The Influence of Air Pressure on Surface Roughness Values in the Sandblasting Process of ST-37 Steel Plates †

Abstract

1. Introduction

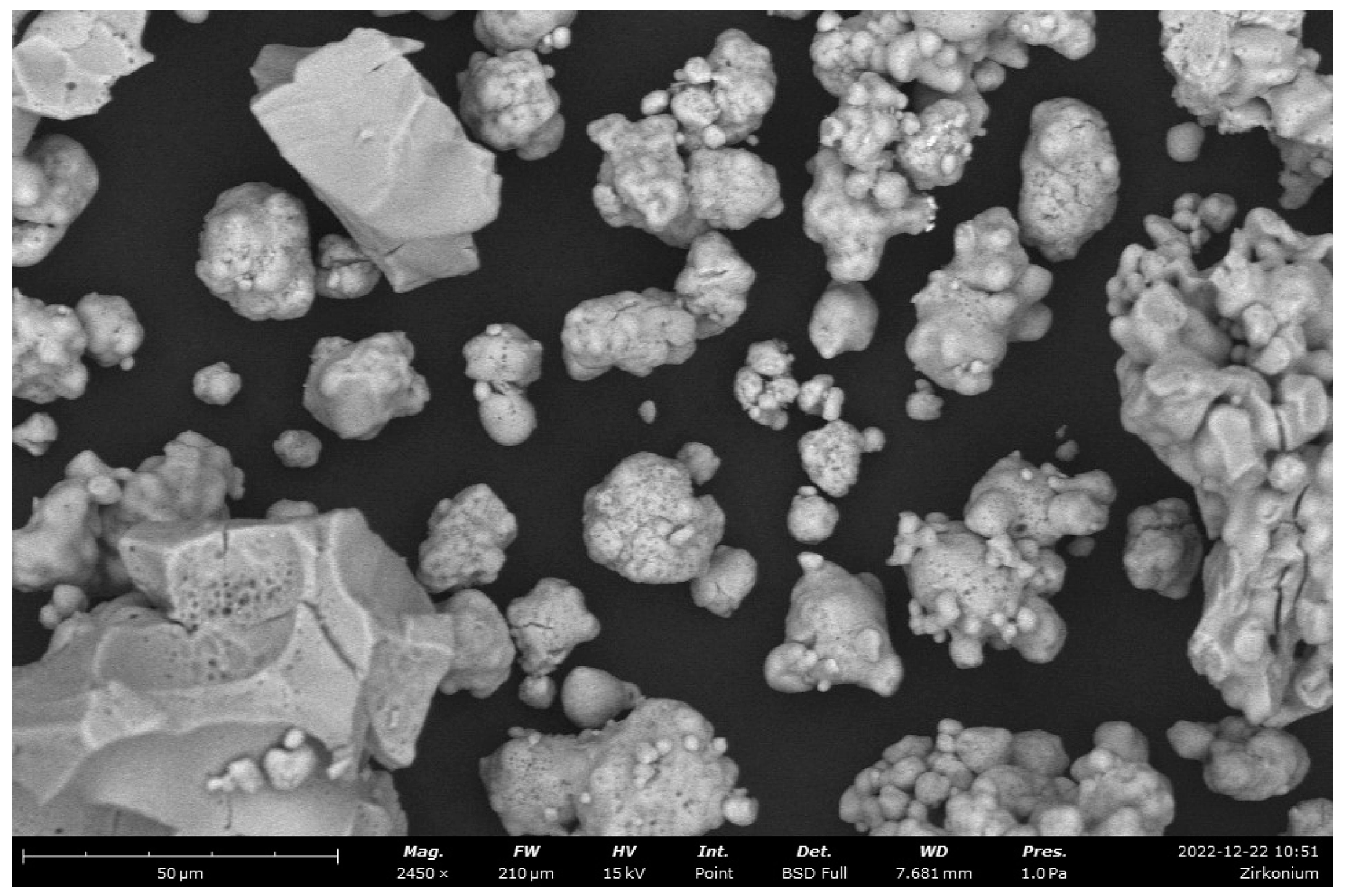

2. Materials and Methods

2.1. Materials and Samples

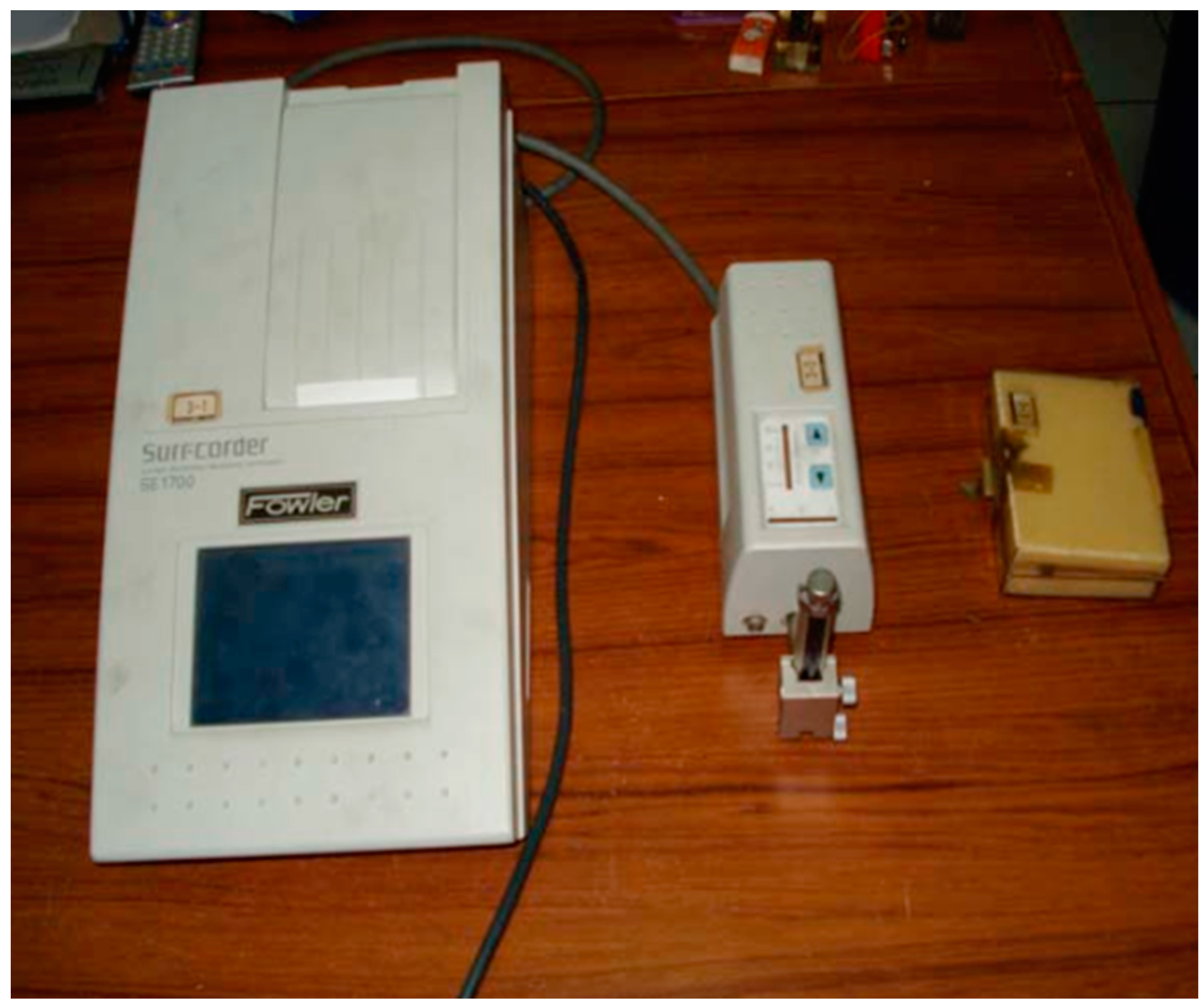

2.2. Methods

- Iron sand is introduced into the upper storage compartment using a screw conveyor operated by an operator. In this upper storage compartment, there are two valves serving as bypass for the filter and grit level to prevent spillage. The bypass directs the grit to the storage tank.

- From the upper storage, it is transferred to the grit mixing tank or lower container through two sets of valves. The first valve is operated manually, directly by the operator. In this case, the operator must be able to determine when the mixing tank is full so that the valve can be promptly closed. The second valve operates automatically, functioning with a switch-level system for grit height located in the mixing tank. If the mixing tank is full, it presses the switch level, which sends a signal to close the valve.

- From the mixing tank, it flows towards the grit addition and reduction valves. These valves operate automatically and are controlled using a cylindrical-shaped air tube. The air tube regulates the grit output from the mixing location by balancing air with grit. If the air mixture is more abundant than the grit, the valve will add grit, and vice versa.

- An additional component in the pipeline is the blow valve, which functions if the pressure inside the pipe is too high. Next, it reaches the pipe where an electrical current is applied to separate water from air using the evaporation method. The vapor is then filtered with a multi-level filter on the outlet pipe. There is a total pressure measuring device filtered as a final step before the air is directed to the next level.

3. Results and Discussion

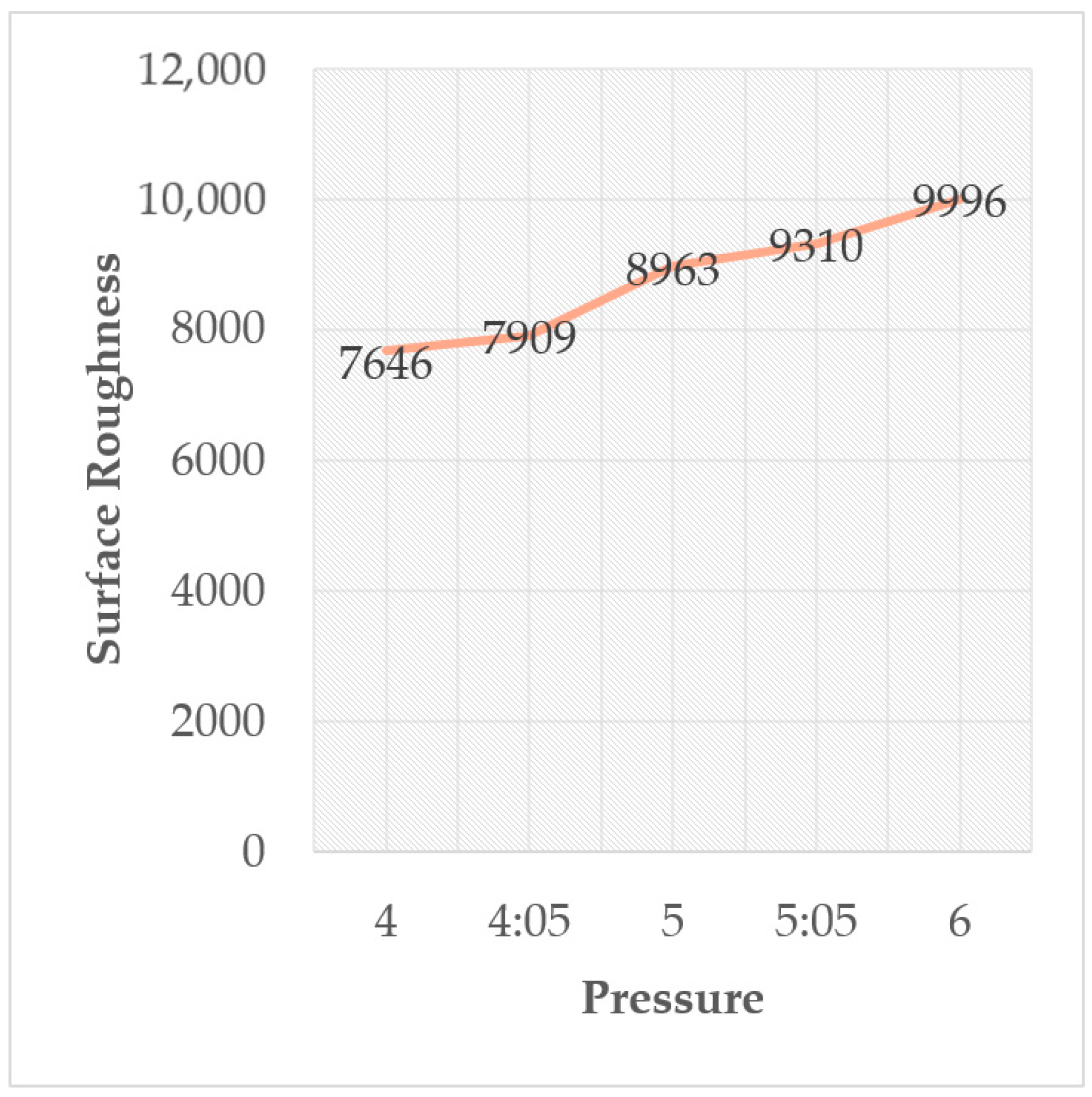

3.1. Data Analysis of the Effect of Air Pressure on Surface Roughness

3.2. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Perkasa, R.E.; Gunawan, L.; Santosa, S.P.; Afdhal, A. Mechanical Anisotropy of Cold-Rolled St-37 Steel Plate Under High Strain Rates Loadings. Int. J. Mech. Eng. Technol. Appl. 2023, 4, 198–211. [Google Scholar] [CrossRef]

- ASTM International. Handbook of Comparative World Steel Standards, 5th ed.; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar] [CrossRef]

- Anggono, A.D.; Kholis, N.; Ngafwan, N. Structure and Mechanical Properties of Double Side Friction Stir Welded Aluminium AA6061 with the Addition of Cu Powder. Mater. Sci. Forum 2022, 1051, 111–118. [Google Scholar] [CrossRef]

- Darmawan, A.S.; Anggono, A.D.; Yulianto, A.; Febriantoko, B.W.; Masyrukan. The Microstructure Evolution and Hardness Improvement of Gray Cast Iron by Addition of FeSiMg Followed by Flame Hardening Process. Acta Metall. Slovaca 2023, 29, 130–137. [Google Scholar] [CrossRef]

- Śmielak, B.; Klimek, L. Effect of air abrasion on the number of particles embedded in zironia. Materials 2018, 11, 259. [Google Scholar] [CrossRef] [PubMed]

- Anaç, N.; Doğan, Z. Effect of Organic Powders on Surface Quality in Abrasive Blasting Process. Processes 2023, 11, 1925. [Google Scholar] [CrossRef]

- Śmielak, B.; Klimek, L.; Krześniak, K. Effect of Sandblasting Parameters and the Type and Hardness of the Material on the Number of Embedded Al2O3 Grains. Materials 2023, 16, 4783. [Google Scholar] [CrossRef] [PubMed]

- Kwon, D.K.; Lee, J.H. Performance Improvement of Micro-Abrasive Jet Blasting Process for Al 6061. Processes 2022, 10, 2247. [Google Scholar] [CrossRef]

- Riyadi, T.W.B.; Setiadhi, D.; Anggono, A.D.; Siswanto, W.A.; Al-Kayiem, H.H. Analysis of mechanical and thermal stresses due to TiN coating of Fe substrate by physical vapor deposition. Forces Mech. 2021, 4, 100042. [Google Scholar] [CrossRef]

- Hariningsih, H.; Sumpena, S.; Sukarjo, H. The effectivity of used-oil as quenching medium of 42-CrMo4 steel for automotive materials. Appl. Res. Smart Technol. (ARSTech) 2020, 1, 28–34. [Google Scholar] [CrossRef]

- Kholis, N.; Nuryanto, N.; Mustofa, A. Characteristics of hardness and microstructure of extraction forceps for dental and oral care made of stainless-steel. Appl. Res. Smart Technol. (ARSTech) 2020, 1, 56–63. [Google Scholar] [CrossRef]

- ISO 9001; Quality management systems. ISO: Geneva, Switzerland, 2015.

- SNI 13-6717-2002; Procedures for Preparing Test Specimens from Aggregate Samples. SNI: Jakarta, Indonesia, 2002.

| Type | Information | Source |

|---|---|---|

| Specimen | ST-37 steel plate | PT INKA |

| Particles | Grit sand very fine 80 mesh | ISO 9001 Standard [12] |

| Air pressure | 4 kg/cm2; 4.5 kg/cm2; 5 kg/cm2; 5.5 kg/cm2; 6 kg/cm2 | |

| Blasting distance | 10 cm | |

| Blasting time | 20 min | |

| Contact angle | 7° | PT INKA Standard National Indonesia [13] |

| Pressure (P) kg/cm2 | Roughness Average () μm |

|---|---|

| 4 | 7.674 |

| 4.5 | 7.909 |

| 5 | 8.963 |

| 5.5 | 9.310 |

| 6 | 9.996 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

As’ad, M.; Febriantoko, B.W.; Riyadi, T.W.B.; Pahlevi, R.F. The Influence of Air Pressure on Surface Roughness Values in the Sandblasting Process of ST-37 Steel Plates. Eng. Proc. 2024, 63, 28. https://doi.org/10.3390/engproc2024063028

As’ad M, Febriantoko BW, Riyadi TWB, Pahlevi RF. The Influence of Air Pressure on Surface Roughness Values in the Sandblasting Process of ST-37 Steel Plates. Engineering Proceedings. 2024; 63(1):28. https://doi.org/10.3390/engproc2024063028

Chicago/Turabian StyleAs’ad, Muhammad, Bambang Waluyo Febriantoko, Tri Widodo Besar Riyadi, and Ryan Fitrian Pahlevi. 2024. "The Influence of Air Pressure on Surface Roughness Values in the Sandblasting Process of ST-37 Steel Plates" Engineering Proceedings 63, no. 1: 28. https://doi.org/10.3390/engproc2024063028

APA StyleAs’ad, M., Febriantoko, B. W., Riyadi, T. W. B., & Pahlevi, R. F. (2024). The Influence of Air Pressure on Surface Roughness Values in the Sandblasting Process of ST-37 Steel Plates. Engineering Proceedings, 63(1), 28. https://doi.org/10.3390/engproc2024063028