Abstract

This study evaluated the index and physico-chemical characteristics of lateritic soil classified as A-2-6 (1) in the American Association of State Highway and Transportation Officials (AASHTO) system and SC in the Unified Soil Classification System (USCS) treated with stepped Bacillus sphaericus (Bs) suspension densities (i.e., 0, 1.5 × 108, 6.0 × 108, 1.2 × 109, 1.8 × 109, 2.4 × 109 cells/mL) for varying cementation reagent (Cr) concentrations (i.e., 0.25, 0.5, 0.75 and 1.0 M), using 25 Bs:75 Cr, 50 Bs:50 Cr, and 75 Bs:25 Cr mix ratios, respectively. The results obtained show that the optimum calcium carbonate contents were 9.0%, 8.7%, and 6.5% for the mix ratios stated above, respectively, for Bs (1.2 × 109 cells/mL) and Cr (0.5 M) with urease activity of 80.8 ms/cm and an optimum pH of 8.99. The bio-treatment of soil with 25% bacteria (1.2 × 109 cells/mL) and 75% Cr (0.5 M) mix ratio reduced the liquid limit (LL) of the natural soil from 36.5 to 34.2%, and the plasticity index (PI) from 16.4 to 11.6%. A microanalysis of specimens showed that the treated soil appeared more uniform and aggregated. The findings of the study show that bio-treatment with 25 Bs (1.2 × 109 cells/mL):75 Cr (0.5 M) mix ratio improved the index and physico-chemical properties of the lateritic soil considered in the study.

1. Introduction

Soil stabilisation or the improvement of soil is employed when it is more economical to overcome a deficiency in a readily available material than to bring in one that fully complies with the specification requirements for the soil [1]. Stabilisers and modifiers can be organic or inorganic chemical compounds, with organic compounds being resinous and bituminous materials acting as water-proofers and sometimes behaving similarly to glue to add cohesive strength. Inorganic chemical compounds include Portland cement, lime, slag, sodium silicate, phosphorus compounds, and sometimes a combination of various inorganic salts, such as sodium chloride and calcium chloride, which have long been used in stabilisation. Their main function is to reduce plasticity and facilitate densification [2].

Previous research on soil improvement considered the use of conventional additives such as bitumen, lime, cement, pozzolanic material, agro-industrial waste, etc., which are either expensive or harmful to the environment and, hence, not sustainable. According to [3], soil improvement techniques like chemical grouting or mixing with cement have shown positive outcomes. These can be described as the artificial injection of chemical formulas that, mostly, alter the soil pH level and cause soil and groundwater contamination; this is not unconnected to the hazardous/toxic nature of the additives [4,5].

Too high a dependence on industrially manufactured soil improving additives (e.g., cement, lime, and bitumen) has kept the cost of stabilisation high. Consequently, underdeveloped and poor nations are unable to provide accessible roads for their rural dwellers, who constitute a higher percentage of their agrarian population. Also, a large quantity of carbon dioxide is released during the production of cement, which is a major construction material worldwide.

Based on the aforementioned points, a better, environmentally friendly, efficient, and effective remedial technique suitable for soil stabilisation might be the biogenic/microbial technique of soil improvement. This trending microbial geotechnology has proven to be highly effective and efficient in soil improvement works, with ease of use and reduced cost, and it enhances environmental sustainability [6].

Microbial-induced calcite precipitation (MICP) is a biochemical soil-strengthening process that utilises urea hydrolysis, sulphate reduction, denitrification, aerobic oxidation, and other processes to produce calcite [7]. When compared to other investigation procedures, urea hydrolysis yields the highest rate of calcite precipitation [1]. During urea hydrolysis, the urease enzyme, which is either externally supplied [8] or produced by micro-organisms in situ [1], facilitates a chemical reaction in which urea (CO(NH2)2) is broken down. This microbial bio-cementation process has very little or no harmful effect on the environment. Microorganisms, in particular, bacteria, can alter the arrangement of the soil particle sizes and influence the arrangement of the soil matrix by enhancing crystallisation within the soil matrix. Subsequently, after these activities, the soil may behave differently (e.g., there may be an increase in hydrodynamic dispersion, chemical retardation, or the migration of fine particles) [1].

Laterites are formed through the process of laterisation, which takes place in a weathering system, resulting in the permanent deposition of sesquioxides (i.e., Al2O3 and Fe2O3) via the breakdown of ferro-aluminosilicate minerals [9]. Most laterites in their natural states are deficient for use in construction work and require some improvement, especially in areas where erosion is a problem. Researchers, over the years, have been looking for less-expensive and more-environmentally friendly strategies to enhance the properties of these deficient soils [4]. The MICP technique of soil improvement modifies the arrangement of soil particle sizes and influences the arrangement of the soil matrix by enhancing crystallisation within the soil matrix. Therefore, this study aimed to assess the impact of different cementation reagent concentrations on the index and physico-chemical properties of the lateritic soil bio-treated with Bacillus sphaericus. The objectives include culturing micro-organisms from the lateritic soil in the large quantities required for the soil-improvement process, the characterisation of the natural soil and B. sphaericus from the soil, the evaluation of the plasticity properties of the natural and bio-treated soil, and a micro-analysis of specimens in the natural and bio-treated soils using scanning electron microscopy (SEM).

2. Materials and Methods

2.1. Materials

2.1.1. Soil

The method of disturbed sampling was used to collect the soil from a site prone to erosion, located in the Abagana district (Latitude 6°12′15″ N and Longitude 7°0′40″ E), Njikoka Local Government Area, Anambra State, at depths in the range of 0.5–3.0 m.

2.1.2. Bacteria

The Gram-positive micro-organism used in the study is Bacillus sphaericus which is a rod-shaped bacterium with a 2–5 µm diameter.

2.1.3. Cementation Reagent

The reagents were varied by using an equal molar concentration of calcium chloride and urea to produce cementation solutions of different molar quantities (i.e., 0.25 M, 0.5 M, 0.75 M, and 1 M).

2.2. Methods

2.2.1. Isolation and Characterisation of Bacteria

The Bacillus sphearicus bacterial type was used in the study. The bacterium was isolated from the soil, of which six (6) different samples were collected and used for the isolation, identification, and characterisation of Bacillus sphearicus. They were inoculated on nutrient broth, yeast extract, nutrient agar, and MICP agar.

2.2.2. Biochemical and Confirmatory Tests

Urease Production

The enzymatic capacity of the test organism to degrade urea agar slant for ammonia and carbon dioxide production through hydrolysis, which enabled the culture medium to turn alkaline, thereby resulting in a change in colour from orange to pink, indicated the presence of a positive urease test organism. This process was carried out by inoculating the test organism on a urea agar slant that was incubated at 37 °C for 24 h.

2.2.3. Index Properties

The index tests for the untreated and bio-treated soils were conducted in accordance with relevant specifications [10,11].

Sample Preparation

The soil sample used was passed through a BS No. 40 sieve (425 µm aperture) and treated using bacteria–cementation mix ratios of 25%:75%, 50%:50%, and 75%:25% (adapted from [2]). The liquid limit (LL) of the natural soil determined this mix ratio. Bacillus sphaericus was administered at suspension densities of 0, 0.5, 2.0, 4.0, 6.0, and 8.0 McFarland standards, corresponding to 0, 1.5 × 108, 6.0 × 108, 12 × 108, 18 × 108 and 24 × 108 cells/mL, respectively, at the varying concentrations of cementation reagent of 0.25, 0.5, 0.75, and 1 M.

2.2.4. Atterberg Limits

Atterberg limit tests are essential for soil classification and identification. The air-dried and pulverised natural soil was sieved using a BS No. 40 sieve prior to its mixture with the bacteria specimen.

2.2.5. Calcite Content

The acid-washing procedure was adopted as reported by [12] for the calcite content determination.

2.2.6. Measurement of Urease Activity Using Electrical Conductivity Test

The test method was carried out, as proposed in the literature [11], by measuring the solution’s electrical conductivity every minute using an electrical conductivity meter to determine the level of activity of the urease.

2.2.7. pH

The growth in urease-producing bacteria, the crystallisation of CaCO3, and the enhancement of soil engineering properties are influenced by the pH value.

2.2.8. Microstructural Analysis

A micro-analysis of lateritic soil (natural and bio-treated) specimens was carried out using scanning electron microscopy (SEM) to determine the change in morphology brought on by the growth of calcite precipitates on the interparticle surface of the biochemically treated soil.

3. Results and Discussion

3.1. Index Properties

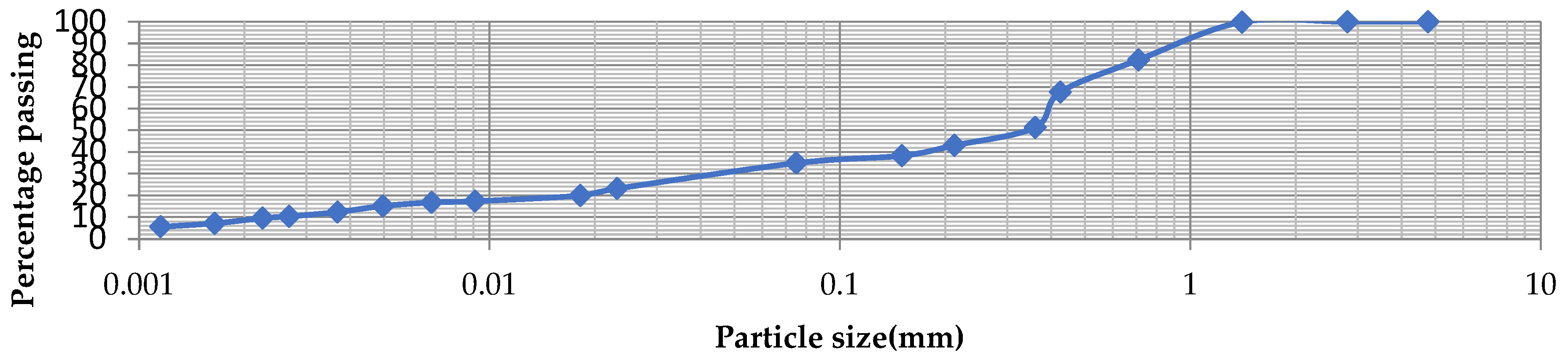

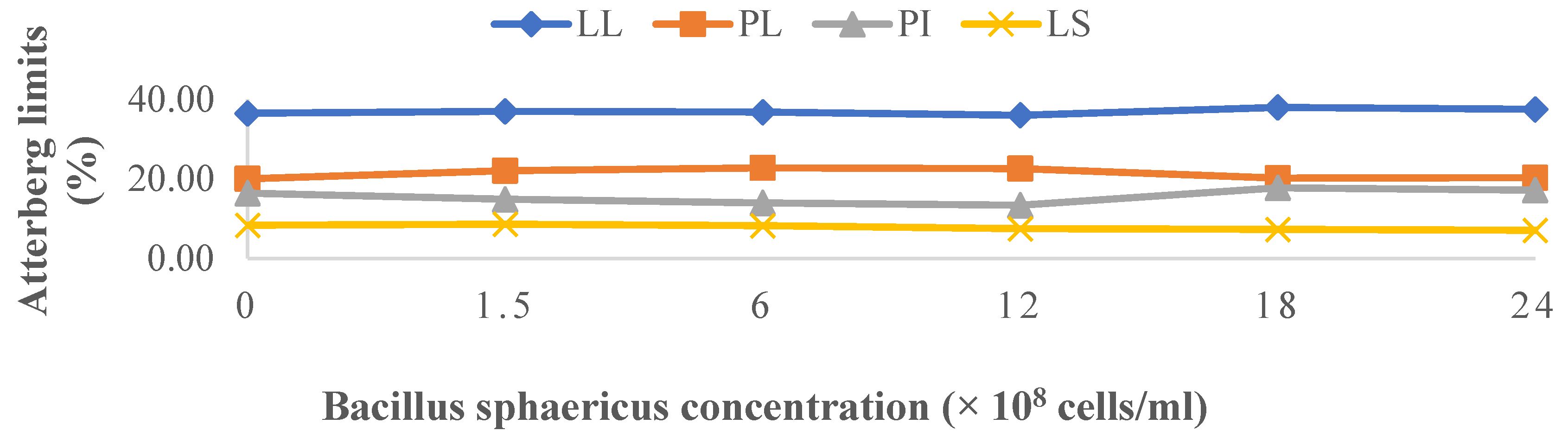

The natural lateritic soil is classified as A-2-6 (1) in the AASHTO system [13] and SC (clayey sand) in the USCS [14] is presented in Figure 1.

Figure 1.

Particle size distribution curve of the natural lateritic soil.

3.2. Physico-Chemical Properties

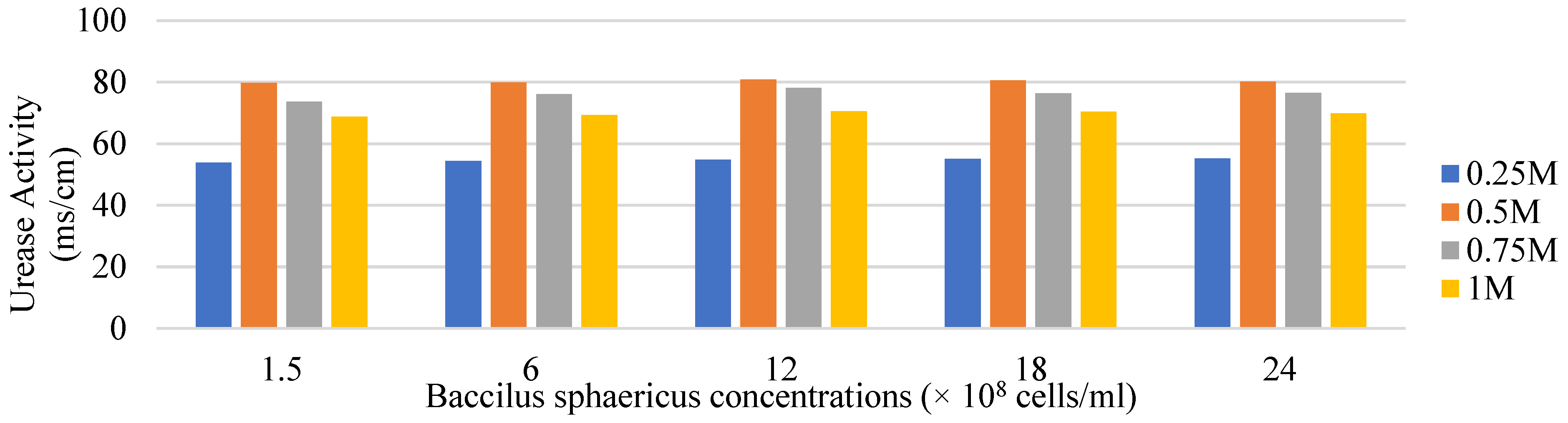

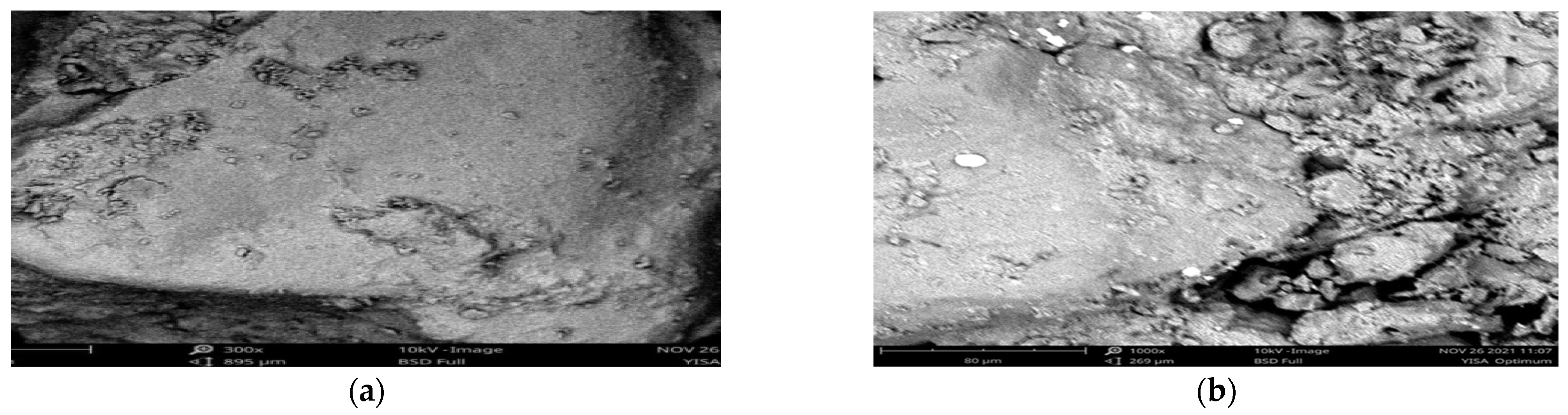

3.2.1. Urease Activity

The electrical conductivity (EC) test was employed to investigate the bacteria urease activity in MICP [15]. The EC test results are presented in Figure 2. The peak urease activity value recorded was 80.8 ms/cm at the cementation reagent concentration of 0.5 M and the bacteria suspension density of 1.2 × 109 cells/mL.

Figure 2.

Variation in the urease activity of lateritic-soil–cementation-solution mixtures with the Bacillus sphaericus suspension density.

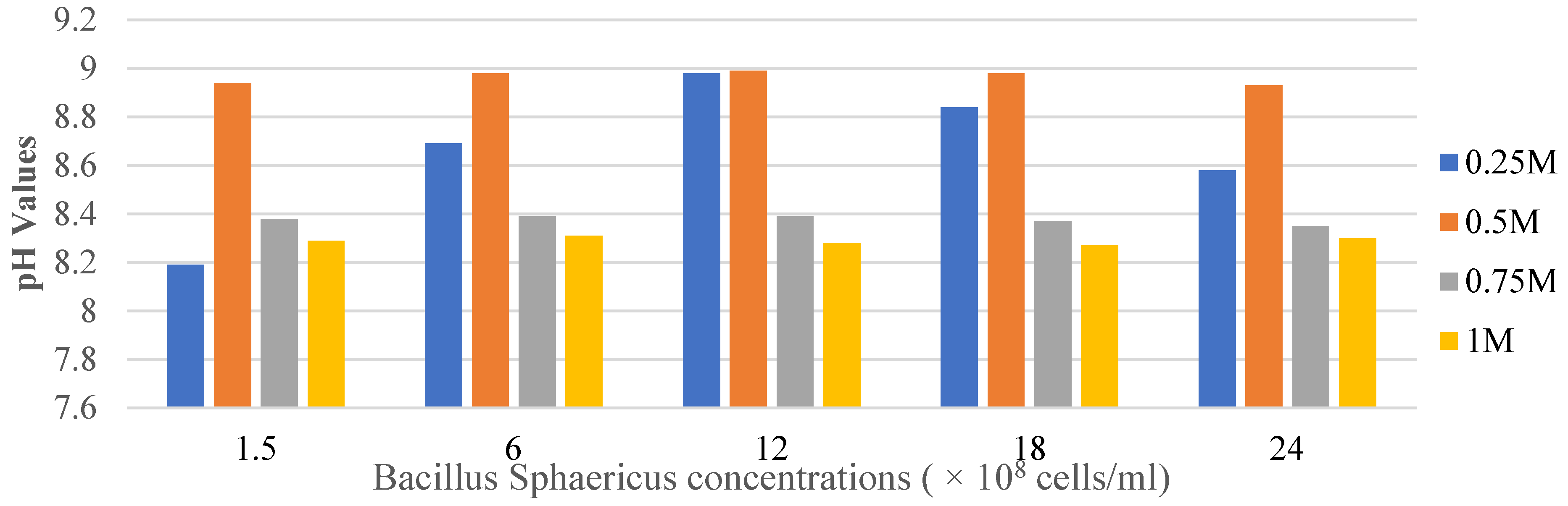

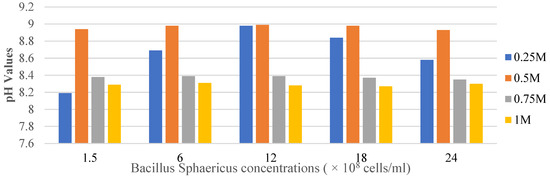

3.2.2. pH

The pH has a significant impact on the MICP technique because it affects the quantity of calcite precipitated at the end of the process, as well as the number and performance of the microbes. The urea activity can also be reflected through the pH [16]. The optimum pH value of 8.99 was recorded at the cementation reagent concentration of 0.5 M and the bacteria suspension density of 1.2 × 109 cells/mL, as presented in Figure 3.

Figure 3.

Variation in the pH values of lateritic-soil–cementation-solution mixtures with the Bacillus sphaericus suspension density.

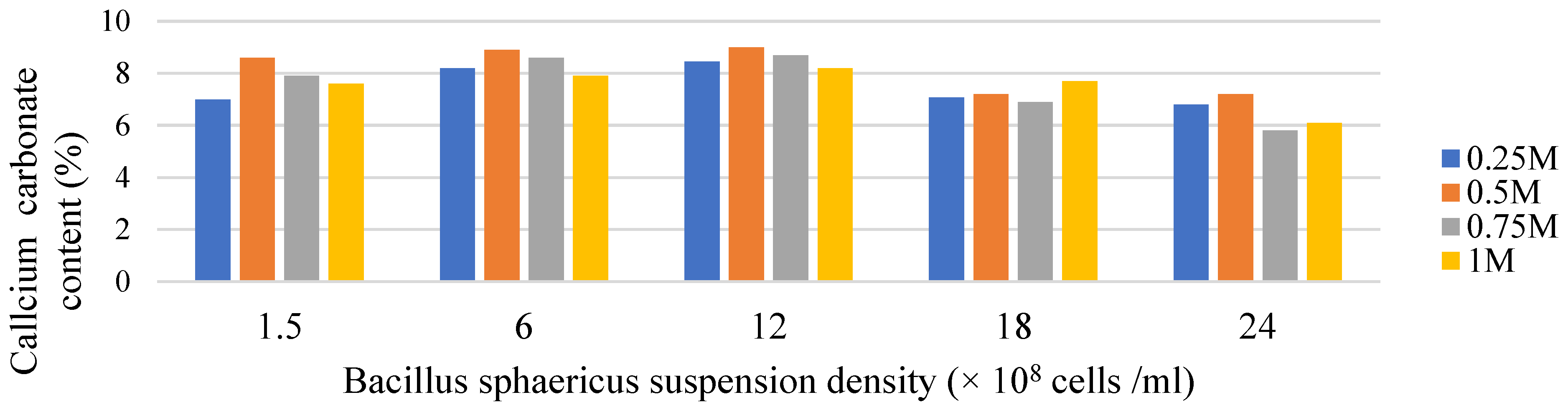

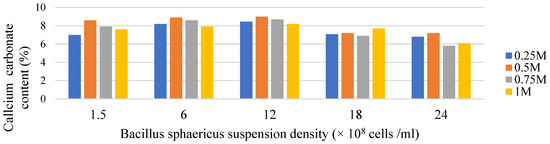

3.2.3. Calcite Content

The lateritic soil was treated, using stepped B. sphaericus suspension densities, with cementation reagent concentration mix ratios of 25%:75%, 50%:50%, and 75%:25%. The typical variation in calcium carbonate formed in the lateritic soil with the B. sphaericus suspension density for the mix ratio of 25%:75% for different cementation reagent concentrations is presented in Figure 4. Generally, the calcite content of all the treated specimens increased as the concentration of the cementation reagent increased to peak values before decreasing. The optimum calcium carbonate content (CCC) values were 9.0%, 8.7%, and 6.5% for the bacteria–cementation-mix ratios of 25%:75%, 50%:50%, and 75%:25%, respectively, at the B. sphaericus suspension density of 1.2 × 109 cells/mL and the cementation reagent concentration of 0.5 M.

Figure 4.

Variation in the calcite content of lateritic-soil–cementation-solution mixtures with the Bacillus sphaericus suspension density (25% BS: 75% cementation reagent mix ratio).

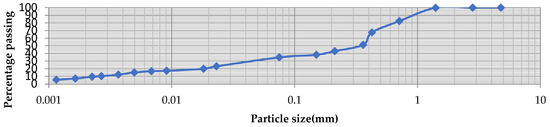

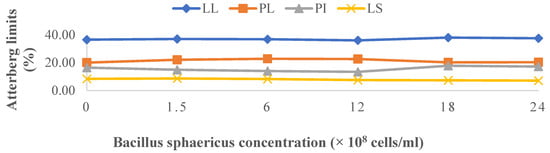

3.2.4. Atterberg Limits

The changes in Atterberg limits (LL, PL, and PI) and linear shrinkage (LS) of the lateritic soil bio-treated with stepped B. sphaericus suspension densities of 0, 1.5 × 108, 6.0 × 108, 1.2 × 109, 1.8 × 109, and 2.4 × 109 cells/mL using bacteria-to-cementation-mix ratios of 25%:75%, 50%:50%, and 75%:25%, respectively, at stepped cementation reagent concentrations of 0.25, 0.5, 0.75, and 1 M, were considered. A typical result for the 0.25 M cementation reagent is presented in Figure 5.

Figure 5.

Variation in the moisture content of lateritic soil with 0.25 M cementation reagent with the B. sphaericus suspension density.

The LL increased from 36.5% for the natural soil, reaching its peak value at 38.0% upon treatment with 1.8 × 109 cells/mL of B. sphaericus and with a further increase in the microbial density to 2.4 × 109 cells/mL, the LL value was reduced to a value of 37.5%. Similarly, the PL increased from 20.1% for the untreated soil to a peak value of 22.8% when treated with a B. sphaericus suspension density of 1.2 × 109 cells/mL; however, at 2.4 × 109 cells/mL, the value decreased to 20.3%. On the other hand, the PI value decreased from 16.4% for the untreated natural soil to 13.4% for a B. sphaericus suspension density of 1.2 × 109 cells/mL. The LS value decreased from 8.4% for the untreated soil to a minimum of 7.2% at 2.4 × 109 cells/mL. Similar results were obtained for samples treated with higher bacterial suspension densities and cementation reagent concentrations.

The study showed that lateritic soil bio-treated with a 25% B. sphaericus (1.2 × 109 cells/mL): 75% cementation reagent (0.5 M) mix ratio gave the best plasticity index value, indicating better potential for soil improvement. The Atterberg limit results obtained in the study are consistent with the findings documented in the literature, such as [17].

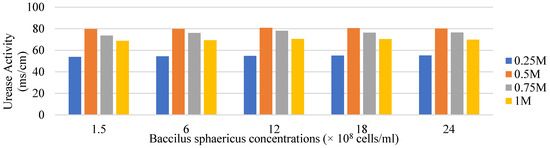

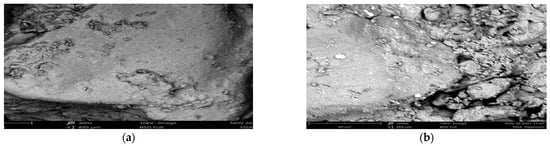

3.3. Microstructural Analysis

The calcite crystal precipitation and growth on a micro scale were examined using scanning electron microscopy (SEM). The micrographs for the untreated natural and the bio-treated lateritic soil specimens are shown in Figure 6a (at ×300 magnification) and I(b) (at ×1000 magnification) for Atterberg-limit specimens prepared with a 25% bacteria (1.2 × 109 cells/mL): 75% cementation reagent (0.5 M) mix ratio. The calcite precipitated, as confirmed using X-ray diffraction (XRD) analysis, on and between the soil grains is depicted in Figure 6b.

Figure 6.

Micrograph of the natural lateritic soil at 300× magnification (a) and micrograph of the bio-treated lateritic soil (b) with 25% bacteria (1.2 × 109 cells/mL): 75% cementation reagent (0.5 M) mix ratio.

4. Conclusions

From the laboratory test results for the physico-chemical and index characteristics of the lateritic soil treated with stepped Bacillus sphaericus (B. sphaericus) suspension densities at varying cementation reagent concentrations, the following can be deduced:

- The Gram-positive, rod-shaped Bacillus sphearicus bacterial type isolated from each of the six (6) separate soil samples collected had a total bacteria count no less than 3.65 × 104 cfu/mL

- For the three mix ratios considered at varying cementation reagent and suspension densities, the PI decreased from 16.4% to the minimum values of 11.6%, 12.2%, and 16.2% for the 25%:75%, 50%:50%, and 75%:25% bacteria–cementation-reagent mix ratios, respectively, for bio-treatments with a B. sphaericus suspension density of 1.2 × 109 cells/mL and a cementation reagent concentration of 0.5 M, 1.8 × 109 cells/mL and 0.5 M, as well as 6.2 × 108 cells/mL and 0.25 M, respectively.

- The micrograph of the bio-treated soil specimen is more uniform and aggregated than that of the natural soil.

5. Recommendation

Based on the results obtained in the study, the physico-chemical and index properties of the A-2-6 or SC soil can be improved using 25% B. sphaericus (1.2 × 109 cells/mL): 75% and a 0.5 M cementation reagent (0.5 M) mix ratio.

Author Contributions

Conceptualization: K.J.O.; Methodology: G.L.Y.; Investigation: G.L.Y.; Writing original draft preparation: G.L.Y.; Writing-review and editing: K.J.O., T.S.I. and A.O.E.; Final review: K.J.O.; Supervision: K.J.O., T.S.I. and A.O.E. All authors have read and agreed to the published version of the manuscript.

Funding

The study was funded by the Nigerian Building and Road Research Institute (NBRRI), Abuja, Nigeria.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All the date used are available and will be provided on request.

Acknowledgments

The authors acknowledge the support of Ahmadu Bello University, Zaria, Nigeria for the use of the Soil Mechanics Research Laboratory in the Civil Engineering Department to conduct all the experiments.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, Y.; Konstantinou, C.; Soga, K.; Biscontin, G.; Kabla, A.J. Use of microfluidic experiments to optimize MICP treatment protocols for effective strength enhancement of MICP-treated sandy soils. Acta Geotech. 2022, 17, 3817–3838. [Google Scholar] [CrossRef]

- Osinubi, K.J.; Eberemu, A.O.; Gadzama, E.W.; Ijimdiya, T.S. Plasticity Characteristics of Lateritic Soil Treated with Sporosarcina pasteurii in Microbial-Induced Calcite Precipitation Application. Springer Nat. Appl. Sci. 2019, 1, 829. [Google Scholar] [CrossRef]

- Mahawish, A.; Bouazza, A.; Gates, W.P. Factors Affecting the Bio-cementing Process of Coarse Sand. Proc. Inst. Civ. Eng. Ground Improv. 2019, 172, 25–36. [Google Scholar] [CrossRef]

- Chittoori, B.C.S.; Burbank, M.; Islam, M.T. Evaluating the effectiveness of soil-native bacteria in precipitating calcite to stabilise expansive soils. ASCE IFCEE Geotech Spec. Publ. 2018, 296, 59–68. [Google Scholar] [CrossRef]

- Bayang, F.; Sani, J.E.; Kevin, O.K.; Ijimdiya, T.S. Influence of Compactive Effort and Strength Characteristics of Lime Treated Lateritic Soil Mixed with Untreated Textile Effluent. Niger. J. Technol. 2023, 42, 199–208. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Chen, R. Adding Aluminium Oxide to Improve the Repairing Effect of Cracks Based on Bio-remediation. J. Adv. Concr. Technol. 2019, 17, 177–187. [Google Scholar] [CrossRef]

- Rajasekar, A.; Wilkinson, S.; Moy, C.K.S. Microbial Induced Calcite Precipitation as a Potential Sustainable Technique to Treat or Entrap Contaminants in the Natural Environment: A review. Environ. Sci. Ecotechnol. 2020, 6, 100096. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.-S.; Yin, L.-Y.; Jiang, N.-J.; Zhu, C.; Zeng, H.; Li, H.; Shi, B. Factors Affecting the Performance of Microbial-Induced Carbonate Precipitation (MICP) Treated Soil: A review. Environ. Earth Sci. 2020, 79, 94. [Google Scholar] [CrossRef]

- Dissanayake, D.M.; Mantilaka, M.M.; De Silva, R.T.; De Silva, K.M.; Pitawala, H.M. Laterite and its potential as an alternative-bauxite. Clean. Mater. 2021, 1, 100016. [Google Scholar] [CrossRef]

- BS 1377; Method of Testing Soils for Civil Engineering Purposes. British Standard Institute (BSI): London, UK, 1990.

- BS 1924; Methods of Tests for Stabilized Soils. British Standard Institute (BSI): London, UK, 1990.

- Osinubi, K.J.; Yohanna, P.; Eberemu, A.O.; Ijimdiya, T.S. Evaluation of Hydraulic Conductivity of Lateritic Soil Treated with Bacillus Coagulans for Use in Waste Containment Applications. In Proceedings of the 8th International Congress on Environmental Geotechnics (ICEG 2018): Towards a Sustainable Geoenvironment; Zhan, L., Chen, Y., Bouazza, A., Eds.; Springer: Singapore, 2019; Volume 3, pp. 401–409. [Google Scholar] [CrossRef]

- AASHTO. Standard Specifications for Transport Materials and Methods of Sampling and Testing, 14th ed.; American Association of State Highway and Transportion Officials (AASHTO): Washington, DC, USA, 1986. [Google Scholar]

- ASTM. Annual Book of Standards; American Society for Testing and Materials: Philadelphia, PA, USA, 1992; Volume 4. [Google Scholar]

- Zhao, Q.; Li, L.; Li, C.; Li, M.; Amini, F.; Zhang, H. Factors Affecting Improvement of Engineering Properties of MICP-Treated Soil Catalyzed by Bacteria and Urease. J. Mater. Civ. Eng. 2014, 26, 04014094. [Google Scholar] [CrossRef]

- Wen, K.; Yang, L.; Shihui, L.; Changming, B.; Lin, L. Evaluation of MICP Treatment through Electric Conductivity and pH Test in Urea Hydrolysis Process. Environ. Geotech. 2021, 8, 274–281. [Google Scholar] [CrossRef]

- Moravej, S.; Habibagahi, G.; Nikooee, E.; Niazi, A. Stabilisation of Dispersive Soils by Means of Biological Calcite Precipitation. Geoderma 2018, 315, 130–137. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).