Synthesis and Characterization of Starch-Based Bioplastics: A Promising Alternative for a Sustainable Future †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Starch and Bioplastic

2.2. Tensile Strength (TS) and Elongation at Break (EAB)

2.3. Scanning Electron Microscope Analysis (SEM) and X-ray Diffraction (XRD) Analysis

3. Results and Discussion

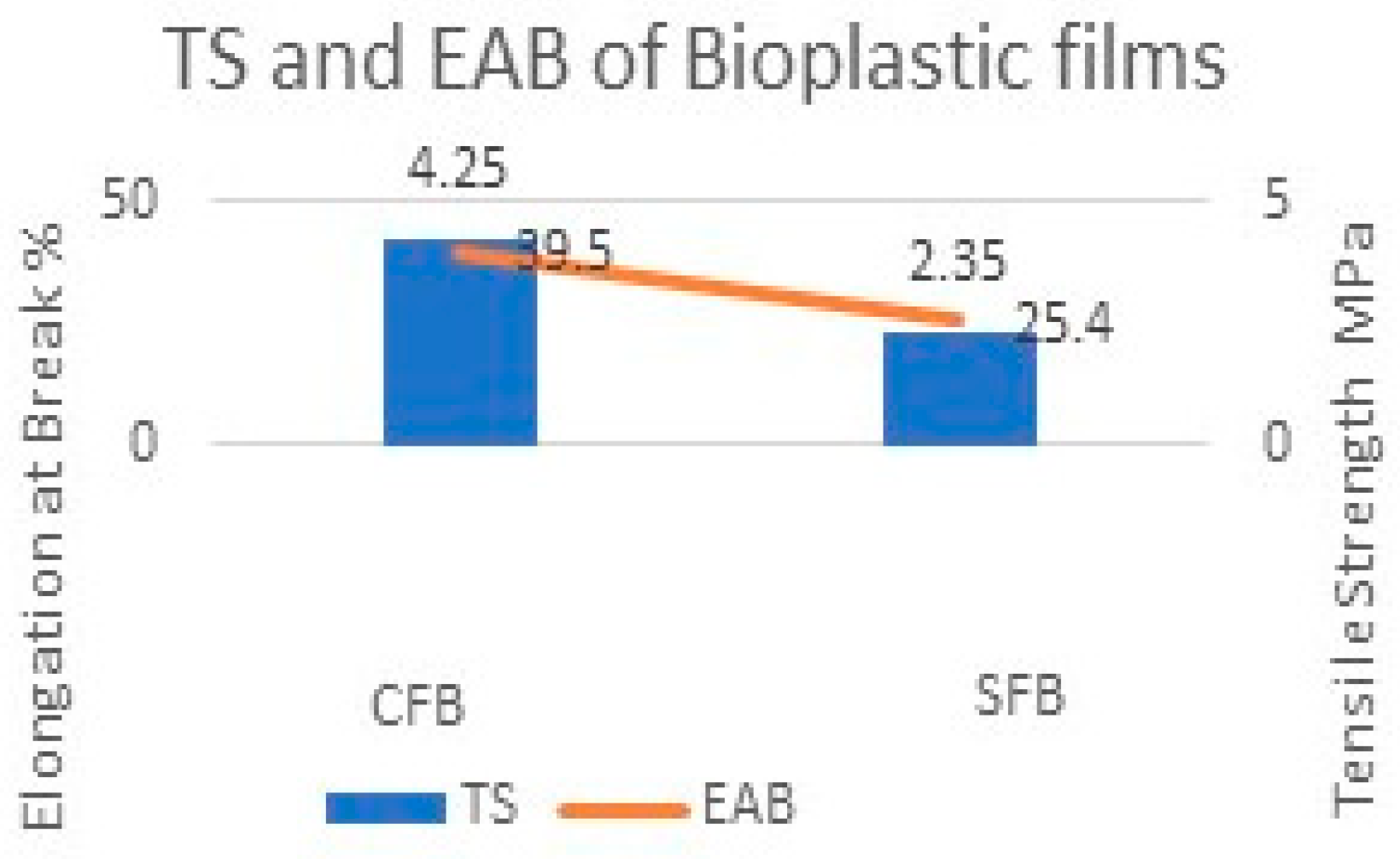

3.1. Tensile Strength (TS) and Elongation at Break (EAB)

3.2. Scanning Electron Microscopic Analysis (SEM)

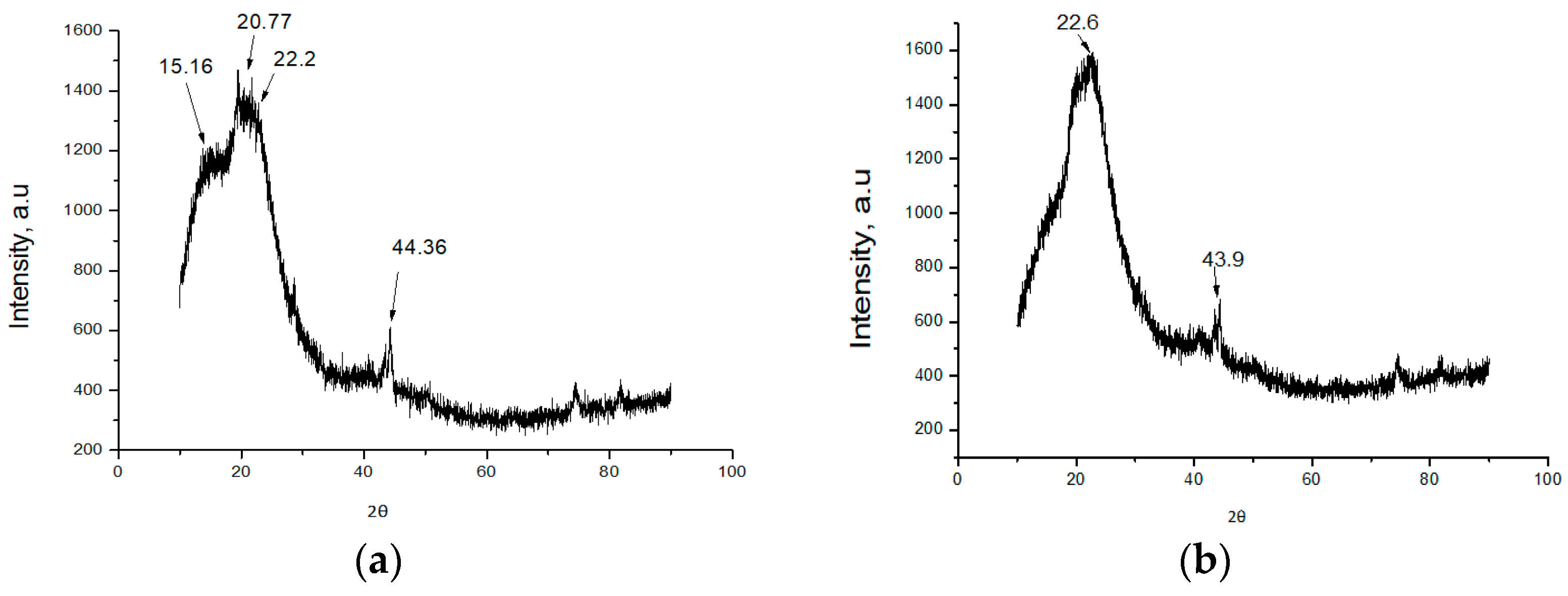

3.3. X-ray Diffraction (XRD) Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Coppola, G.; Gaudio, M.T.; Lopresto, C.G. Bioplastic from renewable biomass: A facile solution for a greener environment. Earth Syst. Environ. 2021, 5, 231–251. [Google Scholar] [CrossRef]

- Balla, E.; Daniilidis, V.; Karlioti, G.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Vlachopoulos, A.; Koumentakou, I.; Bikiaris, D.N. Poly (lactic Acid): A versatile biobased polymer for the future with multifunctional properties—From monomer synthesis, polymerization techniques and molecular weight increase to PLA applications. Polymers 2021, 13, 1819–1822. [Google Scholar] [CrossRef] [PubMed]

- Jiang, T.; Duan, Q.; Zhu, J.; Liu, H.; Yu, L. Starch-based biodegradable materials: Challenges and opportunities. Adv. Ind. Eng. Polym. 2020, 3, 8–18. [Google Scholar] [CrossRef]

- Santana, R.F.; Bonomo, R.C.F.; Gandolfi, O.R.R.; Rodrigues, L.B.; Santos, L.S.; Dos Santos Pires, A.C.; de Oliveira, C.P.; da Costa Ilhéu Fontan, R.; Veloso, C.M. Characterization of starch-based bioplastics from jackfruit seed plasticized with glycerol. J. Food Sci. Technol. 2018, 55, 278–286. [Google Scholar] [CrossRef] [PubMed]

- Neela, S.; Fanta, S.W. Review on nutritional composition of orange-fleshed sweet potato and its role in management of vitamin A deficiency. Food Sci. Nutr. 2019, 17, 1920–1945. [Google Scholar] [CrossRef] [PubMed]

- Qazanfarzadeh, Z.; Kumaravel, V. Hydrophilization approaches of protein-based bioplastics. Trends Food Sci. 2023, 138, 27–43. [Google Scholar] [CrossRef]

- Tyagi, V.; Bhattacharya, B. Role of plasticizers in bioplastics. MOJ Food Process. Technol. 2019, 7, 128–130. [Google Scholar] [CrossRef]

- Syaubari; Safwani, S.; Riza, M. Synthesis of biodegradable plastic from tapioca with N-Isopropylacrylamid and chitosan using glycerol as plasticizer. IOP Conf. Ser. Mater. Sci. Eng. 2018, 345, 012049. [Google Scholar] [CrossRef]

- Yusoff, N.H.; Pal, K.; Narayanan, T.; Gomes de Souza, F. Recent trends on bioplastics synthesis and characterizations: Polylactic acid (PLA) incorporated with tapioca starch for packaging applications. J. Mol. Struct. 2021, 1232, 129954. [Google Scholar] [CrossRef]

- Zainab, R. Standard Test Method for Tensile Properties of Plastics 1. 2019. Available online: https://www.researchgate.net/publication/330713593_Standard_Test_Method_for_Tensile_Properties_of_Plastics_1 (accessed on 1 January 2024).

- Krishnamurthy, A.; Amritkumar, P. Synthesis and characterization of eco friendly bioplastic from low-cost plant resources. SN Appl. Sci. 2019, 1, 1432. [Google Scholar] [CrossRef]

- Gere, D.; Czigany, T. Rheological and mechanical properties of recycled polyethylene films contaminated by biopolymer. Waste Manag. Res. 2018, 76, 190–198. [Google Scholar] [CrossRef]

- Marichelvam, M.K.; Jawaid, M.; Asim, M. Corn and rice starch-based bio-plastics as alternative packaging materials. Fibers 2019, 7, 29–32. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anitha, R.; Jayakumar, K.; Samuel, G.V.; Joice, M.E.; Sneha, M.; Seeli, D.S. Synthesis and Characterization of Starch-Based Bioplastics: A Promising Alternative for a Sustainable Future. Eng. Proc. 2024, 61, 30. https://doi.org/10.3390/engproc2024061030

Anitha R, Jayakumar K, Samuel GV, Joice ME, Sneha M, Seeli DS. Synthesis and Characterization of Starch-Based Bioplastics: A Promising Alternative for a Sustainable Future. Engineering Proceedings. 2024; 61(1):30. https://doi.org/10.3390/engproc2024061030

Chicago/Turabian StyleAnitha, R., K. Jayakumar, G. Vijay Samuel, M. Esther Joice, M. Sneha, and D. Sathya Seeli. 2024. "Synthesis and Characterization of Starch-Based Bioplastics: A Promising Alternative for a Sustainable Future" Engineering Proceedings 61, no. 1: 30. https://doi.org/10.3390/engproc2024061030