Abstract

In the current scenario, renewable energy resources play a vital role in developing countries. Photovoltaic panel-based power plants have great significance for the production of electrical energy, due to automated transitions, easy interaction, and low maintenance costs. The energy-production efficiency depends on various factors and environmental effects. The formulation of a thin layer of dust particles on solar panels diminishes their energy-production capacity due to the limiting of heat transfer to the semiconducting materials. The current paper deals with the design and fabrication of an automated water-jet-assisted robot used to clean the dust particle layer and bird droppings on PV panels. In the water-jet-assisted cleaning robot, there is a two-brush mechanism that works in concert with the rover’s movement. A Bluetooth communication system plays a vital role by controlling the rover; this approach offers a perspective on a rover constructed with an Arduino-UNO micro-controller, along with an HC-05 Bluetooth sensor.

1. Introduction

In recent times robots have played a major role in meeting global demands by manifesting in new sizes and shapes, depending on their tasks. They are utilized in industrial plants, space exploration, food production, military operations, sports, and cleaning. Robots also assist disabled individuals with mobility, provide rehabilitation services, and are deployed in warfare. The tasks robots perform vary based on the application [1]. Robots can be as little as a coin or as extensive as a machine, which convolutes configuration design, yet increments capacities. Robots can improve safety, productivity, efficiency, and product quality, and perform hazardous tasks like nuclear plant operations, potentially saving thousands of lives [2]. They are unaffected by harsh conditions, tireless, and more precise than humans. Robots can multitask and reduce production costs, allowing humans to focus on mental rather than physical labor. Increased global energy demand is a major challenge facing the world.

The solution to this challenge will be accomplished with fossil fuels and renewable energy sources [3,4,5,6,7,8,9,10]. Focusing on fossil fuels results in more energy production, along with increased pollution-causing emissions. To shift the source of energy production from fossil fuels, the world is focusing on renewable energy sources, and, prominently, on solar energy. It is the most abundant energy resource available, although the earth is far away from the sun. In the following, Section 2 will explain the design, control, and operation of the proposed WAC, along with other related robots. Section 3 will discuss the outcomes and performance, and Section 4 will present the conclusion of this paper.

This design and fabrication of a novel automated water-jet robot for PV panel cleaning uses Arduino assisted by a Bluetooth module, which allows the solar panel cleaner to use Internet of Things (IoT) technologies. This project turns a basic solar panel cleaner into a smart solar panel cleaner by integrating a Bluetooth module (HC-O5). Furthermore, the use of IoT technology facilitates the possibility of fresh prospects for additional improvements like self-healing and intuitive operation. All things considered, this concept is a creative way to use IoT technology to update conventional solar panel cleaning.

2. Design of WAC

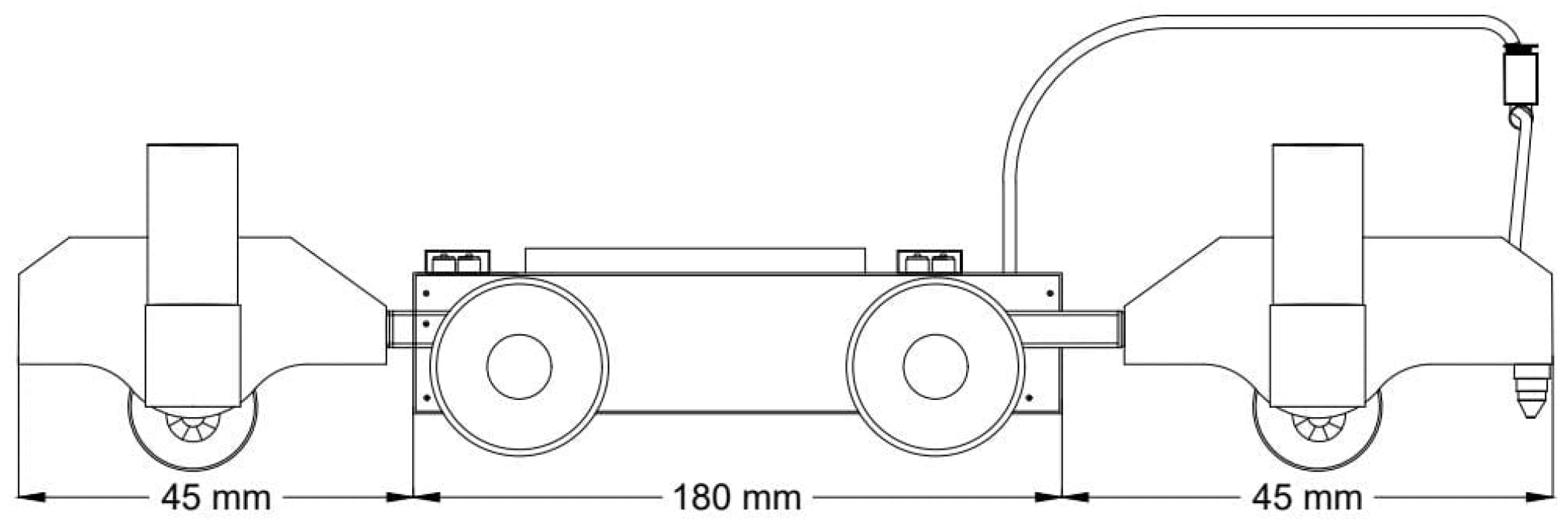

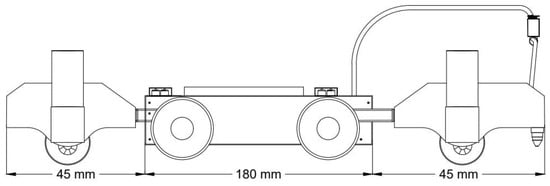

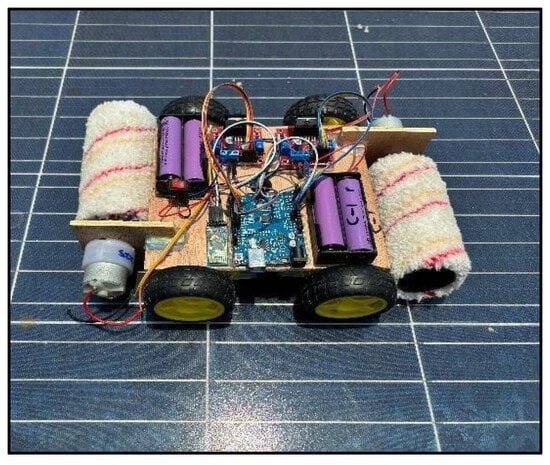

The WAC system is specifically designed to overcome the challenges involved in attempting to clean large and heavy objects more efficiently. This is achieved through the use of lightweight materials in the chassis design, along with the design of a structure that can accommodate all of the controlling components, including the power supply systems. Furthermore, a highly effective cleaning system has been designed for the WAC. The fundamental structure of the WAC is depicted in Figure 1, which provides a visual representation of the system.

Figure 1.

Side view of the structural design of the WAC.

3. Results and Discussion

The evaluation of the performance of the WAC is described in in Table 1, in which it is compared with existing robots in the photovoltaic cleaning market segment. The robots compared are the Ecoppia T4, Antonelli, and MFv01.

Table 1.

Pros and cons of the Ecoppia T4, Antonelli, MFv01, and WAC robots.

Output of the WAC

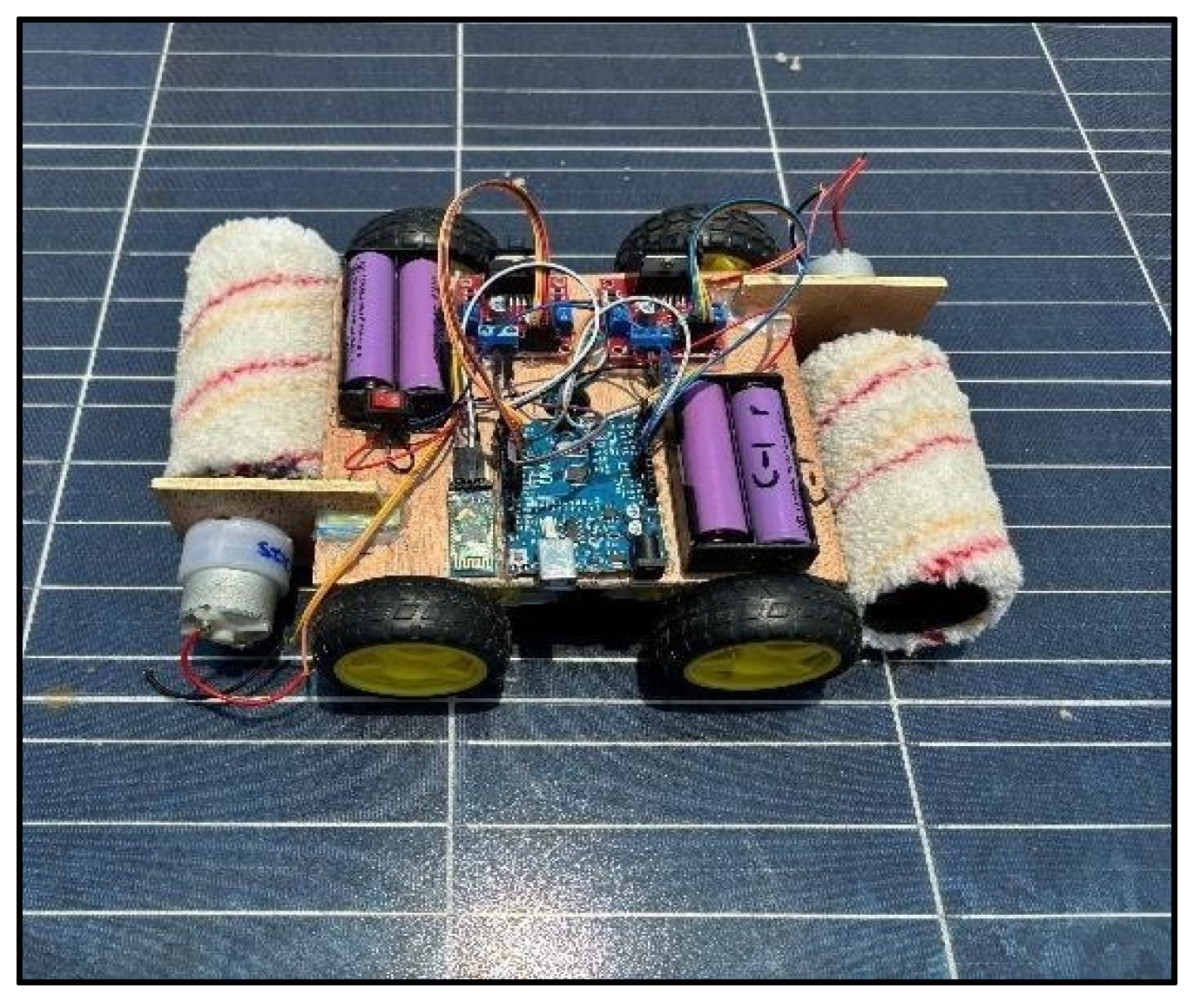

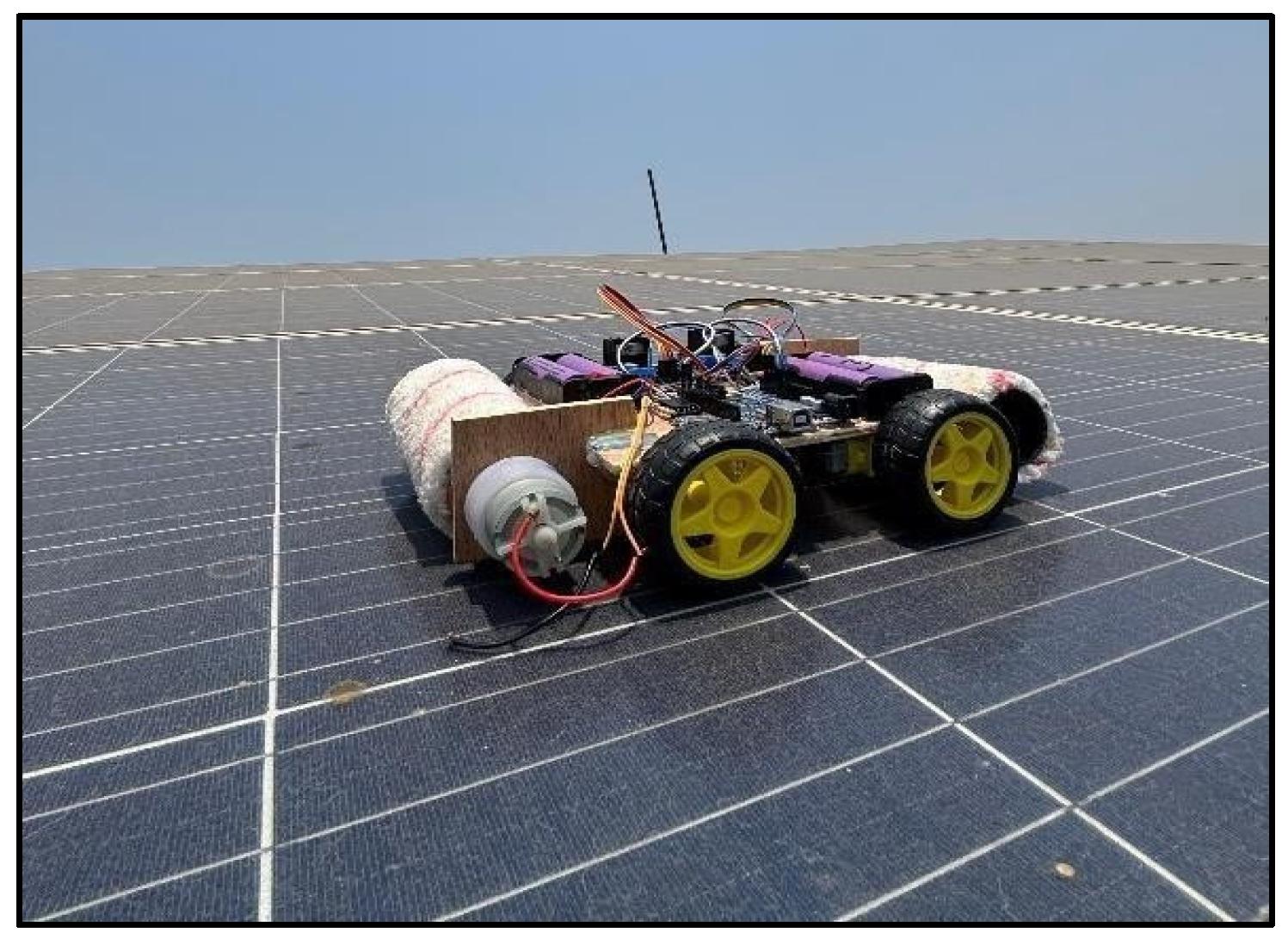

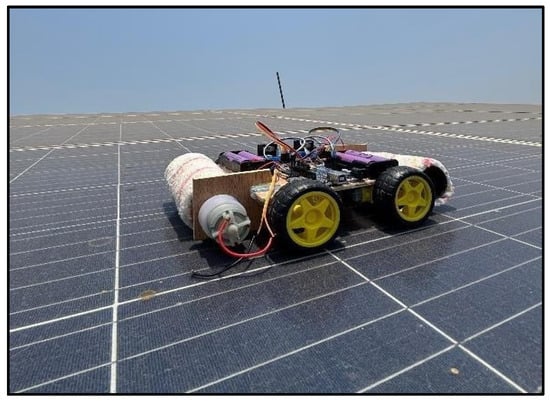

This WAC for photovoltaic cleaning represents a significant improvement in the maintenance of photovoltaic panels, as it addresses the challenges of keeping them clean and efficient. In this paper Figure 2 and Figure 3 shows that there are two cleaning brushes attached to both the front and back sides of the WAC. They have smooth rollers that make it easy to clean dirt from the surface of a photovoltaic panel. Both brushes are powered by two-gear motors and are operated through a controller. This work has developed a sophisticated solution that uses advanced technologies such as Arduino-assisted control and the HC-05 Bluetooth module.

Figure 2.

WAC cleaning the photovoltaic panel (Top View).

Figure 3.

WAC cleaning the photovoltaic panel (Side View).

4. Conclusions

This study provides an in-depth investigation of an example of the technological progress made in solar panel cleaning systems. The study explores a number of aspects of this novel strategy, one which aims to improve photovoltaic panel efficiency by creating an efficient cleaning process. This project has created a complex solution by integrating cutting-edge technology like the HC-05 Bluetooth module and Arduino-assisted control. The Arduino UNO microprocessor drives its high-pressure water jets, which efficiently clear dust and debris from photovoltaic panels. This maximizes the energy-production potential by guaranteeing that sunlight is absorbed without obstruction. With the HC-05 Bluetooth module installed, operators can effortlessly monitor and manage the system remotely. They can wirelessly change parameters and obtain a real-time response. The robot’s energy efficiency is also noteworthy; it uses a rechargeable Li-ion battery to reduce its negative environmental effects while continuing to operate at peak efficiency. The landscape of solar energy maintenance could be changed, allowing a more sustainable future, with even greater benefits potentially being unlocked by further optimization and refinement of the robot’s design. All things considered, this initiative shows how innovation may spur beneficial change in the renewable energy sector.

Author Contributions

Writing—Conceptualization, Y.S.S. and G.R.K.; methodology, A.S.S.; software, R.D.N.; validation, R.D.N. and A.S.S.; formal analysis, Y.S.S.; investigation, E.V.S.S.; resources, G.R.K.; data curation, A.S.S.; writing—original draft preparation, A.S.S.; writing—review and editing, E.V.S.S.; supervision, R.U.; project administration, N.P.M.S.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing is not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mousavi, S.; Farahani, G. Introducing a new method of automatic cleaning of the PV array surface using a suction robot. Mechatronics 2022, 85, 102845. [Google Scholar] [CrossRef]

- Zeng, D.; Liu, Y.; Qu, C.; Cong, J.; Hou, Y.; Lu, W. Design and Human-Robot Coupling Performance Analysis of Flexible Ankle Rehabilitation Robot. IEEE Robot. Autom. Lett. 2023, 9, 579–586. [Google Scholar] [CrossRef]

- Kanazawa, A.; Kinugawa, J.; Kosuge, K. Adaptive Motion Planning for a Collaborative Robot Based on Prediction Uncertainty to Enhance Human Safety and Work Efficiency. IEEE Trans. Robot. 2019, 35, 817–832. [Google Scholar] [CrossRef]

- Hailu, G.; Fung, A.S. Optimum tilt angle and orientation of photovoltaic thermal system for application in greater Toronto area, Canada. Sustainability 2019, 11, 6443. [Google Scholar] [CrossRef]

- Shenouda, R.; Abd-Elhady, M.S.; Kandil, H.A. A review of dust accumulation on PV panels in the MENA and the FAR East regions. J. Eng. Appl. Sci. 2022, 2022, 69. [Google Scholar] [CrossRef]

- Owusu-Brown, B. The Effect of Settling Harmattan Dust on Photovoltaic Modules in Walewale, Northern Ghana. Master’s Thesis, School of Mechanical Engineering, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana, 2016. [Google Scholar]

- Midtdal, K.; Jelle, B.P. Self-cleaning glazing products: A state-of-the-art review and future research pathways. Sol. Energy Mater. Sol. Cells 2013, 109, 126–141. [Google Scholar] [CrossRef]

- Drelich, J.; Chibowski, E.; Meng, D.D.; Terpilowski, K. Hydrophilic and superhydrophilic surfaces and materials. Soft Matter 2011, 7, 9804–9828. [Google Scholar] [CrossRef]

- Nishimoto, S.; Bhushan, B. Bioinspired self-cleaning surfaces with superhydrophobicity, superoleophobicity, and super hydrophilicity. RSC Adv. 2013, 3, 671–690. [Google Scholar] [CrossRef]

- Takekuma, S.; Azuma, S.I.; Ariizumi, R.; Asai, T. Consensus Control of Multi-Hopping-Rover Systems: Convergence Analysis. IEEE Access 2023, 11, 36176–36183. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).