Wire EDM Process of AISI 431 Martensitic Stainless Steel: A Machinability Investigation †

Abstract

:1. Introduction

2. Materials and Methods

2.1. AISI 431 Martensite Alloy and Its Chemical Composition

2.2. Wire EDM of AISI 431 Steel

2.3. Measurement of MRR, SR and Micro-Hardness

3. Results and Discussion

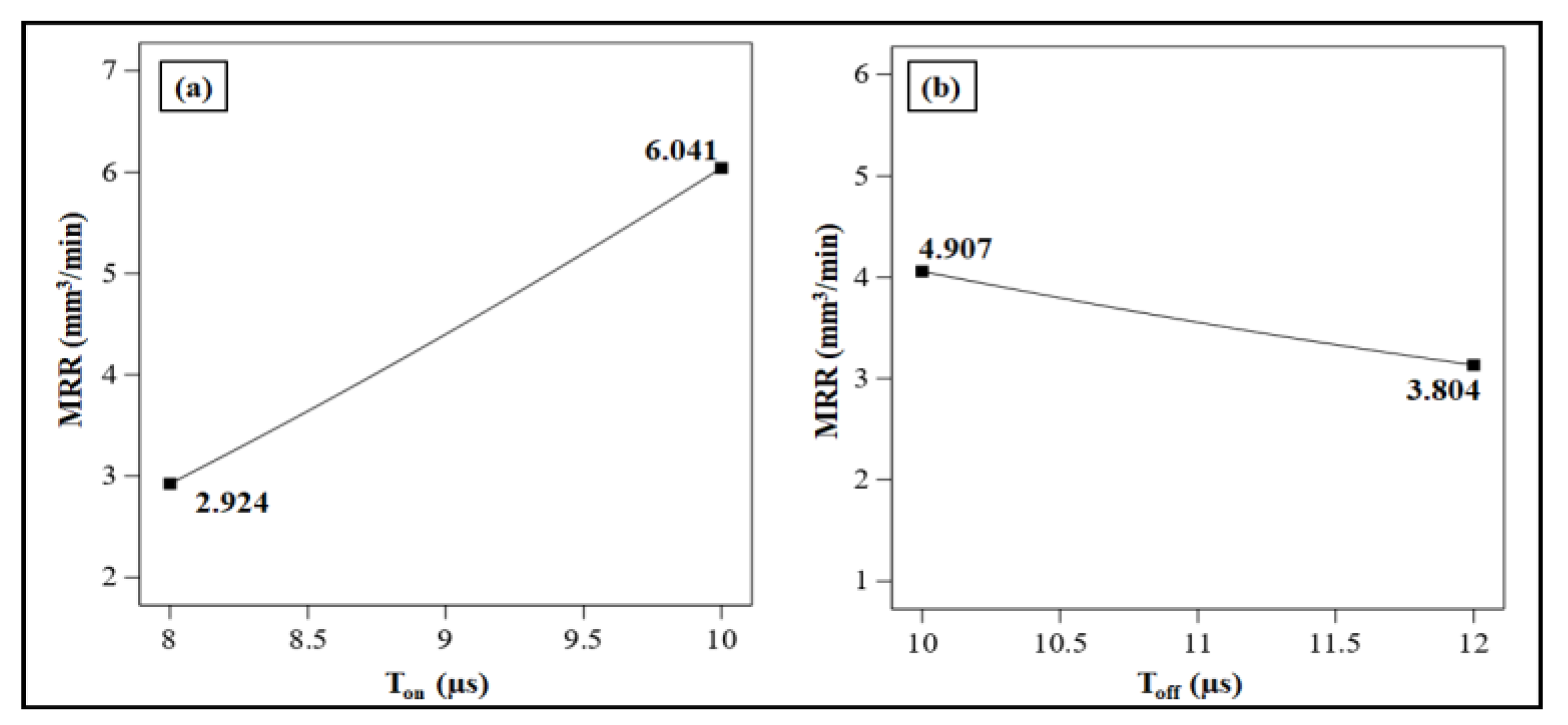

3.1. Statistical Study of the MRR on the AISI 431 Steel

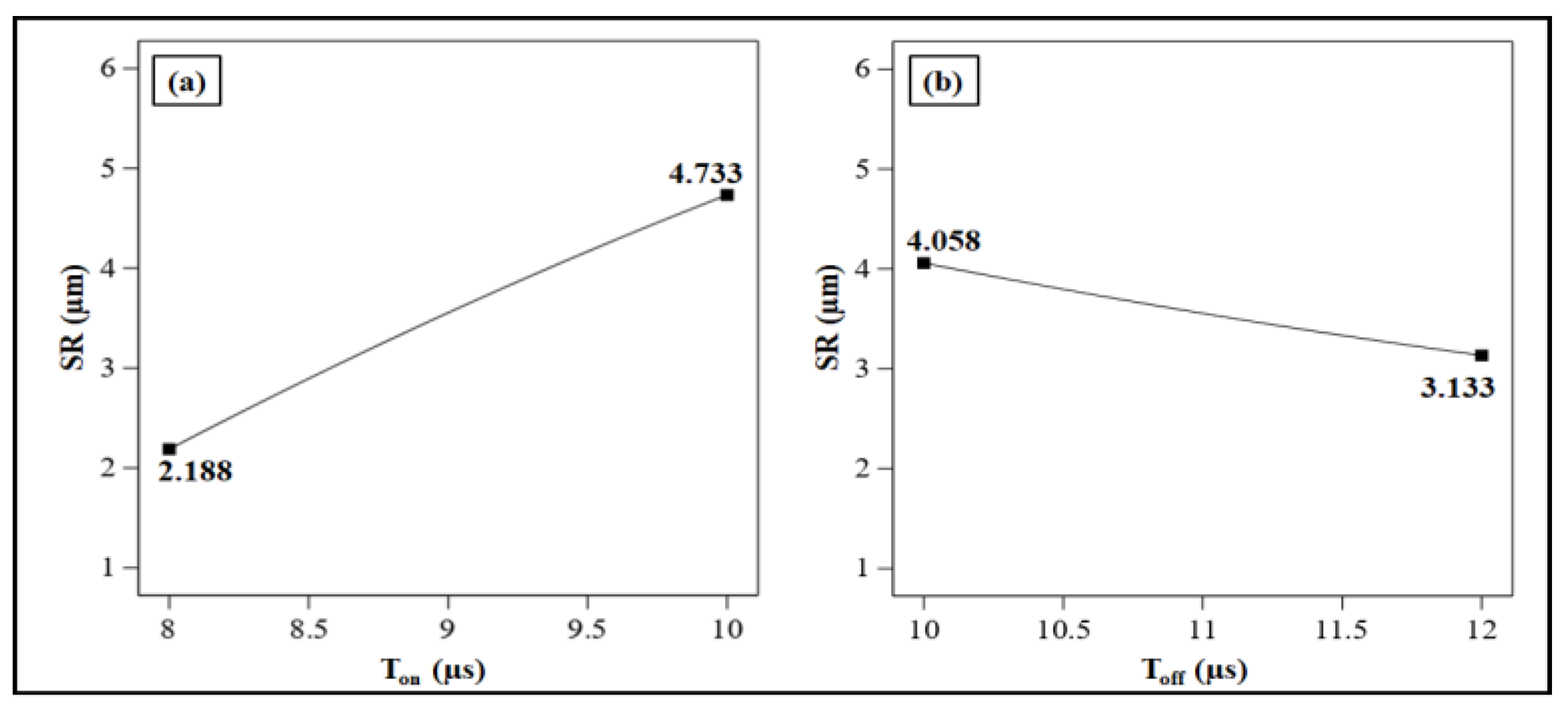

3.2. Statistical Study of the Surface Roughness (SR) of the AISI 431 Steel

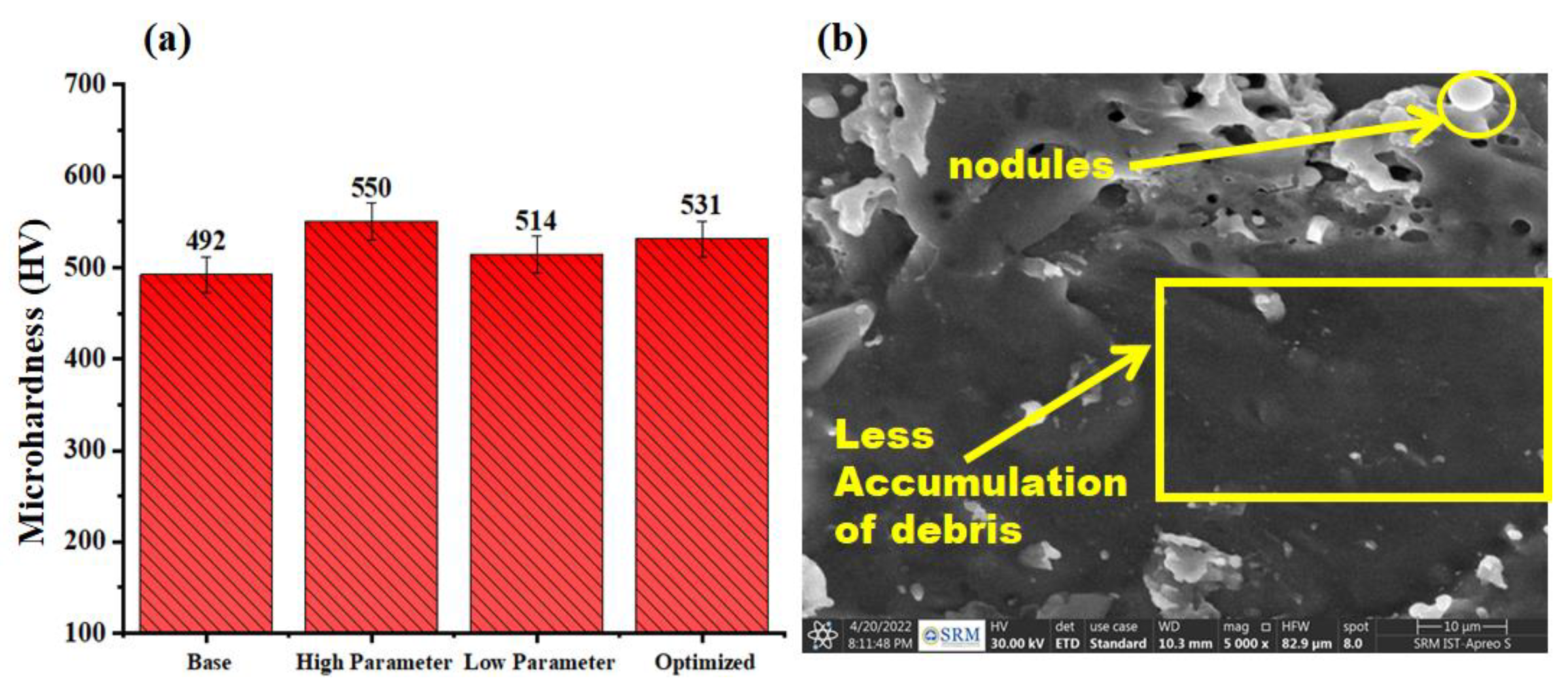

3.3. WEDM Parametric Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Almeida, S.; Mo, J.; Bil, C.; Ding, S.; Wang, X. Comprehensive Servo Control Strategies for Flexible and High-Efficient Wire Electric Discharge Machining. A Systematic Review. Precis. Eng. 2021, 71, 7–28. [Google Scholar] [CrossRef]

- Khorram, A.; Davoodi Jamaloei, A.; Jafari, A.; Moradi, M. Nd:YAG Laser Surface Hardening of AISI 431 Stainless Steel; Mechanical and Metallurgical Investigation. Opt. Laser Technol. 2019, 119, 105617. [Google Scholar] [CrossRef]

- Ishfaq, K.; Ahmad, N.; Jawad, M.; Ali, M.A.; M. Al-Ahmari, A. Evaluating Material’s Interaction in Wire Electrical Discharge Machining of Stainless Steel (304) for Simultaneous Optimization of Conflicting Responses. Materials 2019, 12, 1940. [Google Scholar] [CrossRef] [PubMed]

- Balasubramaniyan, C.; Rajkumar, K. Enhancing Low-Speed WEDM Machining Capabilities on Nitronic-50 with a Constant Frequency Ultrasonic Hybrid Method. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2023. [Google Scholar] [CrossRef]

- Balasubramaniyan, C.; Rajkumar, K.; Santosh, S. Wire-EDM Machinability Investigation on Quaternary Ni 44 Ti 50 Cu 4 Zr 2 Shape Memory Alloy. Mater. Manuf. Process 2021, 36, 1161–1170. [Google Scholar] [CrossRef]

- Balasubramaniyan, C.; Santosh, S.; Rajkumar, K. Surface Quality and Morphology of NiTiCuZr Shape Memory Alloy Machined Using Thermal-Energy Processes: An Examination of Comparative Topography. Surf. Topogr. 2022, 10, 035019. [Google Scholar] [CrossRef]

- Doreswamy, D.; Bongale, A.M.; Piekarski, M.; Bongale, A.; Kumar, S.; Pimenov, D.Y.; Giasin, K.; Nadolny, K. Optimization and Modeling of Material Removal Rate in Wire-EDM of Silicon Particle Reinforced Al6061 Composite. Materials 2021, 14, 6420. [Google Scholar] [CrossRef] [PubMed]

- Balasubramaniyan, C.; Rajkumar, K.; Santosh, S. Enhancement of Machining and Surface Quality of Quaternary Alloyed NiTiCuZr Shape Memory Alloy through Ultrasonic Vibration Coupled WEDM. Proceedings of the Institution of Mechanical Engineers. Proc. Inst. Mech. Eng. Sci. 2022, 236, 816–833. [Google Scholar] [CrossRef]

| Run | Ton, µs | SV, V | Toff, µs | MRR, mm3/min | SR, µm |

|---|---|---|---|---|---|

| 1 | 9 | 45 | 11 | 4.506 | 3.583 |

| 2 | 9 | 40 | 12 | 3.912 | 3.214 |

| 3 | 8 | 50 | 11 | 2.723 | 2.027 |

| 4 | 9 | 50 | 10 | 4.812 | 3.941 |

| 5 | 9 | 40 | 10 | 5.061 | 4.187 |

| 6 | 10 | 45 | 10 | 6.591 | 5.172 |

| 7 | 9 | 45 | 11 | 4.402 | 3.609 |

| 8 | 9 | 50 | 12 | 3.533 | 2.873 |

| 9 | 10 | 50 | 11 | 5.833 | 4.438 |

| 10 | 10 | 45 | 12 | 5.416 | 4.379 |

| 11 | 9 | 45 | 11 | 4.292 | 3.472 |

| 12 | 10 | 40 | 11 | 6.184 | 4.945 |

| 13 | 8 | 40 | 11 | 3.086 | 2.266 |

| 14 | 8 | 45 | 12 | 2.469 | 1.798 |

| 15 | 8 | 45 | 10 | 3.279 | 2.662 |

| Optimized Level | Predicted Values | Experimental Values | % of Error | |||||

|---|---|---|---|---|---|---|---|---|

| Ton | SV | Toff | MRR | SR | MRR | SR | MRR | SR |

| 9 | 50 | 11 | 4.606 | 3.636 | 4.421 | 3.488 | 4.18 | 4.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chandrasekaran, B.; Sampath, S.; Anbalagan, A.; Paneerselvam, V.; Karthick, V. Wire EDM Process of AISI 431 Martensitic Stainless Steel: A Machinability Investigation. Eng. Proc. 2024, 61, 27. https://doi.org/10.3390/engproc2024061027

Chandrasekaran B, Sampath S, Anbalagan A, Paneerselvam V, Karthick V. Wire EDM Process of AISI 431 Martensitic Stainless Steel: A Machinability Investigation. Engineering Proceedings. 2024; 61(1):27. https://doi.org/10.3390/engproc2024061027

Chicago/Turabian StyleChandrasekaran, Balasubramaniyan, Santosh Sampath, Arun Anbalagan, Vengatesh Paneerselvam, and Vignesh Karthick. 2024. "Wire EDM Process of AISI 431 Martensitic Stainless Steel: A Machinability Investigation" Engineering Proceedings 61, no. 1: 27. https://doi.org/10.3390/engproc2024061027

APA StyleChandrasekaran, B., Sampath, S., Anbalagan, A., Paneerselvam, V., & Karthick, V. (2024). Wire EDM Process of AISI 431 Martensitic Stainless Steel: A Machinability Investigation. Engineering Proceedings, 61(1), 27. https://doi.org/10.3390/engproc2024061027