Experimental and Numerical Investigation on Damage Resistance Characteristics of Woven E-Glass/Epoxy Composite Laminates Subjected to Drop-Weight Impacts †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Specimen Fabrication

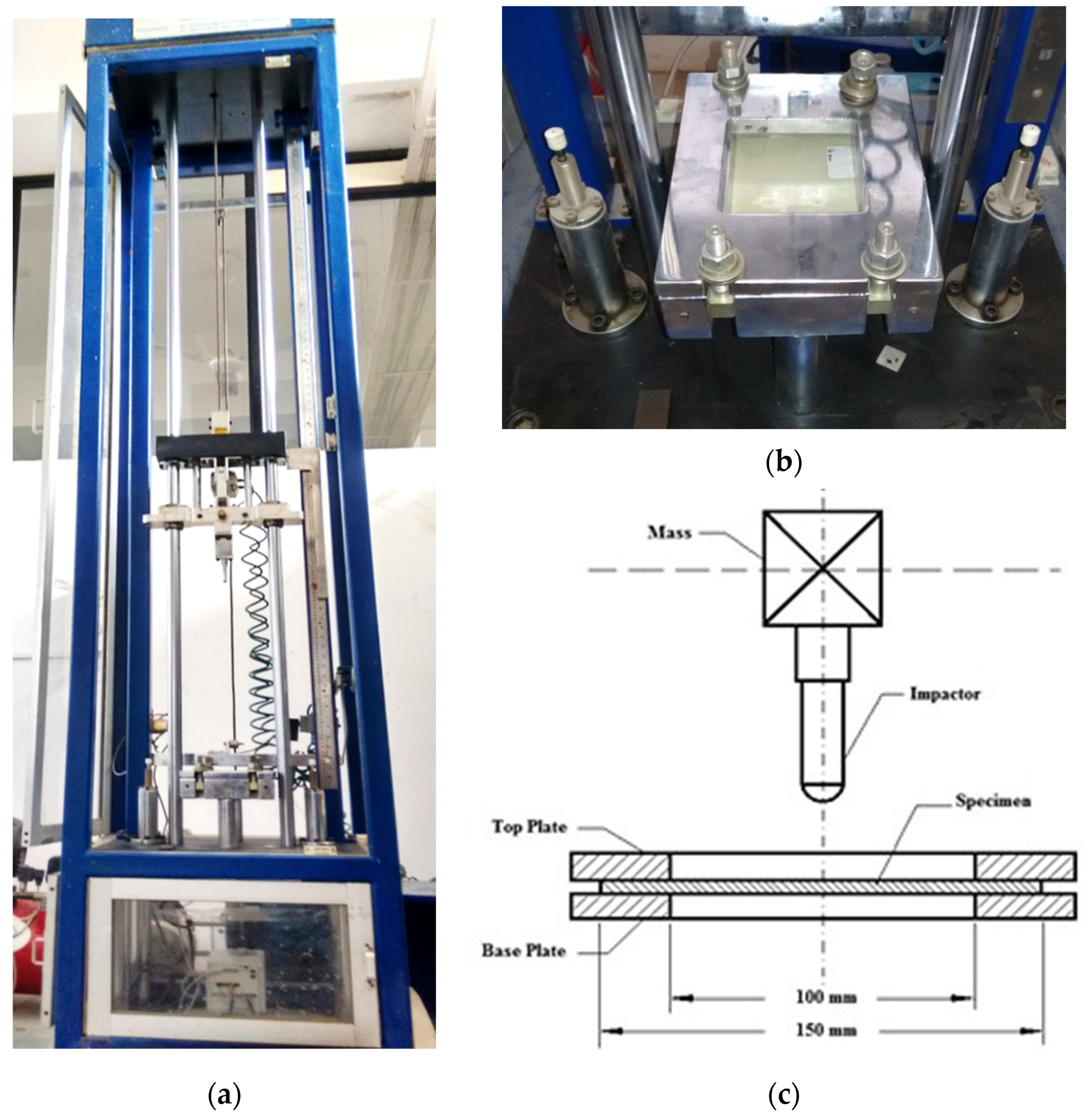

2.2. Low-Velocity Drop-Weight Impact Test

2.3. Numerical Simulation

2.4. Material Model and Failure Criteria

3. Results

4. Discussions

4.1. Force–Time History

4.2. Force–Displacement Curves

4.3. Energy–Time Curves

4.4. Damage Analysis

4.5. Effect of Impact Energy on Damage Resistance Characteristics

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Naik, N.K.; Sekher, Y.C.; Meduri, S. Polymer matrix woven fabric composites subjected to low velocity impact: Part I-damage initiation studies. J. Reinf. Plast. Compos. 2000, 19, 912–954. [Google Scholar] [CrossRef]

- Siow, Y.P.; Shim, V.P.W. An experimental study of low velocity impact damage in woven fiber composites. J. Compos. Mater. 1998, 32, 1178–1202. [Google Scholar] [CrossRef]

- Sutherland, L.S.; Soares, C.G. Impact on low fiber-volume, glass/polyester rectangular plates. Compos. Struct. 2005, 68, 13–22. [Google Scholar] [CrossRef]

- Tita, V.; De Carvalho, J.; Vandepitte, D. Failure analysis of low velocity impact on thin composite laminates: Experimental and numerical approaches. Compos. Struct. 2008, 83, 413–428. [Google Scholar] [CrossRef]

- Belingardi, G.; Vadori, R. Low velocity impact tests of laminate glass-fiber-epoxy matrix composite material plates. Int. J. Impact Eng. 2002, 27, 213–229. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, Y.; Chen, L.; Pan, N. A comparative study on low-velocity impact response of fabric composite laminates. Mater. Des. 2013, 50, 750–756. [Google Scholar] [CrossRef]

- Iannucci, L.; Willows, M.L. An energy based damage mechanics approach to modelling impact onto woven composite materials—Part I: Numerical models. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2041–2056. [Google Scholar] [CrossRef]

- Kreculj, D.; Rašuo, B. Review of Impact Damages Modelling in Laminated Composite Aircraft Structures. Teh. Vjesn./Tech. Gaz. 2013, 20, 485–495. [Google Scholar]

- Sun, M.; Chang, M.; Wang, Z.; Li, H.; Sun, X. Experimental and Simulation Study of Low-velocity Impact on Glass Fiber Composite Laminates with Reinforcing Shape Memory Alloys at Different Layer Positions. Appl. Sci. 2018, 8, 2405. [Google Scholar] [CrossRef]

- Tuo, H.; Lu, Z.; Ma, X.; Ma, X.; Zhang, C.; Chen, S. An Experimental and Numerical Investigation on Low-velocity Impact Damage and Compression-after-impact Behavior of Composite Laminates. Compos. Part B Eng. 2019, 167, 329–341. [Google Scholar] [CrossRef]

- Meon, M.S.; Meon, M.S.; Saedon, J.; Nor, N.H.; Rao, M.N.; Schröder, K.-U. Analysis of Boundary Condition in Modelling the Low-velocity Impact Carbon-fiber Reinforced Polymer Composite Laminates. IOP Conf. Ser. Mater. Sci. Eng. 2020, 788, 012041. [Google Scholar] [CrossRef]

- Amirashjaee, K.; Fakhreddini-Najafabadi, S.; Taheri-Behrooz, F. Numerical and experimental study of carbon/epoxy composite laminate response to low velocity impact. J. Sci. Technol. Compos. 2021, 8, 1461–1472. [Google Scholar]

- Mohsin, M.A.A.; Iannucci, L.; Greenhalgh, E.S. Experimental and Numerical Analysis of Low-Velocity Impact of Carbon Fibre-Based Non-Crimp Fabric Reinforced Thermoplastic Composites. Polymers 2021, 13, 3642. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Qu, P.; Guo, Y.; Zhou, Y.; Wan, G.; Jia, Y. Experimental and Numerical Studies on Low-velocity Impact Damage of Composite Laminates Toughened by Nickel-coated Carbon Fiber Veil. Polym. Compos. 2022, 43, 2460–2476. [Google Scholar] [CrossRef]

- Rabouh, M.; Guerraiche, K.; Zouggar, K.; Guerraiche, D. Bridging the Effect of the Impactor Head Shape to the Induced Damage During Impact at Low Velocity for Composite Laminates. Eng. Technol. Appl. Sci. Res. 2023, 13, 9973–9984. [Google Scholar] [CrossRef]

- Ferreira, L.M.; Coelho, C.A.C.P.; Reis, P.N.B. Numerical Simulations of the Low-Velocity Impact Response of Semicylindrical Woven Composite Shells. Materials 2023, 16, 3442. [Google Scholar] [CrossRef] [PubMed]

- ASTM D7136/D7136M; Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event. ASTM International: West Conshohocken, PA, USA, 2015; pp. 1–16. [CrossRef]

- Livermore Software Technology Corporation (LSTC) LS-DYNA Manual Volume I. Available online: https://www.dynasupport.com/manuals (accessed on 20 October 2021).

- Chang, F.K.; Chang, K.Y. A progressive damage model for laminated composites containing stress concentrations. J. Compos. Mater. 1987, 21, 834–855. [Google Scholar] [CrossRef]

- Sathish, S.; Prasath, J.; Reddy, K.S.; Naik, N.K. Damage evolution in delaminated woven fabric E-glass/epoxy composite plates under transverse static patch loading. Int. J. Damage Mech. 2013, 22, 982–1005. [Google Scholar] [CrossRef]

| Property | Unit | Value |

|---|---|---|

| Density (σ) | Kg/m3 | 1808 |

| Longitudinal Young’s Modulus (E11) | GPa | 20.8 |

| Transverse Young’s modulus (E22) | GPa | 20.8 |

| Shear modulus (G12) | GPa | 3.92 |

| Minor Poisson ratio (𝜈21) | - | 0.173 |

| Longitudinal Tensile strength (XT) | MPa | 250 |

| Longitudinal Compressive strength (XC) | MPa | 183 |

| Transverse Tensile strength (YT) | MPa | 250 |

| Transverse Compressive strength (YC) | MPa | 183 |

| Specimen Code | Height of Fall (m) | Impact Velocity (m/s) | Impact Energy (J) | Max. Force (N) | Absorbed Energy (J) | Displacement at Max. Force (mm) |

|---|---|---|---|---|---|---|

| 1 | 0.5 | 3.132 | 7.85 | 2355 | 6.4 | 10.23 |

| 2 | 1 | 4.429 | 15.70 | 3582 | 13.41 | 15.02 |

| 3 | 1.5 | 5.425 | 23.54 | 4387 | 22.15 | 16.41 |

| Specimen Code | Height of Fall (m) | Impact Velocity (m/s) | Impact Energy (J) | Max. Force (N) | Absorbed Energy (J) | Displacement at Max. Force (mm) |

|---|---|---|---|---|---|---|

| 1 | 0.5 | 3.132 | 7.85 | 2314 | 6.71 | 10.1 |

| 2 | 1 | 4.429 | 15.70 | 3505 | 13.68 | 14.25 |

| 3 | 1.5 | 5.425 | 23.54 | 4263 | 21.62 | 15.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

K., R.; C., P.; N., R.M.; D. S., R.G. Experimental and Numerical Investigation on Damage Resistance Characteristics of Woven E-Glass/Epoxy Composite Laminates Subjected to Drop-Weight Impacts. Eng. Proc. 2023, 59, 88. https://doi.org/10.3390/engproc2023059088

K. R, C. P, N. RM, D. S. RG. Experimental and Numerical Investigation on Damage Resistance Characteristics of Woven E-Glass/Epoxy Composite Laminates Subjected to Drop-Weight Impacts. Engineering Proceedings. 2023; 59(1):88. https://doi.org/10.3390/engproc2023059088

Chicago/Turabian StyleK., Ranjith, Prithvi C., Rajesh Mathivanan N., and Rakshith Gowda D. S. 2023. "Experimental and Numerical Investigation on Damage Resistance Characteristics of Woven E-Glass/Epoxy Composite Laminates Subjected to Drop-Weight Impacts" Engineering Proceedings 59, no. 1: 88. https://doi.org/10.3390/engproc2023059088

APA StyleK., R., C., P., N., R. M., & D. S., R. G. (2023). Experimental and Numerical Investigation on Damage Resistance Characteristics of Woven E-Glass/Epoxy Composite Laminates Subjected to Drop-Weight Impacts. Engineering Proceedings, 59(1), 88. https://doi.org/10.3390/engproc2023059088