Abstract

Hand-arm vibration is a significant occupational hazard commonly faced by industrial workers, particularly those in foundries engaged in fettling activities. The vibration exposure can result in various health problems, such as hand-arm vibration syndrome (HAVS), carpal tunnel syndrome, and other musculoskeletal disorders. Therefore, it is essential to evaluate workers’ vibration environment and exposure levels to prevent such health issues. At first, the present study explored a different type of vibration exposure followed by vibration syndrome and vibration measurement methods. A case study was considered wherein the comparative analysis between pneumatic and swing grinders was performed between vibration magnitude, particularly in the fettling shop. The results revealed that the pneumatic hand grinder worker experienced a vibration magnitude of 3.6 m/s2 at 208 exposure points. In comparison, the swing grinder had a magnitude of 6.5 m/s2 at 668 exposure points for an 8 h workday. It can be noted that regulatory bodies such as ISO 5349 recommend an exposure vibration magnitude of 5 m/s2 for an 8 h workday and in the present context, these exposure levels were found to be higher than the standard limits. Accordingly, proper recommendations to sustain these levels within the limits are suggested. Such recommendations will protect workers from health hazards and help employers avoid costly compensation claims and legal liabilities. This study emphasizes the importance of addressing hand-arm vibration in the workplace for a safe working environment.

1. Introduction

Hand-arm vibration is a common occupational hazard in industries where workers use handheld power tools for extended periods. Workers at fettling shops will likely acquire hand-arm vibration syndrome (HAVS), a debilitating condition affecting the blood vessels, nerves, carpal tunnel syndrome, and other musculoskeletal disorders [1]. The vibration environment in a foundry can be challenging and hazardous for workers, particularly those in fettling shops who use handheld power tools for extended periods. Foundry operations often involve heavy machinery and equipment that generate high levels of vibration and processes that cause ground vibration and shock waves. Handheld power tools such as grinders, chisels, and hammers also generate significant vibration when used, which can exacerbate the effects of whole-body vibration [2]. Commonly used instruments that induce hand-arm vibration include chainsaws and others. Therefore, evaluating workers’ vibration environment and exposure levels is crucial to prevent such health hazards. Moreover, employers must implement effective measures to mitigate the risks associated with the vibration environment in foundries, including vibration monitoring, training, and vibration-dampening equipment and tools [3]. Several researchers have worked on vibration. Gerhardsson et al. [4] reported that vibration exposure is a significant concern in the foundry industry, particularly in the fettling area. The study found that vibration levels exceeding the recommended limits were prevalent among pneumatic and swing grinder workers. Similarly, a study by Nilsson et al. [5] highlighted the importance of considering vibration exposure when designing and selecting tools and equipment for foundry workers. Various regulatory bodies have specified exposure limits for hand-arm vibration. During an 8 h workday, Capua et al. [6] recommended an exposure limit of 5 m/s2 as per ISO 5349 but the American Conference of Governmental Industrial Hygienists (ACGIH) suggests a limit of 2.5 m/s2 [7]. However, compliance with these limits is often challenging, particularly in industries such as foundries where workers are exposed to high vibration levels.

Several interventions have been proposed to reduce hand-arm vibration exposure levels in the workplace. For instance, anti-vibration gloves, hand-arm vibration-reducing gloves, and vibration-absorbing tools can help reduce exposure levels [8]. Similarly, administrative measures such as job rotation, rest breaks, and tool maintenance can help reduce exposure levels. A study by Burström et al. [9] suggested that regular training and information dissemination programs can also help increase workers’ awareness of the risks associated with hand-arm vibration exposure and promote safe working practices. Another study by Forouharmajd et al. explored the interplay of temperature and vibration effects [10]. Hand-arm vibration exposure has been related to hand-arm vibration syndrome, an irreversible disease of the fingers and hands [11]. HAVS is a disease per the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations (RIDDOR) [12]. Ding reviewed the effects of hand-arm vibration on employees who use hand-held vibrating instruments [13]. The risk from vibration in Indian mines was studied by Srivastava and Mandal [14] and showed that 8.6% of the workers are subjected to HAV, and 9.2% are subjected to whole-body vibration. Gender differences in subjective responses to hand-arm vibration were studied by Neely and Burström [15]. The study found that there were no gender variations in threshold limitations. Females, on the other hand, rated perceived severity and pain as higher [16]. Females were much more subjectively responsive than males to higher frequency levels of physical intensity [17]. Barefoot investigated the tractor and reported high hand-transmitted vibration in the steering wheel [18].

Although several works are related to vibration assessment, the comprehensive exploration of vibration exposure, vibration syndrome, and vibration measurement methods must be included for a foundry, especially in the fettling shop. Moreover, the comparative analysis of vibration magnitude between pneumatic and swing grinders must be considered, particularly in a fettling shop. Hence, a case study on the vibration exposure levels of pneumatic and swing grinders in a foundry has been considered and studied. The scope of this research encompasses a comprehensive examination of worker exposure to hand-arm vibration in a foundry’s fettling shop, utilizing experimental methods. The study aims to provide valuable insights and recommendations for enhancing occupational health and safety in similar industrial settings.

2. Materials and Methods

The materials and methods include vibration exposure, vibration syndrome, and vibration measurement, as discussed in the succeeding section.

2.1. Vibration Exposure

In a fettling shop, workers are exposed to various types of vibration, which can adversely affect their health. The primary sources of vibration exposure in a fettling shop are the grinding machines and hand grinders used for the fettling process. The types of vibration exposure can be broadly categorized as hand-arm and whole-body vibration.

- A.

- Hand-Arm vibration

Hand-arm vibration is transmitted to the hands of workers through the use of vibrating hand-held tools and equipment. This type of vibration exposure can result in health issues such as HAVS and other musculoskeletal disorders. HAVS is a debilitating condition that can cause tingling, numbness, and pain in the hands and arms, as well as a loss of dexterity and grip strength. Hand-arm vibration is the predominant occupational workplace disorder. The primary symptoms of HAVS include tingling in the fingers.

- B.

- Whole-Body Vibration (WBV)

Workers in a fettling shop face whole-body vibration (WBV) exposure while operating grinding machines, transmitting vibrations to the entire body. Unlike hand-arm vibration (HAV), WBV enters the body through various pathways and is linked to health issues such as severe lower back pain, particularly in those exposed for extended periods. The lumbar spine is especially vulnerable, causing degeneration, moisture loss, and disc herniation. This discomfort can diminish work productivity, resulting in financial losses. Mitigating WBV exposure involves equipment redesign, anti-vibration devices, rest breaks, and task rotation. Training programs raise awareness, fostering safe practices.

2.2. Vibration Syndrome

Vibration Syndrome, caused by using vibrating instruments, can cause muscular weakness, weariness, and soreness in the hand. Mild and severe symptoms such as muscle weakness and fatigue are significantly found [19]. The condition is caused by the continuous use of vibrating tools and equipment, which can damage the nerves and muscles in the hands. In addition to the physical symptoms, many researchers believe that vibration syndrome can also cause other symptoms, such as headaches, irritability, depression, forgetfulness, and sleeping problems [20]. These symptoms can significantly impact an individual’s quality of life and work productivity. Several studies have reported the prevalence of vibration syndrome among workers in various industries. For example, a study conducted among construction workers in Taiwan found that the prevalence of vibration syndrome was 17.2% [21]. Another study among forestry workers in Sweden reported a prevalence rate of 31% [22]. Vibration syndrome is a serious occupational hazard that can have significant physical and psychological consequences. Employers must implement measures to prevent and manage the condition, including reducing vibration exposure levels, providing adequate training on safe working practices, and conducting regular health monitoring of workers [23,24].

- A.

- Vibration-Induced White Finger

VWF is a condition caused by impaired circulation resulting from the prolonged use of vibrating tools. It is also called “Dead Finger” or “Dead Hand”. The severity of VWF varies and might show after only a few months on the job, or it can take up to 20 to 40 years. The negative consequences of utilizing vibrating tools are determined by the time a worker has used the equipment and the frequency of the vibration. Several Vibration Syndrome symptoms, such as weariness, muscle soreness in the arms and shoulders, and VWF, subside when a person stops using vibrating instruments.

- B.

- Carpal Tunnel Syndrome

CTS is a condition that results from pressure on nerves passing through the wrist’s palm side, causing a group of symptoms in the hand. The symptoms of CTS are characterized by tingling sensations in the fingers. However, unlike the white finger, CTS usually affects only the thumb, index, and middle fingers. Numbness, as well as discomfort in the wrist and fingers, may occur as the illness advances. Those who use tiny hand tools, such as pneumatic screwdrivers, or those who do repeated wrist or finger movements are at risk of developing CTS. The forceful motion of the wrist, such as when using a wrench, can also cause CTS. CTS increases when the wrist is bent upwards, downwards, or sideways, especially during pinching or flexing activities. To prevent these health issues, evaluating the vibration environment and exposure levels of workers in a fettling shop is essential. This can be performed by measuring the vibration levels using specialized equipment and comparing them to the recommended exposure limits set by regulatory bodies such as ISO 5349 [6]. Proper workplace changes, including modifying the design of tools and equipment, replacing equipment with better designs that reduce vibrations, and providing adequate training to workers on safe working practices, can be implemented to reduce these vibration exposure levels and ensure the safety and well-being of workers.

2.3. Vibration Measurement

To measure vibrations, a specialized instrument that includes an accelerometer attachment is connected to a display system through a co-axial cable. This system displays the acceleration, displacement, and frequency of vibration. The maximum vibration level in any axis (or combination of axes) and the maximum exposure time are calculated based on current legislation. Since the magnitude of the acceleration is constantly changing, it is not practical to rely on a single overall value. Instead, the acceleration magnitude is called the root-mean-square (RMS) daily duration of exposure. The measurement duration can vary depending on the situation. For example, if the vibration level is constant throughout the day, a measurement of a few minutes may suffice. On the other hand, if the vibration level changes throughout the day, the measurement should be longer to obtain a more accurate assessment. This research conducted vibration measurements for two types of grinders, namely, the pneumatic hand grinder and the swing grinder. The measurement was conducted for 15 min, and data were recorded every 30 s. Two of the most widely used standards, ISO 5349:1986 for Hand-Arm Vibration (HAV) [6] and ISO 2631:1997 for Whole-Body Vibration (WBV) [25] evaluation, were followed to ensure accurate and reliable measurements. ISO 5349:1986 is a standard for evaluating HAV exposure and guides how to measure, evaluate, and calculate the vibration levels experienced by the hand-arm system. On the other hand, ISO 2631:1997 provides guidelines for measuring, evaluating, and specifying the human response to vibration, including the entire body’s response to vibration. Following these standards, the maximum vibration levels experienced in any axis or combination of axes and the maximum exposure time, based on current legislation, were determined. This allowed us to gain valuable insights into the potential health risks associated with using these grinders and take appropriate measures to mitigate those risks.

2.4. Experiment

The study aimed to assess the hand-arm vibration felt by workers in a typical fettling work setting. To achieve this, a subject was selected, and the purpose of the experimental measurements was explained to them. The measurements were taken regularly during the worker’s job, without disrupting their work, to ensure accurate results. The selected subject was a 52-year-old worker who weighed around 62 kg and had over five years of experience in fettling work. The component being worked on was a sub-assembly. Figure 1 shows the typical posture the worker would assume during work, providing a visual reference for readers to understand the subject’s positioning during the experiment. By selecting an experienced worker and conducting measurements during regular work, the study aimed to provide a more realistic understanding of the hand-arm vibration experienced in the fettling work setting.

Figure 1.

A typical posture of a worker during fettling work.

3. Results

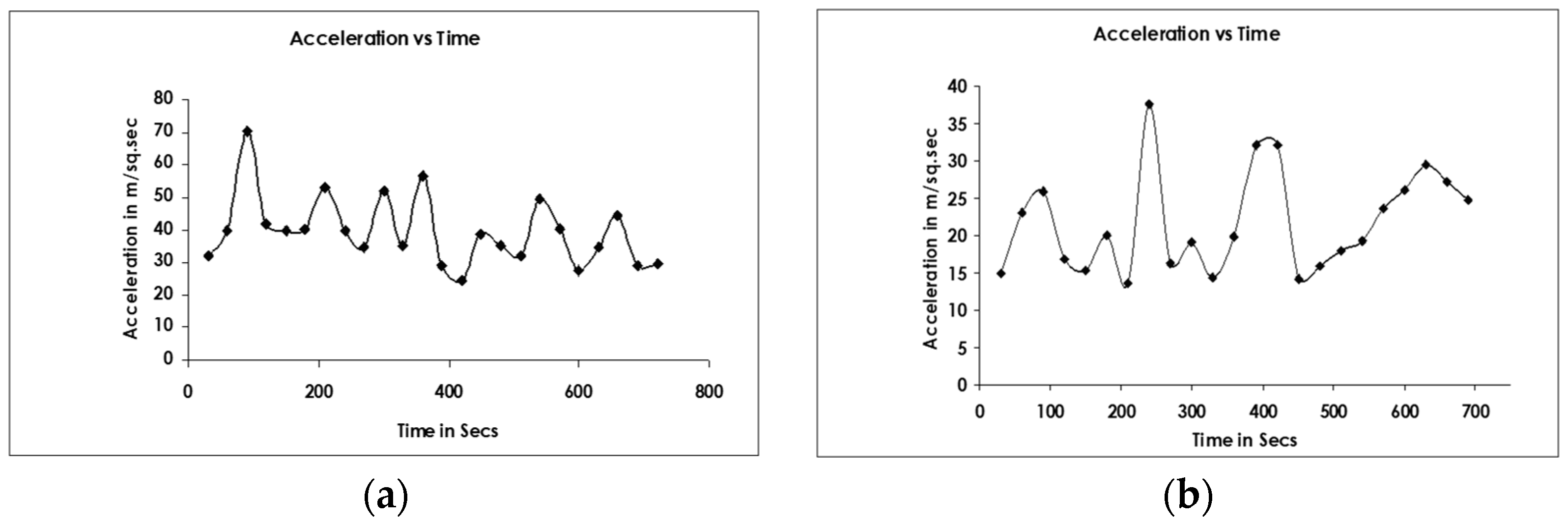

During the study, the vibration levels for the swing grinder were recorded frequently. Figure 2 shows the pattern of vibration recorded during the measurements. It can be observed that there is a wide variation in the acceleration levels produced by the machine during work. However, it is essential to note that these values are the raw data collected on the shop floor and are subject to fluctuations due to various factors. This provides a more reliable representation of the actual vibration exposure experienced by the worker. To accurately assess the risk to the subject, the root-mean-square (RMS) values of each task are estimated individually, after which the exposure points for the subject are calculated.

Figure 2.

Vibration Pattern: (a) swing grinder, and (b) pneumatic hand grinder.

Calculation of Exposure Points

Exposure points are calculated based on the vibration magnitude, duration, and the presence of a frequency-weighting filter. The daily exposure points are determined by adding the product of the vibration magnitude and duration of exposure for each frequency range. The exposure points are then compared with the action and limit values set by regulations. If the exposure points exceed the action value, employers reduce exposure by taking necessary actions and monitoring the worker’s exposure levels. If the exposure points exceed the limit value, the worker must be removed from the task or provided with suitable protective measures to prevent further exposure.

- Exposure Action Value (EAV): EAV is a threshold limit for daily exposure to vibration (i.e., 2.5 m/s2). The risk of injury due to vibration increases as exposure levels increase, and employers must take appropriate action.

- Exposure Limit Value (ELV): ELV is the maximum threshold of vibration to which a worker can be subjected on any particular day (i.e., 5 m/s2). This amount of exposure constitutes a high danger to which personnel should not be exposed, and precautions should be taken to keep exposure below this limit.

Below, RMS values for the measured four-hand grinding processes were presented, ranging from 19.75 to 26.2 m/s² and are presented in Table 1. The RMS values for the swing grinder range from 34.73 to 45.62 m/s² and are presented in Table 2.

Table 1.

Vibration magnitude for hand grinder.

Table 2.

Vibration magnitude for swing grinder.

The HSE has established guidelines to help calculate the total exposure points a worker may be exposed to regarding hand-arm vibration. These guidelines are used to calculate the daily exposure acceleration for a worker. The daily exposure points for the grinding machines in this study were calculated according to these guidelines. It is important to note that these guidelines help establish safe exposure levels for workers and are crucial in reducing the risk of long-term health effects associated with hand-arm vibration.

Using the vibration exposure calculator methodology issued by the HSE, the exposure values were calculated and can be later compared with the standards for deciding on the amount of exposure experienced by the subject. The total daily exposure was 3.6 m/s2 for the pneumatic hand grinder, with total exposure points 208 as presented in Table 3. On the other hand, the swing grinder showed a higher daily exposure of 6.5 m/s2 with total exposure points of 668 as presented in Table 4. The average time taken to reach the EAV was found to be 6 min in a hand grinder, and the average time to reach the ELV was found to be 24.25 min. Similarly, the average time taken to reach the EAV was 1.5 min in the swing grinder, and the average time to reach the ELV was found to be 7.5 min. The values obtained here are calculated assuming that the subject works 8 h a day. Hence, the values are for 8 h of weightage.

Table 3.

Partial vibration magnitude for hand grinder.

Table 4.

Partial vibration magnitude for swing grinder.

4. Discussions

The study’s findings underscore significant concerns regarding the vibration levels associated with the pneumatic hand grinder and swing grinder. Evaluation against permissible vibration values reveals that the pneumatic hand grinder, with a vibration magnitude of 3.6 m/s², falls between the Exposure Action Value (EAV) and Exposure Limit Value (ELV). This signifies a cause for concern, as it poses potential health hazards for workers. In contrast, the swing grinder exhibits a substantially higher exposure magnitude of 6.5 m/s², surpassing the ELV and indicating a heightened risk to worker health. Consequently, imperative changes are necessary to diminish worker exposure to elevated vibration levels. An effective measure to achieve this is the incorporation of anti-vibration gloves and appropriate Personal Protective Equipment (PPE) during fettling operations. These precautions act as a crucial preventive strategy, mitigating whole-body vibration transfer and reducing workers’ associated health risks. It is essential to acknowledge that regulations that the Health and Safety Executive sets regarding permissible vibration values may undergo updates. Employers must remain vigilant and informed about the latest regulations to ensure their workforce’s ongoing safety and well-being. Implementing measures to curtail vibration exposure enhances productivity and minimizes occupational health hazards. This dual benefit fosters a safer and healthier work environment, promoting the overall well-being of all personnel involved. Therefore, a proactive approach in adopting suitable measures aligns with regulatory requirements and the overarching goal of creating a secure and conducive workplace for everyone.

5. Conclusions

Hand-arm vibration is a serious concern in the workplace that can lead to many occupational health hazards for workers. The present study concludes with the following points:

- ▪ The study underscores the severe workplace concern of hand-arm vibration, emphasizing its potential to lead to various occupational health hazards for workers.

- ▪ The research highlights the critical importance of reducing workers’ exposure to hand-arm vibration, aligning with Health and Safety Executive guidelines.

- ▪ The study identifies a high risk associated with using swing grinders, emphasizing the urgent need for steps to mitigate the exposure of workers operating this equipment.

- ▪ Implementing anti-vibration gloves and other protective equipment is crucial in mitigating the adverse effects of hand-arm vibration on workers.

- ▪ Regular tool maintenance, incorporating short breaks during work, and prompt reporting of Hand-Arm Vibration (HAV) symptoms are highlighted as practical strategies to reduce the risk of injury significantly.

Author Contributions

All authors contributed equally in the conceptualization, methodology, data collection, and analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data are available with the corresponding author on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Heaver, C.; Goonetilleke, K.S.; Ferguson, H.; Shiralkar, S. Hand–arm vibration syndrome: A common occupational hazard in industrialized countries. J. Hand Surg. Am. 2011, 36, 354–363. [Google Scholar] [CrossRef] [PubMed]

- Mgonja, C.T. A Review on Effects of Hazards in Foundries to Workers and Environment. Int. J. Innov. Sci. Eng. Technol. 2017, 4, 326–334. [Google Scholar] [CrossRef]

- HSE. Executive, Control the Risks from Hand-Arm Vibration. 2005. Available online: https://www.hse.gov.uk/vibration/hav/advicetoemployers/controlrisks.htm (accessed on 14 January 2024).

- Gerhardsson, L.; Ahlstrand, C.; Ersson, P.; Jonsson, P.; Gustafsson, E. Vibration related symptoms and signs in quarry and foundry workers. Int. Arch. Occup. Environ. Health 2021, 94, 1041. [Google Scholar] [CrossRef] [PubMed]

- Nilsson, T.; Wahlström, J.; Burström, L. Hand-arm vibration and the risk of vascular and neurological diseases—A systematic review and meta-analysis. PLoS ONE 2017, 12, e0180795. [Google Scholar] [CrossRef] [PubMed]

- De Capua, C.; Battaglia, A.; Morello, R.; Piccolo, B. A Virtual Assistant for Safety Measurements Evaluating the Worker Hand-Arm Exposure to Percussion Machines Vibration. In Proceedings of the IEEE International Conference On Virtual Environments, Human-Computer Interfaces and Measurement Systems (VECIMS 2007), Ostuni, Italy, 25–27 June 2007. [Google Scholar]

- Mirbod, S.M.; Iwata, H. Proposal for hand-arm vibration exposure limits adopted for Japanese workers operating hand-held vibrating tools. Int. Arch. Occup. Environ. Health 1997, 69, 418–422. [Google Scholar] [CrossRef]

- Welcome, D.E.; Dong, R.G.; Xu, X.S.; Warren, C.; Thomas, W.C.T. The effects of vibration-reducing gloves on finger vibration. Int. J. Ind. Ergon. 2015, 44, 45–59. [Google Scholar] [CrossRef]

- Burström, L.; Hagberg, M.; Lundström, R.; Nilsson, T. Relationship between hand-arm vibration exposure and onset time for symptoms in a heavy engineering production workshop. Scand. J. Work Environ. Health 2006, 32, 198–203. [Google Scholar] [CrossRef][Green Version]

- Forouharmajd, F.; Yadegari, M.; Ahmadvand, M.; Pourabdian, S. Hand-arm Vibration Effects on Performance, Tactile Acuity, and Temperature of Hand. J. Med. Signals Sens. 2017, 7, 252. [Google Scholar] [CrossRef] [PubMed]

- Shen, S.C.; House, R.A. Hand-arm vibration syndrome: What family physicians should know. Can. Fam. Physician 2017, 63, 206–210. [Google Scholar] [PubMed]

- RIDDOR-Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013-HSE, (n.d.). Available online: https://www.hse.gov.uk/riddor/ (accessed on 14 January 2022).

- Dong, R.G.; Wu, J.Z.; Xu, X.S.; Welcome, D.E.; Krajnak, K. A Review of Hand–Arm Vibration Studies Conducted by US NIOSH since 2000. Vibration 2021, 4, 482–528. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, A.; Mandal, B. Risk from vibration in Indian mines. Indian J. Occup. Environ. Med. 2006, 10, 53. [Google Scholar] [CrossRef]

- Neely, G.; Burström, L. Gender differences in subjective responses to hand-arm vibration. Int. J. Ind. Ergon. 2006, 36, 135–140. [Google Scholar] [CrossRef]

- Salk, R.H.; Hyde, J.S.; Abramson, L.Y. Gender Differences in Depression in Representative National Samples: Meta-Analyses of Diagnoses and Symptoms. Psychol. Bull. 2017, 143, 783. [Google Scholar] [CrossRef]

- Oksuzyan, A.; Dańko, M.J.; Caputo, J.; Jasilionis, D.; Shkolnikov, V.M. Is the story about sensitive women and stoical men true? Gender differences in health after adjustment for reporting behavior. Soc. Sci. Med. 2019, 228, 41–50. [Google Scholar] [CrossRef]

- Barefoot, J.C.; Mortensen, E.L.; Helms, M.J.; Avlund, K.; Schroll, M. A longitudinal study of gender differences in depressive symptoms from age 50 to 80. Psychol. Aging 2001, 16, 342–345. [Google Scholar] [CrossRef] [PubMed]

- Griffin, M.J. Handbook of Human Vibration, 1st ed.; Academic Press: Cambridge, MA, USA, 1990. [Google Scholar]

- Pelmear, P.L.; Wasserman, D.E. Hand–arm vibration: A comprehensive guide for occupational health professionals; 2nd edition. Edited by P. L. Pelmear and D. E. Wasserman. OEM Press, Beverly Farm, MA, USA. ISBN 883595 22 3. Ann. Occup. Hyg. 2000, 44, 236. [Google Scholar] [CrossRef]

- Su, T.A.; Hoe, V.C.W.; Masilamani, R.; Mahmud, A.B.A. Hand-arm vibration syndrome among a group of construction workers in Malaysia. Occup. Environ. Med. 2011, 68, 58–63. [Google Scholar] [CrossRef] [PubMed]

- Burström, L.; Järvholm, B.; Nilsson, T.; Wahlström, J. White fingers, cold environment, and vibration--exposure among Swedish construction workers. Scand. J. Work Environ. Health 2010, 36, 509–513. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, T.J.; Marshall, M.M.; Martin, B.J.; Foulke, J.A.; Grieshaber, D.C.; Malone, G. Exposure to forceful exertions and vibration in a foundry. Int. J. Ind. Ergon. 2002, 30, 163–179. [Google Scholar] [CrossRef]

- Carra, S.; Monica, L.; Vignali, G. Reduction of workers’ hand-arm vibration exposure through optimal machine design: AHP methodology applied to a case study. Saf. Sci. 2019, 120, 706–727. [Google Scholar] [CrossRef]

- Vanerkar, A.P.; Kulkarni, N.P.; Zade, P.D.; Kamavisdar, A.S. Whole body vibration exposure in heavy earth moving machinery operators of metalliferrous mines. Environ. Monit. Assessment 2008, 143, 239–245. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).