Optimized Design of Dead-End Spoiler Using PIV †

Abstract

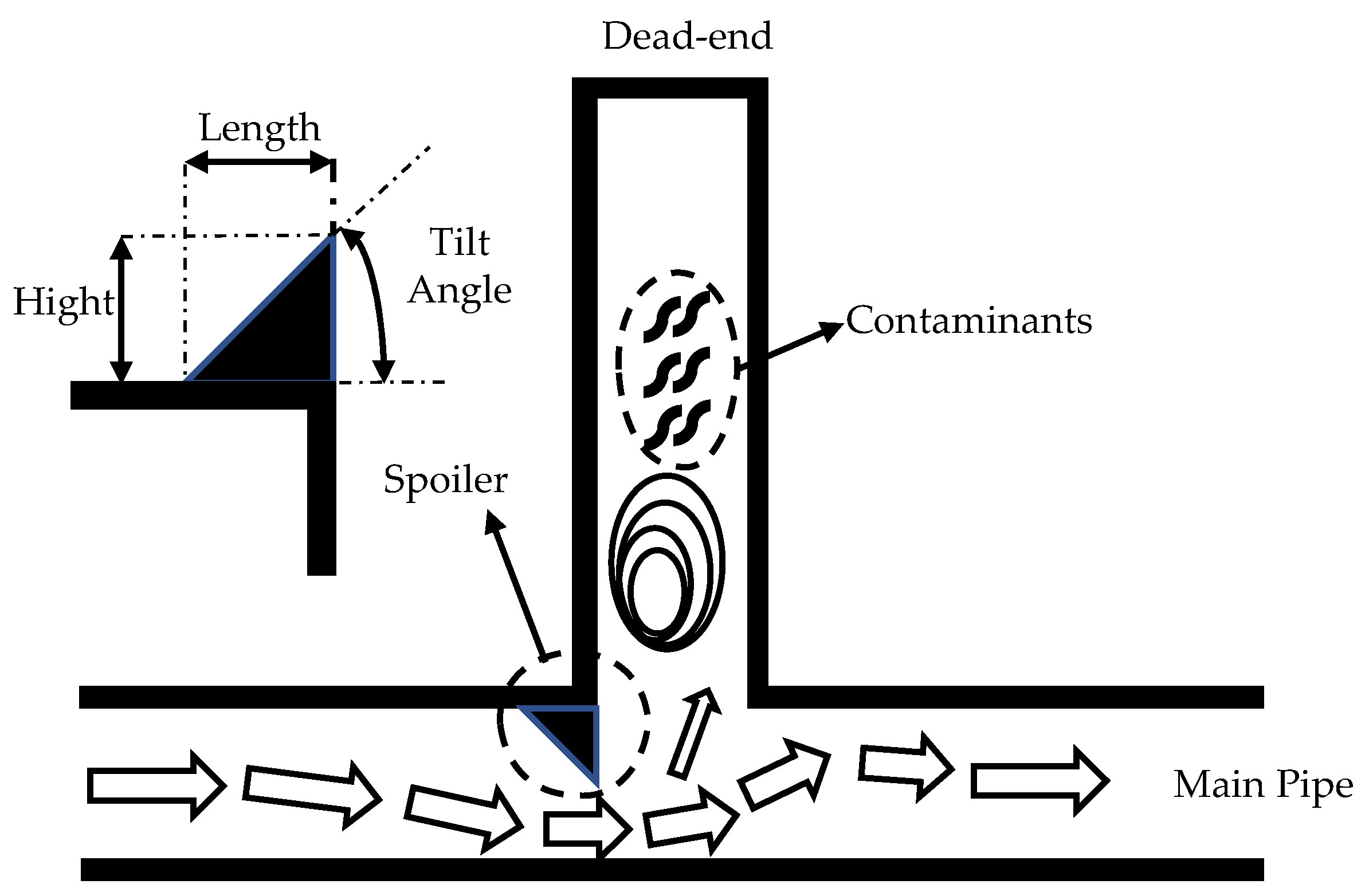

:1. Introduction

2. Methods

2.1. PIV Setup

2.2. Experimental Platform

2.3. Experimental Conditions

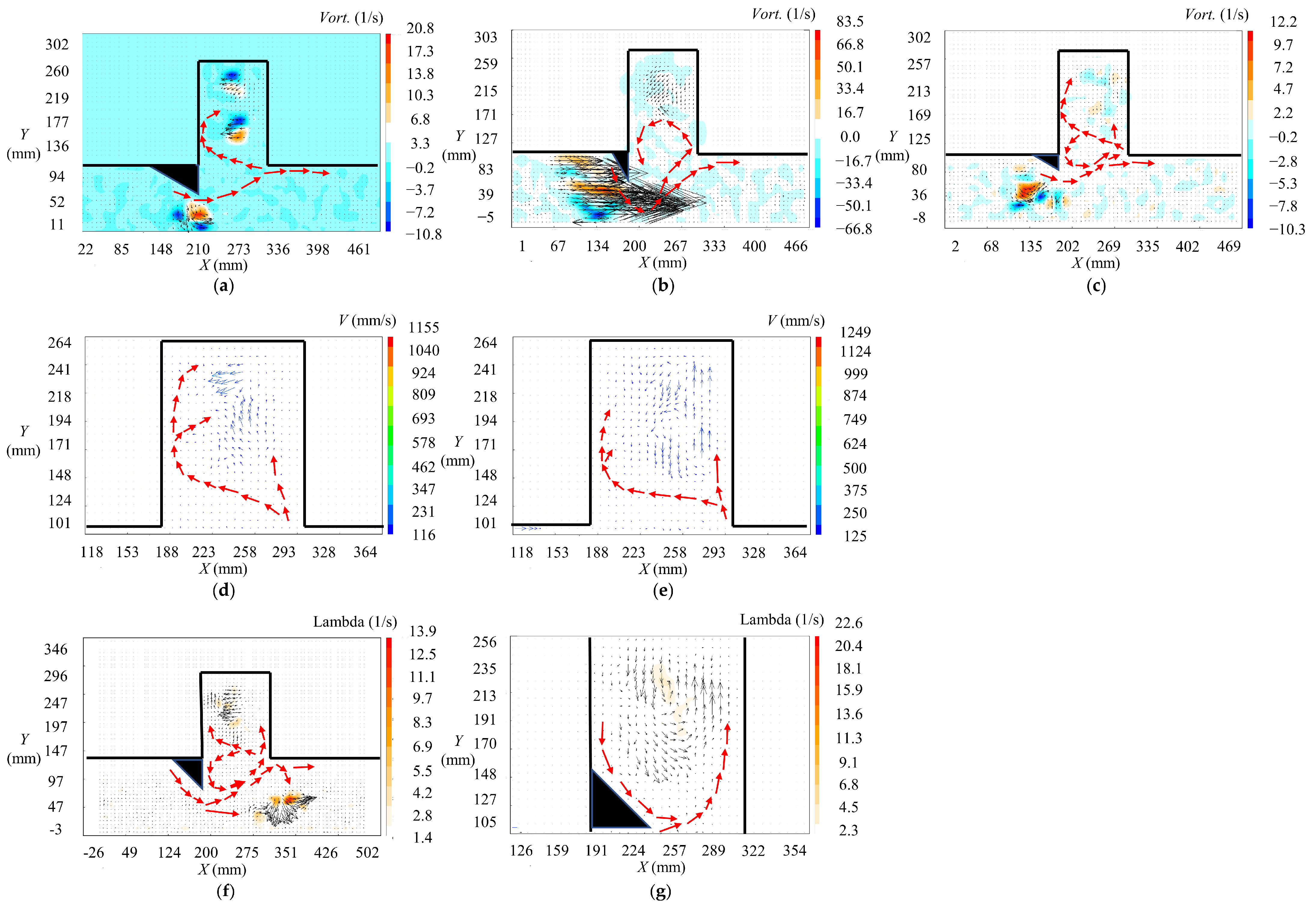

3. Results and Discussion

3.1. Tilt Angle

3.2. Height

3.3. Width

3.4. Installation Position

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ellison, D. Investigation of Pipe Cleaning Methods, 1st ed.; AWWA Research Foundation and American Water Works Association: Denver, CO, USA, 2003; pp. 35–36. [Google Scholar]

- Vitanage, D.; Pamminger, F.; Vourtsanis, T. Safe Piped Water: Managing Microbial Water Quality in Piped Distribution Systems, 1st ed.; World Health Organization and IWA Publishing: London, UK, 2004; pp. 91–94. [Google Scholar]

| No. | Applicable Pipe Diameter | Tilt Angle | Height (cm) | Width (cm) |

|---|---|---|---|---|

| 1 | DN100 | 45° | 2.00 | 8.00 |

| 2 | DN100 | 30° | 2.00 | 8.00 |

| 3 | DN100 | 60° | 2.00 | 8.00 |

| 4 | DN100 | 30° | 1.15 | 8.00 |

| 5 | DN100 | 45° | 2.00 | 4.00 |

| 6 | DN100 | 45° | 2.00 | 2.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, J.; Li, K.; Wu, W.; Qi, S.; Cao, H.; Qiu, W.; He, J.; Zhang, J.; Ding, Y. Optimized Design of Dead-End Spoiler Using PIV. Eng. Proc. 2024, 69, 183. https://doi.org/10.3390/engproc2024069183

Gao J, Li K, Wu W, Qi S, Cao H, Qiu W, He J, Zhang J, Ding Y. Optimized Design of Dead-End Spoiler Using PIV. Engineering Proceedings. 2024; 69(1):183. https://doi.org/10.3390/engproc2024069183

Chicago/Turabian StyleGao, Jinliang, Kunyi Li, Wenyan Wu, Shihua Qi, Huizhe Cao, Wei Qiu, Junjun He, Jiawen Zhang, and Yanchen Ding. 2024. "Optimized Design of Dead-End Spoiler Using PIV" Engineering Proceedings 69, no. 1: 183. https://doi.org/10.3390/engproc2024069183