Prediction of the Reaming Torque Using Artificial Neural Network and Random Forest Algorithm: Comparative Performance Analysis †

Abstract

:1. Introduction

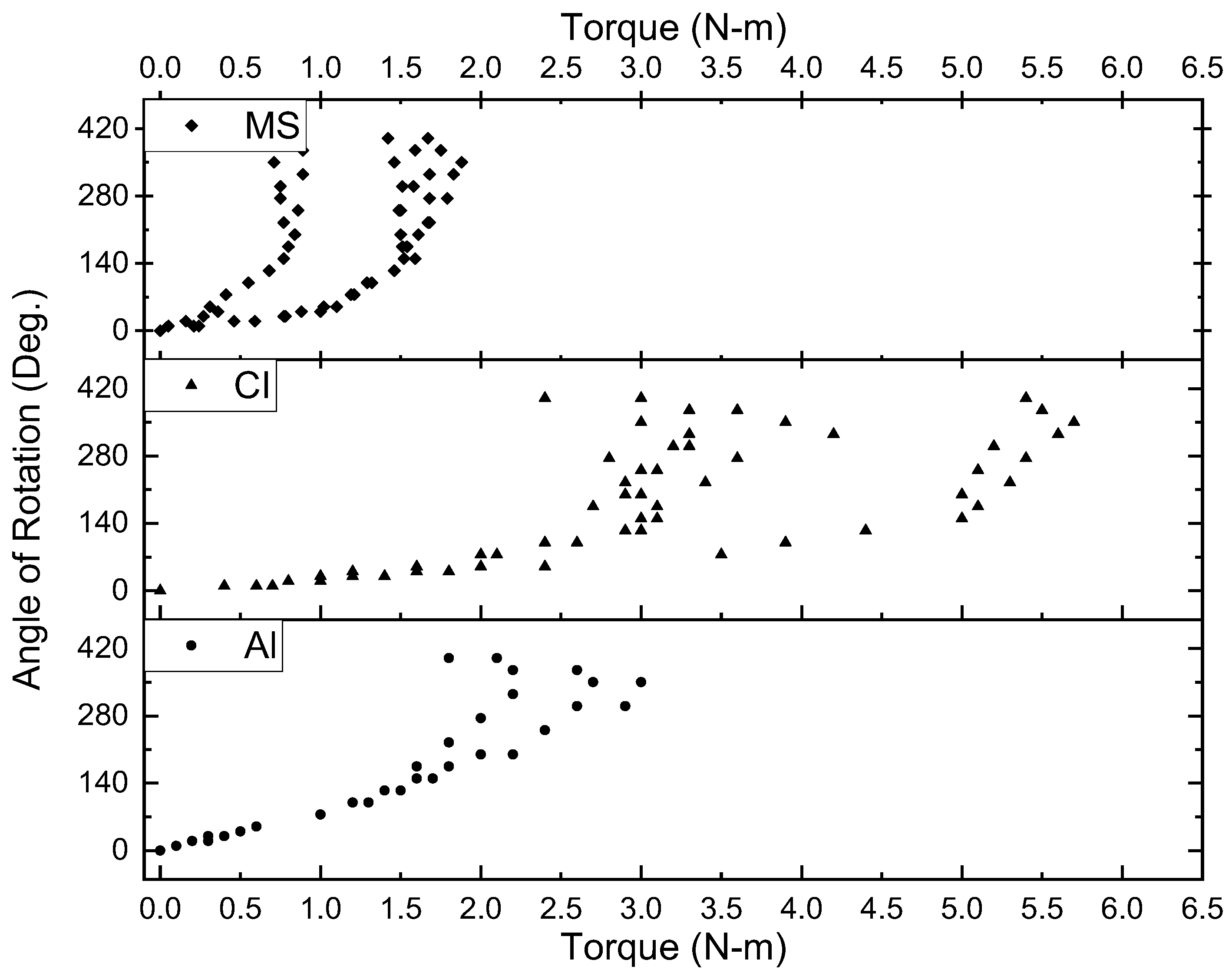

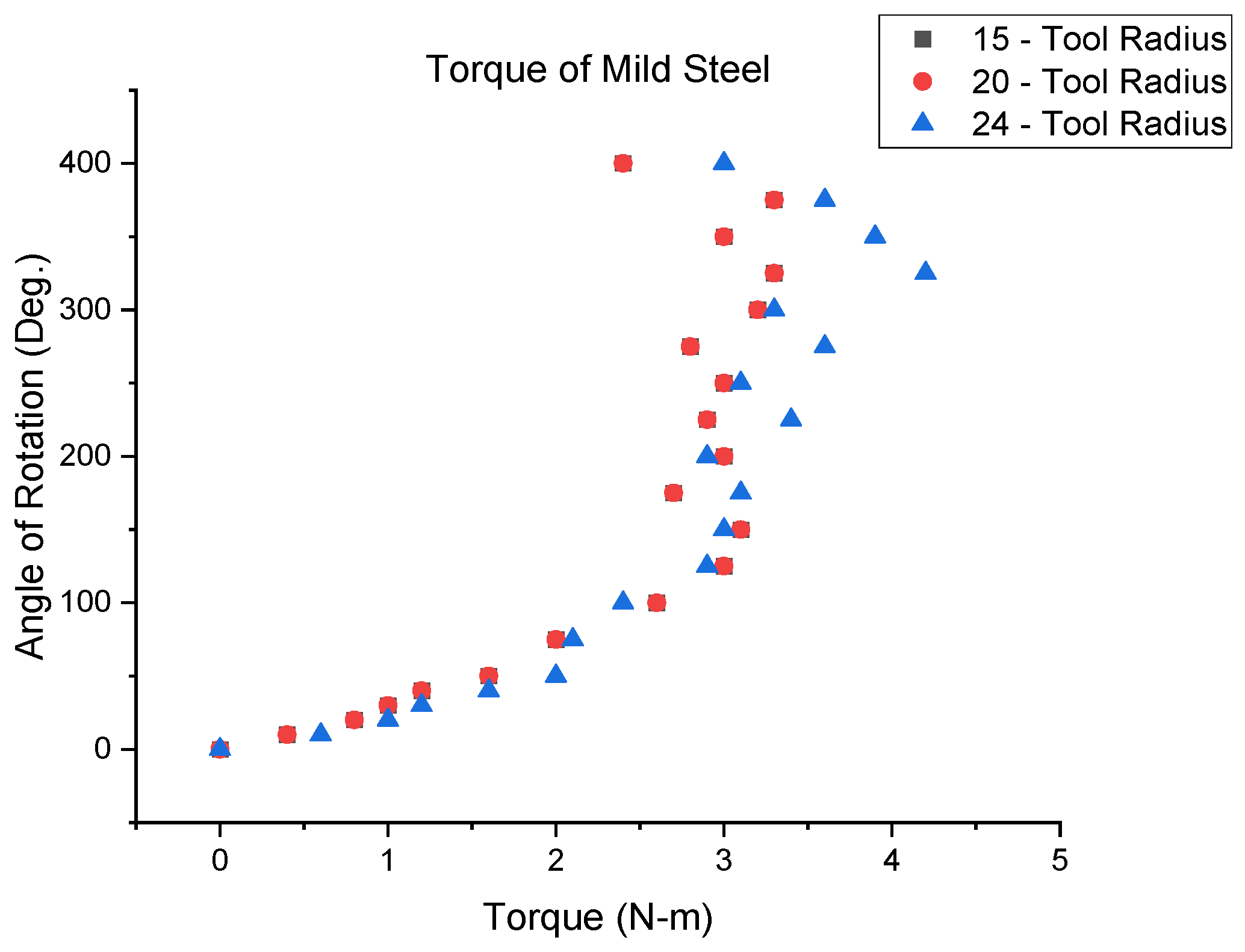

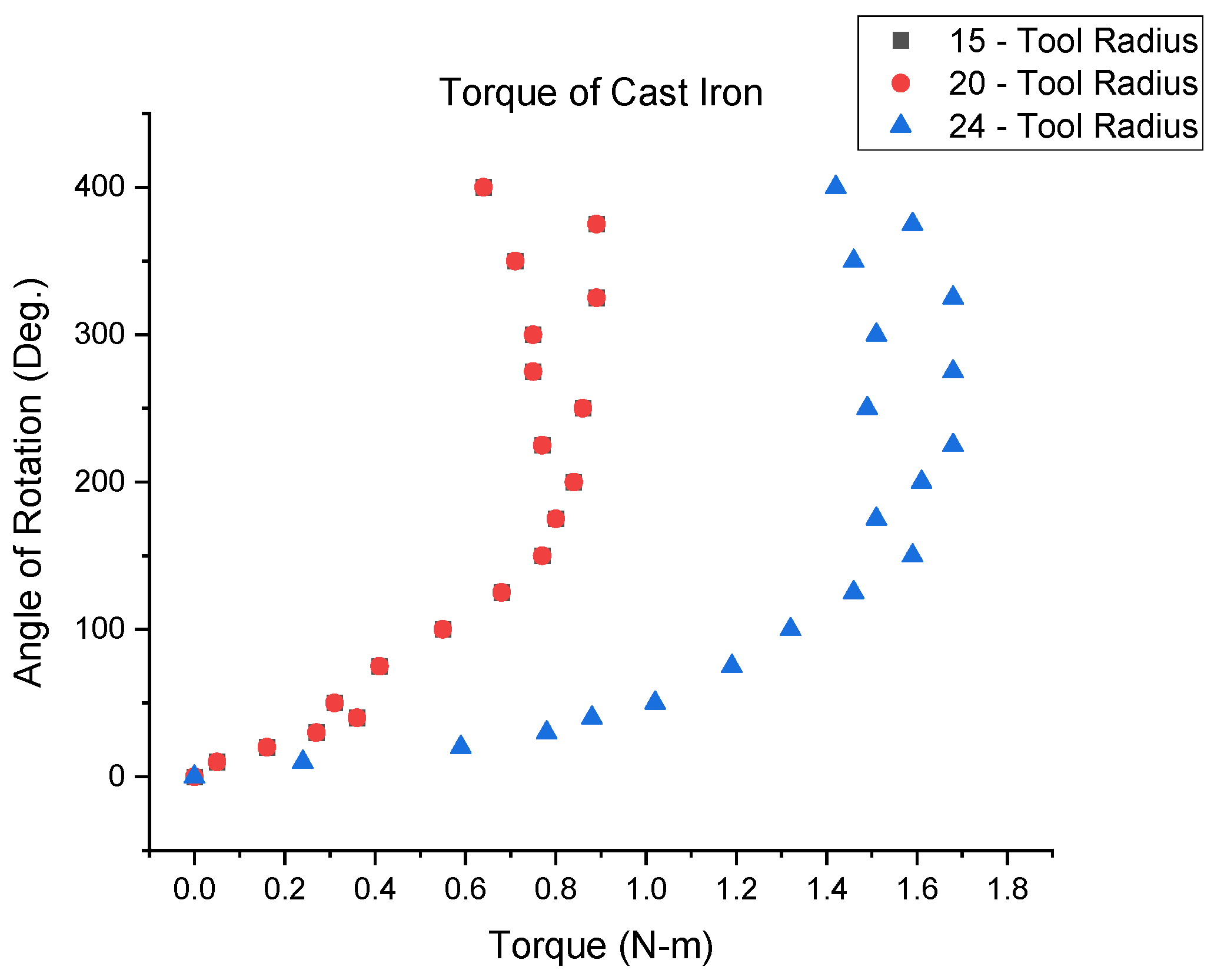

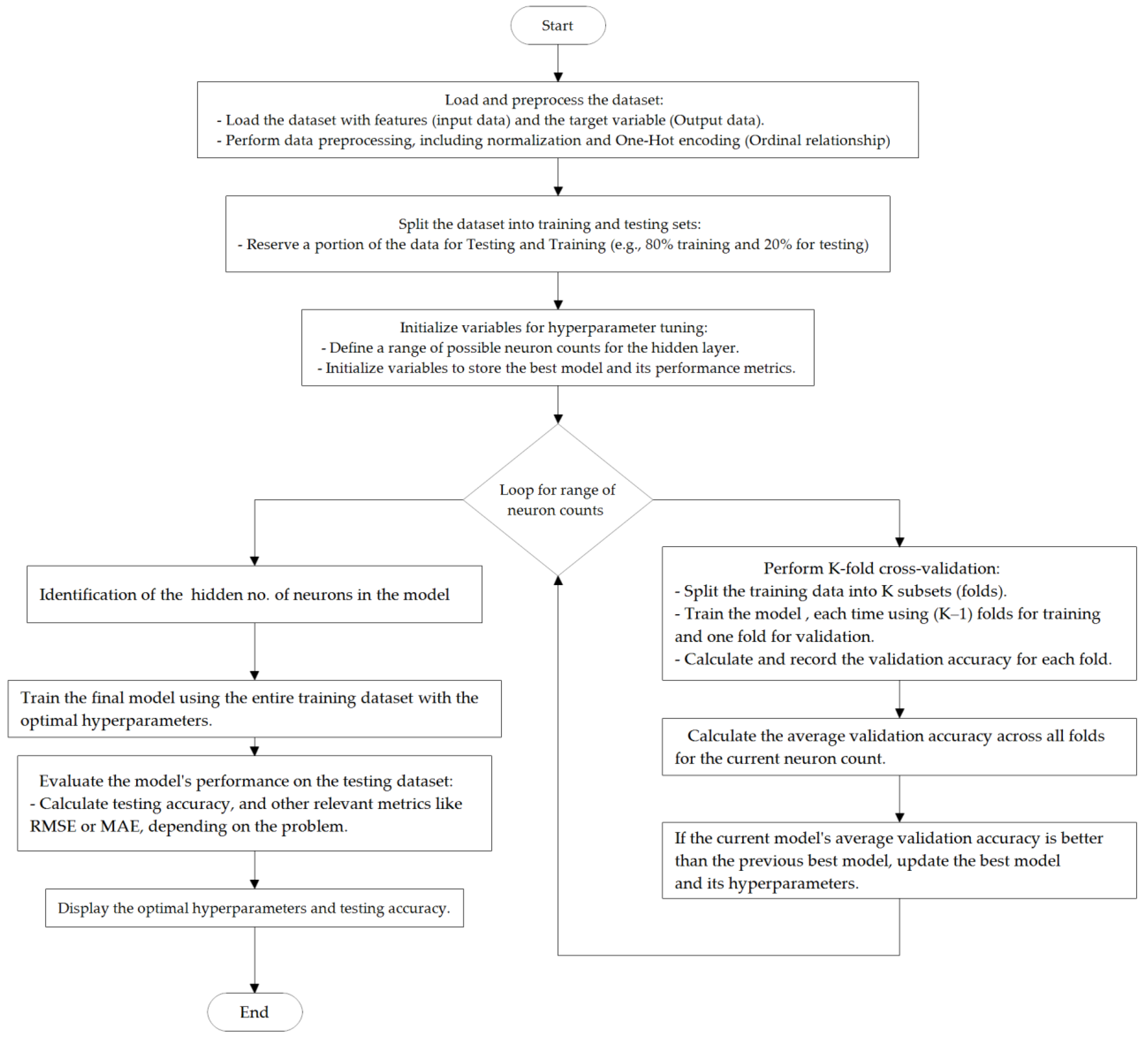

2. Materials and Methods/Methodology

3. Results and Discussion

3.1. Results

3.2. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rom, M.; Brockmann, M.; Herty, M.; Iacomini, E. Machine learning tools in production engineering. Int. J. Adv. Manuf. Technol. 2022, 121, 4793–4804. [Google Scholar] [CrossRef]

- Isaac, A.O.; Jantan, A.; Omolara, E.A.; Dada, V.K.; Mohamed, A.N.; Arshad, H. State-of-the-art in artificial neural network applications: A survey. Heliyon 2018, 4, e00938. [Google Scholar] [CrossRef]

- Serin, G.; Sener, B.; Ozbayoglu, A.M.; Unver, H.O. Review of tool condition monitoring in machining and opportunities for deep learning. Int. J. Adv. Manuf. Technol. 2020, 109, 953–974. [Google Scholar] [CrossRef]

- Schorr, S.; Möller, M.; Heib, J.; Bähre, D. Quality prediction of drilled and reamed bores based on torque measurements and the machine learning method of random forest. Procedia Manuf. 2020, 48, 894–901. [Google Scholar] [CrossRef]

- Naik, N.; Bhat, R.; Shivamurthy, B.; Shetty, R.; Parashar, P.R.; Hegde, A.L. Statistical and artificial neural network coupled technique for prediction of Tribo-performance in amine-cured bio-based epoxy/MMT nanocomposites. J. Compos. Sci. 2023, 7, 372. [Google Scholar] [CrossRef]

- Schorr, S.; Möller, M.; Heib, J.; Bähre, D. In-process quality control of drilled and reamed bores using NC internal signals and machine learning method. Procedia CIRP 2020, 93, 1328–1333. [Google Scholar] [CrossRef]

- Schorr, S.; Möller, M.; Heib, J.; Bähre, D. Comparison of machine learning methods for quality prediction of drilled and reamed bores based on NC-internal signals. Procedia CIRP 2021, 101, 77–80. [Google Scholar] [CrossRef]

- Tan, T.; Zhang, H. A risk prediction method of pipe sticking accidents due to wellbore uncleanness for long horizontal section wells. J. Pet. Sci. Eng. 2022, 210, 110023. [Google Scholar] [CrossRef]

- Luíza da Costa, N.; Dias de Lima, M.; Barbosa, R. Evaluation of feature selection methods based on artificial neural network weights. Expert Syst. Appl. 2021, 168, 114312. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Dangayach, G.S.; Gupta, S. Application of optimization techniques in metal cutting operations: A bibliometric analysis. Mater. Today Proc. 2021, 38, 365–370. [Google Scholar] [CrossRef]

- Fischer, A. Garson’s method trumps Olden’s method in every case—How to determine relative importance of input-variables in nonlinear regression with artificial neural networks. Ecol. Modell. 2015, 309–310, 60–63. [Google Scholar] [CrossRef]

- Shang, G.; Xu, L.; Tian, J.; Cai, D.; Xu, Z. A real-time green construction optimization strategy for engineering vessels considering fuel consumption and productivity: A case study on a cutter suction dredger. Energy 2023, 274, 127326. [Google Scholar] [CrossRef]

- Klein, S.; Schorr, S.; Bähre, D. Quality prediction of honed bores with machine learning based on machining and quality data to improve the honing process control. Procedia CIRP 2020, 1322–1327. [Google Scholar] [CrossRef]

- du Preez, A.; Oosthuizen, G.A. Machine learning in cutting processes as enabler for smart sustainable manufacturing. Procedia Manuf. 2019, 810–817. [Google Scholar] [CrossRef]

- Fratila, D.; Caizar, C. Application of Taguchi method to selection of optimal lubrication and cutting conditions in face milling of AlMg3. J. Clean. Prod. 2011, 19, 640–645. [Google Scholar] [CrossRef]

- Shi, D.; Gindy, N.N. Tool wear predictive model based on least squares support vector machines. Mech. Syst. Signal Process. 2007, 21, 1799–1814. [Google Scholar] [CrossRef]

- Axinte, D.A. Approach into the use of probabilistic neural networks for automated classification of tool malfunctions in broaching. Int. J. Mach. Tools Manuf. 2006, 46, 1445–1448. [Google Scholar] [CrossRef]

- Mo, S.P.; Axinte, D.A.; Hyde, T.H.; Gindy, N.N.Z. An example of selection of the cutting conditions in broaching of heat-resistant alloys based on cutting forces, surface roughness and tool wear. J. Mater. Process. Technol. 2005, 160, 382–389. [Google Scholar] [CrossRef]

- Bonnardel, Q.; Wagner, V.; Dessein, G.; Dutilh, V.; Mandrile, S. Effects of Cutting Parameters over Turning of UDIMET®® 720 Superalloy in a Broaching Process Simulation. Procedia CIRP 2017, 572–577. [Google Scholar] [CrossRef]

- Singh, H.; Singh, K.; Vardhan, S.; Sharma, S.M. A Critical Review of Mechanical and Wear Resistance Characterizations on Developed Aluminium Matrix Composite Reinforced With MgO Particulates. J. Comput. Mech. Manag. 2023, 2, 45–56. [Google Scholar] [CrossRef]

| Sl. No. | ANN | Random Forest | ||

|---|---|---|---|---|

| 1. | No. of hidden layers | 1 | Entropy | 0.44 |

| 2. | No. of neurons in hidden layers | 16 | max features | 2 |

| 3. | Optmizer (Min gradient) | 1.0 × 10−6 | No. of trees | 14,851 |

| 4. | Optmizer (Epochs) | 5000 | Estimators | 8 |

| Sl. No. | Model | Testing Accuracy | RMS |

|---|---|---|---|

| 1. | Artificial Neural Network (ANN) | 94.44% | 0.000483 |

| 2. | Random Forest (Regression model) | 61.96% | 12.87 |

| 3. | Polynomial Regressor model | 19.87% | 42.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rakshith, M.C.; Kamath, R.C.; Vijay, G.S. Prediction of the Reaming Torque Using Artificial Neural Network and Random Forest Algorithm: Comparative Performance Analysis. Eng. Proc. 2023, 59, 97. https://doi.org/10.3390/engproc2023059097

Rakshith MC, Kamath RC, Vijay GS. Prediction of the Reaming Torque Using Artificial Neural Network and Random Forest Algorithm: Comparative Performance Analysis. Engineering Proceedings. 2023; 59(1):97. https://doi.org/10.3390/engproc2023059097

Chicago/Turabian StyleRakshith, M. C., Raghavendra C. Kamath, and G. S. Vijay. 2023. "Prediction of the Reaming Torque Using Artificial Neural Network and Random Forest Algorithm: Comparative Performance Analysis" Engineering Proceedings 59, no. 1: 97. https://doi.org/10.3390/engproc2023059097

APA StyleRakshith, M. C., Kamath, R. C., & Vijay, G. S. (2023). Prediction of the Reaming Torque Using Artificial Neural Network and Random Forest Algorithm: Comparative Performance Analysis. Engineering Proceedings, 59(1), 97. https://doi.org/10.3390/engproc2023059097