Optimization of the Flow-Shop Scheduling Problem under Time Constraints with PSO Algorithm †

Abstract

:1. Introduction

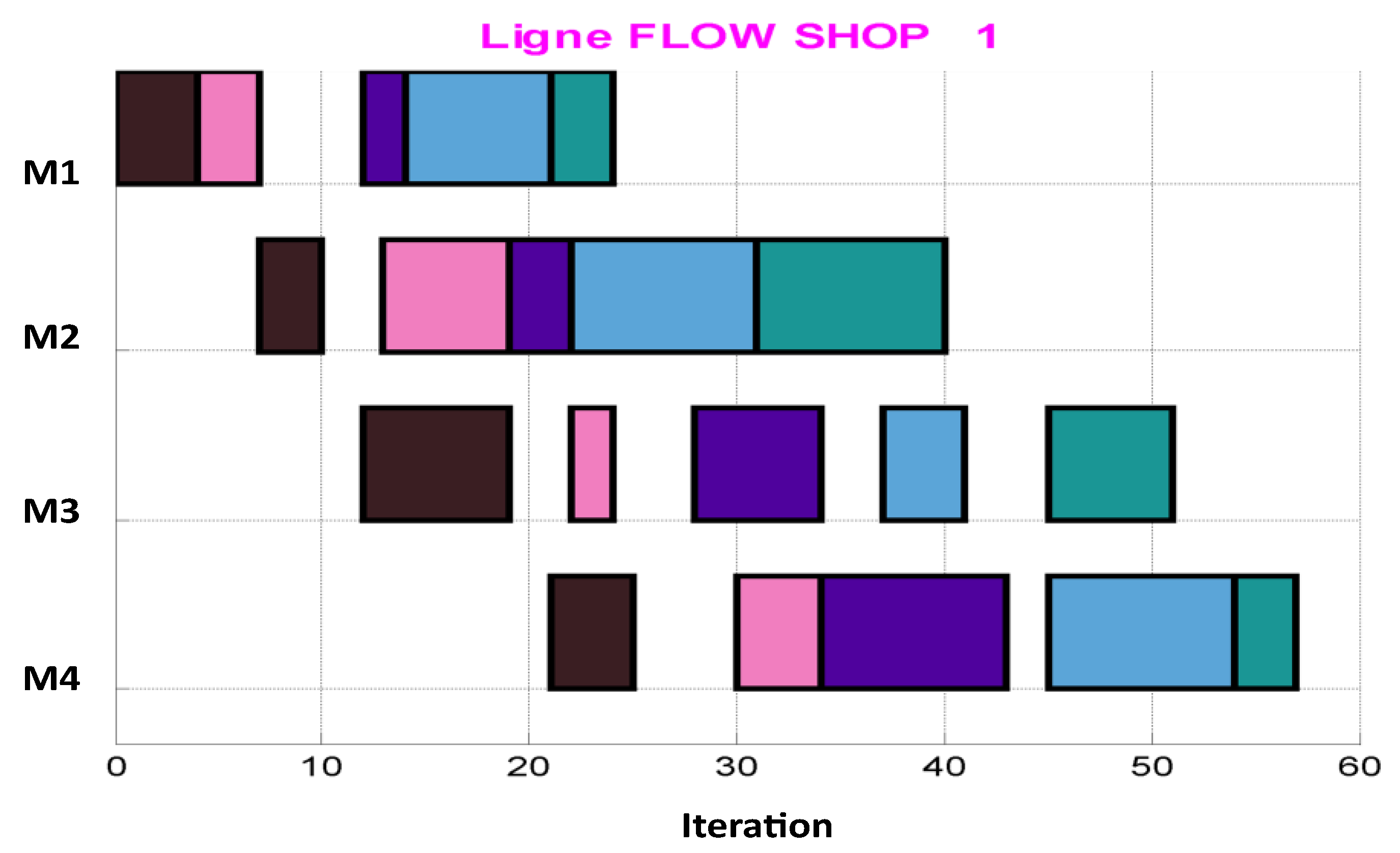

2. Flow-Shop Scheduling under Waiting Time and Release Date Constraints

2.1. Description of the Problem

- Each job follows a production line flow and remains confined to it, traversing all M machines sequentially (ranging from M1 to Mm).

- The production line can manufacture various products.

- Notably, each machine can handle only one task at a given moment, while each job can be processed by only one machine at a time.

- Importantly, task processing occurs continuously, without any interruptions

- The predetermined processing times pi,j for each task, remain constant throughout.

- Equally, the waiting time and release date for tasks are predetermined and remain consistent.

2.1.1. Makespan Objective Function

2.1.2. Wait Time and Release Date Constraints

- The wait time constraint in scheduling determines the maximum allowed time a task can wait after its release before starting the process. Mainly, it resolves conflicts by prioritizing tasks based on urgency or with shorter waiting times. It is used, for example, to wait until the temperature of the part or equipment decreases before further processing.

- The release date specifies the earliest time the task can start and thereby affects task star times. In addition, it contributes to coordinating tasks and ensures that tasks start on time to meet specific scheduling requirements. This constraint is usually used in the assembly process for task coordination.

2.2. Mathematical Problem Formulation

2.3. Complexity of the Problem

3. Particle Swarm Optimization (PSO)

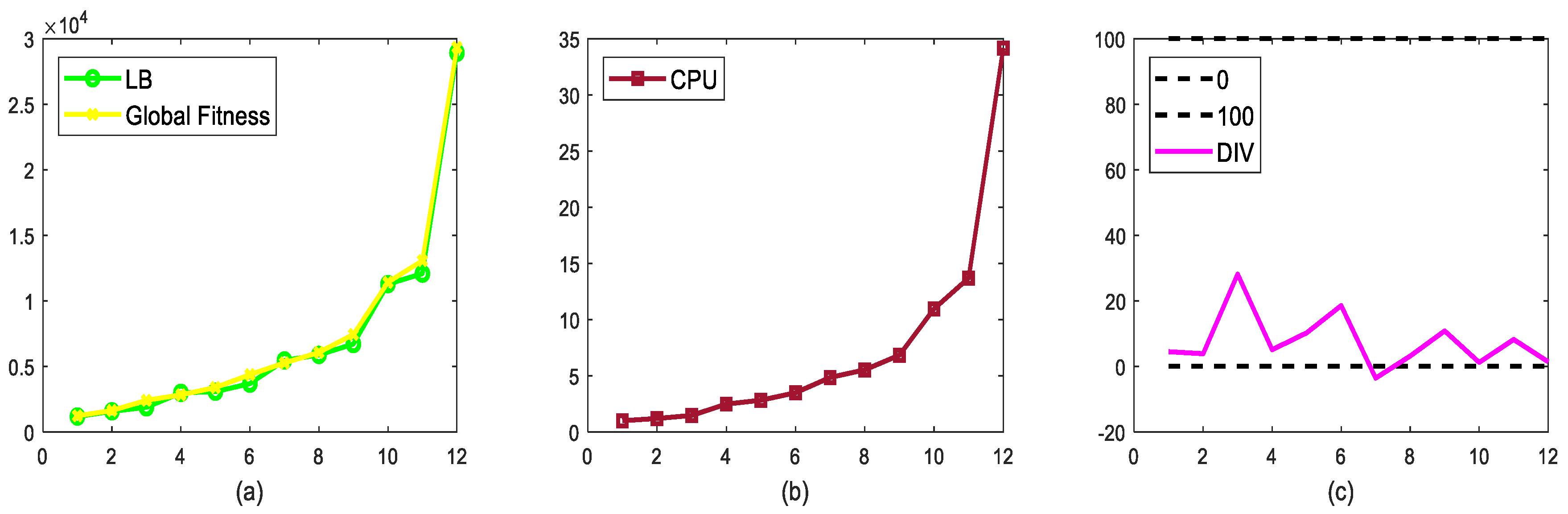

4. Experimental Evaluation and Results

- a.

- The experiment encompassed 12 benchmarks, each one comprising 10 distinct instances. We conducted 10 tests for each of these 12 benchmarks.

- b.

- Each benchmark is characterized by two elements: the number of jobs requiring processing and the number of processing machines.

- c.

- We focused on the following dimensions for small-sized problems: (20 × 05; 20 × 10; 20 × 20; 50 × 05; 50 × 10; 50 × 20).

- d.

- For larger-sized problems, we utilized the following dimensions: (100 × 05, 100 × 10, 100 × 20, 200 × 10, 200 × 20, and 500 × 20).

- e.

- Each trial yielded the following results: CMax, deviation (Div), Lower Bound, and the CPU time.

- f.

- To enhance the result analysis, we selected the best 10 makespan values.

- g.

- For a better interpretation of the results, we employed the relative “index of deviation”.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abdollahpour, S.; Rezaeian, J. Minimizing makespan for flow shop scheduling problem with intermediate buffers by using hybrid approach of artificial immune system. Appl. Soft Comput. 2015, 28, 44–56. [Google Scholar] [CrossRef]

- Irman, A.; Febianti, E.; Khasanah, U. Minimizing makespan on flow shop scheduling using Campbel Dudek and Smith, particle swarm optimization, and proposed heuristic algorithm. IOP Conf. Ser. Mater. Sci. Eng. 2019, 673, 012099. [Google Scholar] [CrossRef]

- Umam, M.S.; Mustafid, M.; Suryono, S. A hybrid genetic algorithm and tabu search for minimizing makespan in flow shop scheduling problem. J. King Saud Univ.-Comput. Inf. Sci. 2022, 34, 7459–7467. [Google Scholar] [CrossRef]

- Sharma, M.; Sharma, M.; Sharma, S. An improved neh heuristic to minimize makespan for flow shop scheduling problems. Decis. Sci. Lett. 2021, 10, 311–322. [Google Scholar] [CrossRef]

- Han, J.H.; Lee, J.Y. Scheduling for a flow shop with waiting time constraints and missing operations in semiconductor manufacturing. Eng. Optim. 2023, 55, 1742–1759. [Google Scholar] [CrossRef]

- Grabowski, J.; Skubalska, E.; Smutnicki, C. On Flow Shop Scheduling with Release and Due Dates to Minimize Maximum Lateness. J. Oper. Res. Soc. 1983, 34, 615. [Google Scholar] [CrossRef]

- Brucker, P.; Knust, S.; Wang, G. Complexity results for flow-shop problems with a single server. Eur. J. Oper. Res. 2005, 165, 398–407. [Google Scholar] [CrossRef]

- Garey, M.R.; Johnson, D.S.; Sethi, R. Complexity of Flowshop and Jobshop Scheduling. Math. Oper. Res. 1976, 1, 117–129. [Google Scholar] [CrossRef]

- Martinez, S.; Dauzère-Pérès, S.; Guéret, C.; Mati, Y.; Sauer, N. Complexity of flowshop scheduling problems with a new blocking constraint. Eur. J. Oper. Res. 2006, 169, 855–864. [Google Scholar] [CrossRef]

- Soukhal, A.; Oulamara, A.; Martineau, P. Complexity of flow shop scheduling problems with transportation constraints. Eur. J. Oper. Res. 2005, 161, 32–41. [Google Scholar] [CrossRef]

- Mansouri, M.; Bahmani, Y.; Smadi, H. A Hybrid Method for the Parallel-Flow Shop-Scheduling Problem. Comput. Sci. Math. Forum 2023, 7, 14413. [Google Scholar] [CrossRef]

- Bank, M.; Ghomi, S.M.T.F.; Jolai, F.; Behnamian, J. Application of particle swarm optimization and simulated annealing algorithms in flow shop scheduling problem under linear deterioration. Adv. Eng. Softw. 2012, 47, 1–6. [Google Scholar] [CrossRef]

- Mansouri, M.; Bahmani, Y.; Smadi, H. Monocriterion Optimization in Parallel Flow Shop; EasyChair: Manchester, UK, 2022. [Google Scholar]

- Liao, C.J.; Tseng, C.-T.; Luarn, P. A discrete version of particle swarm optimization for flowshop scheduling problems. Comput. Oper. Res. 2007, 34, 3099–3111. [Google Scholar] [CrossRef]

| Parameter | Signification | Parameter | Signification |

|---|---|---|---|

| Index of jobs | Completion time | ||

| Index of machines | Starting time | ||

| job in the sequence | waiting time | ||

| Number of jobs to be processed | Release date | ||

| Number of processing machines | Large positive number | ||

| Processing time | Take 1; if is processing on machine , and 0 otherwise Take 1; if is processed before on and 0 otherwise |

| Instance | CPU | DIV | Global Fitness | LB | |

|---|---|---|---|---|---|

| 01 | 20_05 | 0.9989923 | 4.491525424 | 1233 | 1180 |

| 02 | 20_10 | 1.198532533 | 3.875476493 | 1635 | 1574 |

| 03 | 20_20 | 1.469578899 | 28.16153029 | 2412 | 1882 |

| 04 | 50_05 | 2.479333432 | 5.095541401 | 2831 | 2983 |

| 05 | 50_10 | 2.824219993 | 10.24390244 | 3390 | 3075 |

| 06 | 50_20 | 3.489259796 | 18.55670103 | 4370 | 3686 |

| 07 | 100_05 | 4.850529547 | −3.572082799 | 5264 | 5459 |

| 08 | 100_10 | 5.528670233 | 3.163265306 | 6066 | 5880 |

| 09 | 100_20 | 6.834969121 | 10.83619019 | 7436 | 6709 |

| 10 | 200_10 | 10.9573531 | 1.223295807 | 11,419 | 11,281 |

| 11 | 200_20 | 13.69698202 | 8.222240623 | 13,070 | 12,077 |

| 12 | 500_20 | 34.14775248 | 1.413757345 | 29,339 | 28,930 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mansouri, M.; Bahmani, Y.; Smadi, H. Optimization of the Flow-Shop Scheduling Problem under Time Constraints with PSO Algorithm. Eng. Proc. 2023, 56, 220. https://doi.org/10.3390/ASEC2023-15410

Mansouri M, Bahmani Y, Smadi H. Optimization of the Flow-Shop Scheduling Problem under Time Constraints with PSO Algorithm. Engineering Proceedings. 2023; 56(1):220. https://doi.org/10.3390/ASEC2023-15410

Chicago/Turabian StyleMansouri, Milad, Younes Bahmani, and Hacene Smadi. 2023. "Optimization of the Flow-Shop Scheduling Problem under Time Constraints with PSO Algorithm" Engineering Proceedings 56, no. 1: 220. https://doi.org/10.3390/ASEC2023-15410

APA StyleMansouri, M., Bahmani, Y., & Smadi, H. (2023). Optimization of the Flow-Shop Scheduling Problem under Time Constraints with PSO Algorithm. Engineering Proceedings, 56(1), 220. https://doi.org/10.3390/ASEC2023-15410