Enhancing Sustainability in Wine Production: Evaluating Winery Wastewater Treatment Using Sequencing Batch Reactors †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Winery Wastewater

2.2. Sequencing Batch Reactor Set-Up and Experimental Conditions

3. Results and Discussion

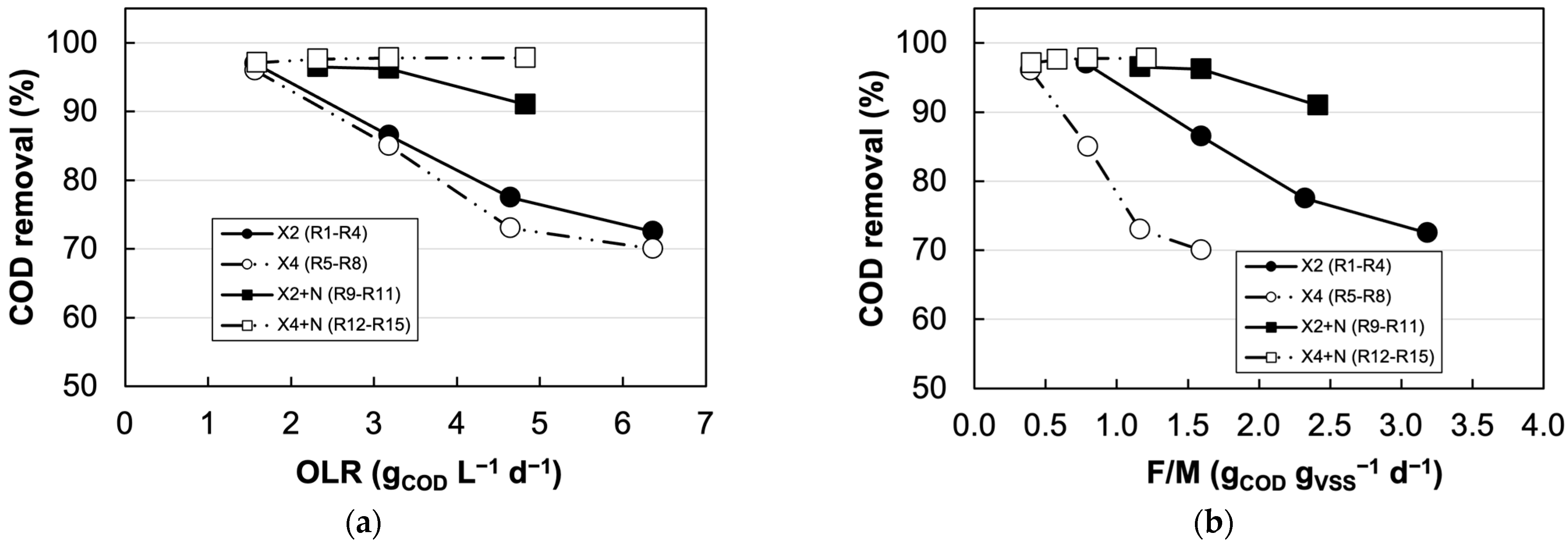

3.1. COD Removal Efficiency

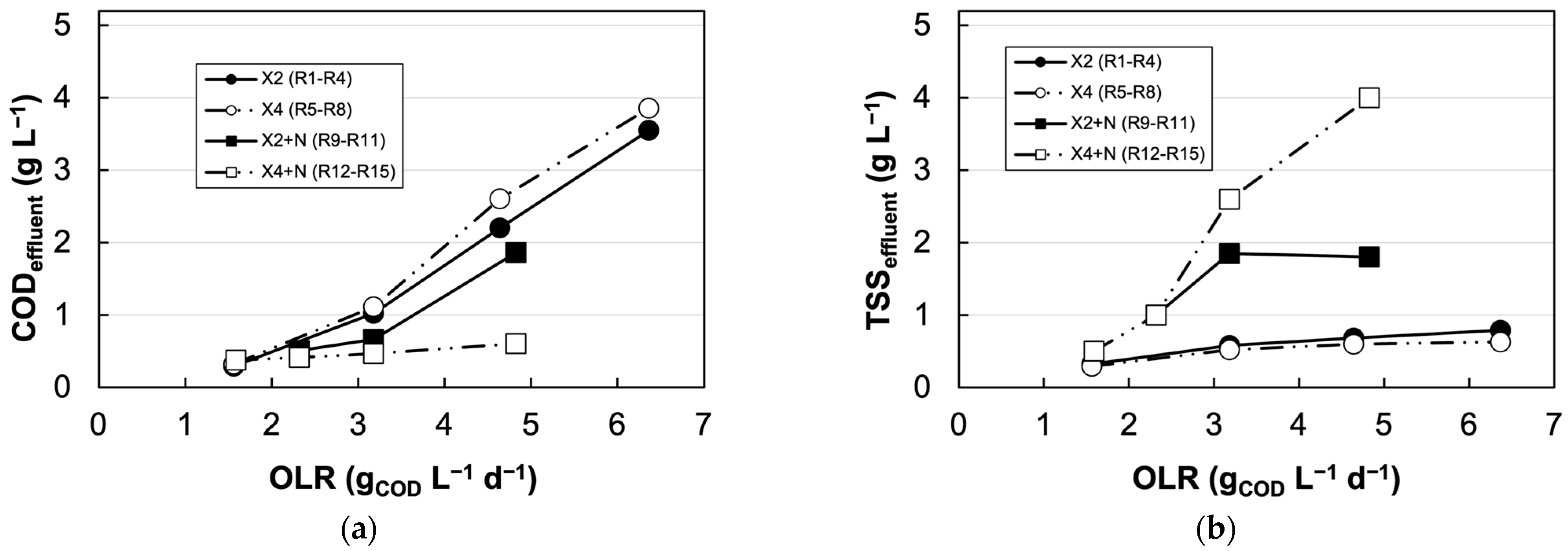

3.2. Effluent Quality and Sludge-Settling Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Flores, L.; García, J.; Pena, R.; Garfí, M. Constructed wetlands for winery wastewater treatment: A comparative Life Cycle Assessment. Sci. Total Environ. 2019, 659, 1567–1576. [Google Scholar] [CrossRef] [PubMed]

- Flores, L.; Josa, I.; García, J.; Pena, R.; Garfí, M. Constructed wetlands for winery wastewater treatment: A review on the technical, environmental and socio-economic benefits. Sci. Total Environ. 2023, 882, 163547. [Google Scholar] [CrossRef] [PubMed]

- Amor, C.; Marchão, L.; Lucas, M.S.; Peres, J.A. Application of Advanced Oxidation Processes for the Treatment of Recalcitrant Agro-Industrial Wastewater: A Review. Water 2019, 11, 205. [Google Scholar] [CrossRef]

- Pirra, A.J.D. Caracterização e Tratamento de Efluentes Vinícolas da Região Demarcada do Douro. Ph.D. Thesis, University of Trás-os-Montes e Alto Douro, Vila Real, Portugal, 2005. Available online: https://repositorio.utad.pt/handle/10348/61 (accessed on 30 October 2023).

- Lofrano, G.; Meric, S. A comprehensive approach to winery wastewater treatment: A review of the state-of the-art. Desalin. Water Treat. 2016, 57, 3011–3028. [Google Scholar] [CrossRef]

- Latessa, S.H.; Hanley, L.; Tao, W. Characteristics and practical treatment technologies of winery wastewater: A review for wastewater management at small wineries. J. Environ. Manag. 2023, 342, 118343. [Google Scholar] [CrossRef] [PubMed]

- Jorge, N.; Teixeira, A.R.; Lucas, M.S.; Peres, J.A. Enhancement of EDDS-photo-Fenton process with plant-based coagulants for winery wastewater management. Environ. Res. 2023, 229, 116021. [Google Scholar] [CrossRef] [PubMed]

- Jorge, N.; Teixeira, A.R.; Lucas, M.S.; Peres, J.A. Combined organic coagulants and photocatalytic processes for winery wastewater treatment. J. Environ. Manag. 2023, 326, 116819. [Google Scholar] [CrossRef] [PubMed]

- Bolzonella, D.; Papa, M.; Da Ros, C.; Muthukumar, L.A.; Rosso, D. Winery wastewater treatment: A critical overview of advanced biological processes. Crit. Rev. Biotechnol. 2019, 39, 489–507. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Srivastava, A.; Saidulu, D.; Gupta, A.K. Advancements of sequencing batch reactor for industrial wastewater treatment: Major focus on modifications, critical operational parameters, and future perspectives. J. Environ. Manag. 2022, 317, 115305. [Google Scholar] [CrossRef] [PubMed]

- Mace, S.; Mata-Alvarez, J. Utilization of SBR Technology for Wastewater Treatment: An Overview. Ind. Eng. Chem. Res. 2002, 41, 5539–5553. [Google Scholar] [CrossRef]

- Torrijos, M.; Moletta, R. Winery wastewater depollution by sequencing batch reactor. Water Sci. Technol. 1997, 35, 249–257. [Google Scholar] [CrossRef]

- López, S.; Dosta, J.; Mata-Álvarez, J. Start-up of an aerobic granular sequencing batch reactor for the treatment of winery wastewater. Water Sci. Technol. 2009, 60, 1049–1054. [Google Scholar] [CrossRef] [PubMed]

- Andreottola, G.; Foladori, P.; Ragazzi, M.; Villa, R. Treatment of winery wastewater in a sequencing batch biofilm reactor. Water Sci. Technol. 2002, 45, 347–354. [Google Scholar] [CrossRef] [PubMed]

- APHA. Standard Methods for the Examination of Water & Wastewater, 21st ed.; APHA: Washington, DC, USA, 2005. [Google Scholar]

- Metcalf and Eddy. Wastewater Engineering: Treatment and Reuse, 4th ed.; Metcalf and Eddy: Boston, MA, USA, 2003. [Google Scholar]

- Hamza, R.A.; Sheng, Z.; Iorhemen, O.T.; Zaghloul, M.S.; Tay, J.H. Impact of food-to-microorganisms ratio on the stability of aerobic granular sludge treating high-strength organic wastewater. Water Res. 2018, 147, 287–298. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.H.; Peng, Y.Z.; Peng, C.Y.; Wang, S.Y.; Chen, Y.; Huang, H.J.; Sun, Z.R. Energy saving achieved by limited filamentous bulking sludge under low dissolved oxygen. Bioresour. Technol. 2010, 101, 1120–1126. [Google Scholar] [CrossRef] [PubMed]

| COD (g L−1) | BOD (g L−1) | TSS (g L−1) | VSS (g L−1) | TN (g L−1) | TP (g L−1) | COD:N:P | |

|---|---|---|---|---|---|---|---|

| Winery Wastewater | 68 | 55 | 14.7 | 12.8 | 0.663 | 0.258 | 100:1:0.4 |

| Reactors | CODinfluent (g L−1) | OLR (g L−1 d−1) | Sludge Concentration (g L−1) | VER % | HRT (d−1) | Nutrient Supplementation |

|---|---|---|---|---|---|---|

| R1 | 3.0 | 1.6 | 2 | 50 | 1.9 | No |

| R2 | 6.1 | 3.2 | ||||

| R3 | 8.9 | 4.6 | ||||

| R4 | 12.2 | 6.4 | ||||

| R5 | 3.0 | 1.6 | 4 | 50 | 1.9 | No |

| R6 | 6.1 | 3.2 | ||||

| R7 | 8.9 | 4.6 | ||||

| R8 | 12.2 | 6.4 | ||||

| R9 | 8.9 | 2.3 | 2 | 25 | 3.8 | Yes |

| R10 | 12.2 | 3.2 | ||||

| R11 | 18.5 | 4.8 | ||||

| R12 | 6.1 | 1.6 | 4 | 25 | 3.8 | Yes |

| R13 | 8.9 | 2.3 | ||||

| R14 | 12.2 | 3.2 | ||||

| R15 | 18.5 | 4.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, S.; Pirra, A.; Jorge, N.; Peres, J.A.; Lucas, M.S. Enhancing Sustainability in Wine Production: Evaluating Winery Wastewater Treatment Using Sequencing Batch Reactors. Eng. Proc. 2023, 56, 163. https://doi.org/10.3390/ASEC2023-15522

Silva S, Pirra A, Jorge N, Peres JA, Lucas MS. Enhancing Sustainability in Wine Production: Evaluating Winery Wastewater Treatment Using Sequencing Batch Reactors. Engineering Proceedings. 2023; 56(1):163. https://doi.org/10.3390/ASEC2023-15522

Chicago/Turabian StyleSilva, Sérgio, António Pirra, Nuno Jorge, José A. Peres, and Marco S. Lucas. 2023. "Enhancing Sustainability in Wine Production: Evaluating Winery Wastewater Treatment Using Sequencing Batch Reactors" Engineering Proceedings 56, no. 1: 163. https://doi.org/10.3390/ASEC2023-15522