Winery Wastewater: Challenges and Perspectives †

Abstract

:1. Introduction

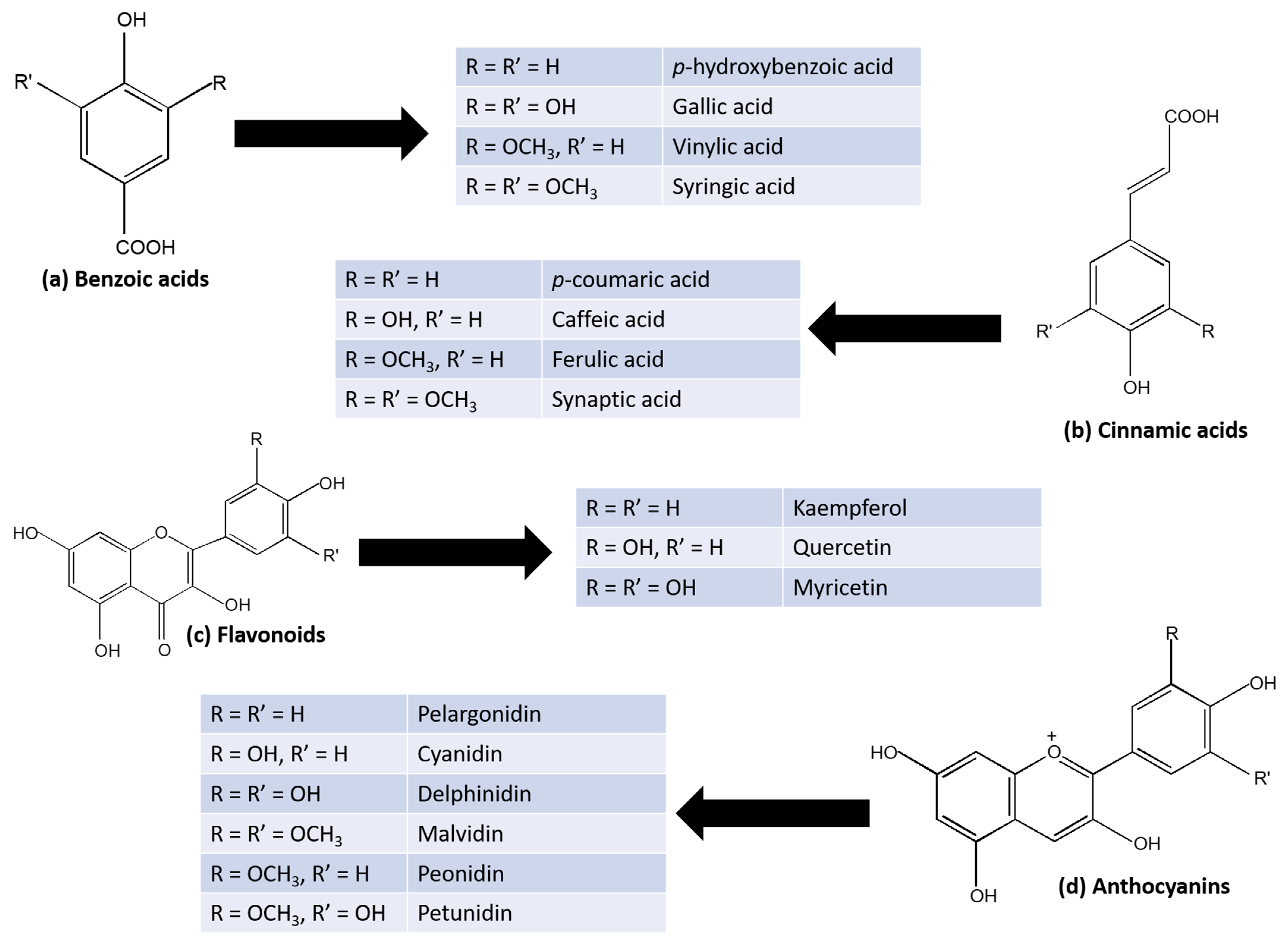

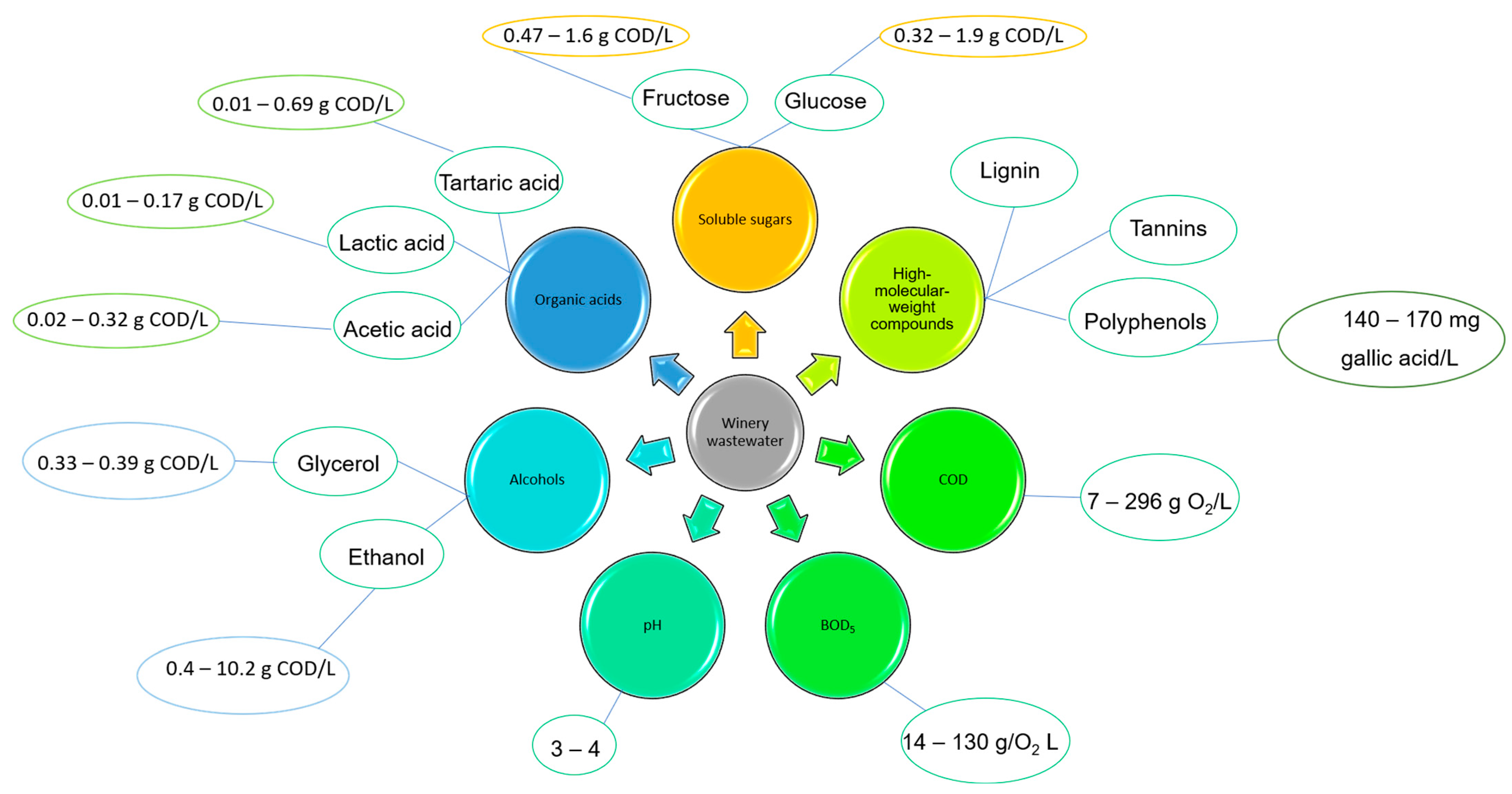

2. Characterization of the Winery Wastewater

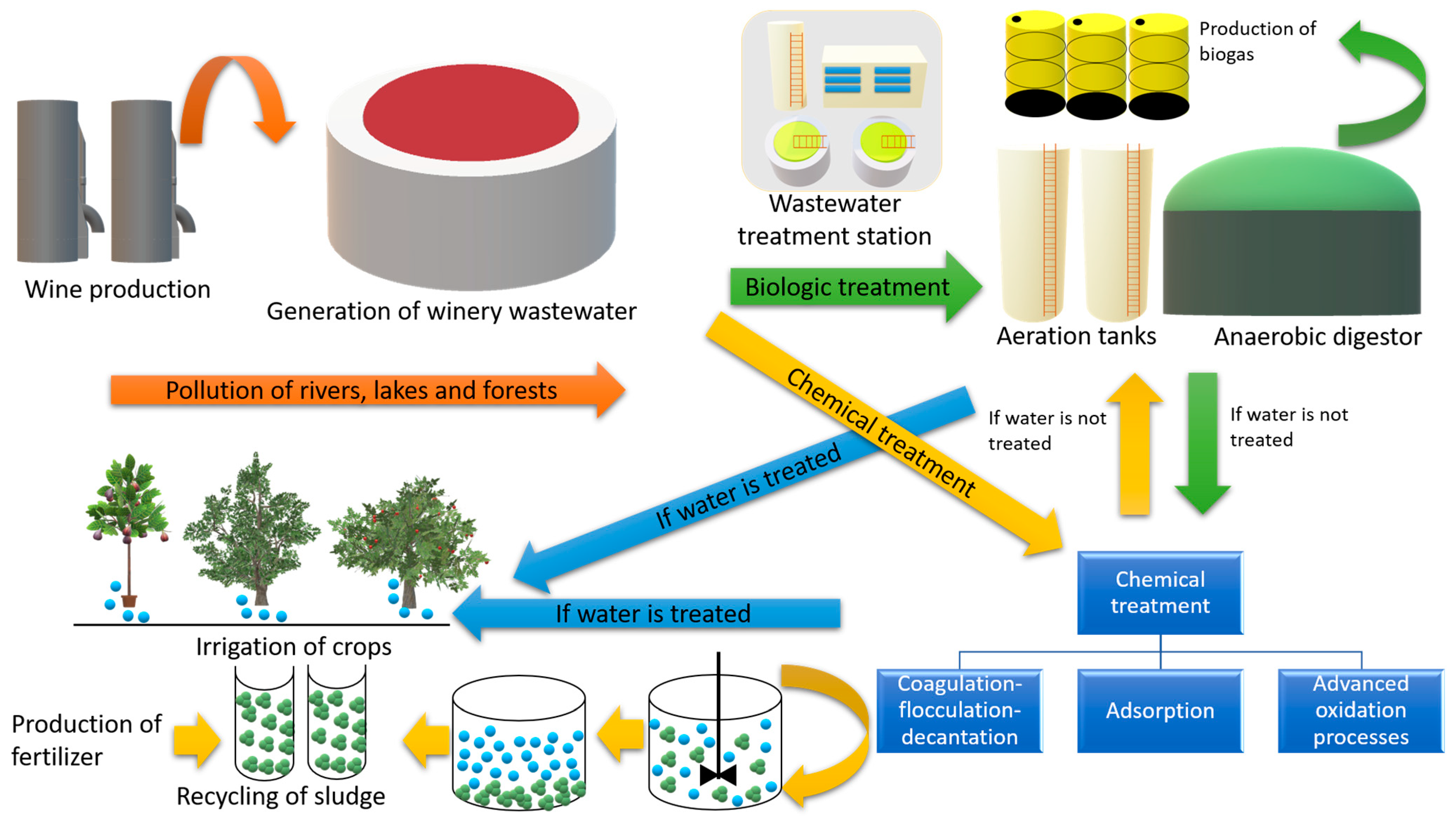

3. Environmental Impact of Winery Wastewater

4. Treatment Processes, Wastewater Reuse, and Sludge Recycling

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- OIV. State of the World Vine and Wine Sector 2021; OIV: Dijon, France, 2022; pp. 1–20. [Google Scholar]

- Jorge, N.; Santos, C.; Teixeira, A.R.; Marchão, L.; Tavares, P.B.; Lucas, M.S.; Peres, J.A. Treatment of Agro-Industrial Wastewaters by Coagulation-Flocculation-Decantation and Advanced Oxidation Processes—A Literature Review. Eng. Proc. 2022, 19, 33. [Google Scholar] [CrossRef]

- Ribéreau-Gayon, P.; Glories, Y.; Maujean, A.; Dubourdieu, D. Handbook of Enology Volume 2 The Chemistry of Wine Stabilization and Treatments, 2nd ed.; John Wiley & Sons: Chichester, UK, 2006; Volume 2, ISBN 9780470010396. [Google Scholar]

- Spennati, E.; Casazza, A.A.; Converti, A. Winery Wastewater Treatment by Microalgae to Production Purposes. Energies 2020, 13, 2490. [Google Scholar] [CrossRef]

- Kyzas, G.Z.; Symeonidou, M.P.; Matis, K.A. Technologies of Winery Wastewater Treatment: A Critical Approach. Desalin. Water Treat. 2014, 57, 3372–3386. [Google Scholar] [CrossRef]

- Kara, S.; Gürbulak, E.; Eyvaz, M.; Yüksel, E. Treatment of Winery Wastewater by Electrocoagulation Process. Desalin. Water Treat. 2013, 51, 5421–5429. [Google Scholar] [CrossRef]

- Agustina, T.E.; Ang, H.M.; Pareek, V.K. Treatment of Winery Wastewater Using a Photocatalytic/Photolytic Reactor. Chem. Eng. J. 2008, 135, 151–156. [Google Scholar] [CrossRef]

- Cañadas, R.; Díaz, I.; Rodríguez, M.; González, E.J.; González-Miquel, M. N Integrated Approach for Sustainable Valorization of Winery Wastewater Using Bio-Based Solvents for Recovery of Natural Antioxidants. J. Clean. Prod. 2022, 334, 130181. [Google Scholar] [CrossRef]

- Chatzilazarou, A.; Katsoyannos, E.; Gortzi, O.; Lalas, S.; Paraskevopoulos, Y.; Dourtoglou, E.; Tsaknis, J. Removal of Polyphenols from Wine Sludge Using Cloud Point Extraction. J. Air Waste Manag. Assoc. 2010, 60, 454–459. [Google Scholar] [CrossRef]

- Ioannou, L.A.; Puma, G.L.; Fatta-Kassinos, D. Treatment of Winery Wastewater by Physicochemical, Biological and Advanced Processes: A Review. J. Hazard. Mater. 2015, 286, 343–368. [Google Scholar] [CrossRef]

- Strong, P.J.; Burgess, J.E. Treatment Methods for Wine-Related and Distillery Wastewaters: A Review. Bioremediat. J. 2008, 12, 70–87. [Google Scholar] [CrossRef]

- Nair, C.I.; Jayachandran, K.; Shashidhar, S. Biodegradation of Phenol. African J. Biotechnol. 2008, 7, 4951–4958. [Google Scholar] [CrossRef]

- Lucas, M.S.; Mouta, M.; Pirra, A.; Peres, J.A. Winery Wastewater Treatment by a Combined Process: Long Term Aerated Storage and Fenton’s Reagent. Water Sci. Technol. 2009, 60, 1089–1095. [Google Scholar] [CrossRef]

- Souza, B.S.; Moreira, F.C.; Dezotti, M.W.C.; Vilar, V.J.P.; Boaventura, R.A.R. Application of Biological Oxidation and Solar Driven Advanced Oxidation Processes to Remediation of Winery Wastewater. Catal. Today 2013, 209, 201–208. [Google Scholar] [CrossRef]

- Marchão, L.; Fernandes, J.R.; Sampaio, A.; Peres, J.A.; Tavares, P.B.; Lucas, M.S. Microalgae and Immobilized TiO2/UV-A LEDs as a Sustainable Alternative for Winery Wastewater Treatment. Water Res. 2021, 203, 117464. [Google Scholar] [CrossRef] [PubMed]

- Ngwenya, N.; Gaszynski, C.; Ikumi, D. A Review of Winery Wastewater Treatment: A Focus on UASB Biotechnology Optimisation and Recovery Strategies. J. Environ. Chem. Eng. 2022, 10, 108172. [Google Scholar] [CrossRef]

- Lauzurique, Y.; Fermoso, F.G.; Sánchez, N.; Castillo, A.; Salazar, R.; García, V.; Huiliñir, C. Biogas Production from Winery Wastewater: Effect of the Substrate-Inoculum Ratio on Fly Ash Addition and Iron Availability. J. Water Process Eng. 2022, 47, 102826. [Google Scholar] [CrossRef]

- Akhtar, J.; Amin, N.A.S.; Shahzad, K. A Review on Removal of Pharmaceuticals from Water by Adsorption. Desalin. Water Treat. 2016, 57, 12842–12860. [Google Scholar] [CrossRef]

- Jorge, N.; Teixeira, A.R.; Lucas, M.S.; Peres, J.A. Combination of Adsorption in Natural Clays and Photo-Catalytic Processes for Winery Wastewater Treatment. In Advances in Geoethics and Groundwater Management: Theory and Practice for a Sustainable Development; Abrunhosa, M., Chambel, A., Peppoloni, S., Chaminé, H.I., Eds.; Springer: Cham, Switzerland, 2021; pp. 291–294. ISBN 978-3-030-59320-9. [Google Scholar]

- Guimarães, V.; Lucas, M.S.; Peres, J.A. Combination of adsorption and heterogeneous photo-Fenton processes for the treatment of winery wastewater. Environ. Sci. Pollut. Res 2019, 26, 31000–31013. [Google Scholar] [CrossRef] [PubMed]

- Rytwo, G.; Lavi, R.; Rytwo, Y.; Monchase, H.; Dultz, S.; König, T.N. Clarification of olive mill and winery wastewater by means of clay–polymer nanocomposites. Sci. Total Environ. 2013, 442, 134–142. [Google Scholar] [CrossRef]

- Braz, R.; Pirra, A.; Lucas, M.S.; Peres, J.A. Combination of Long Term Aerated Storage and Chemical Coagulation/Flocculation to Winery Wastewater Treatment. Desalination 2010, 263, 226–232. [Google Scholar] [CrossRef]

- Jorge, N.; Teixeira, A.R.; Lucas, M.S.; Peres, J.A. Combined Organic Coagulants and Photocatalytic Processes for Winery Wastewater Treatment. J. Environ. Manag. 2023, 326, 116819. [Google Scholar] [CrossRef]

- Jorge, N.; Teixeira, A.R.; Lucas, M.S.; Peres, J.A. Agro-Industrial Wastewater Treatment with Acacia dealbata Coagulation/Flocculation and Photo-Fenton-Based Processes. Recycling 2022, 7, 54. [Google Scholar] [CrossRef]

- Johnson, M.B.; Mehrvar, M. Treatment of Actual Winery Wastewater by Fenton-like Process: Optimization to Improve Organic Removal, Reduce Inorganic Sludge Production and Enhance Co-Treatment at Municipal Wastewater Treatment Facilities. Water 2021, 14, 39. [Google Scholar] [CrossRef]

- Jorge, N.; Teixeira, A.R.; Lucas, M.S.; Peres, J.A. Enhancement of EDDS-Photo-Fenton Process with Plant-Based Coagulants for Winery Wastewater Management. Environ. Res. 2023, 229, 116021. [Google Scholar] [CrossRef] [PubMed]

- Lucas, M.S.; Peres, J.A. Treatment of olive mill wastewater by a combined process: Fenton’s reagent and chemical coagulation. J. Environ. Sci. Health A 2009, 44, 198–205. [Google Scholar] [CrossRef]

- Rodríguez-Chueca, J.; Amor, C.; Silva, T.; Dionysiou, D.D.; Puma, G.L.; Lucas, M.S.; Peres, J.A. Treatment of winery wastewater by sulphate radicals: HSO5−/transition metal/UV-A LEDs. J. Chem. Eng. 2017, 310, 473–483. [Google Scholar] [CrossRef]

- Jorge, N.; Teixeira, A.R.; Matos, C.C.; Lucas, M.S.; Peres, J.A. Combination of Coagulation–Flocculation–Decantation and Ozonation Processes for Winery Wastewater Treatment. Int. J. Environ. Res. Public Health 2021, 18, 8882. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jorge, N.; Teixeira, A.R.; Gomes, A.; Peres, J.A.; Lucas, M.S. Winery Wastewater: Challenges and Perspectives. Eng. Proc. 2023, 56, 267. https://doi.org/10.3390/ASEC2023-15968

Jorge N, Teixeira AR, Gomes A, Peres JA, Lucas MS. Winery Wastewater: Challenges and Perspectives. Engineering Proceedings. 2023; 56(1):267. https://doi.org/10.3390/ASEC2023-15968

Chicago/Turabian StyleJorge, Nuno, Ana R. Teixeira, Ana Gomes, José A. Peres, and Marco S. Lucas. 2023. "Winery Wastewater: Challenges and Perspectives" Engineering Proceedings 56, no. 1: 267. https://doi.org/10.3390/ASEC2023-15968