The Effect of Metal Filler on the Mechanical Performance of Epoxy Resin Composites †

Abstract

:1. Introduction

2. Literature Survey

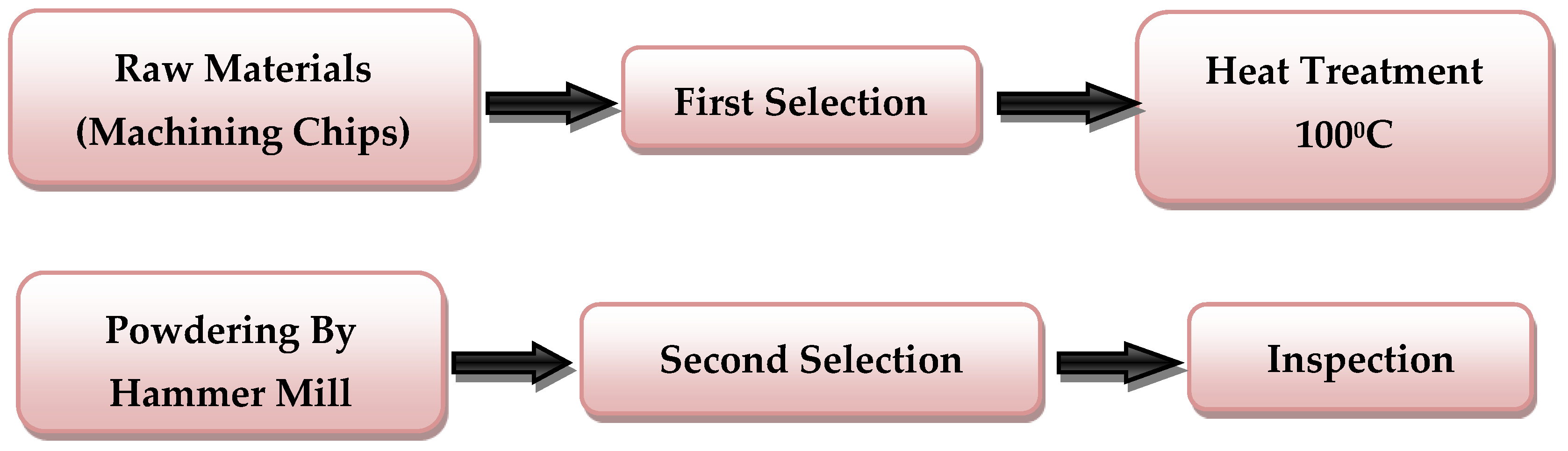

3. Specimen Fabrication

4. Experimentation and Testing

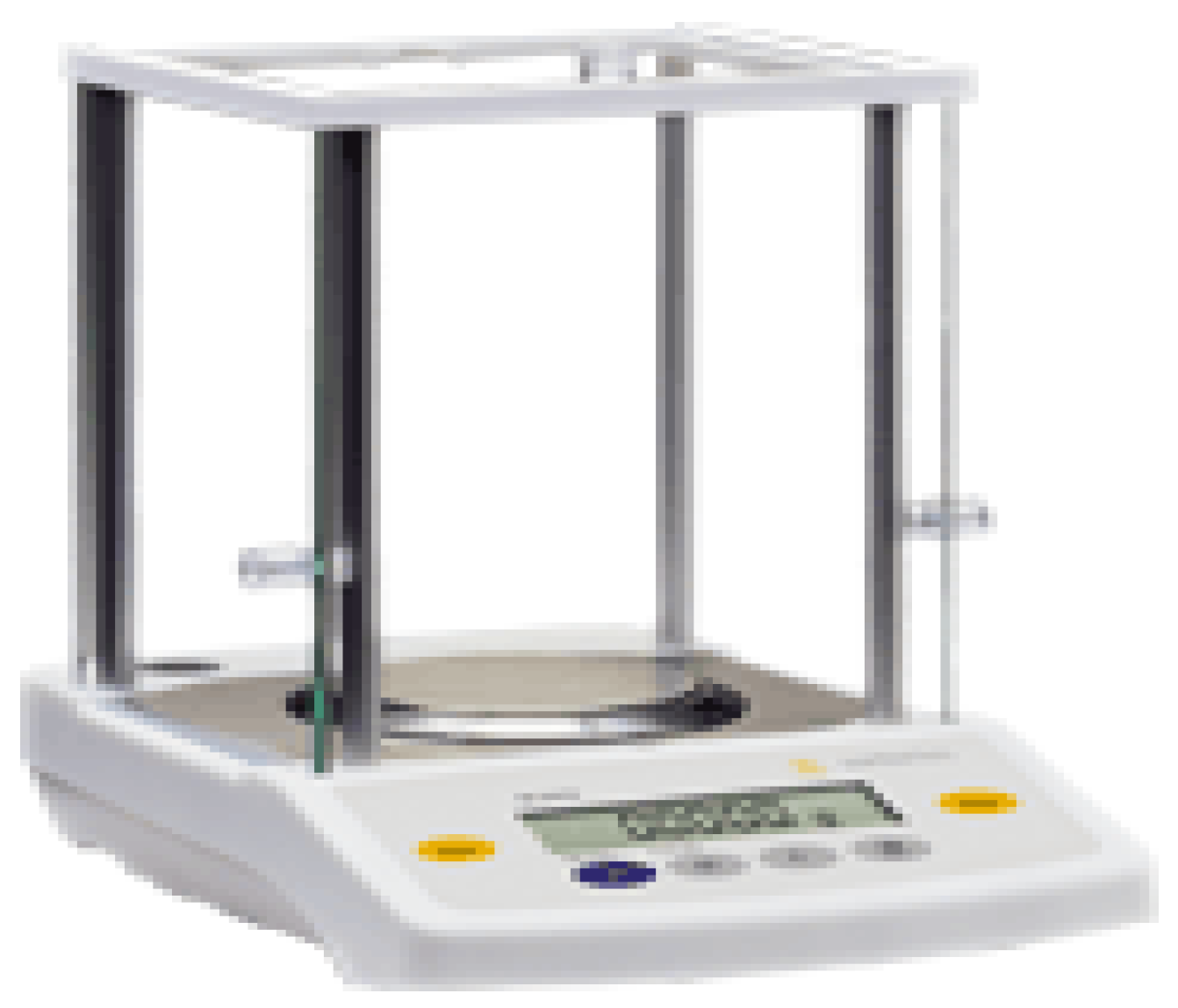

4.1. Density

4.2. Hardness

4.3. Tensile Properties

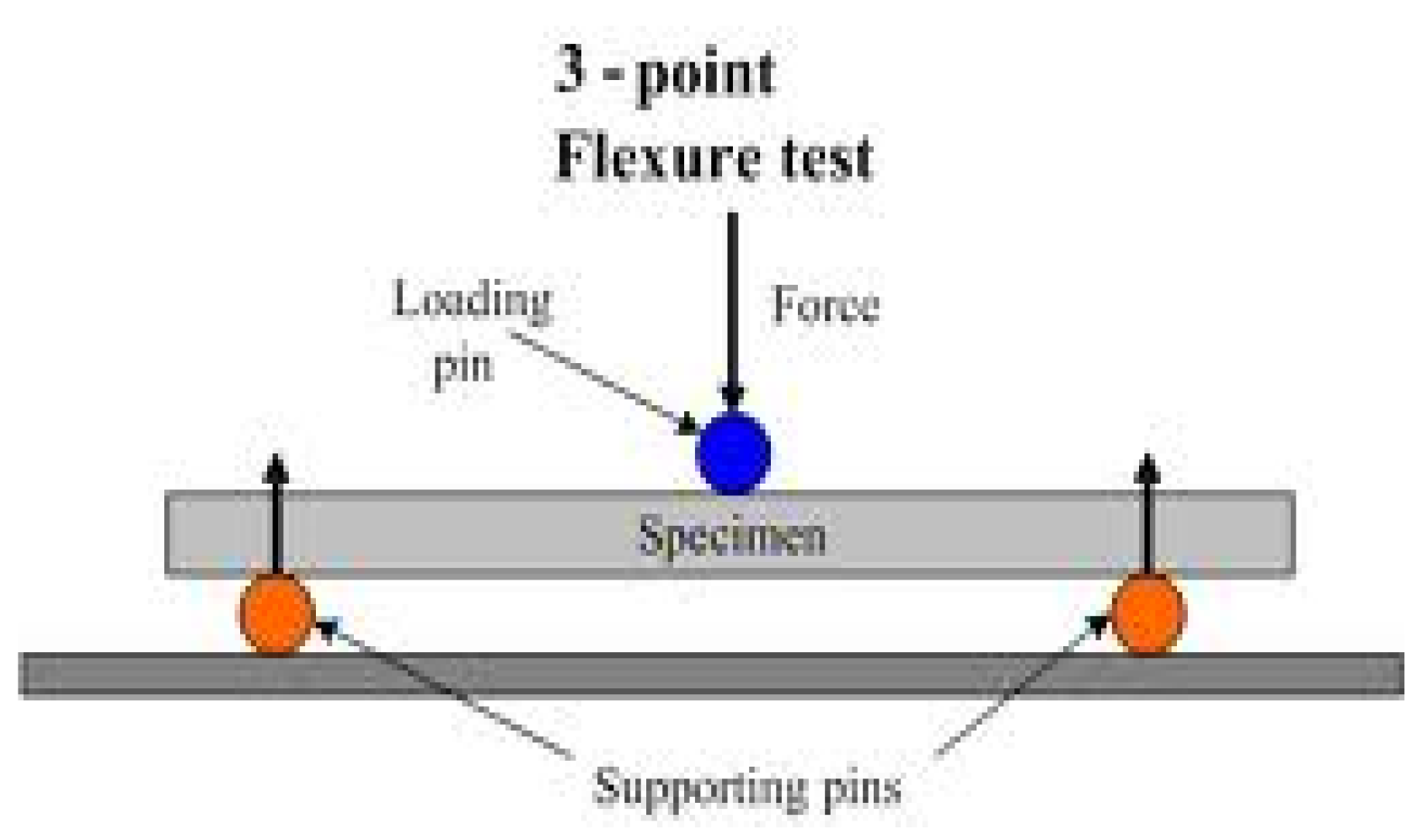

4.4. Flexural Properties

4.5. Impact Strength

4.6. Mechanical Testing Standards

5. Results and Discussion

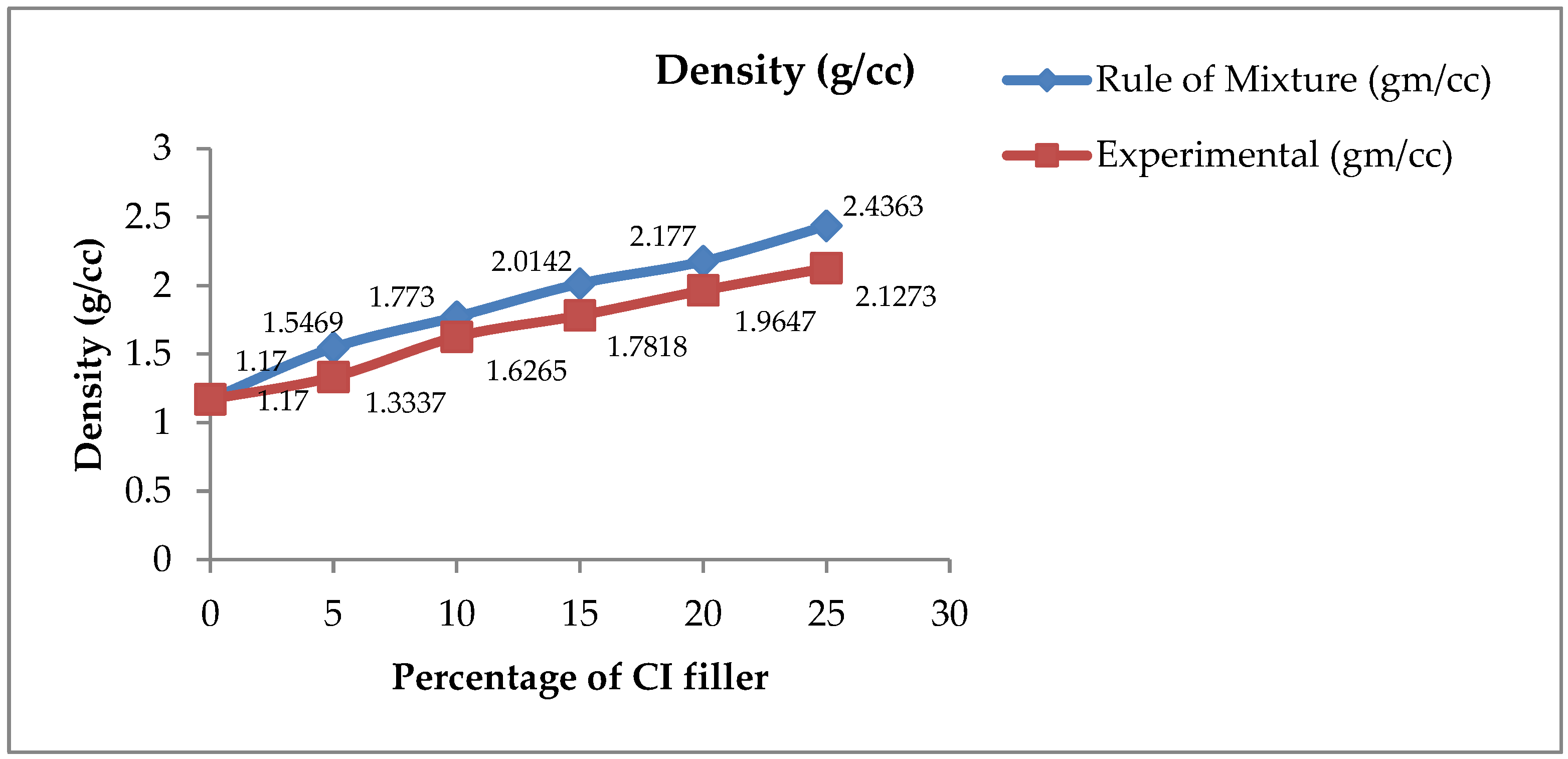

5.1. Density

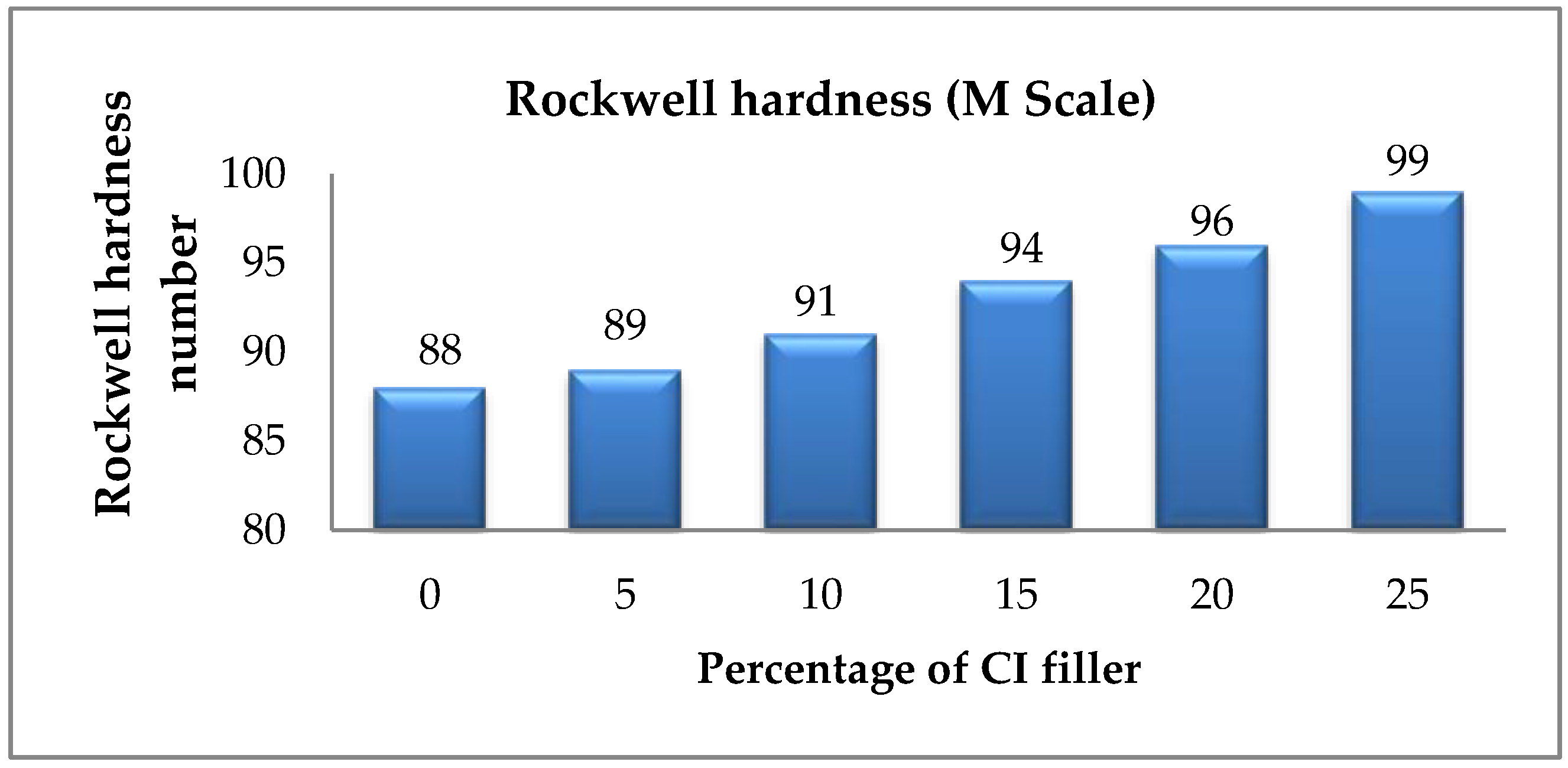

5.2. Hardness

5.3. Tensile Properties

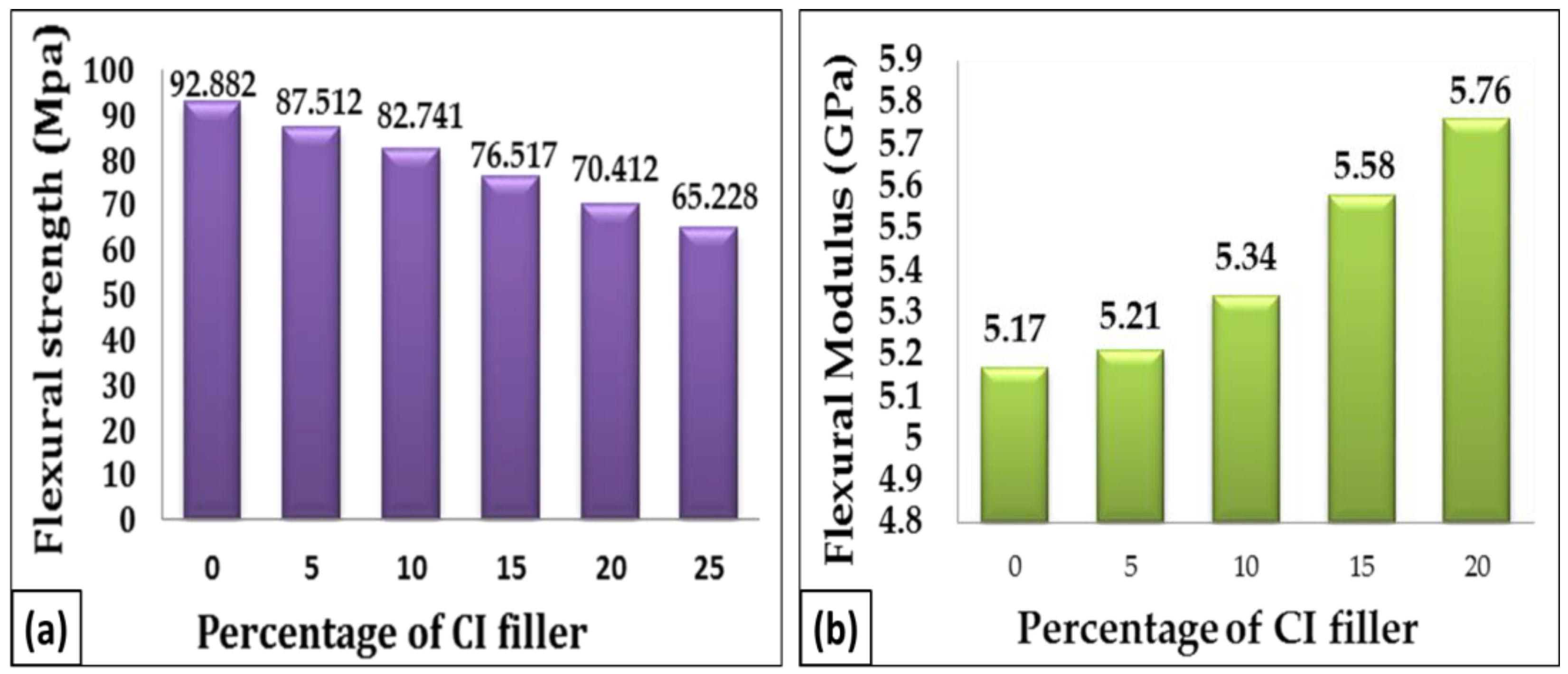

5.4. Flexural Properties

5.5. Impact Strength

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chung, S.; Im, Y.; Jeong, H.; Nakagawa, T. The effects of metal filler on the characteristics of casting resin for semi-metallic soft tools. J. Mater. Process. Technol. 2003, 134, 26–34. [Google Scholar] [CrossRef]

- Bhagyashekar, M.S.; Rao, R.M.V.G.K. Effects of Material Test Parameters on the Wear Behavior of Particulate Filled Composites Part 2: Cu-Epoxy and Al-Epoxy Composites. J. Reinf. Plast. Compos. 2007, 26, 1769–1780. [Google Scholar] [CrossRef]

- Durand, J.M.; Vardavoulias, M.; Jeandin, M. Role of reinforcing ceramic particles in the wear behavior of polymer based model composites. Wear 1995, 181–183, 833–839. [Google Scholar] [CrossRef]

- Sudheer, M.; Subbaya, K.M.; Jawali, D.; Bhat, T. Mechanical Properties of Potasium Titanate Whisker Reinforced Epoxy Resin Composites. J. Miner. Mater. Charact. Eng. 2012, 11, 193–210. [Google Scholar]

- Stabik, J.; Dybowska, A.; Pluszyñski, J.; Szczepanik, M.; Suchoñ, Ł. Magnetic induction of polymer composites filled with ferrite powders. Arch. Mater. Sci. Eng. 2010, 41, 13–20. [Google Scholar]

- Suresha, B.; Chandramohan, G.; Sampathkumaran, P.; Seetharamu, S. Friction and wear characterstics of carbon-epoxy and glassepoxy woven roving fiber composites. J. Reinf. Plast. Compos. 2006, 25, 771–782. [Google Scholar] [CrossRef]

- Brito, Z.; Sanchez, G. Influence of metallic fillers on the thermal and mechanical behavior in composites of epoxy matrix. Compos. Struct. 2000, 48, 79–81. [Google Scholar] [CrossRef]

- Murugesh, M.C.; Sadashivappa, K. Influence of Filler Material on Glass Fiber/Epoxy Composite Laminates during Drilling. Int. J. Adv. Eng. Technol. 2012, 3, 233. [Google Scholar]

- Happer, C.A. Handbook of Plastics, Elastomers and Composites, 4th ed.; McGraw-Hill Publications: New York, NY, USA, 2004. [Google Scholar]

- Rothon, R. Particulate Filled Polymer Composites, 2nd ed.; Rapra Technology Ltd.: Shrewsbury, UK, 2003. [Google Scholar]

- ASTM: D792-20; Density and Specific Gravity (Relative Density) of Plasticsby Displacement. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM D785-03; Standard Test Method for Rockwell Hardness of Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2004.

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTM D 790-03; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2003.

- ASTM D256-10; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2018.

- Prashanth, M.; Gouda, P.S.; Manjunatha, T.S.; Banapurmath, N.R.; Edacheriane, A. Understanding the impact of fiber orientation on mechanical, interlaminar shear strength, and fracture properties of jute–banana hybrid composite laminates. Polym. Compos. 2021, 42, 5475–5489. [Google Scholar] [CrossRef]

- Badyankal, P.V.; Gouda, P.S.; Manjunatha, T.S.; Prashanth, B.M.; Shivayogi, B.H. Realization of mechanical and tribological properties of hybrid banana, sisal, and pineapple fiber epoxy composites using naturally available fillers. Eng. Res. Express 2023, 5, 015070. [Google Scholar] [CrossRef]

- Madugu, I.A.; Abdulwahab, M.; Aigbodion, V.S. Effect of iron fillings on the properties and microstructure of cast fiber–polyester/iron filings particulate composite. J. Alloys Compd. 2009, 476, 807–811. [Google Scholar] [CrossRef]

- Tsetlin, M.B.; Teplov, A.A.; Belousov, S.I.; Chvalun, S.N.; Golovkova, E.A.; Krasheninnikov, S.V.; Golubev, E.K.; Pichkur, E.B.; Dmitryakov, P.V.; Buzin, A.I. Composite material based on polytetrafluoroethylene and Al–Cu–Fe quasi-crystal filler with ultralow wear: Morphology, tribological, and mechanical properties. J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 2018, 12, 277–285. [Google Scholar] [CrossRef]

- Murthy, B.R.N.; Rao, U.S.; Naik, N.; Potti, S.R.; Nambiar, S.S. A Study to Investigate the Influence of Machining Parameters on Delamination in the Abrasive Waterjet Machining of Jute-Fiber-Reinforced Polymer Composites: An Integrated Taguchi and Response Surface Methodology (RSM) Optimization to Minimize Delamination. J. Compos. Sci. 2023, 7, 475. [Google Scholar] [CrossRef]

- Naik, N.; Shivamurthy, B.; Thimmappa, B.H.; Gupta, A.; Guo, J.Z.; Seok, I. A review on processing methods and characterization techniques of green composites. Eng. Sci. 2022, 20, 80–99. [Google Scholar] [CrossRef]

- Prashantha, B.H.; Maruthi, T.S.; Manjunatha, P.S.; Gouda, S.K.; Edacherian, A. Improved mechanical properties of jute-banana fiber phenol formaldehyde composites through low-cost portable hot pressing machine. Mater. Perform. Charact. 2021, 10, 49–65. [Google Scholar] [CrossRef]

- Kowshik, S.; Shettar, M.; Rangaswamy, N.; Chate, G.; Somdee, P. Effect of nanoclay on mechanical, flammability, and water absorption properties of glass fiber-epoxy composite. Cogent Eng. 2022, 9, 2069070. [Google Scholar] [CrossRef]

| Sample Code | Matrix | Filler | wt.% |

|---|---|---|---|

| C0 | Epoxy | - | - |

| C5 | Epoxy | Cast iron | 5 |

| C10 | Epoxy | Cast iron | 10 |

| C15 | Epoxy | Cast iron | 15 |

| C20 | Epoxy | Cast iron | 20 |

| C25 | Epoxy | Cast iron | 25 |

| ASTM Standards | Properties to Be Tested |

|---|---|

| ASTM D792 [11] | Density |

| ASTM D785 [12] | Hardness (Rockwell M Scale) |

| ASTM D638 [13] | Tensile Properties |

| ASTM D790 [14] | Flexural Properties |

| ASTM D256 [15] | Impact Strength |

| Sample Code | Rule of Mixture, (gm/cc) | Experimental, (gm/cc) |

|---|---|---|

| C0 | 1.17 | 1.17 |

| C1 | 1.5469 | 1.3337 |

| C2 | 1.773 | 1.6265 |

| C3 | 2.0142 | 1.7818 |

| C4 | 2.177 | 1.9647 |

| C5 | 2.4363 | 2.1273 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

K, B.; M, P.P.; M, S.; C G, R.; B H, M.P.; B, K.K. The Effect of Metal Filler on the Mechanical Performance of Epoxy Resin Composites. Eng. Proc. 2023, 59, 200. https://doi.org/10.3390/engproc2023059200

K B, M PP, M S, C G R, B H MP, B KK. The Effect of Metal Filler on the Mechanical Performance of Epoxy Resin Composites. Engineering Proceedings. 2023; 59(1):200. https://doi.org/10.3390/engproc2023059200

Chicago/Turabian StyleK, Bhavith, Prashanth Pai M, Sudheer M, Ramachandra C G, Maruthi Prashanth B H, and Kiran Kumar B. 2023. "The Effect of Metal Filler on the Mechanical Performance of Epoxy Resin Composites" Engineering Proceedings 59, no. 1: 200. https://doi.org/10.3390/engproc2023059200

APA StyleK, B., M, P. P., M, S., C G, R., B H, M. P., & B, K. K. (2023). The Effect of Metal Filler on the Mechanical Performance of Epoxy Resin Composites. Engineering Proceedings, 59(1), 200. https://doi.org/10.3390/engproc2023059200