Abstract

Self-compacting concrete (SCC) is an innovative building material having special properties such as increased flowability, good segregation resistance and compaction without vibration, etc. Despite the benefits of SCC over conventional concrete, there are very few methods reported in the literature that can predict the 28-day compressive strength of SCC accurately. Thus, to promote the use of SCC in the construction industry, an innovative machine learning technique named multi-expression programming (MEP) was employed to forecast the 28-day compressive strength of SCC. A database consisting of 216 points was constructed using an extensive literature search. The resulting equation obtained by employing the MEP algorithm relates the compressive strength of SCC with the six most influential parameters, i.e., water–cement ratio, fly ash and silica fume, quantities of fine and coarse aggregate and superplasticizer dosage. The database was split into training and validation datasets used for the training and validation of the algorithm, respectively. The accuracy of the algorithm was verified by using three statistical error metrics: mean absolute error (MAE), root mean square error (RMSE), and coefficient of correlation (R). The results revealed that the errors were within the prescribed limits for both the training and validation sets and that the developed equation has excellent generalization capacity. This was also verified from the scatter plots of the training and validation datasets. Thus, the developed equation can be used practically to forecast the strength of SCC containing fly ash and silica fume.

1. Introduction

SCC is a unique type of concrete possessing properties such as good segregation resistance and enhanced flowability, and it can compact itself without external vibrations [1]. It leads to better-quality concrete by eliminating the need for compaction, accelerates the construction of precast concrete products and improves working conditions [2].

The use of SCC results in reduced costs and time needed to compact and place concrete. The mixture composition of SCC is designed such that it can achieve the required self-compacting and flowing characteristics. One major component of this mixture composition is to use a high level of fines to fill the spaces between the coarse aggregates. These fines typically include sand, fly ash, silica fume or other industrial wastes mixed with a chemical admixture called a superplasticizer, which helps to increase the flowing ability of concrete. Several studies [3,4,5,6] have reported the use of waste materials in the production of SCC. SCC also has a high water-to-cement ratio, being less quantity of coarse aggregates to achieve the flowing and self-compacting properties [7]. Despite the many advantages of SCC over conventional concrete, there is a lack of studies regarding the accurate estimation of its strength. This is mainly due to the highly non-linear behaviour of SCC in relation to its mixture components [8]. This is because any changes in cement and sand content, mineral and chemical admixtures can have significant impact on the strength of SCC [9]. Thus, this study aimed to develop an accurate prediction model that can predict the strength of SCC based on its mixture composition.

Recently, the prediction of different properties of SCC using machine learning (ML) algorithms have attracted the attention of researchers as an effective way to accurately estimate different properties of concrete [10,11,12]. Although researchers are using ML algorithms to predict different properties of SCC, there are very few works focusing on estimating the 28-day compressive strength of SCC containing fly ash and silica fume as mineral admixtures, particularly using multi-expression programming (MEP). Thus, this study was focused on developing an effective model to forecast the strength of SCC using MEP.

2. Multi-Expression Programming (MEP)

MEP is a variant of evolutionary algorithms developed recently by Oltean [13]. It is a method used to find the solution to a problem by constructing and evolving a population of mathematical expressions. It simply constructs a population of mathematical expressions and uses evolutionary rules to select the best performing expressions [14]. It is different from other variants of genetic programming because it uses a linear representation of chromosomes, and it can encode multiple computer programs in a single chromosome, whereas other variants like gene expression programming (GEP) can only encode one solution in a chromosome.

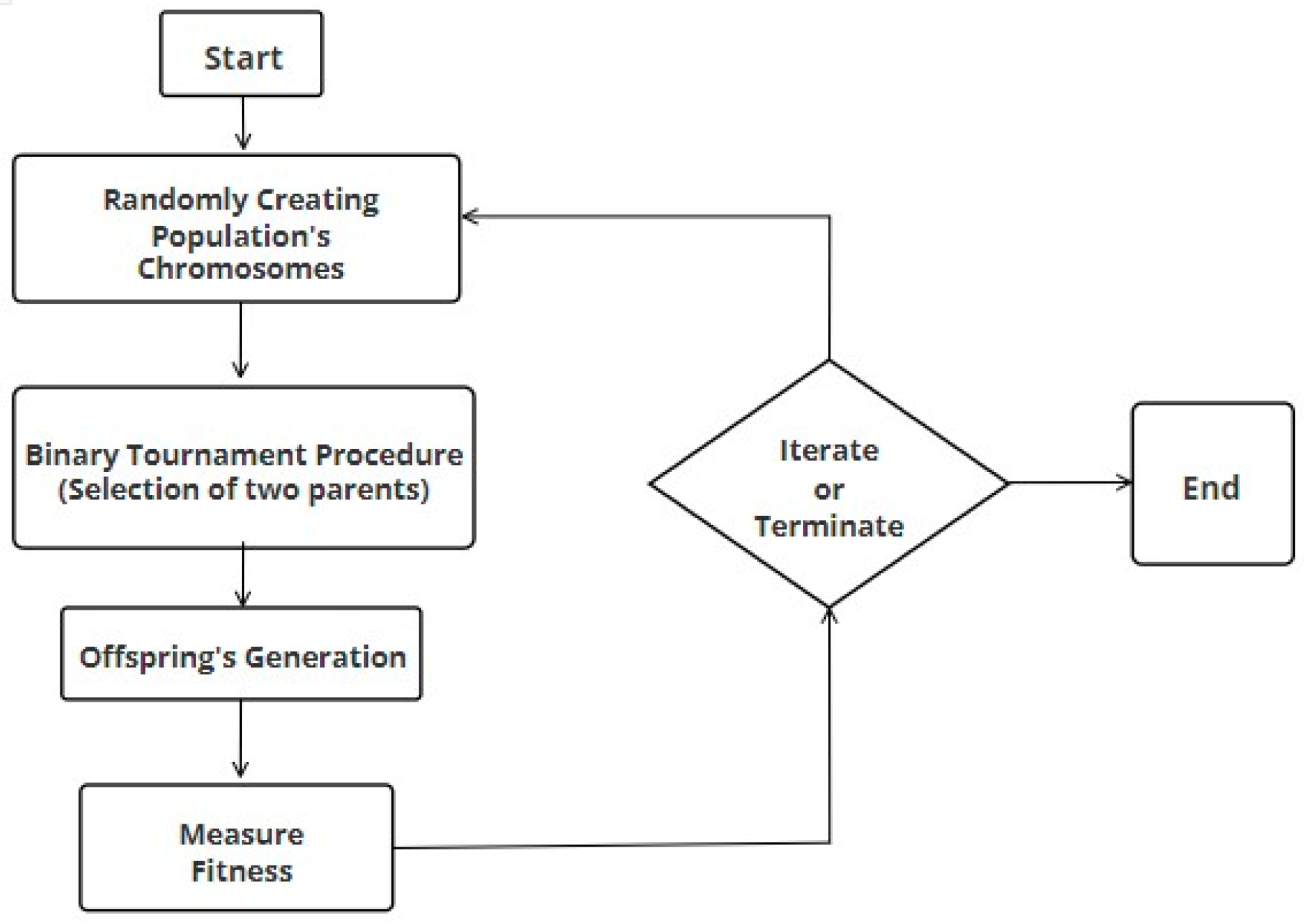

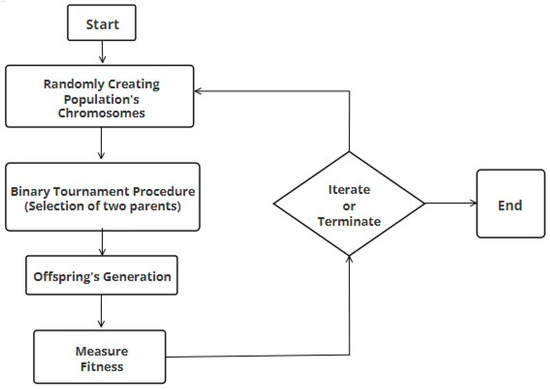

The MEP algorithm initializes by creating a population of random chromosomes, and then two parents are selected from the population through the process of a binary tournament. The two parents then undergo the process of recombination and crossover to produce two offspring [13]. The offspring are then mutated, and the worst-performing individuals are replaced with the best-performing ones. This process continues until the solution converges [15]. This iterative procedure of constructing and evaluating expressions makes MEP a useful tool for solving problems. The flow chart of the MEP algorithm [16] is shown in Figure 1.

Figure 1.

Flow chart of MEP algorithm.

3. Data Collection and Analysis

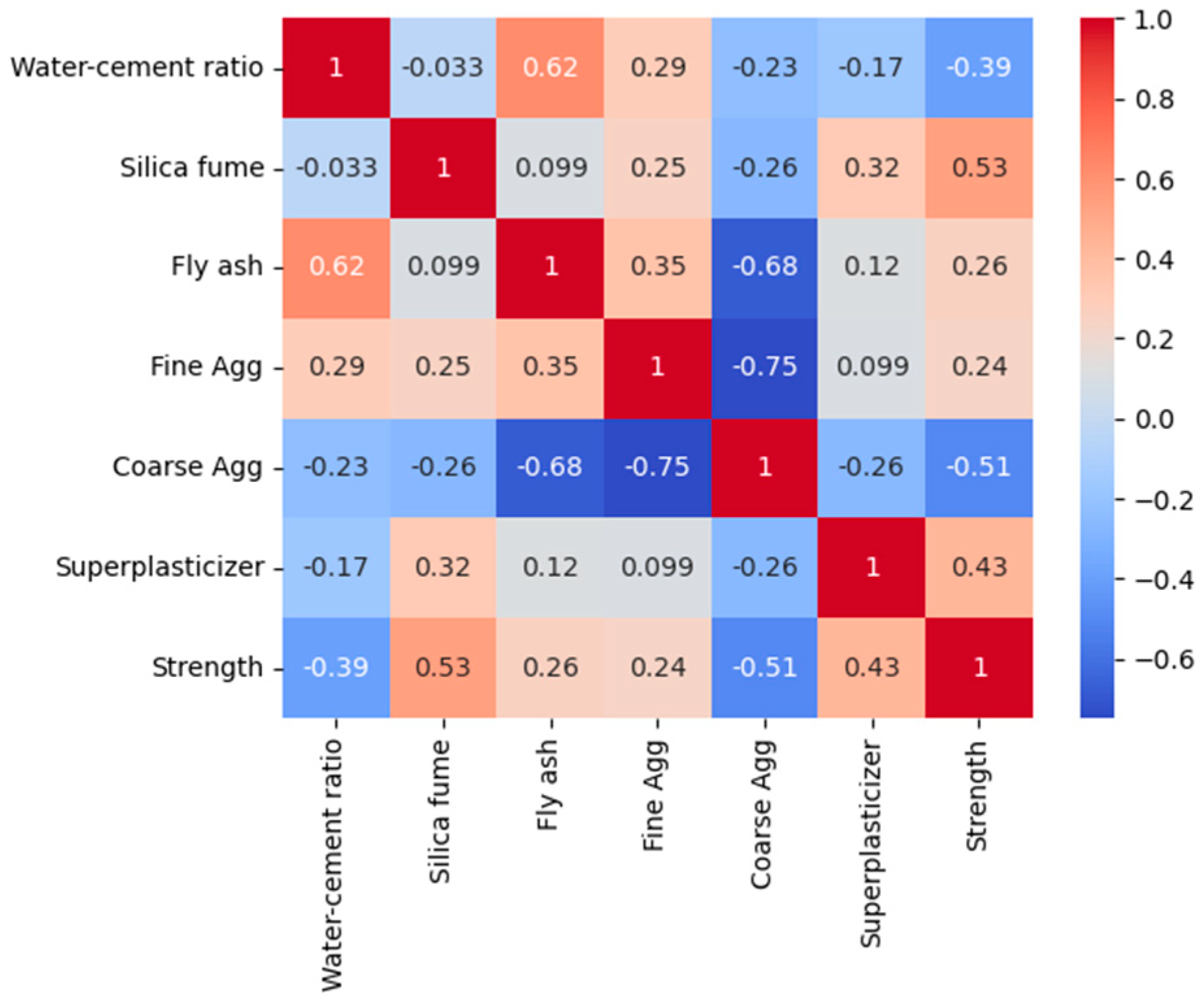

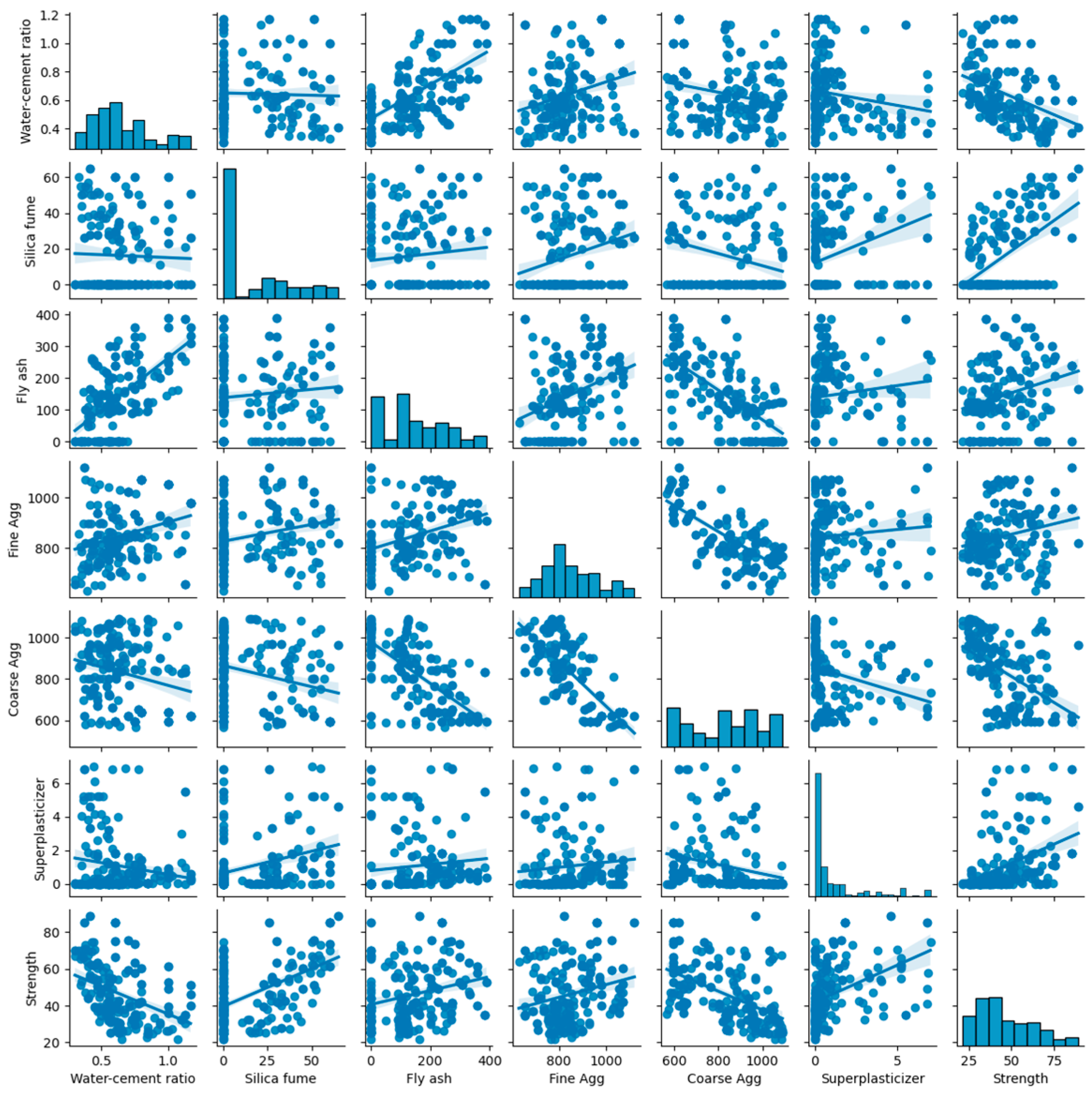

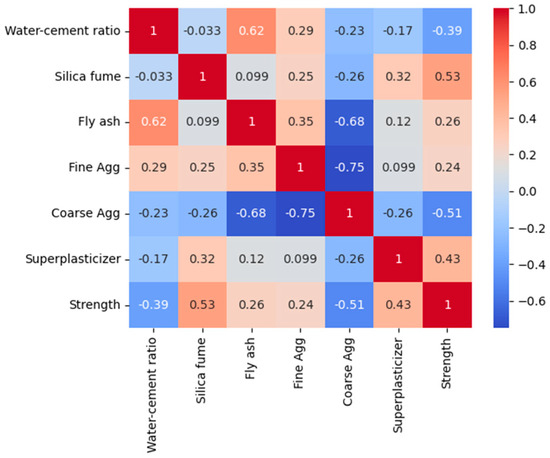

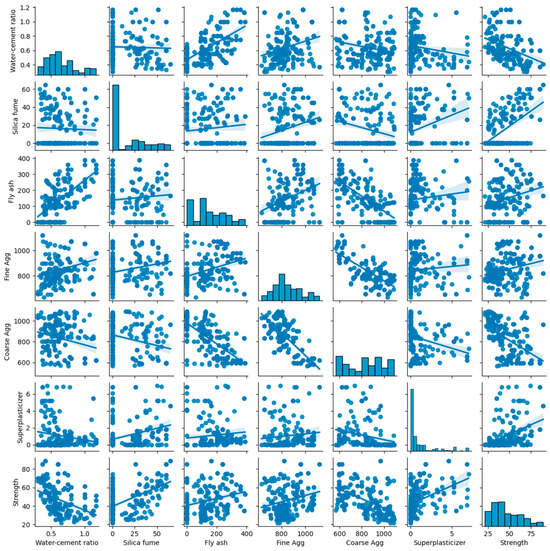

The development of a database is essential for an MEP model. Hence, a comprehensive database of 216 instances was created from the internationally published literature [17,18,19,20,21,22,23,24]. For the selection of most influential parameters, several trials were performed, and the following six input parameters were chosen: water–cement ratio, silica fume (), fly ash (), coarse aggregate (), fine aggregate () and superplasticizer (). The whole dataset was divided into two parts named the training dataset, having 70% of the data, and the validation dataset, having 30% of the data. The training and validation datasets were used to train and validate the algorithm, respectively [25]. The reason for splitting the data was to make sure that the developed model does not overfit the training data and performs well on the validation data too. The correlation matrix of the variables is shown in Figure 2. It is used to better understand the variance and covariance between the variables used in the development of the model. It provides information about the relationship between the variables. Note that the correlation matrix has both positive and negative correlations. However, the correlations having values closer to zero are generally of higher importance. The paired correlations of the variables are shown in the form of a scatter matrix in Figure 3. The diagonal of the scatter matrix shows the frequency distribution of the input and output variables.

Figure 2.

Correlation matrix of the variables used.

Figure 3.

Scatter matrix of the variables used.

4. Model Development and Performance Assessment

4.1. MEP Model Development

The MEP algorithm was implemented using a software, MEPX 2021.05.18.0. For the development of an effective and accurate model, numerous MEP tunning parameters need to be selected. These parameters influence the accuracy and complexity of the resulting equation. These parameters are chosen using recommendations in the literature [26] and a trial-and-error method until the optimal set of parameters presented in Table 1 are obtained. The subpopulation size indicates the number of programs present in the population. Increasing the subpopulation size increases the accuracy and complexity of the model, but increasing it beyond a certain point may cause overfitting.

Table 1.

Fitting parameters used in MEP model development.

4.2. Performance Assessment

The accuracy of the developed equation was assessed by using the following three error metrices:

For a model to be reliable, its R value should be greater than 0.8. The two error metrics MAE and RMSE measure the average magnitude of error between the actual and predicted values and, thus, should be minimized [27].

5. Results

The output of the MEP algorithm is given in Equation (1). In Equation (1), represents compressive strength (measured in MPa) and represent the water–cement ratio, silica fume, fly ash, fine aggregate, coarse aggregate, and superplasticizer, respectively.

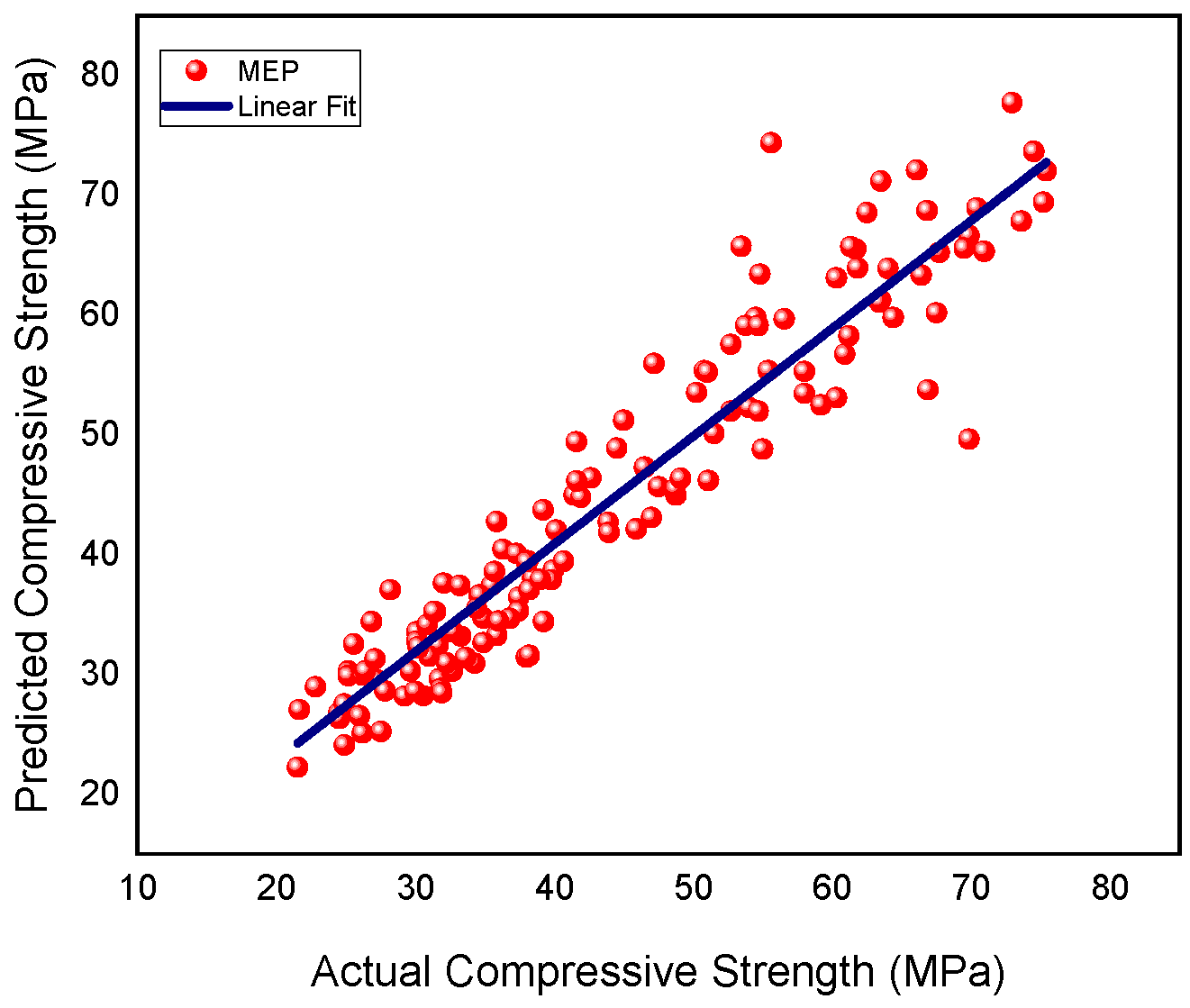

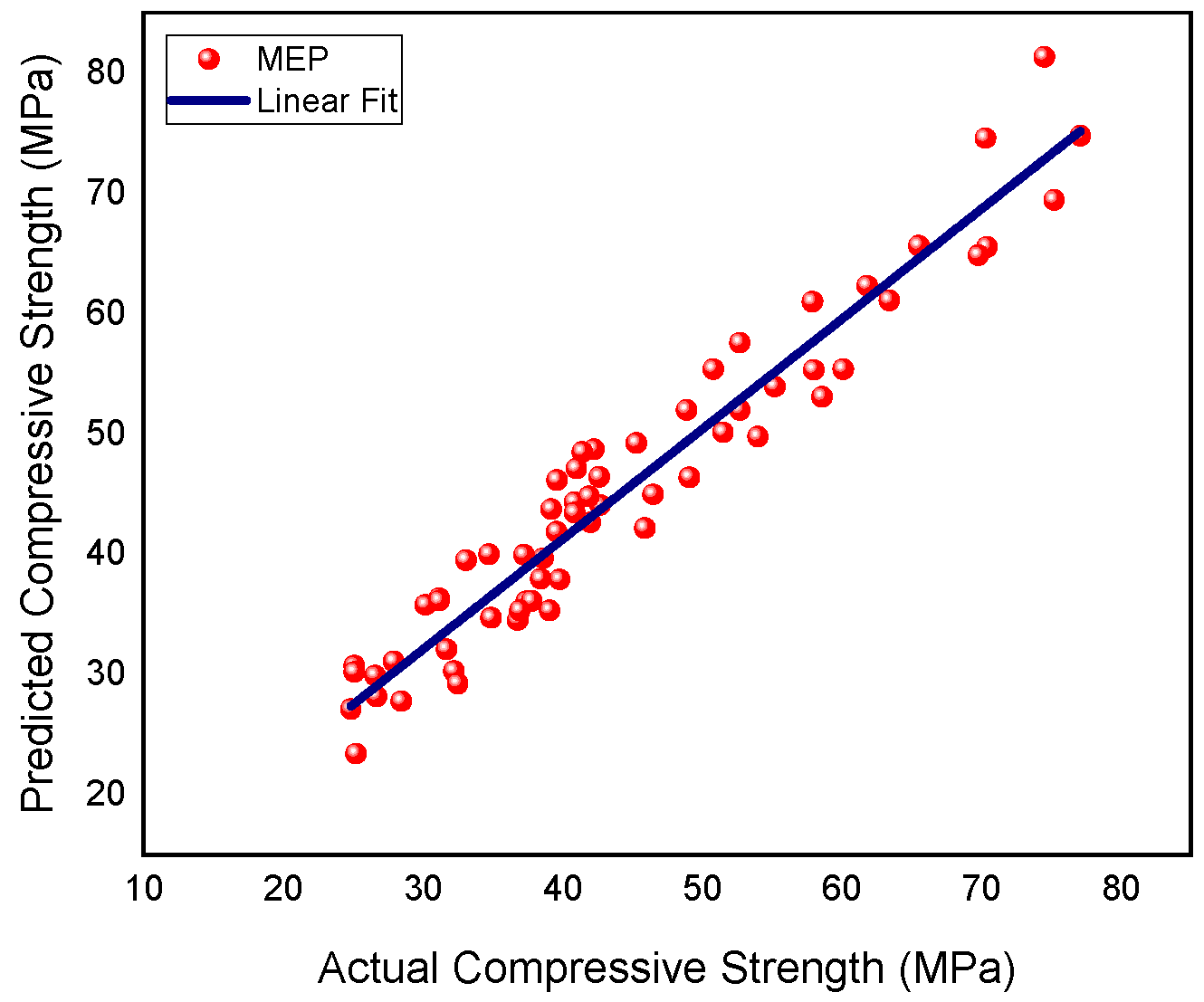

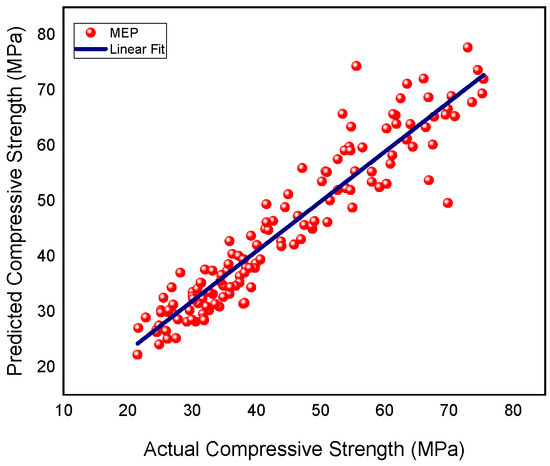

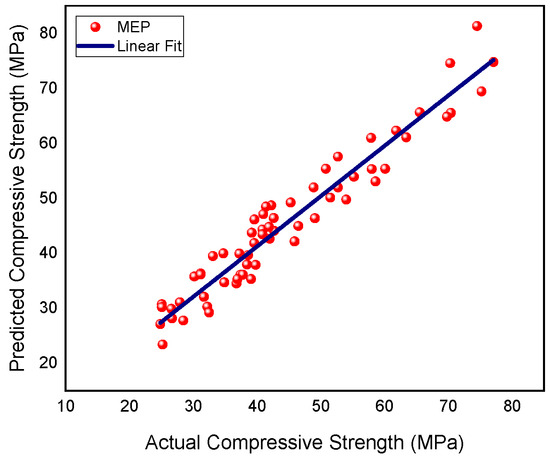

The accuracy of the algorithm can be visualized by plotting scatter plots between the actual and predicted strength values for both training and validation datasets. Figure 4 and Figure 5 represent the scatter plots of training and validation data, respectively. The error metrics calculated for both the training and validation datasets are shown in Table 2. Notice from Table 2 that the value of R for both the training and validation datasets is greater than 0.8, which shows that the developed equation is accurate and reliable.

Figure 4.

Scatter plot of training data.

Figure 5.

Scatter plot of validation data.

Table 2.

Error metrics of training and validation data.

6. Conclusions

This study focused on enhancing the use of SCC containing industrial wastes in the concrete industry by developing an empirical equation to estimate its 28-day compressive strength using the MEP algorithm. The comprehensive database of 216 points was used for this purpose, which resulted in an equation relating strength with six most influential input parameters. The accuracy of the algorithm was checked by drawing scatter plots and calculating the commonly used error metrics for both training and validation datasets. The statistical assessment showed that the developed equation is accurate and reliable and can be effectively used to predict the 28-day compressive strength of SCC.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are available with the author and will be furnished upon request.

Conflicts of Interest

The authors declared no conflict of interest.

References

- Brouwers, H.J.H.; Radix, H.J. Self-compacting concrete: Theoretical and experimental study. Cem. Concr. Res. 2005, 35, 2116–2136. [Google Scholar] [CrossRef]

- Kumar, R.; Samanta, A.K.; Roy, D.K.S. Characterization and Development of Eco-Friendly Concrete Using Industrial Waste-A Review. J. Urban Environ. Eng. 2014, 8, 98–108. [Google Scholar] [CrossRef]

- Yazici, H. The effect of silica fume and high-volume Class C fly ash on mechanical properties, chloride penetration and freeze-thaw resistance of self-compacting concrete. Constr. Build. Mater. 2008, 22, 456–462. [Google Scholar] [CrossRef]

- Ofuyatan, O.M.; Adeniyi, A.G.; Ighalo, J.O. Evaluation of fresh and hardened properties of blended silica fume self-compacting concrete (SCC). Res. Eng. Struct. Mater. 2021, 7, 211–223. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, S.; Yu, L.; Xu, L. A comprehensive study on the hardening features and performance of self-compacting concrete with high-volume fly ash and slag. Materials 2021, 14, 4286. [Google Scholar] [CrossRef]

- Choudhary, R.; Gupta, R.; Nagar, R. Impact on fresh, mechanical, and microstructural properties of high strength self-compacting concrete by marble cutting slurry waste, fly ash, and silica fume. Constr. Build. Mater. 2020, 239, 117888. [Google Scholar] [CrossRef]

- Valcuende, M.; Marco, E.; Parra, C.; Serna, P. Influence of limestone filler and viscosity-modifying admixture on the shrinkage of self-compacting concrete. Cem. Concr. Res. 2012, 42, 583–592. [Google Scholar] [CrossRef]

- Asteris, P.G.; Kolovos, K.G.; Douvika, M.G.; Roinos, K. Prediction of self-compacting concrete strength using artificial neural networks. Eur. J. Environ. Civ. Eng. 2016, 20, s102–s122. [Google Scholar] [CrossRef]

- Boukendakdji, O.; Kenai, S.; Kadri, E.H.; Rouis, F. Effect of slag on the rheology of fresh self-compacted concrete. Constr. Build. Mater. 2009, 23, 2593–2598. [Google Scholar] [CrossRef]

- Asteris, P.G.; Kolovos, K.G. Self-compacting concrete strength prediction using surrogate models. Neural Comput. Appl. 2019, 31, 409–424. [Google Scholar] [CrossRef]

- Douma, O.B.; Boukhatem, B.; Ghrici, M.; Tagnit-Hamou, A. Prediction of properties of self-compacting concrete containing fly ash using artificial neural network. Neural Comput. Appl. 2017, 28, 707–718. [Google Scholar] [CrossRef]

- Siddique, R.; Aggarwal, P.; Aggarwal, Y. Prediction of compressive strength of self-compacting concrete containing bottom ash using artificial neural networks. Adv. Eng. Softw. 2011, 42, 780–786. [Google Scholar] [CrossRef]

- Oltean, M. Multi Expression Programming for solving classification problems Fruit recognition from images using deep learning View project Optical Computing View project Mihai Oltean Multi Expression Programming for solving classification problems. Res. Sq. 2022. [Google Scholar] [CrossRef]

- Zhang, Q.; Meng, X.; Yang, B.; Liu, W. MREP: Multi-reference expression programming. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Berlin/Heidelberg, Germany, 2016; pp. 26–38. [Google Scholar] [CrossRef]

- Crina, M.O.; Gros, G. A Comparison of Several Linear GP Techniques A Comparison of Several Linear Genetic Programming Techniques. 2003. Available online: www.mep.cs.ubbcluj.ro (accessed on 1 January 2020).

- Jalal, F.E.; Iqbal, M.; Ali Khan, M.; Salami, B.A.; Ullah, S.; Khan, H.; Nabil, M. Indirect Estimation of Swelling Pressure of Expansive Soil: GEP versus MEP Modelling. Adv. Mater. Sci. Eng. 2023, 2023, 1827117. [Google Scholar] [CrossRef]

- Ardalan, R.B.; Joshaghani, A.; Hooton, R.D. Workability retention and compressive strength of self-compacting concrete incorporating pumice powder and silica fume. Constr. Build. Mater. 2017, 134, 116–122. [Google Scholar] [CrossRef]

- Wongkeo, W.; Thongsanitgarn, P.; Ngamjarurojana, A.; Chaipanich, A. Compressive strength and chloride resistance of self-compacting concrete containing high level fly ash and silica fume. Mater. Des. 2014, 64, 261–269. [Google Scholar] [CrossRef]

- Şahmaran, M.; Yaman, I.Ö.; Tokyay, M. Transport and mechanical properties of self consolidating concrete with high volume fly ash. Cem. Concr. Compos. 2009, 31, 99–106. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, W.; Wu, X.; Gao, B. The properties of the self-compacting concrete with fly ash and ground granulated blast furnace slag mineral admixtures. J. Clean. Prod. 2015, 95, 66–74. [Google Scholar] [CrossRef]

- Guo, Z.; Jiang, T.; Zhang, J.; Kong, X.; Chen, C.; Lehman, D.E. Mechanical and durability properties of sustainable self-compacting concrete with recycled concrete aggregate and fly ash, slag and silica fume. Constr. Build. Mater. 2020, 231, 117115. [Google Scholar] [CrossRef]

- Leung, H.Y.; Kim, J.; Nadeem, A.; Jaganathan, J.; Anwar, M.P. Sorptivity of self-compacting concrete containing fly ash and silica fume. Constr. Build. Mater. 2016, 113, 369–375. [Google Scholar] [CrossRef]

- Farooq, F.; Czarnecki, S.; Niewiadomski, P.; Aslam, F.; Alabduljabbar, H.; Ostrowski, K.A.; Śliwa-Wieczorek, K.; Nowobilski, T.; Malazdrewicz, S. A comparative study for the prediction of the compressive strength of self-compacting concrete modified with fly ash. Materials 2021, 14, 4934. [Google Scholar] [CrossRef] [PubMed]

- Tran, V.Q.; Mai, H.V.T.; Nguyen, T.A.; Ly, H.B. Assessment of different machine learning techniques in predicting the compressive strength of self-compacting concrete. Front. Struct. Civ. Eng. 2022, 16, 928–945. [Google Scholar] [CrossRef]

- Gholampour, A.; Gandomi, A.H.; Ozbakkaloglu, T. New formulations for mechanical properties of recycled aggregate concrete using gene expression programming. Constr. Build. Mater. 2017, 130, 122–145. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Alavi, A.H.; Gandomi, A.H.; Esmaeili, M.A.; Gandomi, M. A data mining approach to compressive strength of CFRP-confined concrete cylinders. Struct. Eng. Mech. 2010, 36, 759. [Google Scholar] [CrossRef]

- Heshmati AA, R.; Salehzade, H.; Alavi, A.H.; Gandomi, A.H.; Abadi, M.M. A Multi Expression Programming Application to High Performance Concrete. World Appl. Sci. J. 2008, 5, 215–223. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).