Abstract

Purpose—This study examines the relationships among factors that can potentially influence the effectiveness of operations management in real-time productivity accounting data that can measure the real-time performance of any business operations. The focus is to develop and research this area of productivity management to advance its implementation and adoption in improving business operations. The study objective is to review productivity management-related fields to reveal the location of attention of previous studies. A bibliometric analysis was adopted for this investigation, and data were gathered from the Web of Science (ISI). Keywords such as “Productivity management”, “Productivity measurement”, and “Productivity Improvement” were selected to source documentation from the database. VOSviewer was chosen as the most advanced system that can be used to formulate a co-authorship and co-occurrence map based on the bibliographic data gathered. The study findings discovered that the emphasis is placed on time, systems, impact, work, cost, and labour productivity. The research findings exposed a knowledge gap in the literature that can be explored in emerging countries, predominantly, in Africa, to improve operations management by improving productivity measurements within the continent.

1. Introduction

Today, productivity has become a vital issue with planners, policymakers, and other professionals. Economic production growth has become strongly linked with gains in productivity, which highlights that achieving high productivity implies obtaining as much output as possible from a given number of units of production factors. The main factors influencing productivity are capital resources, technology, and people [1,2]. Productivity management has mainly been practiced informally. There has been a need for it to be formalised. Productivity management has four factors as a base for the application of continuous improvement: (i) productivity measurement, (ii) productivity evaluation, (iii) productivity planning, and (iv) productivity improvement [2,3]. Moreover, Ref. [4] describes productivity as “the ratio of what is produced to what is required to produce it”. This definition suggests that productivity is based on the affiliation between inputs comprising factors of production, such as labour resources, capital, material, equipment, and building; and outputs, such as the products and services produced in manufacturing operations [3]. Based on the literature review discussed above regarding the productivity concept, the following formula for productivity in manufacturing is presented using the following equation [5]:

Productivity = (Output)/Input

Ref. [5] advocates for measuring productivity to ensure manufacturing operations progress (productivity improvements). The investigation shows that productivity enhancement has three significant concerns: production cost, profitability, and efficiency indicator mobility. In terms of production cost, it is known that stocking density can directly influence cost input and benefit the culture process. The total revenue performance was mainly related to production and unit price [6]. Productivity management creates a competitive environment; a business must persuade a group of potential clienteles to buy its products or services at a price that is higher than its cost of production. Increasing competition in the global market necessitates that productivity should be an efficiency indicator to measure effectiveness [7]. Ref. [8] apply the tools and techniques of continuous improvement by implementing lean manufacturing tools within the business operations. The public and private sectors can adopt the application. This has a more significant impact on improving productivity within the business operations. Productivity measurement differs from operation to operation, reflecting general output and all other input factors. Ref. [3] explains that productivity measurement in manufacturing operations is based on the output produced, such as profit and quality concerning the financial and nonfinancial gains. However, recent studies have explored the context of productivity enhancement through detailed management processes, external and internal factors of productivity improvement, and supply chain management [1,2,9]. Ref. [2] further explores total management techniques to enhance efficiency and value management process, which allow sustainably manufacturers to set guidelines to improve productivity. Consequently, while various efficiency improvement drivers and productivity management strategies are widely recognised, best productivity evaluation and operation improvement practices create knowledge gaps [1,2,9], predominantly, in emerging countries, and particularly, in Africa, to improve operations management by improving productivity measurements within the continent. Hence, the study uses bibliometric analysis from the Web of Science (ISI) data to review productivity management-related fields. This will help bridge the knowledge gaps and answer the following research questions, further enriching the application of productivity management among stakeholders and manufacturing firms. The study’s preliminary findings will provide an understanding of the current trends in productivity management studies and potential future research direction in productivity management.

2. Literature Review

The literature review is a known and commonly used study method of defining and receiving accustomed to scientific offerings associated with the investigation’s substance [10]. The examination of journal articles permits scholars to increase their bibliographic database associated with a specific topic and to evade the re-invention of already described challenges and current resolutions [11]. Nevertheless, such an approach to directing change is reliant on the nature of the literature review, which can be broad, systematic, or perilous [12]. The methodology selected depends significantly on the development of the topic and the scope of interrelated literature [13]. The systematic literature review should be understood as an investigation method with fundamentals of valuation of the sources and a rational conception of the investigations [12].

Furthermore, in this tactic, the topic of scientific interest is firmly contracted using exact search terms. A clear crystal process of data gathering, extraction, and examination outcomes should be delivered to permit the reproducibility of the investigations [12,14]. In this study, a systematic literature review was selected as a process to examine the subject matter of productivity management-related fields.

3. Methodology

Our study analyses and classifies the research on productivity management and related fields until 2020 by applying the quantitative method of bibliometric analysis. The method was adopted to point out knowledge gaps by classifying investigation configurations. The methods used during the investigation are portrayed in Figure 1. A reproducible and systematic methodology is applied to collect and filter the data sample. A systematic bibliometric method is applied to examine the collected data samples. Applying this process results in a global overview of the productivity management concept-related tools and concepts [15]. Web of Science (ISI) was reflected as the foremost database; along with Elsevier Science, it has become the most popular database and leading choice for literature search. In most instances, the existence of data overlaps in either database [16]. This current study focused on research works from the Web of Science as a database recognised among scientific scholars [15]. This bibliometric analysis consists of the following main steps: (i) performing a keyword search in the Web of Science database; (ii) performing an individual search in the database of the journals selected; (iii) refining, using manufacturing/operation-related fields, language, and publication type; (iv) extracting papers; (v) interpreting data using VOSviewer; and (vi) categorising articles based on contents. In this type of examination, quantitative data concerning scientific fabrication, such as the publications per country, publications per document source, most-cited publications, co-authorship network, and co-occurrences network of keywords, are resolute. Access to information permits the recognising of various relationship networks to indicate countries, authors, and establishments significantly involved in the analysed domain. In the first step of the bibliometric analysis, we conducted a keyword search in the Web of Science database using the keywords: (i) “Productivity Management”, (ii) “Productivity Measurement”, and (iii) Productivity Improvement”. We also refined the examination to include relevant conference proceedings and published journal articles within the operations/production/manufacturing research areas such as the engineering industrial, engineering manufacturing, and material sciences. The literature search was conducted in January 2021 and resulted in 668 articles. Afterward, 246 published articles in the journals were selected. The selected journals have articles published in the last five years and have been cited one time, on average. The choice of selecting journal articles was emphasised by the reliable source of knowledge and considered more succinct and detailed than other sources of information [16]. As indicated above, “the results are presented based on the number of publications per year, the number of publications per country, top-cited documents, the number of publications per document sources, publication per authors, co-authorship, and keywords co-occurrence network”. The results are interpreted using VOSviewer v1.6.10, a literature review software that suggests the basic functionality required for visualising bibliometric linkages. The application demonstrates only the nodes in visualisation of bibliometric linkages. The bibliometric network/linkage provides distance-based visualisations rather than graph-based visualisation, VOSviewer presents, making it easier to show pictures of large networks/linkages [17]. The number of publications per country was developed using a map chart.

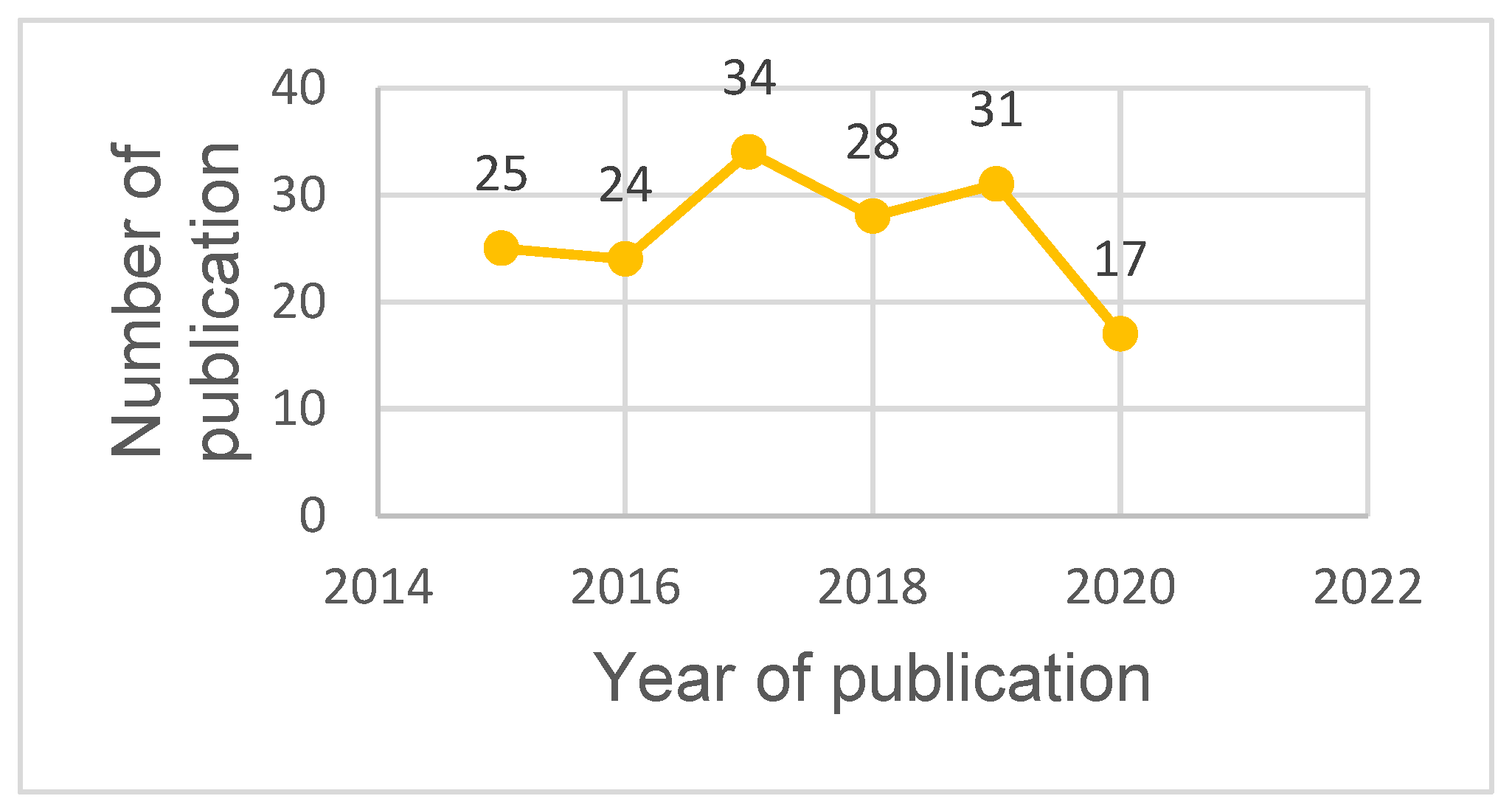

Figure 1.

Number of publications per year.

4. Results and Discussion

4.1. Publications per Year

This section shows an upsurge and a decline in the number of publications per year, that are cited at least once between 2015 and 2020. A total of 246 journal articles on productivity management were extracted. Figure 1 shows the number of publications per year from 2015 to 2020, with 25 publications in 2015 and 24 publications in 2016, with a rise from 24 publications in 2016 to 34 publications in 2017, the year with the highest number of publications in the said five-year period. Productivity management is the key competitive measure for any growing or sustainable country globally [18]. Publications fell from 31 publications in 2019 to 17 publications in 2020. The topic must become the centre of any country’s operation to gain a better competitive advantage. Through “productivity management or productivity improvement or measurement”, research focuses on developing a framework that can be easily adopted and implemented within the manufacturing space.

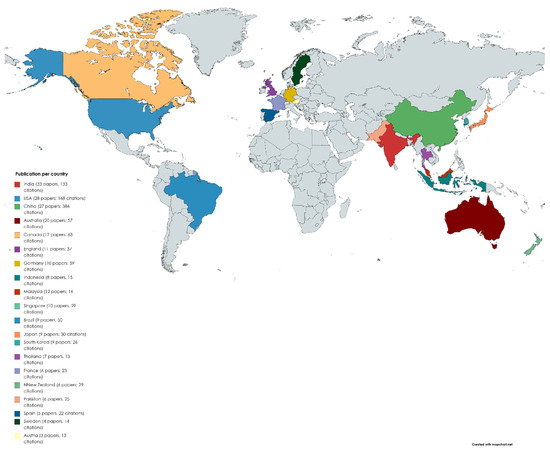

4.2. Publications per Country

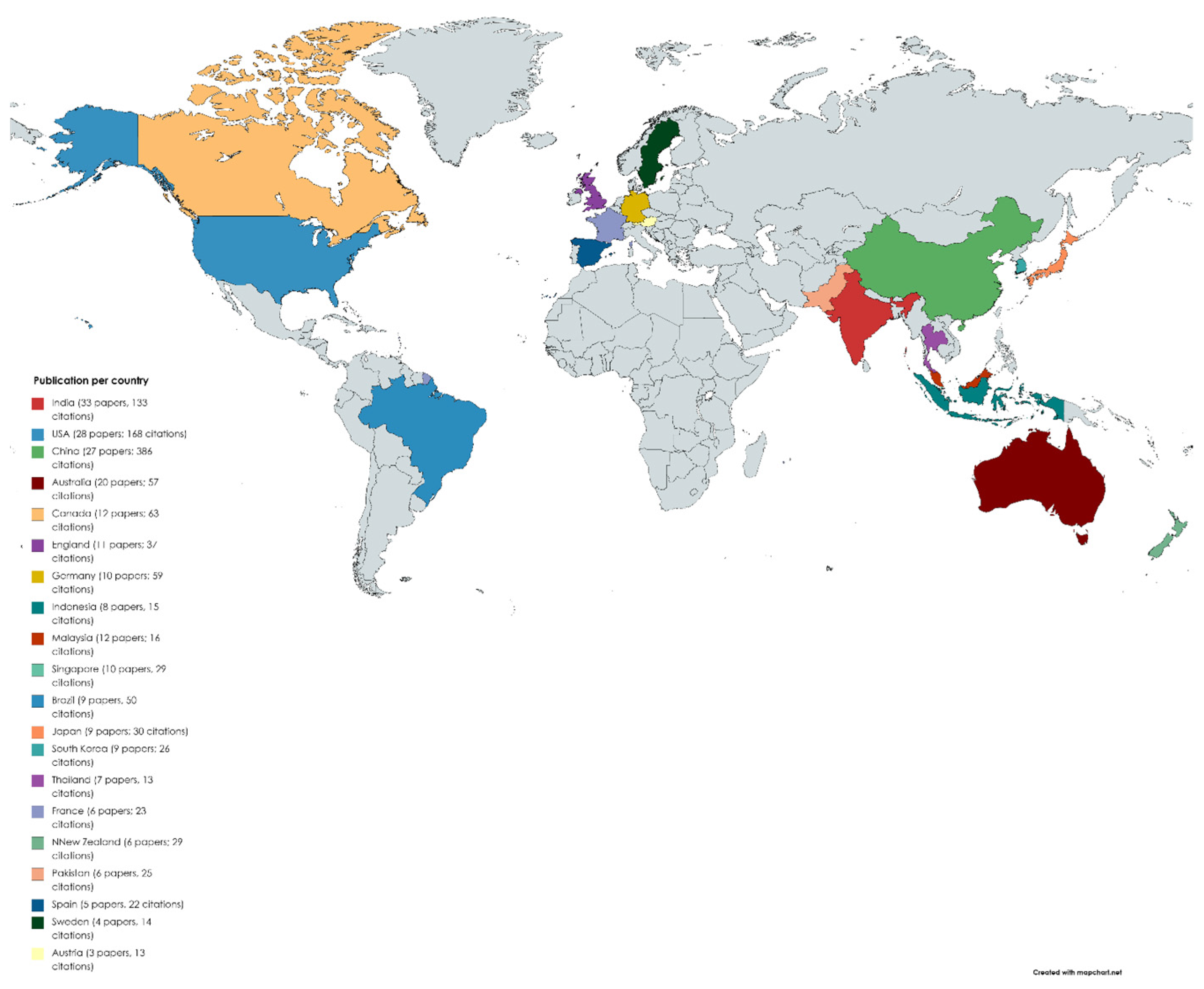

This section presents the originated publications per country, which reveals that some countries have produced more journal article publications with more citations within the five years. Figure 2 illustrates countries with at least three papers and more than 10 citations per publication. India tops the list with 33 research papers with 133 citations. This is followed by the USA (28 papers; 168 citations), China (27 papers; 386 citations), Australia (20 papers; 57 citations), Canada (12 papers; 63 citations), Malaysia (12 papers; 16 citations), England (11 papers; 37 citations), Germany (10 papers; 59 citations), Singapore (10 papers; 29 citations), Brazil (nine papers; 50 citations), Japan (nine papers; 30 citations), South Korea (nine papers; 26 citations), Indonesia (eight papers; 15 citations), Thailand (seven papers; 13 citations), France (six papers; 23 citations), New Zealand (six papers; 29 citations), Pakistan (six papers; 25 citations), Spain (five papers; 22 citations), Sweden (four papers; 14 citations), and Austria (three papers; 13 citations). Amongst other factors, the Institute of Management Development (IMD) also reveals some of these competitions as sustainable in generating value by improving business efficiency, infrastructure, economic performance, and government efficiency, such countries that fall within the world’s competitiveness ranking, like China, USA, Canada, Singapore, and Sweden, amongst others [19].

Figure 2.

Number of publications per country.

Table 1 below illustrates that no African country can have a foothold in this area of research—this expression of a knowledge gap in Africa’s productivity management space.

Table 1.

Number of publications per source.

4.3. Publications per Document Source

An evaluation of extracted papers per source title was selected. At least 246 extracted publications were circulated in 156 diverse journals and conference events/proceedings, of which 14 had only one publication within five years. Table 1 below illustrates only those sources with at least three published papers on productivity management-related fields. The “International Journal of Productivity and Performance Management” topped the list with 21 publications and 63 citations. This was not astonishing, as the journals focus on studies examining profitability, total factor productivity, productivity, performance measurement, and throughput. This is followed by the International Journal of Production Research (13 papers; 71 citations) and the International Journal of Lean Six Sigma (six papers; 31 citations).

4.4. Most-Cited Publications

To completely comprehend the investigation in productivity management-related fields, the most-cited papers and their area of concentration were analysed from the extracted papers. Out of the 246 extracted papers, only 11 have been cited at least 15 times, has at least been cited 148 times, focusing on productivity improvement. Most of these papers were case studies and experimental. The intention for this can be qualified by the fact that product management is still in its early stages or is not a common topic for many organisations, especially small micro-enterprises [20,21,22], considering that the several means of adopting the theory within the operations management is vital. This can only be accomplished through case studies and experiments to obtain the correct blend for the manufacturing trade.

4.5. Publication per Author and Co-Authorship Network

Concerning authorships, the evaluated 246 documents had 697 authors. This comprises both the leading authors and their co-authors, with the minimum number of papers per author was set at two, and only 15 authors were exposed. This section presents the topmost authors that have transcribed in the area of productivity management-related fields and are cited more than three times [23] (four papers; five citations)], [24] (three papers; eight citations). It can also be seen that while Ref. [22] only have two documents, they have been cited 24 times. In Refs. [22,24,25,26,27,28] were the earliest authors to start publishing in productivity management-related fields from 2016 to 2018, as presented in the below map, highlighted in the deep blue to lighter blue cluster between 2016 and 2018. Nevertheless, the most modern authors publishing in productivity management-related fields are in Refs. [22,23,29,30,31]. Their publication is from 2018 to 2019, and it can be seen in the lighter green and yellow clusters in the map below.

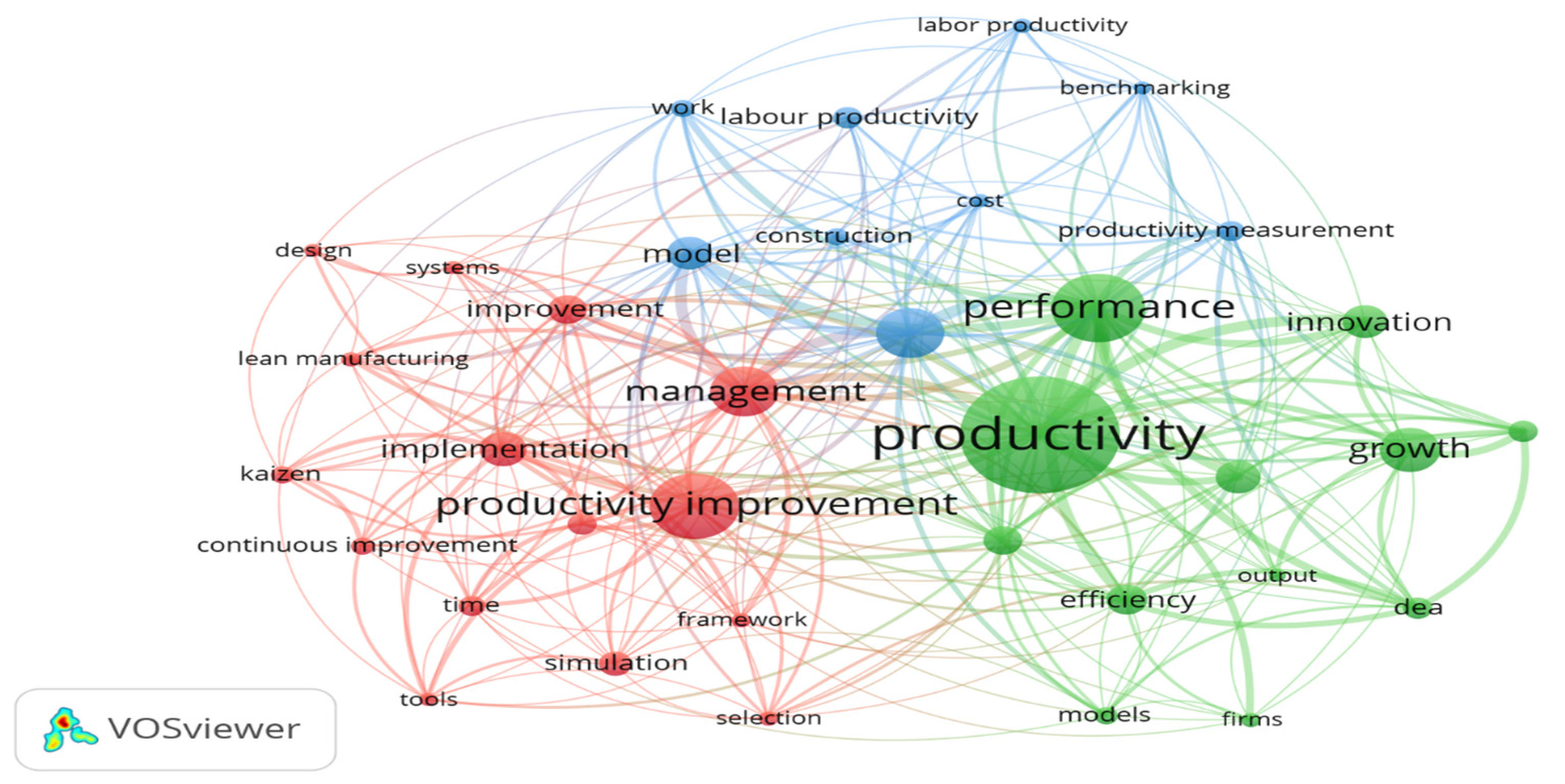

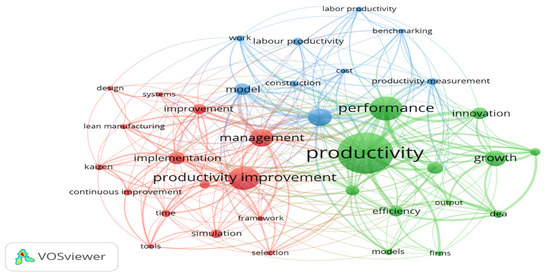

4.6. Research Focus Based on Co-Occurring Keywords

This section focuses on constructing a co-occurrence map based on gathering bibliographic data to interpolate and extract the lowest number of co-occurrences for keyword clusters. Clustering these keywords into themes is essential to explicate the focus areas for those past studies. While VOSviewer predefined the lowest number of co-occurring keywords as five, for this study, we adopted a minimum of six co-occurrences that gave a significant number of repeated keywords. “This suggests that for a keyword to be extracted, it must have at least six co-occurrences. The analysis revealed 1383 keywords for all 246 extracted publications co-occurrences in the author and source indexed keywords. Of these keywords, 36 met the threshold of 6 co-occurrences and were further grouped into 3 clusters. It is important to note that the closer the keywords are to each other, the higher their co-occurrence [16]”.

4.7. Research Focus Based on Years of Publication

With a minimum of six occurrences, from the observation from 2017 to 2017.5, research focused on efficiency management and its application is clearly stated. As shown in Figure 3, keywords marked in this period include data envelopment analysis, efficiency, firms, growth, industry, innovation, models, output, performance, productivity, and quality. These keywords are represented by the green cluster of the map from 2017 to 2018. The cluster focuses its investigation on process improvement. Figure 3 further details that keywords evident in this period include continuous improvement, design, framework, implementation, improvement, kaizen, lean manufacturing, management, productivity improvement, selection, simulation, system/s, time, and tools. Areas like lean manufacturing, kaizen, and continuous improvement are the cornerstones or enablers for productivity improvements in business operations. These are the foundation of business performance globally [32,33,34]. Although areas such as time, systems, impact, work, cost, and labour productivity are the recently emerged topics that are being explored, the correlation between these keywords or areas of investigation should be aligned to productivity management benefits; this is the area that should be given substantial attention in future.

Figure 3.

Network visualisation map for co-occurring keywords.

5. Conclusions

This study comprehensively reviews productivity management-related fields using two distinct techniques and combining bibliometric and systematic literature reviews to examine studies published within the past five years and indexed in the Web of Science (ISI) database. The findings show a significant decrease in publications per year, from 31 in 2019 to 17 in 2020. This trend underscores the importance of productivity management as a key factor in any country’s operations to gain a competitive advantage. Likewise, the research focuses on developing a framework for productivity management improvement or measurement and has identified a notable knowledge gap in the literature from African countries. This gap presents an opportunity for further research to enhance manufacturing operations on the continent. Furthermore, the study highlights the various clusters of research in productivity management-related fields, which primarily focus on implementing practices such as time, systems, impact, work, cost, and labour productivity. However, the study findings suggest that future research should consider economic and practical indicators to measure, control, and improve productivity as a guide to evaluate and enhance productivity management. Nevertheless, while this study contributes enormously to the existing literature on productivity management, care must be taken in generalising its outcomes, as data were gathered from the Web of Science (ISI) database.

Author Contributions

Conceptualization, N.M. and B.F.O.; methodology, B.F.O. and C.A.; software, N.M. and B.F.O.; validation, N.M., B.F.O., and C.A.; formal analysis, N.M. and B.F.O.; investigation, N.M.; resources, N.M. and B.F.O.; data curation, B.F.O.; writing—original draft preparation, N.M. and B.F.O.; writing—review and editing, B.F.O. and C.A.; visualization, N.M. and C.A.; supervision, B.F.O. and C.A.; project administration, B.F.O. and C.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Ethics Committee of the Faculty of Engineering and the Built Environment at the University of Johannesburg, UJ_FEBE_FEPC_00780, 24 July 2023.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

No new data were created.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Soto Lopez, D.; Garshasbi, M.; Kabir, G.; Bari, A.M.; Ali, S.M. Evaluating interaction between internal hospital supply chain performance indicators: A rough-DEMATEL-based approach. Int. J. Product. Perform. Manag. 2022, 71, 2087–2113. [Google Scholar] [CrossRef]

- Minh, N. Toyota’s production efficiency improvement management: Best practice for productivity evaluation and operation improvement. J. Adv. Manag. Res. 2023, 20, 385–408. [Google Scholar] [CrossRef]

- Stainer, A. Productivity management: The Japanese experience. Manag. Decis. 1995, 33, 4–12. [Google Scholar] [CrossRef]

- Hussain, A.; Ahmad, Q.W.; Haq, I.U.; Nazir, A.; Imran, S.; Islam, B.U. Improving Productivity and Quality in SMEs of Pakistan: A case study. Tech. J. 2015, 20, 103–114. [Google Scholar]

- Yemane, A.; Gebremicheal, G.; Meraha, T.; Hailemicheal, M. Productivity improvement through line balancing using simulation modelling (case study Almeda garment factory). J. Opt. Ind. Eng. 2020, 13, 153–165. [Google Scholar]

- Klingner, S.; Pravemann, S.; Becker, M. Service productivity in different industries—An empirical investigation. Benchmarking Int. J. 2015, 22, 238–253. [Google Scholar] [CrossRef]

- Huang, C.T.; Vinh, N.P.; Chen, Y.T.; Liang, T.T.; Nan, F.H.; Liu, P.C. Improving productivity management of commercial abalone Haliotis diversicolor supertexta and Haliotis discus hannai aquaculture in Taiwan: A bioeconomic analysis. Aquaculture 2019, 512, 734323. [Google Scholar] [CrossRef]

- Khan, J.H. Impact of total quality management on productivity. TQM Mag. 2003, 15, 374–380. [Google Scholar] [CrossRef]

- Nguyen, H.K.; Phan, A.C. Determinants for labour productivity improvement in hotel service: Empirical evidence from Vietnam. Int. J. Product. Qual. Manag. 2024, 41, 1–31. [Google Scholar] [CrossRef]

- De Oliveira, A.L.G.; da Rocha Junior, W.R. Productivity Improvement through the Implementation of Lean Manufacturing in a Medium-Sized Furniture Industry: A Case Study. S. Afr. J. Ind. Eng. 2019, 30, 172–188. [Google Scholar] [CrossRef]

- Brocke, J.V.; Simons, A.; Niehaves, B.; Niehaves, B.; Reimer, K.; Plattfaut, R.; Cleven, A. Reconstructing the giant: On the importance of rigour in documenting the literature search process. In Information Systems in a Globalising World: Challenges, Ethics and Practices; Newell, S., Whitley, E., Pouloudi, N., Wareham, J., Mathiassen, L., Eds.; Università di Verona, Facoltà di Economia, Departimento de Economia Aziendale: Verona, Italy, 2009; pp. 2206–2217. [Google Scholar]

- Baker, M.J. Writing a literature review. Market. Rev. 2000, 1, 219–247. [Google Scholar] [CrossRef]

- Fernandez, K.V. Critically reviewing the literature: A tutorial for new researchers. Australas. Market. J. (AMJ) 2019, 27, 187–196. [Google Scholar] [CrossRef]

- Torraco, R.J. Writing integrative literature reviews: Guidelines and examples. Hum. Resour. Dev. Rev. 2005, 4, 356–367. [Google Scholar] [CrossRef]

- Robinson, P.; Lowe, J. Literature reviews vs systematic reviews. Aust. N. Z. J. Public Health 2015, 39, 103. [Google Scholar] [CrossRef]

- Gil, M.; Wróbel, K.; Montewka, J.; Goerlandt, F. A bibliometric analysis and systematic review of shipboard Decision Support Systems for accident prevention. Saf. Sci. 2020, 128, 104717. [Google Scholar] [CrossRef]

- Aghimien, D.O.; Aigbavboa, C.O.; Oke, A.E.; Thwala, W.D. Mapping out research focus for robotics and automation research in construction-related studies: A bibliometric approach. J. Eng. Des. Technol. 2019, 18, 1063–1079. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Visualizing bibliometric networks. In Measuring Scholarly Impact: Methods and Practice; Ding, Y., Rousseau, R., Wolfram, D., Eds.; Springer: Cham, Switzerland, 2014; pp. 285–320. [Google Scholar]

- Wagstaff, C.; Kendrick, F.; Dennis, C.; Hollington, P.; Hess, T.; Brameld, J.; Mason, B. Productivity framework. Food Sci. Tech. (IFST Q. Mag.) 2018, 32, 52–57. [Google Scholar]

- Bamgbose, O.A.; Ogunbayo, B.F.; Aigbavboa, C.O. Barriers to Building Information Modelling Adoption in Small and Medium Enterprises: Nigerian Construction Industry Perspectives. Buildings 2024, 14, 538. [Google Scholar] [CrossRef]

- Yu, M. Processing trade, tariff reductions and firm productivity: Evidence from Chinese firms. Econ. J. 2015, 125, 943–988. [Google Scholar] [CrossRef]

- Du, J.; Chen, Y.; Huang, Y. A Modified Malmquist-Luenberger Productivity Index: Assessing Environmental Productivity Performance in China. Eur. J. Oper. Res. 2018, 269, 171–187. [Google Scholar] [CrossRef]

- Afsharian, M.; Ahn, H. Multi-period productivity measurement under centralized management with an empirical illustration of German saving banks. OR Spectr. 2017, 39, 881–911. [Google Scholar] [CrossRef]

- Nallusamy, S.; Saravanan, V. Optimization of process flow in an assembly line of manufacturing unit through lean tools execution. Int. J. Eng. Res. Afr. 2018, 38, 133–143. [Google Scholar] [CrossRef]

- Abolhassani, A.; James Harner, E.; Jaridi, M. Empirical analysis of productivity enhancement strategies in the North American automotive industry. Int. J. Prod. Econ. 2019, 208, 140–159. [Google Scholar] [CrossRef]

- Diewert, W.E.; Fox, K.J. Sunk costs and the measurement of commercial property depreciation. Can. J. Econ. 2016, 49, 1340–1366. [Google Scholar] [CrossRef]

- Mbachu, J.; Egbelakin, T.; Rasheed, E.O.; Shahzad, W.M. Influence of key role players on productivity outcomes in the residential building lifecycle. J. Eng. Des. Technol. 2017, 15, 528–551. [Google Scholar] [CrossRef]

- Rasheed, E.O.; Byrd, H. Can self-evaluation measure the effect of IEQ on productivity? A review of literature. Facilities 2017, 35, 601–621. [Google Scholar] [CrossRef]

- Schreyer, P.; Zinni, M.B. Productivity Measurement, R&D Assets, and Mark-Ups in OECD Countries. Rev. Income Wealth 2020, 67, 787–809. [Google Scholar]

- Purba, H.H.; Mukhlisin; Aisyah, S. Productivity improvement picking order by appropriate method, value stream mapping analysis, and storage design: A case study in automotive part center. Manag. Prod. Eng. Rev. 2018, 9, 71–81. [Google Scholar]

- Gopalakrishnan, M.; Skoogh, A. Machine criticality-based maintenance prioritization: Identifying productivity improvement potential. Int. J. Product. Perform. Manag. 2018, 67, 654–672. [Google Scholar] [CrossRef]

- Hwang, B.; Krishnankutty, P.; Zhu, L.; Caldas, C.H.; Shounak, A.; Mulva, S. Improving labour productivity in process construction maintenance and shutdown/turnaround projects. Int. J. Constr. Manag. 2018, 20, 822–836. [Google Scholar] [CrossRef]

- Pacheco, D.; Pergher, I.; Vaccaro, G.L.R.; Jung, C.F.; ten Caten, C. 18 comparative aspects between Lean and Six Sigma: Complementarity and implications. Int. J. Lean Six Sigma 2015, 6, 161–175. [Google Scholar] [CrossRef]

- Helleno, A.L.; Pimentel, C.A.; Ferro, R.; Santos, P.F.; Oliveira, M.C.; Simon, A.T. Integrating value stream mapping and discrete events simulation as decision making tools in operation management. Int. J. Adv. Manuf. Technol. 2015, 80, 1059–1066. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).