Abstract

This study explores the potential of antimicrobial agents in high-performance concrete (HPC) to combat biodeterioration without compromising compressive strength. Response surface methodology (RSM) was used to create 21 combinations of nanosized TiO2 and ZnO (ranging from 0–2% by weight of cement in HPC). Results show that ZnO negatively impacts compressive strength as its content increases from 0–2%, while TiO2 enhances it by up to 17% with 2% TiO2. By optimizing TiO2 and varying ZnO within the 0–2% range, compressive strengths between 81–100 MPa can be achieved. The quadratic model, with significant statistical values, accurately depicts the effects of nanoparticles on compressive strengths.

1. Introduction

The vulnerability of concrete to biodeterioration, which is brought about by the growth and spread of microorganisms such as bacteria, fungi, algae, and lichens, has been recognised as a noteworthy concern that impacts the engineering characteristics of concrete in diverse settings and circumstances [1,2,3]. Microbial deterioration is mostly initiated by the penetration of CO2 from the atmosphere into the concrete. The presence of CO2, lowers the alkalinity of the concrete, thereby reducing the pH to values below 9.5 [3,4,5]. Deterioration of concrete by microorganisms is also common in pipes, oil storage tanks and oil carrying structures because of the sulphuric content of the containing liquid [6,7]. Noeiaghaei et al. [6] claims that any aerobic environment containing sulphur from oil and fuel spills will also stimulate the growth of sulphur oxidising bacteria (SOB) and sulphate reducing bacteria (SRB) like Thiobacillii and Desulfovibrio. These group of diverse bacteria have the capacity to convert sulphur to sulphate in the presence of oxygen, which ultimately leads to the formation of sulphuric acid that is deleterious to both reinforced and unreinforced concrete [8]. As evidenced by past research results, it has also been discovered that the deterioration of concrete structures in oil-marine water systems can also be associated with the mutualistic relationship between aerobic oil-oxidizing bacteria (OOB) and SRBs [7,9].

In order to protect concrete against biodeterioration, early initiatives by researchers and experts centred predominantly on the utilisation of biocides (i.e., pesticides or herbicides) commonly employed in the agricultural sector. A number of these chemicals were applied to the surface of the concrete or added to the concrete mixture as an admixture with the purpose of impeding the proliferation of microorganisms, thus conferring an antimicrobial property to the concrete [10,11,12,13].

The gradual acceptance of this technology posed a formidable challenge owing to the inherent hazards that these chemicals pose to both human well-being and the ecosystem. The efficacy of antimicrobial concrete is contingent upon a multitude of factors, including the antimicrobial agent employed, the nature of the microorganisms under consideration, and the precise conditions of application. It is of utmost significance to meticulously contemplate these variables whilst selecting antimicrobial concrete for a particular application. There exist various antimicrobial agents that are viable for use in anti-microbial concrete, such as biocides, silver ions, copper ions, heavy metals and their oxides. The agents operate through the perturbation of the metabolic or reproductive processes of microorganisms, thereby impeding their ability to proliferate and flourish on the surface of the concrete [14,15,16,17,18].

To effectively harness these materials, there is the need to combine two or more of these materials for adoption as admixtures in concrete production. Up until now, in-stances where these substances have been implemented, the emphasis has primarily been on their individual effects, with only a limited number of attempts made to investigate the combined effects of these antimicrobial agents on the mechanical properties of concrete [19,20,21]. The use of Response Surface Methodology (RSM) provides an avenue to explore this option most especially in situations where several input variables (that is, independent variables) determines the characteristics or performance measure of a process [22,23]. The effectiveness of this approach has been demonstrated by various authors [22,24,25]. RSM helps to understand individualistic and synergistic relationships between input fac-tors and output also known as responses.

In view of the foregoing, there remains a knowledge gap regarding the effect of various combinations of antimicrobial agents on the mechanical properties of High-Performance Concrete (HPC). As a result, this paper attempts to develop a model that describes the effects of various combinations of TiO2 and ZnO antimicrobial agents on the 28-day compressive strength of HPC with a target strength of 80 ± MPa. To do this, RSM was utilized in producing 21 different combinations of TiO2 and ZnO within the range of 0–2% by weight of the cement. The methods, results, and conclusions based on the experimental work are presented in the following sections.

2. Materials and Methods

Grade 52.5N Ordinary Portland Cement (OPC), Silica Fume (SF), Titanium Oxide Nanoparticles (TiO2 NPs) anatase 99.5%, Zinc Oxide Nanoparticles (ZnO NPs), coarse and fine aggregates were used in developing different mixes of HPC. Only the content of TiO2 NPs and ZnO NPs were varied within the range of 0–2% by weight of the cement. De-sign Expert software was employed in generating 21 different combinations of TiO2 NPs and ZnO NPs as provided in Table 1 below. The proportioning of both NPs as presented in Table 1 formed the basis for the replacement of each NPs in the concrete mix. The compressive strength test was conducted on three (3) 100 mm cubes in accordance with the provisions of ASTM C 39. The average compressive strength of the three (3) samples after 28 days of curing was obtained as the compressive strength of the concrete. Model equation for fitting the combined effects of TiO2 and ZnO on the 28-day compressive strength of HPC was developed by using the standard form of the second order response surface model provided as Equation (1) below. Performance indicators such as p-value, residual predicted plots, and coefficient of determination (R2) value were used to assess the performance of RSM model.

Table 1.

Combination of TiO2 and ZnO based on RSM.

3. Results and Discussion

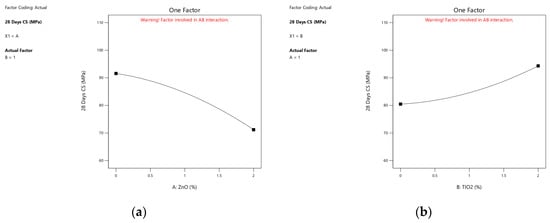

The individual as well as combined effects of TiO2 and ZnO on the 28-day compressive strength of HPC is depicted in Figure 1, Figure 2 and Figure 3. From Figure 1a,b, it can be seen that as the content of ZnO increased in the mix there was a corresponding decrease in the compressive strength of the concrete. On the other hand, TiO2 had a contrasting effect on the performance of the compressive strength of the concrete. Samples with 2% TiO2 had as much as 17% enhancement in the compressive strength. The reduction in strength observed in samples containing ZnO can be attributed to the formation of calcium zinc hydroxide dihydrate (CaZn2(OH)6·2H2O) as a result of the reaction between formation ZnO and Ca(OH)2, leading to retardation of the concrete [26].

Figure 1.

(a) Individual effect of TiO2 on the 28-day compressive strength of HPC (b) Individual effect of ZnO on the 28-day compressive strength of HPC.

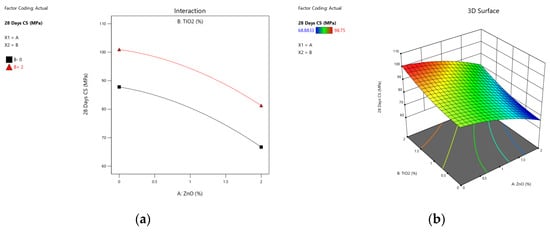

Figure 2.

(a) Interactive effects of TiO2 and ZnO on the 28-day compressive strength of HPC (b) Conversion response surface effects of TiO2 and ZnO on the 28-day compressive strength of HPC.

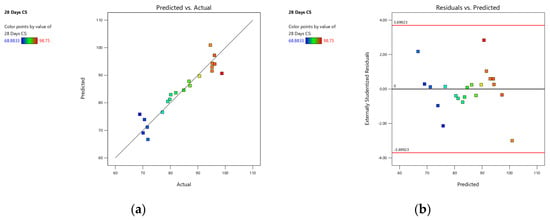

Figure 3.

(a) Validation of experimental values against RSM model (b) Plots of residuals against predictions from RSM Model.

The interactive plots in Figure 2a,b revealed that for optimal performance in compressive strength of HPC with combinations of TiO2 and ZnO. A combination of both NPs with high contents of TiO2 and low contents of ZnO has the potential of obtaining compressive strengths as high as 100 MPa as indicated by the red curve in Figure 2a. This is validated by the results obtained from the ANOVA in Table 2 which shows that based on the F-value of 23.4 and low p-values for the model as well as model terms A and B, both ZnO and TiO2 had significant effect on the compressive strength of HPC.

Table 2.

Results of ANOVA for effects of TiO2 and ZnO on 28-day compressive strength.

According to [22,27] the probability of low and F- and p-values of such magnitude being the result of noise is extremely low, at only 0.01%. Therefore, suggesting that the quadratic model presented as Equation (1) and developed based on the experimental values are well adequate to predict the effects of both NPs on the 28-day compressive strength of HPC.

The level of accuracy of this model is depicted by Figure 3a,b as well as the R2 value of 0.8863. Low margin of residuals (−3, +3) obtained from the residual-predicted plot is indicative of a strong agreement between the experimental results and the predictions based on the values obtained from the quadratic equation.

4. Conclusions

This study employed response surface methodology (RSM) to develop and model the effects of TiO2 and ZnO antimicrobial agents on the compressive strength of high-performance concrete (HPC). By exploring a wide range of combinations of both nanoparticles (NPs), a comprehensive understanding of their individual and combined effects on HPC’s compressive strength was obtained. The findings highlight the importance of optimizing the TiO2 content at 2% while varying the ZnO content accordingly to achieve the optimum compressive strength. The statistical indices, including p-value, F-value, R2, and residual plots, collectively indicate the strong performance of the quadratic model in accurately capturing the effects of TiO2 and ZnO on HPC’s compressive strength. Overall, this research enhances the body of knowledge on how TiO2 and ZnO antimicrobial agents influence HPC’s compressive strength, providing valuable insights for the development of more durable and resilient concrete materials.

Author Contributions

Conceptualization, A.U.A. and N.S.; methodology, A.U.A.; software, V.K., I.A. and O.J.O., validation, S.N.A.R.; formal analysis, A.U.A.; writing—original draft preparation, A.U.A.; writing—review and editing, S.A.F. and I.A.; visualization, A.U.A. and O.J.O., supervision, N.S. and S.A.F.; project administration, S.A.F.; funding acquisition, A.U.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Petroleum Technology Development Fund (PTDF), Nigeria. Grant Number/PTDF/ED/OSS/PHD/AUA/1743/20, Nigeria Abiola Usman Adebanjo has received scholarship and research support from PTDF for a PhD in Civil Engineering at the Universiti Teknologi PETRONAS Malaysia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is available on request.

Acknowledgments

The Lead Author (Abiola Usman Adebanjo) will like to express his profound gratitude to by Petroleum Technology Development Fund (PTDF), Nigeria for the award of a scholarship. Staff of the concrete laboratory of Universiti Teknologi PETRONAS (UTP) are also acknowledged for their technical support.

Conflicts of Interest

The authors declare that there is no conflict of interest among the authors.

References

- Ogunsona, E.O.; Muthuraj, R.; Ojogbo, E.; Valerio, O.; Mekonnen, T.H. Engineered Nanomaterials for Antimicrobial Applications: A Review. Appl. Mater. Today 2020, 18, 100473. [Google Scholar] [CrossRef]

- Ding, L.; Weiss, W.J.; Blatchley, E.R. Effects of Concrete Composition on Resistance to Microbially Induced Corrosion. J. Environ. Eng. 2017, 143, 04017014. [Google Scholar] [CrossRef]

- Harilal, M.; Anandkumar, B.; Lahiri, B.B.; George, R.P.; Philip, J.; Albert, S.K. Enhanced Biodeterioration and Biofouling Resistance of Nanoparticles and Inhibitor Admixed Fly Ash Based Concrete in Marine Environments. Int. Biodeterior. Biodegrad. 2020, 155, 105088. [Google Scholar] [CrossRef]

- Wei, S.; Jiang, Z.; Liu, H.; Zhou, D.; Sanchez-Silva, M. Microbiologically Induced Deterioration of Concrete—A Review. Braz. J. Microbiol. 2013, 44, 1001–1007. [Google Scholar] [CrossRef]

- Adebanjo, A.U.; Olonade, K.A.; Emmanuel, E. Carbon Dioxide Capture and Sequestration: An Overview of the Challenges, Potentials an Opportunities for Cement Industry in Nigeria. In Proceedings of the 2nd International Conference on Engineering and Environmental Sciences, Osogbo, Nigeria, 9 November 2021; p. 2. [Google Scholar]

- Noeiaghaei, T.; Dhami, N.; Mukherjee, A. Nanoparticles Surface Treatment on Cemented Materials for Inhibition of Bacterial Growth. Constr. Build. Mater. 2017, 150, 880–891. [Google Scholar] [CrossRef]

- Noeiaghaei, T.; Mukherjee, A.; Dhami, N.; Chae, S.R. Biogenic Deterioration of Concrete and Its Mitigation Technologies. Constr. Build. Mater. 2017, 149, 575–586. [Google Scholar] [CrossRef]

- Mehta, P.K. Concrete in the Marine Environment; Elsevier: Amsterdam, The Netherlands, 1991. [Google Scholar]

- Hughes, P.; Fairhurst, D.; Sherrington, I.; Renevier, N.; Morton, L.H.G.; Robery, P.C.; Cunningham, L. Microbial Degradation of Synthetic Fibre-Reinforced Marine Concrete. Int. Biodeterior. Biodegrad. 2014, 86, 2–5. [Google Scholar] [CrossRef]

- Pan, X.; Shi, Z.; Shi, C.; Ling, T.C.; Li, N. A Review on Surface Treatment for Concrete—Part 2: Performance. Constr. Build. Mater. 2017, 133, 81–90. [Google Scholar] [CrossRef]

- Adebanjo, A.U.; Dahunsi, B.I.O.; Labiran, J.O. Effects of Concrete Grades on Strength Characteristics of Metakaolin Modified Recycled Aggregate Concrete. Niger. J. Technol. Dev. 2021, 18, 184–193. [Google Scholar] [CrossRef]

- Adebanjo, A.; Kareem, M.; Olawuyi, O.; Ishola, K.; Odefemi, A. Effects of Waste Steel Fibres on The Mechanical Properties of Modified Self Compacting Concrete. J. Eng. Stud. Res. 2022, 28, 7–16. [Google Scholar] [CrossRef]

- Olawale, S.O.A.; Kareem, M.A.; Ojo, O.Y.; Adebanjo, A.U.; Thanni, M.O. Strength Characteristics of M40 Grade Concrete Using Waste Pet as Replacement for Sand. Niger. J. Technol. Dev. 2021, 18, 209–218. [Google Scholar] [CrossRef]

- Wattanawong, N.; Aht-Ong, D. Antibacterial Activity, Thermal Behavior, Mechanical Properties and Biodegradability of Silver Zeolite/Poly(Butylene Succinate) Composite Films. Polym. Degrad. Stab. 2021, 183, 109459. [Google Scholar] [CrossRef]

- Qiu, L.; Dong, S.; Ashour, A.; Han, B. Antimicrobial Concrete for Smart and Durable Infrastructures: A Review. Constr. Build. Mater. 2020, 260, 120456. [Google Scholar] [CrossRef] [PubMed]

- Reshma, T.V.; Manjunatha, M.; Bharath, A.; Tangadagi, R.B.; Vengala, J.; Manjunatha, L.R. Influence of ZnO and TiO2 on Mechanical and Durability Properties of Concrete Prepared with and without Polypropylene Fibers. Materialia 2021, 18, 101138. [Google Scholar] [CrossRef]

- Schifano, E.; Cavallini, D.; De Bellis, G.; Bracciale, M.P.; Felici, A.C.; Santarelli, M.L.; Sarto, M.S.; Uccelletti, D. Antibacterial Effect of Zinc Oxide-Based Nanomaterials on Environmental Biodeteriogens Affecting Historical Buildings. Nanomaterials 2020, 10, 335. [Google Scholar] [CrossRef] [PubMed]

- Olonade, K.A.; Akindahunsi, A.A.; Ajagbe, W.O.; Adebanjo, A.U.; Tijani, M.A. Pretreatment of Recycle Aggregates; Wood Head Publishing: Cambridge, UK, 2023; ISBN 9780323898386. [Google Scholar]

- Abdalla, J.A.; Thomas, B.S.; Hawileh, R.A.; Yang, J.; Jindal, B.B.; Ariyachandra, E. Influence of Nano-TiO2, Nano-Fe2O3, Nanoclay and Nano-CaCO3 on the Properties of Cement/Geopolymer Concrete. Clean. Mater. 2022, 4, 100061. [Google Scholar] [CrossRef]

- Goyal, R.; Verma, V.K.; Singh, N.B. Effect of Nano TiO2 & ZnO on the Hydration Properties of Portland Cement. Mater. Today Proc. 2022, 65, 1956–1963. [Google Scholar] [CrossRef]

- Dyshlyuk, L.; Babich, O.; Ivanova, S.; Vasilchenco, N.; Atuchin, V.; Korolkov, I.; Russakov, D.; Prosekov, A. Antimicrobial Potential of ZnO, TiO2 and SiO2 Nanoparticles in Protecting Building Materials from Biodegradation. Int. Biodeterior. Biodegrad. 2020, 146, 104821. [Google Scholar] [CrossRef]

- Usman, A.; Hartadi Sutanto, M.; Bin Napiah, M.; Shehu Aliyu Yaro, N. Response Surface Methodology Optimization in Asphalt Mixtures: A Review. In Response Surface Methodology in Engineering Science; IntechOpen: London, UK, 2021. [Google Scholar]

- Singh, P.; Adebanjo, A.; Shafiq, N.; Razak, S.N.A.; Kumar, V.; Farhan, S.A.; Adebanjo, I.; Singh, A.; Dixit, S.; Singh, S.; et al. Development of Performance-Based Models for Green Concrete Using Multiple Linear Regression and Artificial Neural Network. Int. J. Interact. Des. Manuf. 2023, 17, 1–12. [Google Scholar] [CrossRef]

- Baghaee Moghaddam, T.; Soltani, M.; Karim, M.R.; Baaj, H. Optimization of Asphalt and Modifier Contents for Polyethylene Terephthalate Modified Asphalt Mixtures Using Response Surface Methodology. Measurement 2015, 74, 159–169. [Google Scholar] [CrossRef]

- Yıldırım, Z.B.; Karacasu, M. Modelling of Waste Rubber and Glass Fibber with Response Surface Method in Hot Mix Asphalt. Constr. Build. Mater. 2019, 227, 117070. [Google Scholar] [CrossRef]

- Amor, F.; Baudys, M.; Racova, Z.; Scheinherrová, L.; Ingrisova, L.; Hajek, P. Contribution of TiO2 and ZnO Nanoparticles to the Hydration of Portland Cement and Photocatalytic Properties of High Performance Concrete. Case Stud. Constr. Mater. 2022, 16, e00965. [Google Scholar] [CrossRef]

- Kumar, V.; Kutty, S.R.M.; Abd Razak, S.N.; Shafiq, N.; Adebanjo, A.; Baloo, L.; Azougagh, A.A.; Iseni, R. Exploring the Untapped Potentials of Oily Sludge Ash Blended with Fly Ash for Geopolymer Binder via Waste Valorisation Approach. J. Hazard. Mater. Lett. 2023, 4, 100076. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).