Abstract

Paper-based microfluidics provides a versatile platform for numerous applications, including diagnostics at the point of care, environmental detection, and food quality control. Utilizing paper as a substrate offers numerous benefits, including flexibility, biodegradability, low cost, and capillary-driven flow. Despite significant advancements in paper-based microfluidic devices, regulating fluid flow effectively within the paper channel remains a persistent challenge. In order to resolve this problem, our research proposes a method for manipulating fluid flow in the paper channel by altering the surface contact between the storage medium and the paper channel. According to the results, increasing the contact area between the reservoir and the paper surface decreases the flow velocity and increases the fluidic time delay. This is due to the increased diffusion area between the storage medium and the paper channel, which creates resistance to liquid flow. Therefore, the liquid takes longer to travel through the paper channel, resulting in a decrease in velocity relative to contact areas of 50% or 70%. We are confident that this method of flow control can enable lateral flow sensing devices with enhanced flow variation options for use in medical, environmental, or food quality applications.

1. Introduction

Microfluidics is an interdisciplinary field concerned with the precise manipulation and control of microscopic fluid volumes [1]. It involves the study and development of devices and systems capable of managing microliter or nanoliter volumes of fluids [2]. Microfluidics enables a variety of applications, including chemical analysis, biomedical diagnostics, drug delivery, and DNA sequencing, by capitalizing on the unique properties of fluids at these scales. The ability of this technology to miniaturize and automate laboratory processes has revolutionized industries, providing benefits such as decreased sample and reagent consumption, quicker analysis times, and increased portability [3]. Microfluidics has enormous potential for advancing research, diagnostics, and technological advancements in a variety of fields. The field of microfluidics includes a subfield known as “paper-based microfluidics”, which employs paper or porous membranes to facilitate fluid transport via capillary action.

First, paper-based microfluidics can operate without pumps or additional apparatus, making them portable and self-contained. This feature facilitates preparation and simplifies the experimental or diagnostic procedure. In addition, these devices are less expensive than conventional microfluidic devices, making them accessible to a broader audience. Furthermore, the disposal of paper-based microfluidic devices is easier and more eco-friendly [4]. Another notable advantage of paper is the simplicity of production. The manufacturing process is relatively simple and can be accomplished using standard printing techniques or straightforward cutting and folding techniques. This accessibility permits rapid prototype development and scalability [5]. These point-of-care devices offer expeditious and dependable outcomes for a wide range of medical conditions, enabling timely interventions and ultimately improving patient outcomes [6].

The manipulation and regulation of fluid flow within paper substrates have been the subject of extensive research, employing diverse methodologies. For instance, in 2010, Fu et al. demonstrated a successful approach by modifying the dimensions of the filter paper, thereby influencing the fluid flow velocity through the material [7]. Similarly, Gao et al. explored the control of flowrate through the adoption of various paper cutting techniques [8], whereas Mendez et al. employed two-dimensional patterning on the paper surface to achieve flow control [9]. Another notable method involved wax treatment to alter surface wettability in paper, effectively retarding the flow of liquids [10]. These recent advancements in the realm of flow manipulation within paper-based microfluidic systems have found practical applications in diverse fields, including food safety.

However, despite the significant advancements that have been made in flow control techniques for paper microfluidics, there has been a discernible lack of investigation into the impact the reservoirs in paper fluidics. Hence, in this research, we present a new way to alter the flowrate in porous membranes (filter paper). We investigate fluid flow through a porous medium, especially concentrating on how modifying the contact between the storage reservoir and paper strip may affect the flowrate in the paper channel. This is carried out so that we can better understand how a fluid can flow through a porous medium. We hope this will contribute to the current body of knowledge and improve the adaptability of lateral flow strips for different biomedical and food quality applications.

2. Theoretical Background

The correlation between the travel distance (L) and time (t) for one-dimensional flow in paper, as outlined by the Lucas–Washburn equation, is illustrated by Equation (1) presented hereinafter. This equation posits that the distance traversed is directly proportional to [11].

This equation incorporates several variables such as contact angle (), time (t), the liquid’s surface tension (), dynamic viscosity (), and pore size (). Another famous model for porous media for the fully wetted condition is given by Darcy’s law [12].

where is the volumetric flowrate, is the cross-sectional area across flow direction, is the permeability, and represents the pressure differential across the system.

3. Materials and Methods

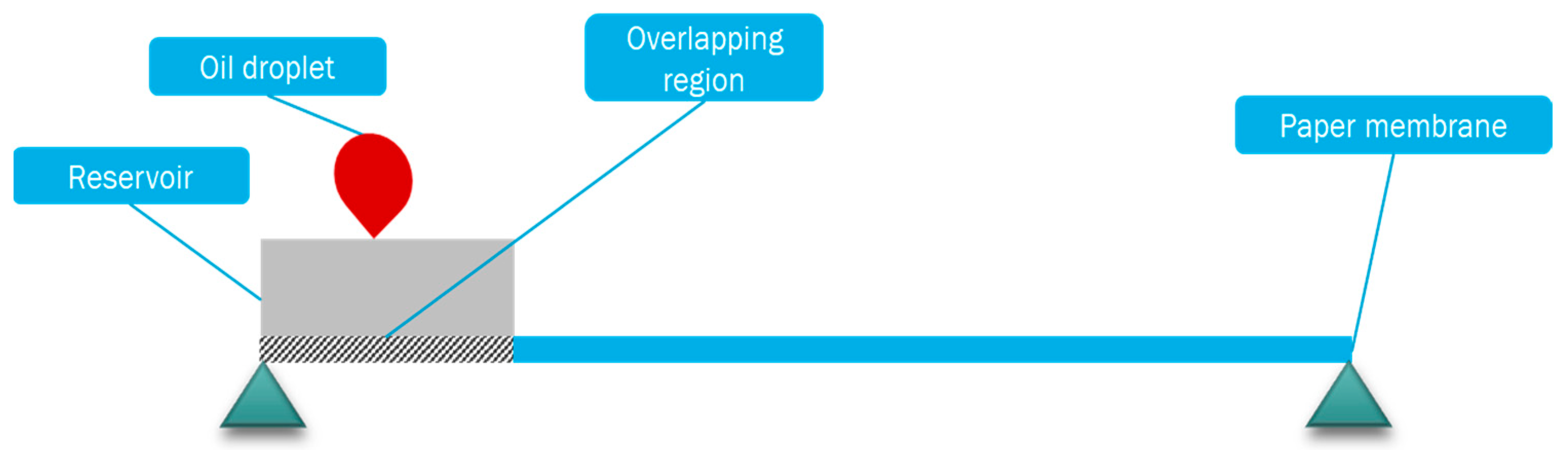

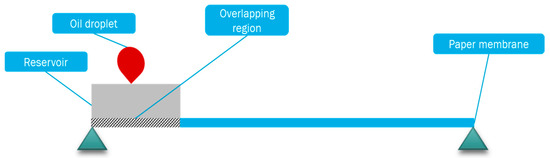

The materials utilized in the experiment consisted of Whatman filter paper No. 1 and an absorbing pad. The working fluid employed was octanoic acid. Figure 1 illustrates the experimental setup, featuring an infinite reservoir volume and adjustable contact between the absorbing pad (serving as the storage reservoir) and the paper strip. A paper channel was cut and connected to this reservoir, wherein the length of fluid travel needs to be measured. The length, width, and thickness of the paper strip were 50 mm, 17 mm, and 0.18 mm, respectively, and those of the absorbent pad were 10 mm, 17 mm, and 1 mm, respectively. The absorbent pad and the paper strip were cut with a CO2 laser. ImageJ was utilized for measuring the length of travel using image analysis.

Figure 1.

Experimental setup with reservoir and paper membrane connected for fluid flow with varying contact area.

4. Results and Discussion

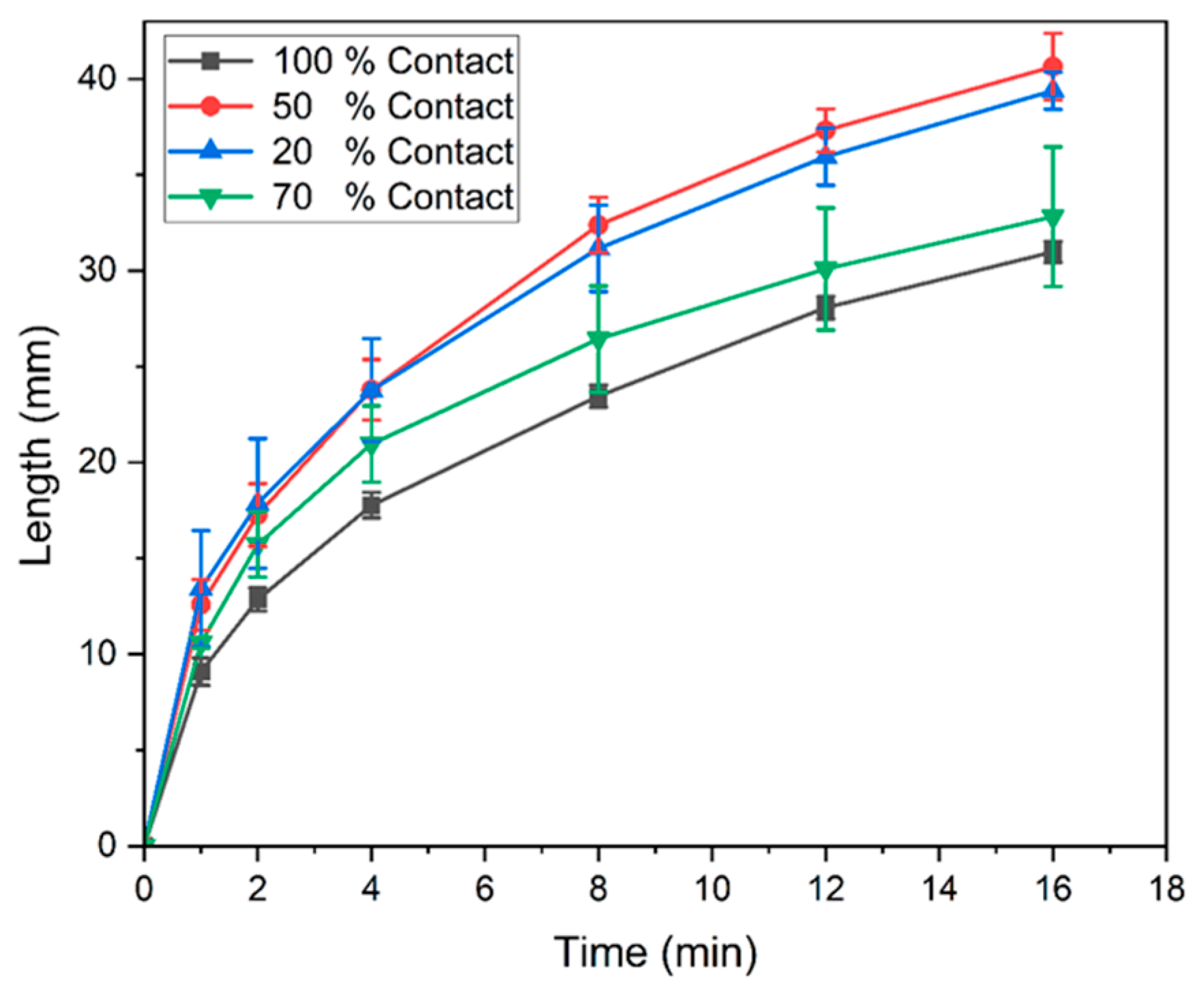

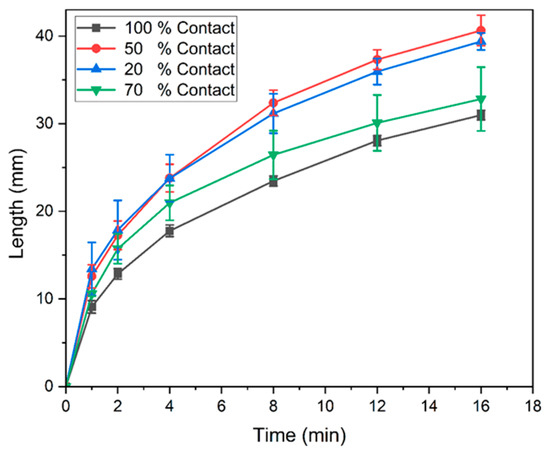

In Figure 2, the length–time curve of the experiment is depicted, focusing on the utilization of an infinite reservoir with paper strips and varying the contact area between the reservoir and the paper strip. This study explores the impact of the contact area while maintaining an infinite fluid volume within the storage reservoir. We observed that, initially, the gradient of length is steep, indicating fast flow. The contact areas of 20% and 50% are nearly identical and differ as the flowrate decreases with time. The minimum flowrate achieved is at 100% contact and the maximum flowrate is achieved at 50% contact between the storage reservoir and the paper strip. The reason is that the fluid must travel from the absorbing pad into the paper strip and then in the whole length of the paper, because as the contact is increased, more fluid must be diffused into the paper strip to start the fluid flow; hence, the flowrate decreases. At 20% contact, the storage has an ample amount of fluid however, because of the lower contact area, the flowrate is lower than the maximum flowrate at 50% contact area. Hence, we can use this factor to increase or decrease the flowrate in the paper strip.

Figure 2.

Flowrate at different contact areas between the reservoir and paper channel.

5. Conclusions

In summary, our study introduces a new method for flow variation by manipulating the contact area between the storage reservoir and the paper strip. We deduce that in addition to the length of the paper channel, the contact area among the reservoir and main channel, as well as the fluid available in the reservoir, affects the dynamics of imbibition in porous membrane. We have successfully demonstrated that the lowest and highest flowrates within the paper strip correspond to 100% and 50% contact. These findings enable the addition of lateral flow paper strips to benefit from flow control. By precisely adjusting the contact area, we can optimize flowrates and enhance the accuracy of environmental data collection. Overall, our research offers new insight into flow control and its potential applications in various domains.

Author Contributions

Conceptualization, H.A., M.A. (Mubashar Ali) and A.T.J.; methodology, H.A. and M.A. (Mubashar Ali); validation, N.N. and H.U.; formal analysis, H.A.; resources, M.A. (Moazzam Ali); writing—original draft preparation, H.A. and M.A. (Mubashar Ali); writing—review and editing, H.A. and A.T.J.; supervision, A.T.J.; project administration, A.T.J.; funding acquisition, A.T.J. All authors have read and agreed to the published version of the manuscript.

Funding

We are extremely grateful for the financial support by the National Research Programs for Universities (NRPU-14816) and the Technology Transfer Support Fund (TTSF-74) kindly provided by the Higher Education Commission (HEC) of Pakistan.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data is not publicly available due to confidentiality.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tian, W.-C.; Finehout, E. Introduction to Microfluidics. In Microfluidics for Biological Applications; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1–34. [Google Scholar]

- Cottet, J.; Renaud, P. Introduction to Microfluidics. In Drug Delivery Devices and Therapeutic Systems; Elsevier: Amsterdam, The Netherlands, 2021; pp. 3–17. [Google Scholar]

- Dietzel, A. A brief introduction to microfluidics. In Microsystems for Pharmatechnology: Manipulation of Fluids, Particles, Droplets, and Cells; Springer Nature: Berlin, Germany, 2016; pp. 1–21. [Google Scholar]

- Li, X.; Tian, J.; Garnier, G.; Shen, W. Fabrication of paper-based microfluidic sensors by printing. Colloids Surf. B Biointerfaces 2010, 76, 564–570. [Google Scholar] [CrossRef] [PubMed]

- Gong, M.M.; Sinton, D. Turning the page: Advancing paper-based microfluidics for broad diagnostic application. Chem. Rev. 2017, 117, 8447–8480. [Google Scholar] [CrossRef] [PubMed]

- Soum, V.; Park, S.; Brilian, A.I.; Kwon, O.S.; Shin, K. Programmable paper-based microfluidic devices for biomarker detections. Micromachines 2019, 10, 516. [Google Scholar] [CrossRef] [PubMed]

- Fu, E.; Lutz, B.; Kauffman, P.; Yager, P. Controlled reagent transport in disposable 2D paper networks. Lab Chip 2010, 10, 918–920. [Google Scholar] [CrossRef] [PubMed]

- Gao, F.; Mei, D.; Wang, Y.; Szanyi, J.; Peden, C.H. Selective catalytic reduction over Cu/SSZ-13: Linking homo-and heterogeneous catalysis. J. Am. Chem. Soc. 2017, 139, 4935–4942. [Google Scholar] [CrossRef] [PubMed]

- Elías, A.L.; Botello-Méndez, A.R.; Meneses-Rodríguez, D.; Jehová González, V.; Ramírez-González, D.; Ci, L.; Muñoz-Sandoval, E.; Ajayan, P.M.; Terrones, H.; Terrones, M. Longitudinal cutting of pure and doped carbon nanotubes to form graphitic nanoribbons using metal clusters as nanoscalpels. Nano Lett. 2010, 10, 366–372. [Google Scholar] [CrossRef] [PubMed]

- Noh, H.; Phillips, S.T. Fluidic timers for time-dependent, point-of-care assays on paper. Anal. Chem. 2010, 82, 8071–8078. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Jin, T.; Kou, J.; Zou, S.; Xiao, J.; Meng, Q. Lucas–Washburn equation-based modeling of capillary-driven flow in porous systems. Langmuir 2021, 37, 1623–1636. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Lin, Q.; Bijeljic, B.; Blunt, M.J. Pore-scale dynamics and the multiphase Darcy law. Phys. Rev. Fluids 2020, 5, 013801. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).