The Valorization of a Crude Refinery’s By-Product: A Case Study on the Heavy Residue Gasifier †

Abstract

:1. Introduction

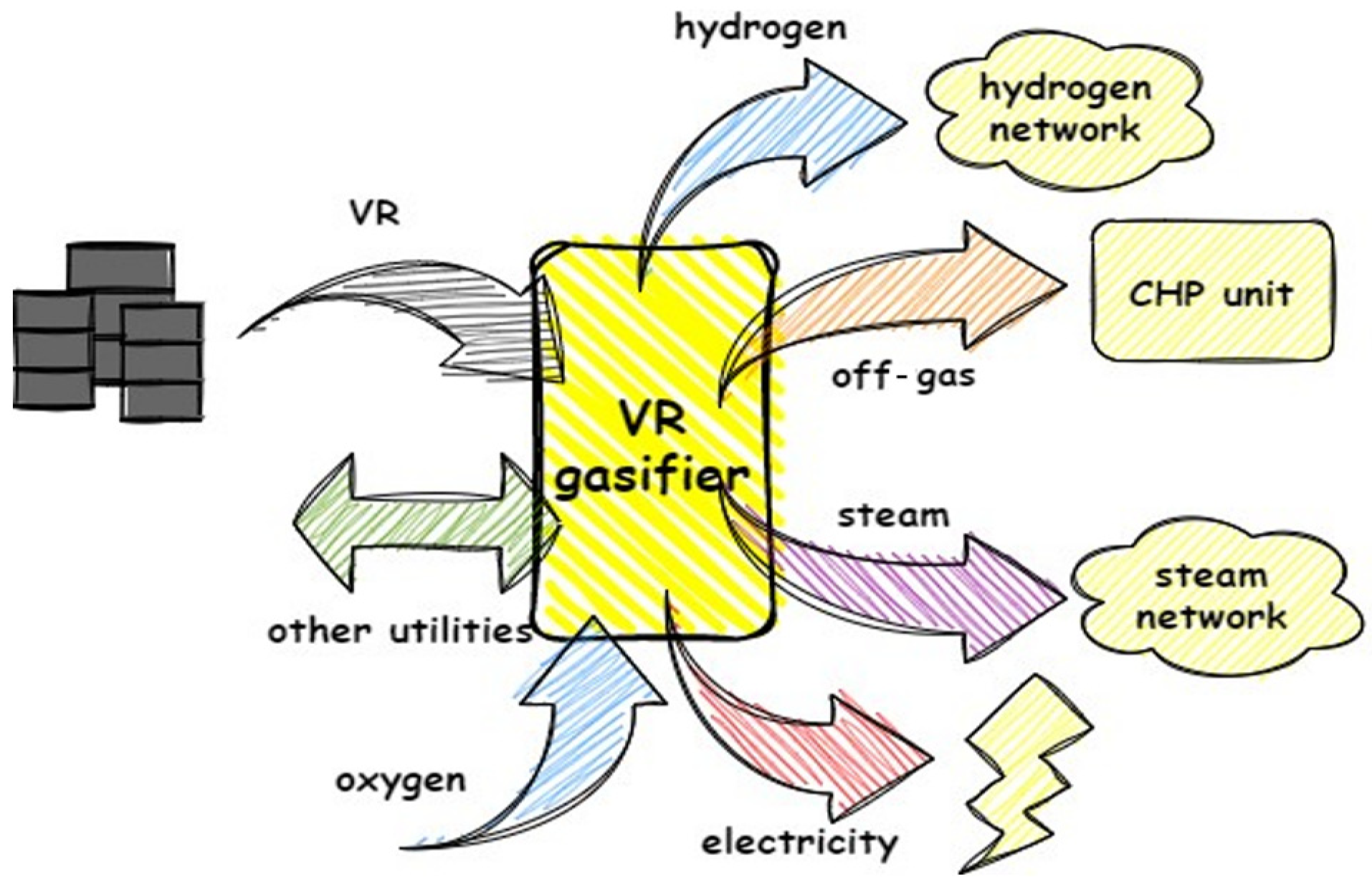

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Murugan, S.; Horák, B. Tri and polygeneration systems—A review. Renew. Sustain. Energy Rev. 2016, 60, 1032–1051. [Google Scholar] [CrossRef]

- Neves, A.; Godina, R.; Azevedo, S.G.; Matias, J.C.O. A Comprehensive Review of Industrial Symbiosis. J. Clean. Prod. 2020, 247, 119113. [Google Scholar] [CrossRef]

- Stöcker, M. Biofuels and biomass-to-liquid fuels in the biorefinery: Catalytic conversion of lignocellulosic biomass using porous materials. Angew. Chem. Int. Ed. Engl. 2008, 47, 9200–9211. [Google Scholar] [CrossRef] [PubMed]

- Rajabloo, T.; De Ceuninck, W.; Van Wortswinkel, L.; Rezakazemi, M.; Aminabhavi, T. Environmental management of industrial decarbonization with focus on chemical sectors: A review. J. Environ. Manag. 2022, 302, 114055. [Google Scholar] [CrossRef] [PubMed]

- Abdin, Z.; Zafaranloo, A.; Rafiee, A.; Mérida, W.; Lipiński, W.; Khalilpour, K.R. Hydrogen as an energy vector. Renew. Sustain. Energy Rev. 2020, 120, 109620. [Google Scholar] [CrossRef]

- Wu, W.; Kuo, P.-C. Conceptual designs of hydrogen production, purification, compression and carbon dioxide capture. Energy Convers. Manag. 2015, 103, 73–81. [Google Scholar] [CrossRef]

- Navarro, R.M.; Peña, M.A.; Fierro, J.G.L. Hydrogen Production Reactions from Carbon Feedstocks: Fossil Fuels and Biomass. Chem. Rev. 2007, 107, 3952–3991. [Google Scholar] [CrossRef]

- Sarabia, D.; de Prada, C.; Gómez, E.; Gutierrez, G.; Cristea, S.; Sola, J.M.; Gonzalez, R. Data reconciliation and optimal management of hydrogen networks in a petrol refinery. Control Eng. Pract. 2012, 20, 343–354. [Google Scholar] [CrossRef]

- Choi, Y.C.; Lee, J.G.; Yoon, S.J.; Park, M.H. Experimental and Theoretical Study on the Characteristics of Vacuum Residue Gasification in an Entrained-flow Gasifier. Korean J. Chem. Eng. 2007, 24, 60–66. [Google Scholar] [CrossRef]

- Szwaja, S.; Poskart, A.; Zajemska, M.; Szwaja, M. Theoretical and Experimental Analysis on Co-Gasification of Sewage Sludge with Energetic Crops. Energies 2019, 12, 1750. [Google Scholar] [CrossRef]

- Reyhani, H.A.; Meratizaman, M.; Ebrahimi, A.; Pourali, O.; Amidpour, M. Thermodynamic and economic optimization of SOFC-GT and its cogeneration opportunities using generated syngas from heavy fuel oil gasification. Energy 2016, 107, 141–164. [Google Scholar] [CrossRef]

- Al-Rowaili, F.N.; Khalafalla, S.S.; Al-Yami, D.S.; Jamal, A.; Ahmed, U.; Zahid, U.; Al-Mutairi, E.M. Techno-economic Evaluation of Methanol Production via Gasification of Vacuum Residue and Conventional Reforming Routes. Chem. Eng. Res. Des. 2022, 177, 365–375. [Google Scholar] [CrossRef]

- Podolský, S.; Variny, M.; Kurák, T. Carbon-Energy Impact Analysis of Heavy Residues Gasification Plant Integration into Oil Refinery. Resources 2023, 12, 66. [Google Scholar] [CrossRef]

- Cheli, L.; Guzzo, G.; Adolfo, D.; Carcasci, C. Steady-state analysis of a natural gas distribution network with hydrogen injection to absorb excess renewable electricity. Int. J. Hydrogen Energy 2021, 46, 25562–25577. [Google Scholar] [CrossRef]

- Dehdari, L.; Burgers, I.; Xiao, P.; Li, K.G.; Singh, R.; Webley, P.A. Purification of hydrogen from natural gas/hydrogen pipeline mixtures. Sep. Purif. Technol. 2022, 282, 120094. [Google Scholar] [CrossRef]

- Nordio, M.; Wassie, S.A.; Van Sint Annaland, M.; Tanaka, D.A.P.; Sole, J.L.V.; Gallucci, F. Techno-economic evaluation on a hybrid technology for low hydrogen concentration separation and purification from natural gas grid. Int. J. Hydrogen Energy 2021, 46, 23417–23435. [Google Scholar] [CrossRef]

- Hoppej, D. Lowering Carbon Footprint of Hydrogen Production. Diploma Thesis, Slovak University of Technology in Bratislava, Bratislava, Slovakia, 2022. Available online: https://opac.crzp.sk/?fn=detailBiblioFormChildG9THL&sid=4F55101800366CEF5CF4C0DB109A&seo=CRZP-detail-kniha (accessed on 2 August 2023). (In Slovak).

- Hoppej, D.; Variny, M. Industrial-Scale Hydrogen Production Plant Modelling. Adv. Therm. Process. Energy Transform. 2021, 4, 9–15. [Google Scholar] [CrossRef]

- Podolský, S. Conceptual Design of Heavy Oil Residues Gasifier. Bachelor Thesis, Slovak University of Technology in Bratislava, Bratislava, Slovakia, 2022. Available online: https://opac.crzp.sk/?fn=detailBiblioFormChildE9UEM&sid=A8C5898CD77493B3E1FB3F491516&seo=CRZP-detail-kniha (accessed on 2 August 2023). (In Slovak).

| Hydrogen Content in NG, % vol. | NG Consumption in SMR, kWh (HHV)/kg H2 | Steam Export from SMR, kg/kg H2 |

|---|---|---|

| 0 | 62.3 | 18.0 |

| 10 | 61.5 | 17.2 |

| 20 | 60.3 | 16.0 |

| Operational State | Utility/Medium | A0 1 | B0 1 | C0 1 | A10 | B10 | C10 | A20 | B20 | C20 |

|---|---|---|---|---|---|---|---|---|---|---|

| Consumption (GWh/year) | NG | 3043 | 1277 | 757 | 2998 | 1276 | 793 | 2933 | 1230 | 786 |

| VR | 3402 | 5149 | 6259 | 3449 | 5153 | 6248 | 3476 | 5166 | 6206 | |

| Production (GWh/year) | Steam export total | 1682 | ||||||||

| H2 total | 56 | |||||||||

| VR gasifier off-gas | 0 | 2228 | 2820 | 0 | 2208 | 2799 | 0 | 2228 | 2820 | |

| Electricity | 363 | 277 | 335 | 365 | 279 | 337 | 369 | 272 | 321 | |

| Sale | VR (GWh/year) | 2898 | 1151 | 41 | 2851 | 1147 | 52 | 2824 | 1134 | 94 |

| Refinery’s CO2 2 | 1633 | 1774 | 1975 | 1629 | 1772 | 1977 | 1613 | 1763 | 1963 | |

| Overall CO2 balance 2 | 2447 | 2098 | 1987 | 2429 | 2094 | 1992 | 2407 | 2082 | 1989 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Variny, M.; Podolský, S.; Kurák, T. The Valorization of a Crude Refinery’s By-Product: A Case Study on the Heavy Residue Gasifier. Eng. Proc. 2024, 64, 10. https://doi.org/10.3390/engproc2024064010

Variny M, Podolský S, Kurák T. The Valorization of a Crude Refinery’s By-Product: A Case Study on the Heavy Residue Gasifier. Engineering Proceedings. 2024; 64(1):10. https://doi.org/10.3390/engproc2024064010

Chicago/Turabian StyleVariny, Miroslav, Slavomír Podolský, and Tomáš Kurák. 2024. "The Valorization of a Crude Refinery’s By-Product: A Case Study on the Heavy Residue Gasifier" Engineering Proceedings 64, no. 1: 10. https://doi.org/10.3390/engproc2024064010

APA StyleVariny, M., Podolský, S., & Kurák, T. (2024). The Valorization of a Crude Refinery’s By-Product: A Case Study on the Heavy Residue Gasifier. Engineering Proceedings, 64(1), 10. https://doi.org/10.3390/engproc2024064010