1. Introduction

Green manufacturing is the most recent sustainable manufacturing method that has the potential to alleviate most of the problems that Indian SMEs are now facing. Small- and medium-sized firms (SMEs) may have been left out of legal and societal constraints for a variety of reasons [

1,

2]. It is no longer possible to ignore the environmental implications of SMEs. Small- and medium-sized businesses are critical to all economies, but they can have a substantial negative environmental effect. Green manufacturing is quickly developing as a sustainable manufacturing solution with the ability to address most of the world’s issues. The purpose of green manufacturing is to create and produce goods that have the least negative impact on the environment throughout manufacturing, use, and disposal [

3,

4,

5,

6]. The term “green manufacturing” refers to a production process that is environmentally friendly from start to finish, from the initial idea to the final disposal of the product. This is achieved through the efficient use of materials, the prevention of pollution, and the conservation of natural resources. Green manufacturing includes creating, producing, transporting, and disposing of items that have the least harmful impact on the environment and society while being economically viable [

7].

Through the use of green manufacturing technology, businesses may lessen their negative impact on the environment while simultaneously increasing their bottom line. These technologies comprise several strategies for reducing material waste, including recycling, replacement with less hazardous alternatives, internal waste consumption, and remanufacturing [

8]. From the perspective of operational technology, green manufacturing studies focus on reducing or eliminating the creation of wasteful by-products, harmful chemicals, and processes that add no value to the final product. Green manufacturing technologies may range from those focused on preventing problems early in the process to those focused on cleaning up at the end of the pipeline and fostering collaboration between companies [

5]. These technologies range from classic to more modern closed-loop systems that need integration with standard production processes.

4. The Role of SMEs

In the future landscape of global manufacturing, the competition will shift towards green technologies, prioritising energy conservation and pollution reduction over traditional factors like money, resources, and labour force. Green manufacturing, as envisioned by Kumar et al. [

17] encompasses a comprehensive approach to reducing environmental impact by optimising resource utilisation and minimising waste.

Small- and medium-sized enterprises (SMEs), vital for national economies, face the imperative of embracing environmental sustainability for long-term economic development. Despite the global emphasis on such practices, research by Kumar et al. [

17] reveals limited beneficial improvements in corporate environmental practices.

The compelling need for greener enterprises is underscored by the urgency of addressing environmental issues. SMEs, no longer insulated, must consider diverse factors such as employee needs, safety policies, corporate culture, innovation, stakeholder relationships, and market trends for success in green manufacturing. While the adoption of green systems involves significant costs, a well-planned approach can lead to procedural and technical enhancements, reducing operating costs and increasing product value.

4.1. Managerial Attitude in SMEs

Managers who are thinking about implementing green manufacturing in their organisations should first make sure it is a viable option before they devote time and resources to identifying the application and planning its implementation.

Lacking quantification of green manufacturing’s benefits, managers are unable to evaluate the impact of green manufacturing, making it hard to justify green manufacturing as an option.

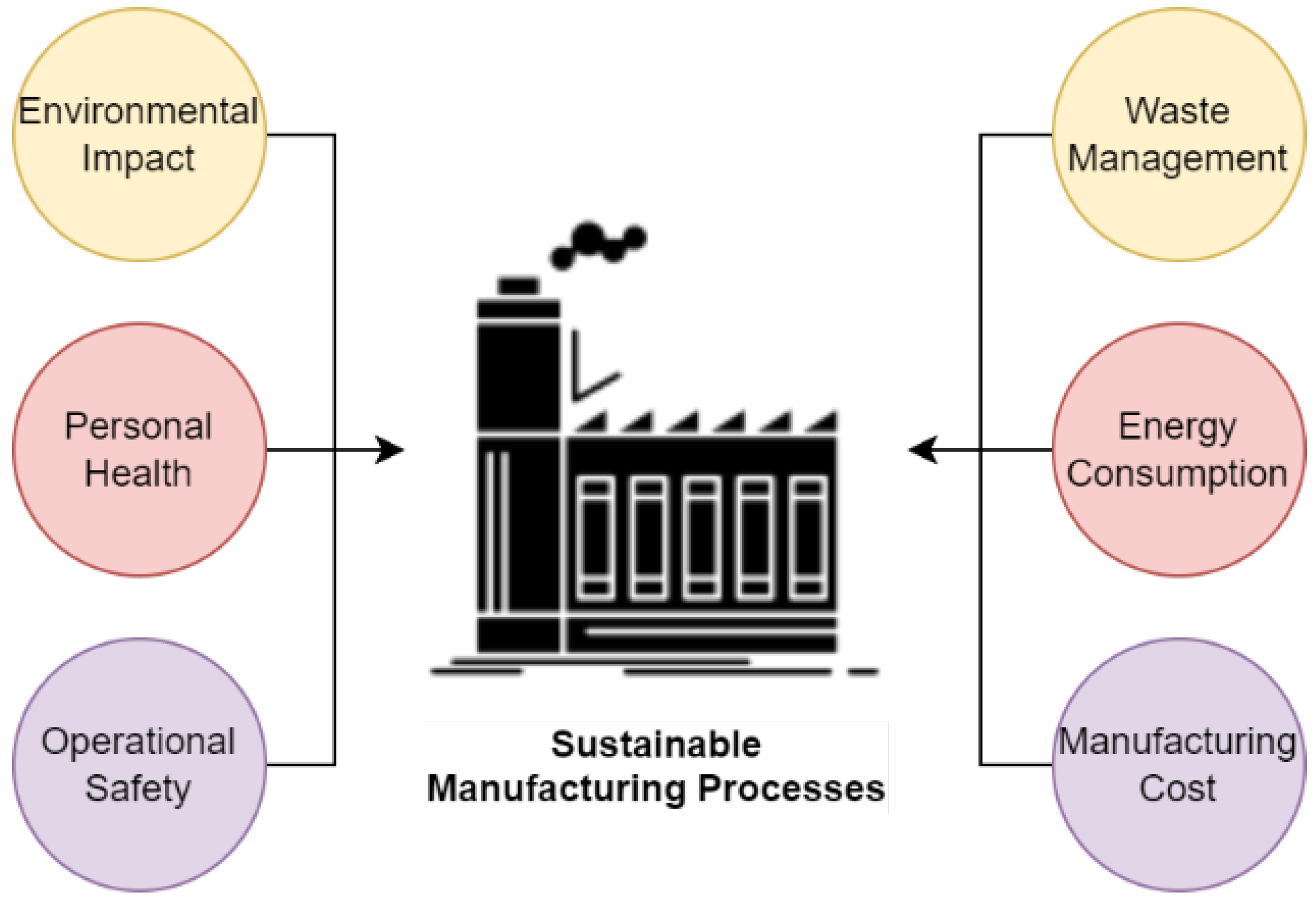

In addition to boosting efficiency and synergy among business partners and their leading organisations, green supply chain management is also thought to raise environmental performance, decrease waste, and save costs, as can be seen in

Figure 1.

It is hoped that by working together, the company’s brand will be bolstered along with its competitive edge and marketing reach.

The advantages of green manufacturing as noticed by different SMEs are as follows:

Increased organisational inventiveness (product, process, and managerial innovation).

The competitiveness of the organisation (cost containment, revenue generation, liability management, corporate image, and export performance).

Amenities that are safer and cleaner.

Decreased future disposal costs and worker safety.

Fewer environmental and health concerns, and superior product quality at a lower cost and with more productivity.

4.2. Green Supply Chains and SMEs

Many companies, especially in the Southeast Asian region, are tackling environmental issues by using green supply chain management as a form of operational environmental improvement. Environmental performance, waste reduction, and financial savings are just a few of the many benefits often attributed to green supply chain management. It is hoped that by working together, the company’s brand will be bolstered along with its competitive edge and marketing reach.

There must be evidence linking green supply chain management practices with increased economic performance and competitiveness if all SMEs in India are to fully embrace them. There is a definite need for research to illustrate the probable association between green supply chain activities and greater competitiveness and economic performance in order to provide motivation for enterprises to make their supply networks green.

Illustrating the practical application and benefits of green manufacturing in Indian SMEs, Kirloskar Oil Engines Ltd. (KOEL), Bhubaneswar, India prioritised sustainable techniques, reducing waste and conserving energy. This not only enhanced operational effectiveness but also reduced costs and environmental impact. Welspun India, a leading textile manufacturer, invested in renewable energy sources like solar power, gaining energy independence and cost benefits while reducing its environmental impact. Ambuja Cements, a major player in the Indian cement market, implemented green manufacturing, emphasising alternative fuels and sustainable raw material sourcing, resulting in decreased carbon emissions and increased operating efficiency. Mahindra & Mahindra, a prominent automobile firm, integrated green practices like recycling waste and energy-efficient techniques, enhancing social responsibility and environmental sustainability. Tata Motors aggressively pursued sustainable production practices, embracing energy-efficient technologies, water-saving, waste minimisation, and renewable energy sources. Godrej Industries integrated green methods across its business divisions, achieving cost reduction and advancing environmental sustainability.

Due to globalisation, tough global competition, rapid technological breakthroughs, shorter product life cycles, and environmental and social concerns, Indian industry is under enormous pressure to embrace sustainable manufacturing. As environmental issues become more pressing, several companies have researched solutions. Consequently, several studies have focused on the implementation of green manufacturing by examining various strategies, performance metrics, and technical and managerial obstacles.

Indian SMEs seeking green manufacturing excellence can leverage globally recognised best practices. Drawing inspiration from the Energy Star program (United States), SMEs can adopt energy-efficient practices, fostering cost savings. Embracing the Circular Economy Package (European Union) encourages Indian SMEs to implement closed-loop systems, enhancing resource efficiency. Denmark’s Clean Production Agreements showcase collaborative voluntary commitments, providing a model for Indian SMEs to engage with regulatory bodies. Implementing a green industry certification system akin to South Korea promotes comprehensive environmental management. Aligning with the United Nations’ SDGs offers a global framework for sustainable business practices, contributing to India’s progress on the international stage.

5. The Quantitative Benefits

Green concerns have acquired prominence in today’s globalisation. Because of the social and environmental considerations involved, industrial processes (

Figure 2) have become more aware of green issues in recent years. However, the drivers of green manufacturing have not been adequately examined. Because of limited resources and a rising population, environmental quality preservation has become critical. Environmental issues have hampered regional and global collaboration and even sparked conflicts in numerous ways. As a result, green activities have become obligatory to balance these tensions; even industrial processes cannot be exempt.

This modern concept of “green manufacturing” refers to the continuing enhancement of products, processes, and operations with regard to their impact on the environment. An environmental life cycle strategy must be implemented in green manufacturing. The goal is to design and distribute products with minimal environmental effects throughout their entire life cycle (from raw material extraction to final disposal). Green production has quantifiable advantages in areas such as waste management (less money spent on waste collection, sorting, treatment, disposal, and storage) and product life cycle management (less money spent on transportation, packaging, and final product price) as well as production (less money spent on making the product) and use (less money spent on user operation, use, maintenance, and repair). The high factor loading values show that the positive effects do not rely on any other variables.

6. Drivers of Green Manufacturing in Indian SMEs

An obvious need for a developing nation like India is the creation of new jobs, and green manufacturing’s ability to strike this balance while also improving the efficiency of the nation’s use of its resources is a key component of this goal. The term “drivers” refers to the external, internal, societal, and contractual factors that lead businesses to adopt green manufacturing practices. Because of these factors, more and more businesses are opting to become green, whether by choice or because they have to. In the adoption process, challenges are bound to be encountered, yet solutions are never beyond the horizon.

Table 1 reflects various challenges and solutions for green manufacturing’s implementation.

Small- and medium-sized Indian enterprises (SMEs) often embrace green manufacturing practices via three primary strategies: green energy, green commodities, and green processes in firm operations. Strategic industrial decisions increasingly factor in environmental considerations. In light of this, research into environmentally friendly production techniques is more important than ever. Production managers and CEOs are also worried about the feasibility of green manufacturing.

7. Results and Findings

7.1. The Canvas

The ability to manage operations in a way that reduces the direct and indirect negative environmental effects of manufacturing is becoming more important for SMEs. But it is also true that you cannot manage what you cannot measure.

It is evident that “green performance measurement” is crucial and something that every organisation should understand when the demand for environmental friendliness is mixed with the necessity for performance assessment.

7.2. Green Manufacturing Systems

Businesses approach environmental challenges through concept, compliance, and system approaches in green manufacturing. Concept approaches involve environmental protection measures and biodegradable products, compliance adheres to regulations with continuous improvement plans, and system approaches involve implementing green manufacturing comprehensively. Green manufacturing performance measures are crucial for various stakeholders, such as governments, communities, shareholders, customers, and environmental groups, guiding improvements.

Table 2 provides a comprehensive comparative analysis of key green manufacturing technologies, outlining their descriptions, associated benefits, and challenges. This comparative analysis serves as a valuable reference for understanding the nuances of each technology’s application in green manufacturing.

In recent years, small- and medium-sized enterprises (SMEs) have shown increased interest in green manufacturing systems (GMSs) globally. Despite challenges, GMSs offer substantial intangible benefits often overlooked in conventional approaches, posing a challenge in engineering economics. A lack of adequate performance indicators hinders managers from evaluating the impact of green manufacturing, emphasising the need for comprehensive assessments. Integrating all aspects impacting the environment, green manufacturing systematically enhances product design, emissions, tools, energy, transportation, water, and waste. There is a compelling argument for businesses to adopt environmentally friendly practices promptly, given the urgency of global environmental issues. Traditional green practices gain strategic importance for waste reduction and enhanced industrial efficiency, emphasising the necessity for proactive and sustainable approaches in the face of potential harm and adverse consequences. The incorporation of AI, the IoT, and blockchain heralds a transformative era for green manufacturing in SMEs. AI facilitates predictive maintenance, energy optimisation, and efficient supply chains. The IoT enables real-time monitoring, waste reduction, and transparent supply chains. Blockchain ensures traceability, smart sustainability contracts, and reliable carbon footprint tracking. Despite challenges, collaboration with tech providers, government incentives, and industry partnerships can overcome implementation hurdles. This convergence of technologies empowers SMEs to enhance sustainability, efficiency, and environmental impact, shaping a greener future for small- and medium-sized enterprises.

7.3. Future Trajectory of Green Manufacturing in Indian SMEs

The future of green manufacturing in Indian SMEs envisions a transformative shift driven by the integration of advanced technologies like the IoT, AI, and blockchain. Collaboration and knowledge sharing will be pivotal, with SMEs engaging in collective efforts for greener practices. Government initiatives, policy support, and circular economy adoption are anticipated, fostering sustainability. A growing consumer demand for sustainable products will influence manufacturing strategies, providing a competitive edge for eco-friendly SMEs. Continuous performance measurement and improvement will be integral, ingraining a commitment to measurable progress and enhancing overall sustainability profiles in the evolving landscape of Indian SMEs.

8. Conclusions

Although sustainable practices in product development and manufacturing are widely recognised in principle, in practice, they are still uncommon. New ways of thinking and decision-making instruments are required to integrate environmental factors across a product’s whole life cycle. Facilitating the adoption of green manufacturing in small- and medium-sized enterprises (SMEs) requires a multifaceted policy framework. Financial incentives, including tax benefits, serve as crucial catalysts, encouraging SMEs to invest in eco-friendly technologies. Government subsidies further alleviate economic burdens tied to implementing advanced systems like AI, the IoT, and blockchain. Allocating funds for green technology research and development through grants spurs innovation, making sustainability more feasible. Encouraging collaborative platforms and industry collaborations fosters knowledge exchange, while streamlined environmental compliance procedures simplify adherence. Public procurement policies favoring green suppliers create additional incentives for SMEs. Capacity-building programs, awareness campaigns, and long-term support initiatives ensure a smooth and sustained transition to green manufacturing. This comprehensive approach aligns Indian SMEs with global sustainability standards, fostering a greener industrial landscape. It is still necessary to conduct a thorough analysis of the green manufacturing process and associated metrics in a nation like India. In order to make progress and make the process more understandable, new methods and government-approved assessment criteria are essential. The main problem right now is figuring out whether the technique is any good. In light of the readiness of SMEs in India to embrace green manufacturing, the government should give serious consideration to building a measurement framework.