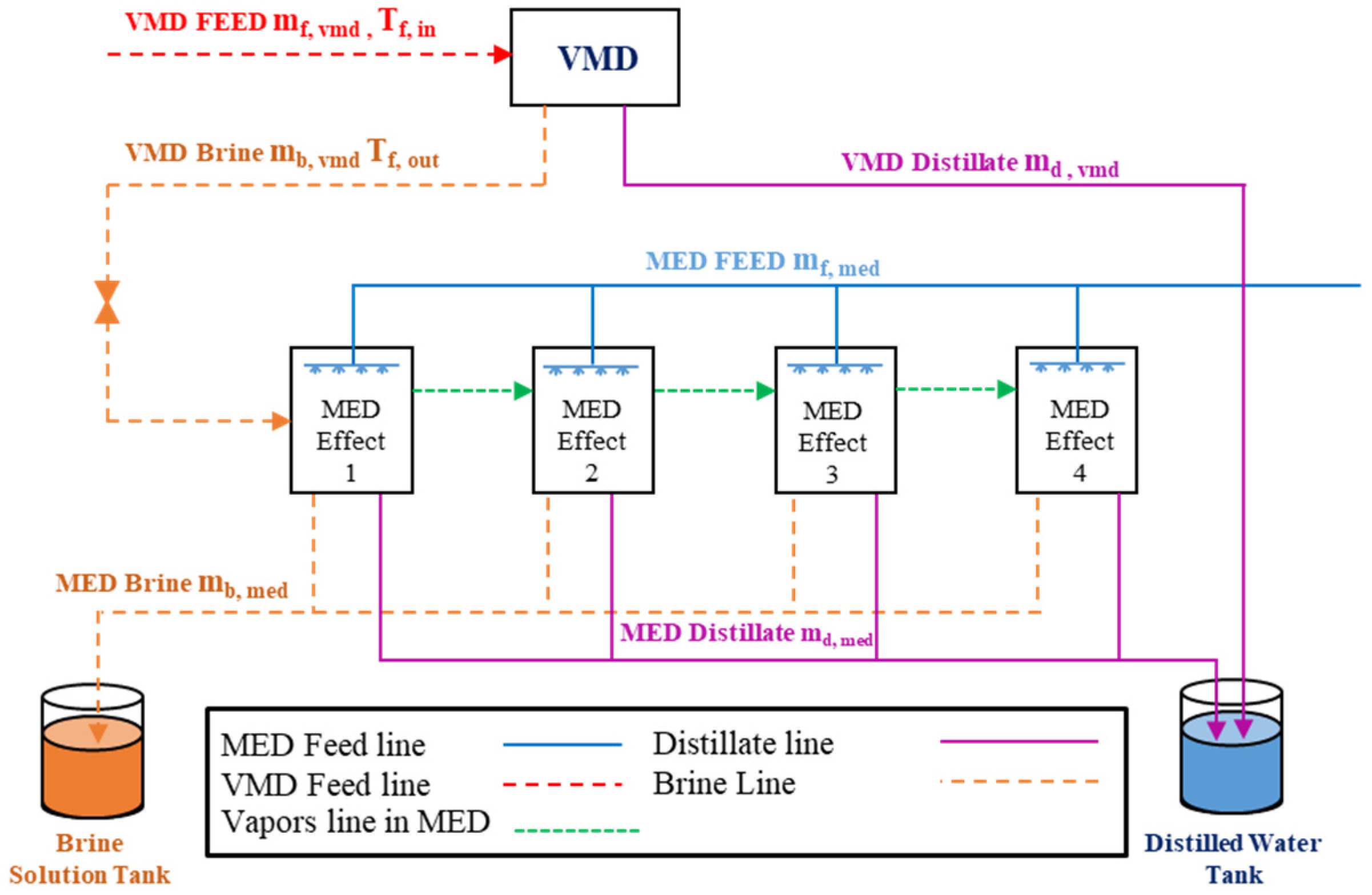

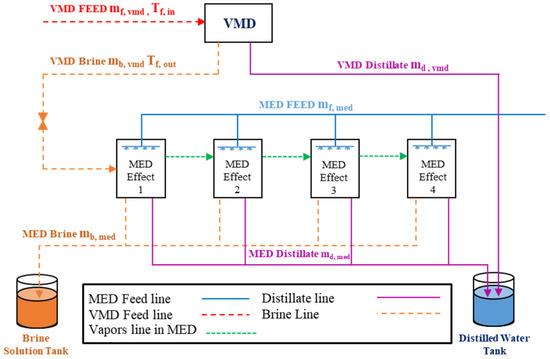

To minimize the energy consumption of desalination technologies, the integration of VMD with MED has been proposed. In this model, the brine output from VMD, which carries a significant amount of heat potential, is utilized as a heat source in the first effect of MED. Subsequently, the vapor generated in each preceding effect is used as a heat source for the subsequent effects. The total distillate is the combined distillate from both VMD and MED , collected in the distilled water tank, as depicted in Figure 2. The reject of the VMD is fed into the four effects of MED. The total distillate flux is collected in the tank. To determine the most efficient hybrid system, key performance indicators, such as specific thermal energy consumption, were calculated for each individual system, as well as for the hybrid system, aiming to achieve sustainable desalination.

Figure 2.

Block diagram of hybrid VMD/MED and VMD-HR/MED desalination system.

3. Results and Discussion

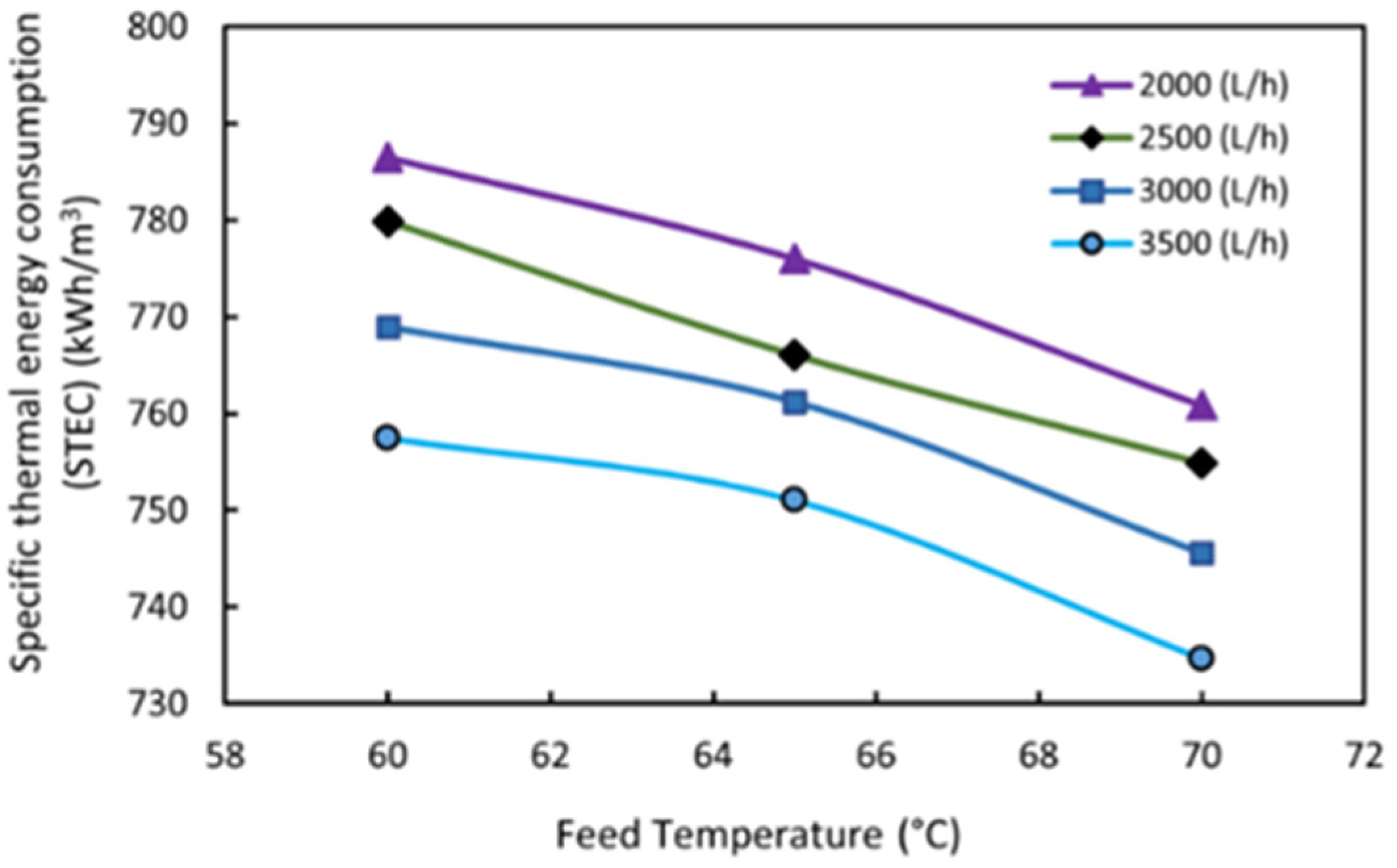

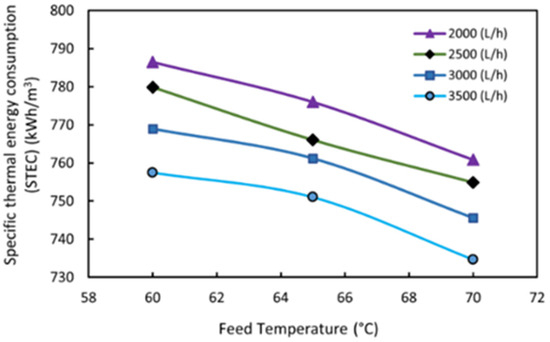

Figure 3 depicts the relationship between the increase in feed temperature and the corresponding reduction in specific thermal energy consumption in the case of VMD alone. This decrease can be attributed to the concurrent rise in the permeating flux of the membrane distillation (MD) process when higher feed temperatures are employed. Additionally, an increase in the feed flow rate results in a decrease in specific thermal energy consumption (STEC). Although there is a slight increase in the temperature drop across the membrane module as the feed temperature rises, it is considerably smaller compared to the significant enhancement in permeate flux. For example, at a feed flow rate of 3500 L/h, as the feed temperature increases from 65 to 70 °C, the specific thermal energy consumption decreases from 757.45 kWh/m3 to 734.63 kWh/m3.

Figure 3.

Impact of feed temperature and feed rate on specific thermal energy consumption of VMD alone.

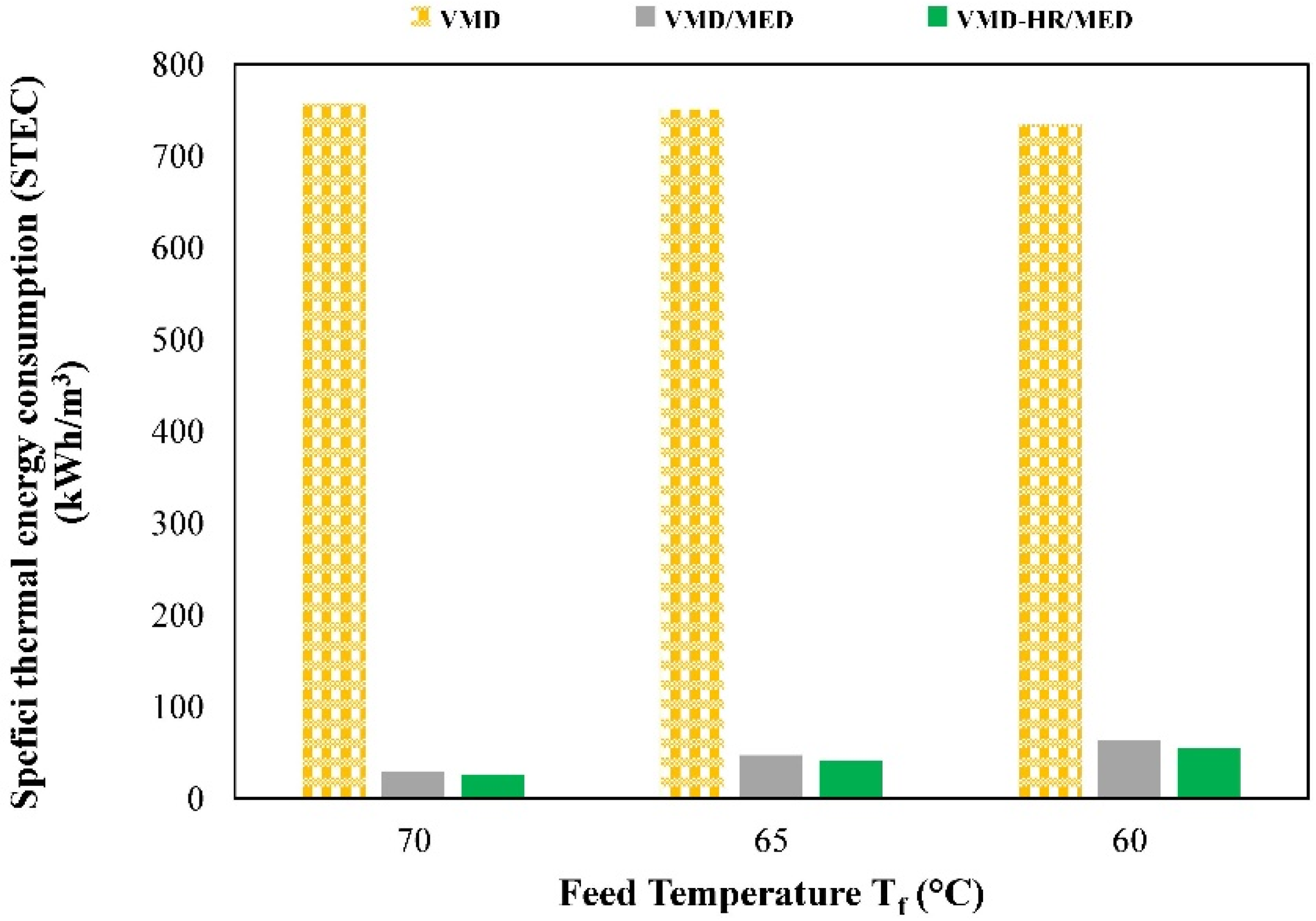

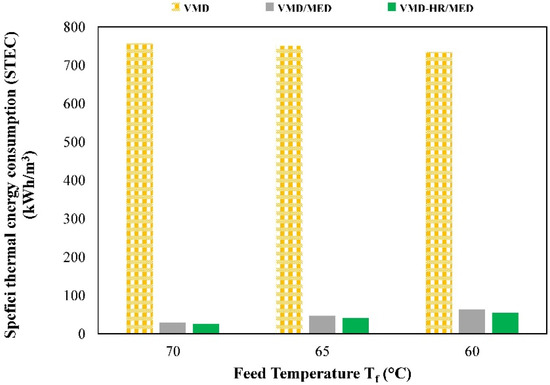

Figure 4 illustrates the variation in Specific Thermal Energy Consumption (STEC) for the hybrid VMD-MED (without heat recovery) and VMD-HR/MED (with heat recovery) systems at different feed temperatures. It is evident that standalone VMD systems consume a significantly higher amount of specific thermal energy compared to hybrid systems, with or without heat recovery. In the hybrid VMD-MED system, the sensible heat from the rejected brine of VMD is fully utilized in MED as a heat source, while the latent heat of vapor in the VMD condenser is used to preheat MED feed water. Consequently, the hybrid system achieves the maximum flux production, resulting in a decrease in specific thermal energy consumption compared to VMD and hybrid systems. By integrating VMD with MED, the specific thermal energy consumption is substantially reduced to 29.96 kWh/m3 for VMD/MED and 26.38 kWh/m3 for VMD-HR/MED, in contrast to the initial value of 757.45 kWh/m3 for VMD alone at a feed temperature of 60 °C. Similar analyses were conducted at inlet feed temperatures of 65 °C and 70 °C, consistently yielding positive results.

Figure 4.

Comparison of STEC for hybrid system with VMD alone at different inlet feed temperatures.

It is important to highlight that there is a correlation between the rising feed temperature and the increasing trend of specific thermal energy consumption. This is due to the fact that higher temperatures raise the transmembrane temperature, leading to a decrease in brine temperature. As a result, when all variables in Equation (3) are taken into consideration, it can be observed that there is an overall escalation in specific thermal energy consumption.

4. Conclusions

In the present study, we explored innovative hybrid desalination systems to evaluate the impact on specific thermal energy consumption (STEC) in comparison to the use of vacuum membrane distillation (VMD) alone. The findings suggest that the hybrid system demonstrates a decrease in STEC at higher feed temperatures and flow rates, which presents significant advantages. The development of this hybrid system contributes to enhancing overall performance by reducing STEC. These results underscore the potential of hybrid systems in achieving enhanced energy efficiency in desalination processes.

Author Contributions

F.I. and M.A. contributed equally to this work. All authors have read and agreed to the published version of the manuscript.

Funding

Higher Education Commission (HEC) Pakistan, NRPU #5550.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data supporting our reported results is available as specified in our article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Alam, W.; Asif, M.; Bibi, W.; Rabbi, J. Effect of Multi-staging in Vacuum Membrane Distillation on Productivity and Temperature Polarization. J. Membr. Sci. Res. 2022, 8, 534548. [Google Scholar] [CrossRef]

- Zuo, G.; Wang, R.; Field, R.; Fane, A.G. Energy efficiency evaluation and economic analyses of direct contact membrane distillation system using Aspen Plus. Desalination 2011, 283, 237–244. [Google Scholar] [CrossRef]

- Si, Z.; Han, D.; Gu, J.; Chen, J.; Zheng, M.; Song, Y.; Mao, N. Study on vacuum membrane distillation coupled with mechanical vapor recompression system for the concentration of sulfuric acid solution. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 473. [Google Scholar] [CrossRef]

- Kim, Y.-D.; Kim, W.-S. Experimental and Theoretical Investigations of a Novel Multi-Stage Direct Contact Membrane Distillation Module. In Proceedings of the 2nd World Congress on New Technologies (NewTech’16), Budapest, Hungary, 18–19 August 2016. [Google Scholar] [CrossRef]

- Ahmed, F.E.; Hashaikeh, R.; Hilal, N. Hybrid technologies: The future of energy efficient desalination—A review. Desalination 2020, 495, 114659. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).