Abstract

This study evaluated the influence of asphalt binder and biochar-based geopolymer composites on the permanent deformation resistance (PDR) of asphalt concrete. The influence of three design variations, asphalt binder, biochar, and geopolymer content, was evaluated by employing the response surface method (RSM) based on the Box Behnken approach. The asphalt binder content ranged between 4 and 6%, whereas the biochar and geopolymer content ranged between 0 and 4%. The average rut depth of Bio-Geopolymer Asphalt concrete (BGAC) was employed as the response variable. The synergetic influence of the design variable was examined using the RSM approach, and a model was developed to determine optimum contents for improving PDR. The model has very high R2 values and adequate precision, showing that there is a significant relationship between the experimental and predicted values. The study ANOVA revealed that the asphalt binder and a biochar-based geopolymer composite modifier showed a significant effect in enhancing the PDR of BGAC. Furthermore, the optimization shows that the optimal content for biochar, geopolymer, and asphalt binder are 3.22%, 1.81%, and 5.4%, respectively. The generated model’s percentage error was found to be 5%, showing a significant correlation between the actual and predicted data. The results of this study show that using RSM to predict and optimize the PDR of BGAC is a very efficient and effective technique.

1. Introduction

Road infrastructure building and upkeep have always been critical for societies all over the world. Roads are transportation lifelines, facilitating economic activity, improving connections, and contributing to general societal development [1]. Asphalt concrete, sometimes known as asphalt pavement, is an essential component of modern transport systems. Its widespread use could be due to its superior load-bearing capability, low cost, and convenience of construction [2]. However, the premature deterioration of asphalt pavements, caused primarily by variables such as traffic loading, environmental conditions, and inferior materials, offers a substantial challenge to the long-term viability of these critical assets [3]. Permanent deformation, also known as rutting, is a major problem among the different distress mechanisms impacting asphalt pavements. Rutting not only affects road safety but also raises maintenance expenses, resulting in significant economic constraints. Permanent deformation, also known as rutting, transpires when the asphalt pavement develops excessive and permanent distortion because of frequent traffic loading, eventually leading to decreased road safety, pavement failure, and increased maintenance costs [4]. To address this issue, researchers and engineers have been investigating novel techniques to enhance the permanent deformation resistance (PDR) of asphalt concrete. One potential area of research is the use of composites as modifiers to enhance the asphalt binder and concrete performance. The development and application of new asphalt binders and geopolymer-based composites with biochar, which has the potential to improve the performance and durability of asphalt concrete, is one promising path [5].

Asphalt binders are essential for retaining aggregate particles in asphalt concrete and they are subjected to environmental and traffic stress, which causes premature aging. Recently, researchers have been looking into new options, such as geopolymer composites, which are made up of inorganic binders, and have received a lot of interest recently because of their potential to improve the properties of asphalt concrete [4]. Geopolymers made from alkali-activated aluminosilicates increase the mechanical characteristics and durability of asphalt mixtures. Also, biochar, a carbon-rich byproduct of biomass pyrolysis improves asphalt binder characteristics and rutting resistance. Biochar, a byproduct of biomass pyrolysis, has also emerged as a viable and environmentally benign component for geopolymer composites [6]. Geopolymer composites, when mixed with biochar, have the potential to provide numerous benefits in terms of rutting resistance, long-term durability, and sustainability. The researchers want to produce green and improved asphalt concrete with a higher permanent deformation resistance by mixing biochar and geopolymer to form a sustainable composite as a modifier. Asphalt pavement modification to improve PDR is an important topic in asphalt concrete design and maintenance. As a result, optimizing the materials used in the modification process, as well as building prediction models for asphalt concrete PDR, is required. In this case, mathematical modeling, and optimization methods such as response surface methodology (RSM) can be effective for analysis and optimization [7,8]. The use of statistical modeling and optimization methods, such as the response surface method, is extremely advantageous in measuring the impact of asphalt binder and biochar geopolymer composites (BGC) on the permanent deformation resistance of asphalt concrete [7]. Using such methodologies, researchers can acquire significant insights into the interplay between variables [9] and, as a result, contribute to the creation of more lasting and sustainable asphalt concrete pavement

The goal of this investigation is to evaluate the influence and interaction of the asphalt binder and BGC when used as a sustainable modifier on asphalt concrete’s permanent deformation resistance by employing the response surface method.

2. Materials and Methods

2.1. Asphalt Binder and Aggregate

The penetration grade 60/70 was utilized as a control binder, as well as in the preparation of the modified asphalt binder. The dense gradation method was used to obtain excellent aggregate interlocking. The mineral aggregate used in the study is crushed stones with a maximum standard size of 14 mm, and the gradation is shown in Table 1. This coarse aggregate was mixed with fine aggregate to make a well-balanced mixture. The filler material in the study was stone dust passing sieve No. 200.

Table 1.

Aggregate gradation for asphalt concrete AC14.

2.2. Bio-Geopolymer Composite

High-quality chemicals and reagents were purchased from a Malaysian chemical laboratory, while waste materials like palm oil fuel ash and rice straw were procured from local businesses. Following a thorough rinsing, organic material removal, and drying, the POFA was crushed and sieved. A local vendor provided the metakaolin, which was calcined, while the rice straw waste was cleaned, submerged, washed, dried, pulverized, and processed to pass through a particle passing sieve of No. 200 size. These materials were then employed in the production of geopolymer and biochar composite.

2.3. Modified Asphalt Binder Preparation

In this study, composite-modified binders were created by mixing biochar and geopolymer with a 60/70 pen-grade asphalt binder. Biochar at various contents was added at a high mixing speed of 1500 rpm to the control asphalt binder for about 60 min at 140 °C, to ensure a homogeneous blend. Following that, various percentages of geopolymer were gradually added and mixed for 30 min at the same mixing speed. This mixing process sought to improve the asphalt binder, and viscoelastic properties, resulting in an improvement in the performance of the asphalt concrete mixture.

2.4. Permanent Deformation Test

The permanent deformation test in this study was carried out using the Wessex wheel tracker following the BS 598-110 specification [10]. The test used a standard axle with a diameter of 200 mm and a width of 50 mm, with an applied weight of 520 N. The test was conducted at a temperature of 55 °C, and the samples were preconditioned for 6 h at the testing temperature. The Wessex wheel tracker recorded the average rut depth (ARD) as the wheel went back and forth over the samples in a repeating motion, performing 42 passes each minute. The test lasted for 45 min.

2.5. RSM Design of Experiment and Analysis

The RSM-based Box Behnken design was employed in this study to investigate the influence of three independent parameters (Biochar, geopolymer, and asphalt binder content) on the ARD of asphalt concrete samples. For statistical analysis and experimental designs, the Design Expert software version 13.0.0 was employed. The asphalt binder content ranged between 4 and 6%, whereas the biochar and geopolymer content ranged between 0 and 4%, respectively. Table 2 depicts the design of the experiment, which contained 17 runs that were carried out in a randomized order, with five replications of the center point to correctly assess experimental errors [9]. The response variable was determined using the polynomial function of the order two equation, as depicted in Equation (1):

Table 2.

Study design of experimental matrix.

The equation depicts the relationship between the expected outcome (Y), a constant response value (), the linear effects (), the interaction effect (), coded components ( and ), and the random error in the model ().

3. Results and Discussion

3.1. RSM Statistical Assessment

A quadratic model for predicting rutting depth was successfully created using regression analysis. The addition of higher-order polynomials that demonstrated statistical significance and were not influenced by software limitations led to the selection of a quadratic model [9]. The derived model for ARD is represented by Equation (2). The positive and negative signs preceding the terms represent the synergistic or antagonistic effects of individual variables on the response variable.

The ANOVA summary for the ARD model is displayed in Table 3. The coefficient of determination () was utilized to assess the models’ correlation. The model has an value of 0.997 and predicted value 0.995 with discrepancies of less than 0.2. This implies that neither overfitting nor underfitting affects the models. The significance of the response model and its component terms in the ARD study are determined using a 95% confidence interval (p < 0.05). The low p-value suggests that the quadratic model and its terms are statistically significant. In this study, the 95% confidence interval equates to a likelihood of a p-value of less than 0.05. The outcomes indicate that there is a very low likelihood (0.01%) that the observed F-value of 9.99 in the rutting depth model is attributable to random noise. This reinforces the conclusion that the model and its terms are significant in understanding variations in the permanent deformation of asphalt concrete.

Table 3.

ANOVA and fit statistics for the study’s ARD model.

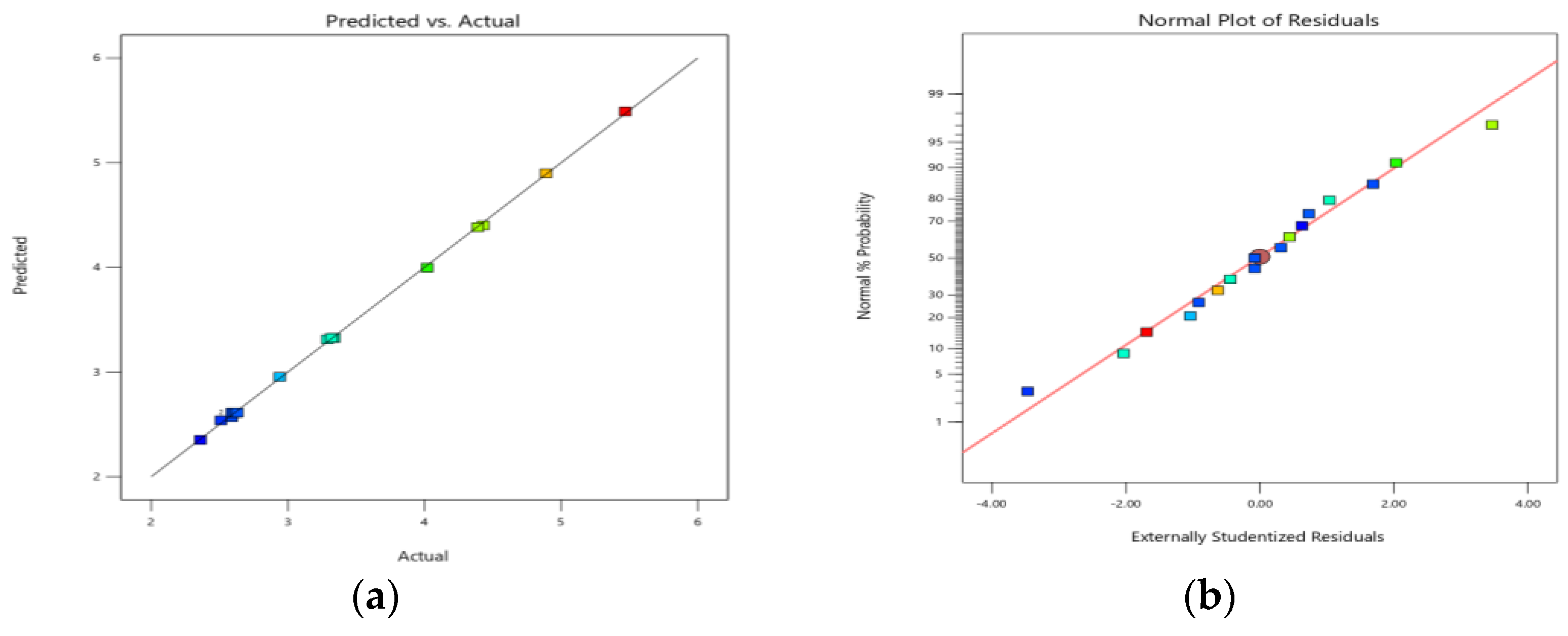

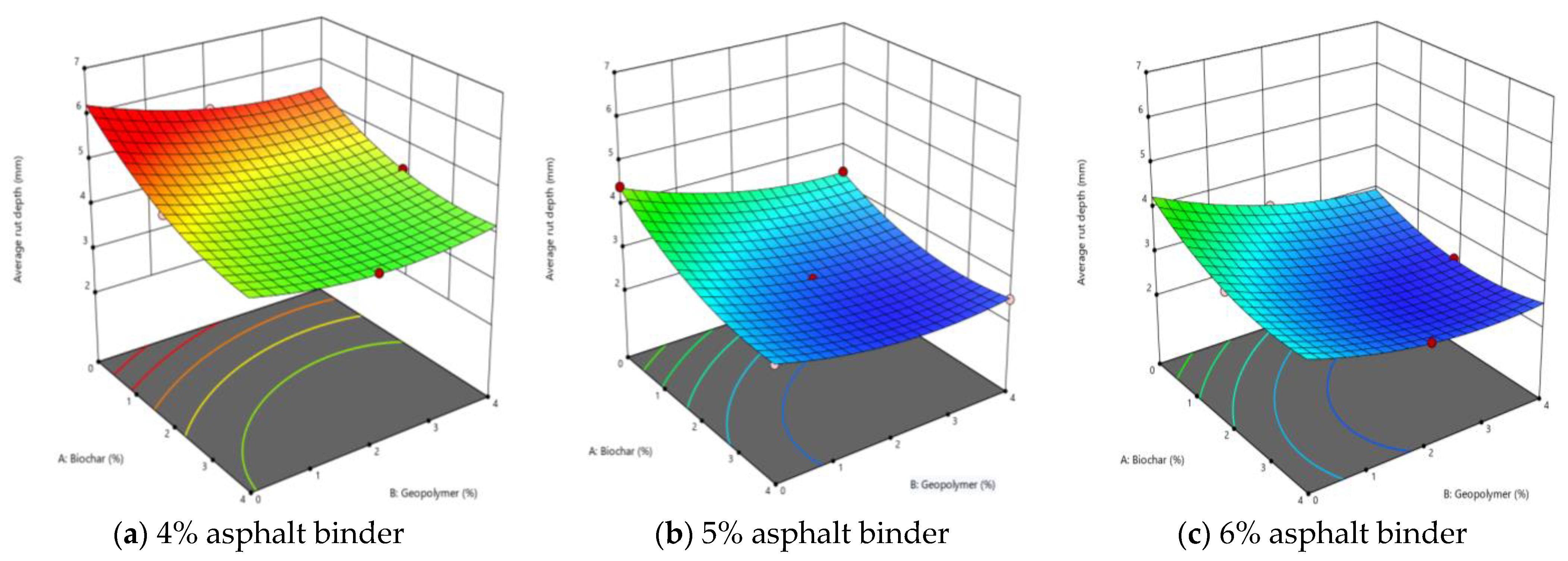

Figure 1 depicts a plot of predicted vs. actual values and a normal plot of residuals to evaluate the suitability of the model. Figure 1a shows that all the data are tightly distributed around the line of equality. This shows a good level of agreement between the model’s predicted findings and the actual observed findings, and Figure 1b shows the normal plot of residuals for the data set, indicating that the model has a sufficient degree of fitting precision and is also significant. The proximity of the points to the line of parity shows that the models have a good level of fitting precision [11]. The colors in Figure 1a,b correspond to different levels of interaction, with blue indicating a low interaction region, green representing a medium interaction region, and red indicating an optimised interaction between the input variables. The red circle represents the study data’s central point. The 3D response surface plots the rutting depth model at various asphalt binder contents. Figure 2a–c depicts the 3D surface plot. The 3D contour lines have elliptical shapes, indicating a strong interaction between the input variables.This implies that all the variables have a considerable impact on the model’s response [12]. The increased PDR in the asphalt concrete can be attributed to the asphalt binder’s improved viscoelasticity and stiffness due to the incorporation of the composite binder. These contribute to a more efficient aggregate covering and promote a well-connected aggregate binder structure, which improves asphalt concrete permanent deformation resistance.

Figure 1.

Degree of agreement between predicted and experimental results. (a) predicted vs. actual values; (b) normal plot of residuals.

Figure 2.

3D synergetic influence of biochar and geopolymer on permanent deformation at different asphalt binder contents.

3.2. Design Parameters’ Optimisation

In this study, a numerical optimization method was used to optimize the design variables and assess the accuracy of the developed model. Specific goals were set for material minimization, with ranges defined for biochar, geopolymer (0–4%), and asphalt binder (4–6%). From the design expert software, the optimum mix of design solutions with the highest desirability score of 1.0 was selected. An extra experiment was conducted based on the optimized model to validate its performance, and the percentage error (%) between the experimental and predicted findings was calculated, as shown in Table 4. The data show that the percentage error discrepancies are all lower than 5%. This indicates that the RSM-predicted values produced from the generated models are in great agreement with the experimental data, indicating that the predictions are accurate [12].

Table 4.

Verification of optimized findings.

4. Conclusions

The following conclusions can be drawn from the study’s findings.

The incorporation of biochar-based geopolymer composite as a modifier significantly impacts the rut depth resistance of asphalt concrete. Also, the RSM models used in this study demonstrated a high degree of correlation, predictability, and level of agreement between predicted and experimental outcomes, as proven by the high R2 values and appropriate accuracy (>4.0), indicating their reliability and efficacy in exploring the model space. Furthermore, RSM optimization identified the optimum content of biochar, geopolymer, and asphalt binder (at 3.22%, 1.81%, and 5.4%, respectively), with a percentage error of <5% between the RSM and experimental data.

Future studies should evaluate BGAC’s long-term performance, environmental impact, and techno-economic viability. More field experiments including different mechanical performances are also encouraged. Furthermore, standardization, advanced modeling, and case studies are crucial for developing sustainable road construction practices.

Author Contributions

Conceptualization, N.S.A.Y.; methodology, N.S.A.Y. and A.U.; software, N.S.A.Y.; validation, N.S.A.Y. and A.H.J.; formal analysis, N.S.A.Y. and A.U.; investigation, N.S.A.Y., A.B.M. and A.H.J.; data curation, N.S.A.Y. and A.B.M.; writing—original draft preparation, N.S.A.Y.; writing—review and editing, N.Z.H. and L.B.; visualization, N.S.A.Y. and A.U.; supervision, M.H.S. and N.Z.H.; project administration, M.H.S. and N.Z.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The author would like to express gratitude to Universiti Teknologi Petronas and Ahmadu Bello University Zaria for their support during the study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, L.; Xue, X.; Zhao, Z.; Wang, Z. The impacts of transportation infrastructure on sustainable development: Emerging trends and challenges. Int. J. Environ. Res. Public Health 2018, 15, 1172. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Chen, J.; Han, Z.; Liu, W. A review on solutions for improving rutting resistance of asphalt pavement and test methods. Constr. Build. Mater. 2018, 168, 893–905. [Google Scholar] [CrossRef]

- Chen, J.; Dan, H.; Ding, Y.; Gao, Y.; Guo, M. New innovations in pavement materials and engineering: A review on pavement engineering research 2021. J. Traffic Transp. Eng. 2021, 8, 815–999. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Sutanto, M.H.; Habib, N.Z.; Usman, A.; Kaura, J.M.; Murana, A.A.; Birniwa, A.H.; Jagaba, A.H. A Comprehensive Review of Biochar Utilization for Low-Carbon Flexible Asphalt Pavements. Sustainability 2023, 15, 6729. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.M.; Al-Fakih, A.; Noura, S.; Yaghoubi, E.; Alaloul, W.; Al-Mansob, R.A.; Khan, M.I.; Yaro, N.S.A. Utilization of palm oil and its by-products in bio-asphalt and bio-concrete mixtures: A review. Constr. Build. Mater. 2022, 337, 127552. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Ye, X.P.; Shu, X.; Jia, X. Utilizing bio-char as a bio-modifier for asphalt cement: A sustainable application of bio-fuel by-product. Fuel 2014, 133, 52–62. [Google Scholar] [CrossRef]

- Usman, A.; Sutanto, M.H.; Napiah, M.; Zoorob, S.E.; Yaro, N.S.A.; Khan, M.I. Comparison of performance properties and prediction of regular and gamma-irradiated granular waste polyethylene terephthalate modified asphalt mixtures. Polymers 2021, 13, 2610. [Google Scholar] [CrossRef] [PubMed]

- Jagaba, A.H.; Kutty, S.R.M.; Baloo, L.; Birniwa, A.H.; Lawal, I.M.; Aliyu, M.K.; Yaro, N.S.A.; Usman, A.K. Combined treatment of domestic and pulp and paper industry wastewater in a rice straw embedded activated sludge bioreactor to achieve sustainable development goals. Case Stud. Chem. Environ. Eng. 2022, 6, 100261. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Sutanto, M.H.; Habib, N.Z.; Napiah, M.; Usman, A.; Muhammad, A. Comparison of Response Surface Methodology and Artificial Neural Network approach in predicting the performance and properties of palm oil clinker fine modified asphalt mixtures. Constr. Build. Mater. 2022, 324, 126618. [Google Scholar] [CrossRef]

- BS 598-110; Methods of Test for the Determination of Wheel-Tracking Rate and Depth, in Sampling and Examination of Bituminous Mixtures for Roads and Other Paved Areas. British Standard: London, UK, 1998.

- Ghaleb, A.A.S.; Kutty, S.R.M.; Ho, Y.-C.; Jagaba, A.H.; Noor, A.; Al-Sabaeei, A.M.; Almahbashi, N.M.Y. Response surface methodology to optimize methane production from mesophilic anaerobic co-digestion of oily-biological sludge and sugarcane bagasse. Sustainability 2020, 12, 2116. [Google Scholar] [CrossRef]

- Usman, A.; Sutanto, M.H.; Napiah, M.B.; Yaro, N.S.A. Response surface methodology optimization in asphalt mixtures: A review. In Response Surface Methodology in Engineering Science; IntechOpen: London, UK, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).