Method for Quantitative Assessment of Moisture Content of Porous Building Materials Based on Measurement of Thermal Inertia with Active Infrared Thermography †

Abstract

:1. Introduction

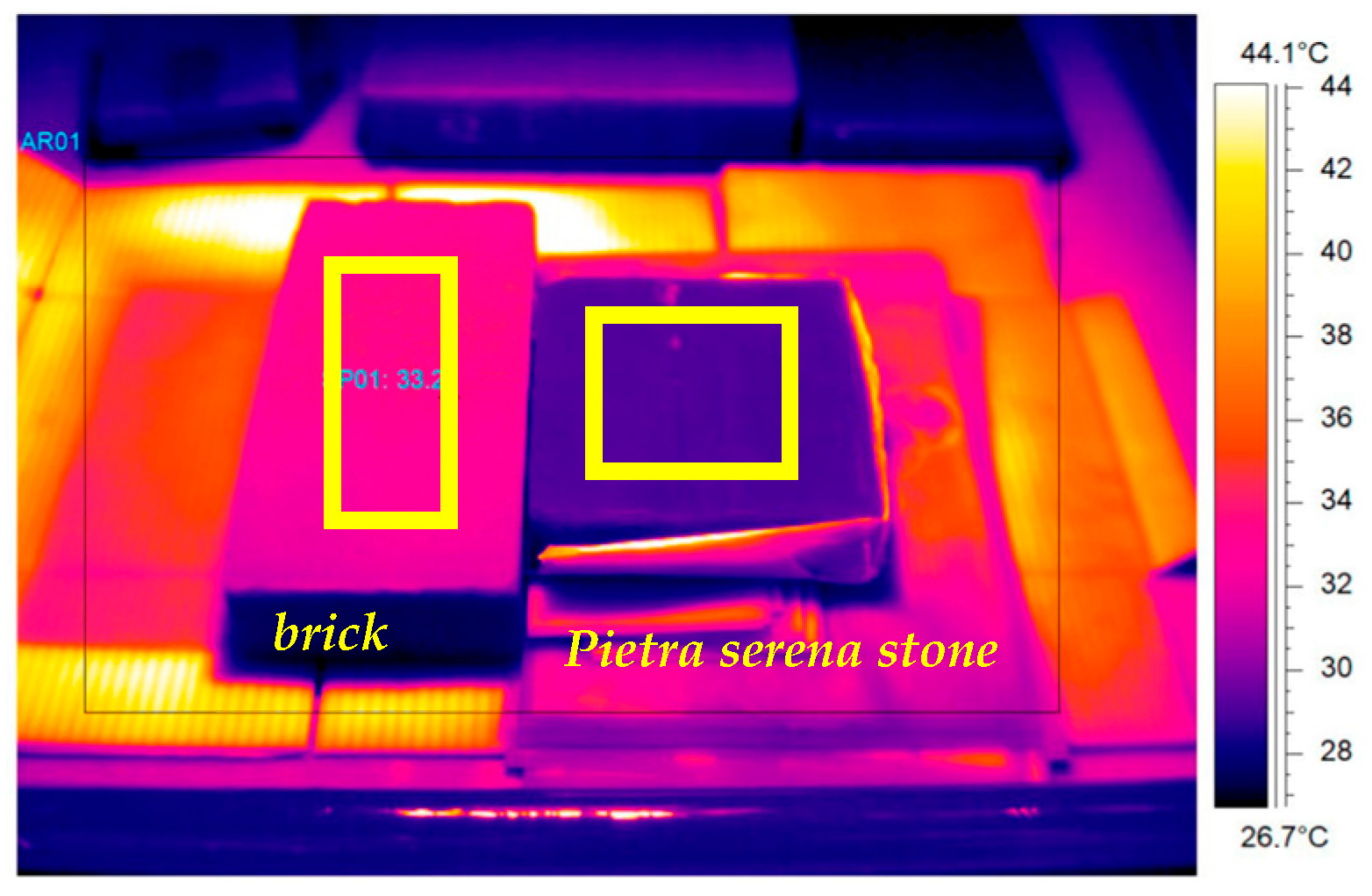

2. Materials and Methods

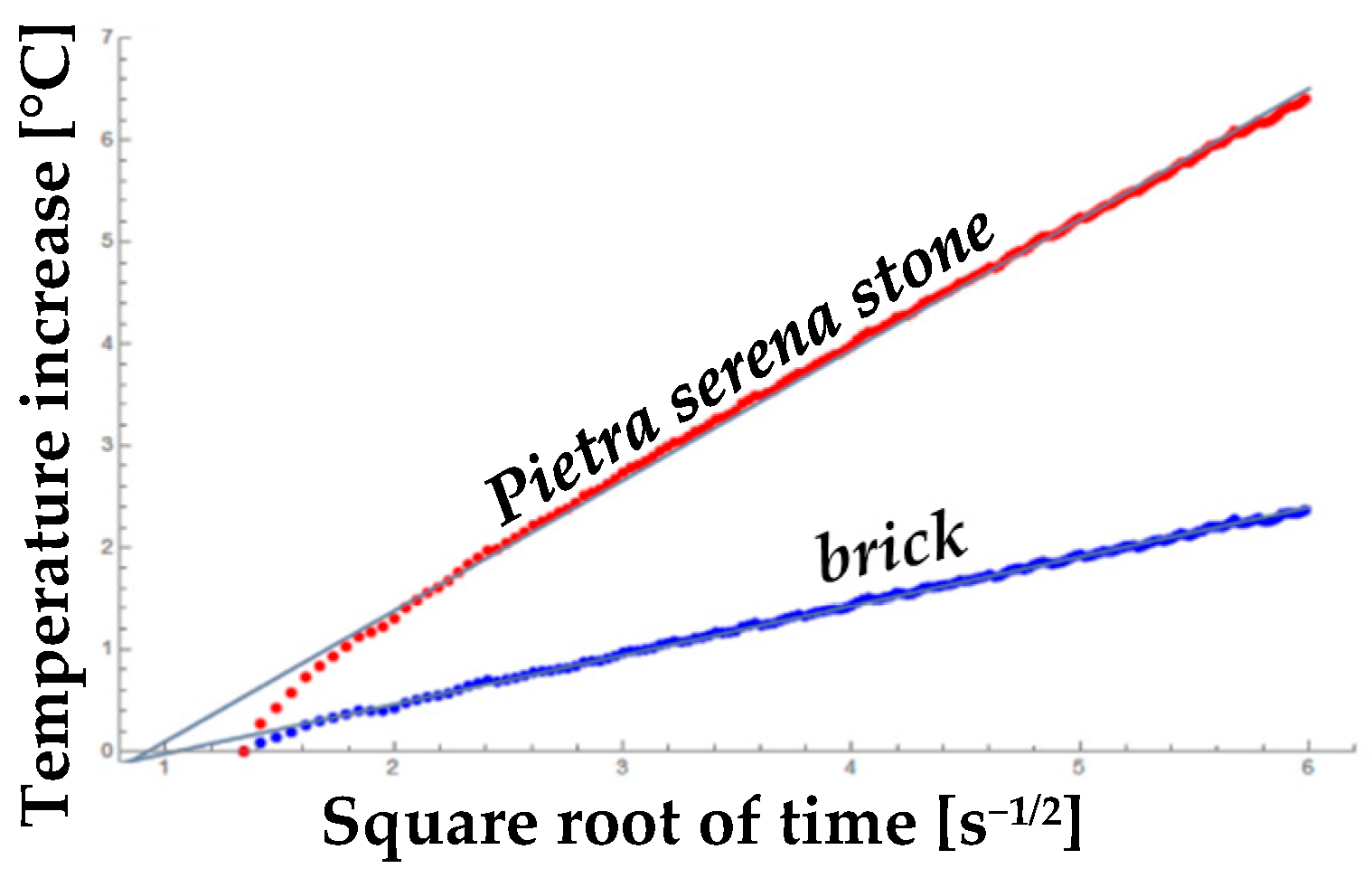

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Camuffo, D. Microclimate for Cultural Heritage: Conservation, Restoration, and Maintenance of Indoor and Outdoor Monuments; Elsevier: New York, NY, USA, 2013. [Google Scholar]

- UNI 11085:2003; Beni Culturali–Materiali Lapidei Naturali Ed Artificiali–Determinazione Del Contenuto D’acqua: Metodo Ponderale. UNI: Milano, Italy, 2003.

- Maldague, X. Theory and Practice of Infrared Technology for Nondestructive Testing; Wiley: Hoboken, NJ, USA, 2001. [Google Scholar]

- Grinzato, E.; Rosina, E. Infrared and thermal testing for conservation of historic buildings. In Nondestructive Testing Handbook: Infrared and Thermal Testing; Maldague, X., Ed.; ASNT: Columbus, OH, USA, 2001; Volume 3. [Google Scholar]

- Grinzato, E.; Bison, P. Building material characterization by using IR thermography for efficient heating systems. In Thermosense XXX; SPIE: Bellingham, WA, USA, 2008; Volume 6939. [Google Scholar]

- ISO 22007-2:2015; Determination of Thermal Conductivity and Thermal Diffusivity—Part 2: Transient Plane Heat Source (Hot Disc) Method. ISO: Geneva, Switzerland, 2015.

- ISO 11357-4:2014; Differential Scanning Calorimetry (DSC)—Part 4: Determination of Specific Heat Capacity. ISO: Geneva, Switzerland, 2014.

- Torquato, S. Random Heterogeneous Materials—Microstructure and Macroscopic Properties; Springer: New York, NY, USA, 2002. [Google Scholar]

| Material | Specific Heat [J·kg−1·K−1] | Density [kg·m−3] | Thermal Conductivity [W·m−1·K−1] | Open Porosity [%] |

|---|---|---|---|---|

| Brick A (dry) | 797 ± 6 | 1470 ± 13 | 0.559 ± 0.004 | 34 ± 1 |

| Brick B (dry) | 796 ± 2 | 1680 ± 14 | 0.64 | 32 ± 1 |

| Serena Stone | 818 ± 2 | 2480 ± 10 | 2.36 ± 0.02 | - |

| Water | 4182 | 1000 | 0.6 | - |

| Air (at 25 °C) | 1006 | 1.185 | 0.02 | - |

| Brick A | Brick B | |||||||

|---|---|---|---|---|---|---|---|---|

| Water content (IRT method) [%] | 34 ± 0.3 | 30 ± 0.3 | 26 ± 0.2 | 20 ± 0.1 | 35 ± 0.4 | 29 ± 0.3 | 22 ± 0.3 | 13 ± 0.1 |

| Water content (gravimetric method) [%] | 36 ± 0.3 | 28 ± 0.3 | 23 ± 0.2 | 16 ± 0.1 | 32 ± 0.3 | 26 ± 0.2 | 19 ± 0.2 | 13 ± 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cadelano, G.; Stecchetti, N.; Bison, P.; Bortolin, A.; Facci, M.; Ferrarini, G.; Galgaro, A.; Rossi, S.; Di Sipio, E. Method for Quantitative Assessment of Moisture Content of Porous Building Materials Based on Measurement of Thermal Inertia with Active Infrared Thermography. Eng. Proc. 2023, 51, 19. https://doi.org/10.3390/engproc2023051019

Cadelano G, Stecchetti N, Bison P, Bortolin A, Facci M, Ferrarini G, Galgaro A, Rossi S, Di Sipio E. Method for Quantitative Assessment of Moisture Content of Porous Building Materials Based on Measurement of Thermal Inertia with Active Infrared Thermography. Engineering Proceedings. 2023; 51(1):19. https://doi.org/10.3390/engproc2023051019

Chicago/Turabian StyleCadelano, Gianluca, Nicola Stecchetti, Paolo Bison, Alessandro Bortolin, Marina Facci, Giovanni Ferrarini, Antonio Galgaro, Stefano Rossi, and Eloisa Di Sipio. 2023. "Method for Quantitative Assessment of Moisture Content of Porous Building Materials Based on Measurement of Thermal Inertia with Active Infrared Thermography" Engineering Proceedings 51, no. 1: 19. https://doi.org/10.3390/engproc2023051019