Mechanical Characterization of Ultra-Violet-Curable Resin-Based Polymer Foams Containing Triply Periodic Minimal Surface Lattice Structures †

Abstract

1. Introduction

2. Materials and Methods

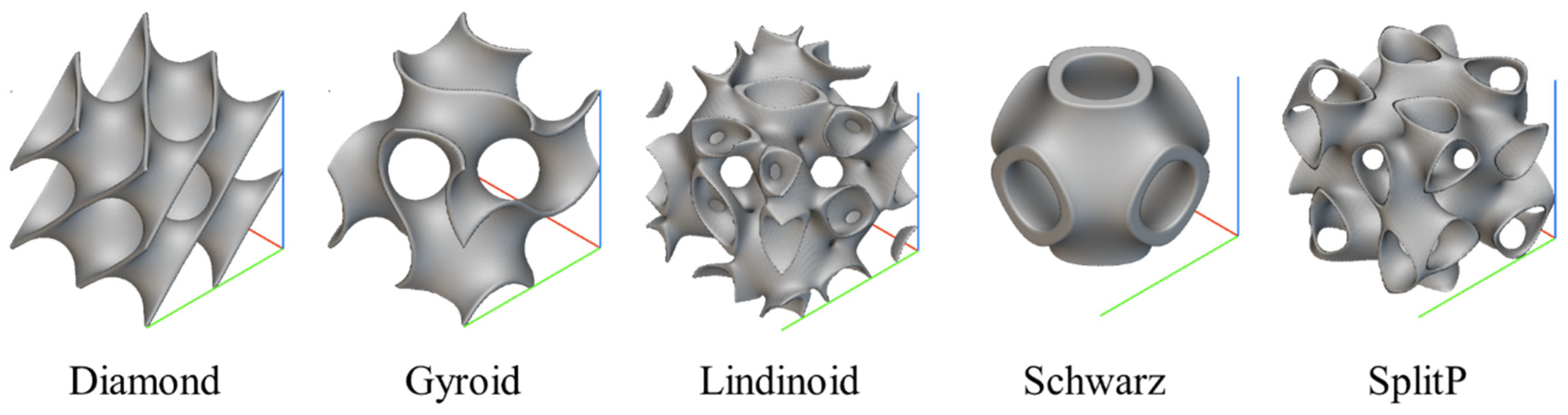

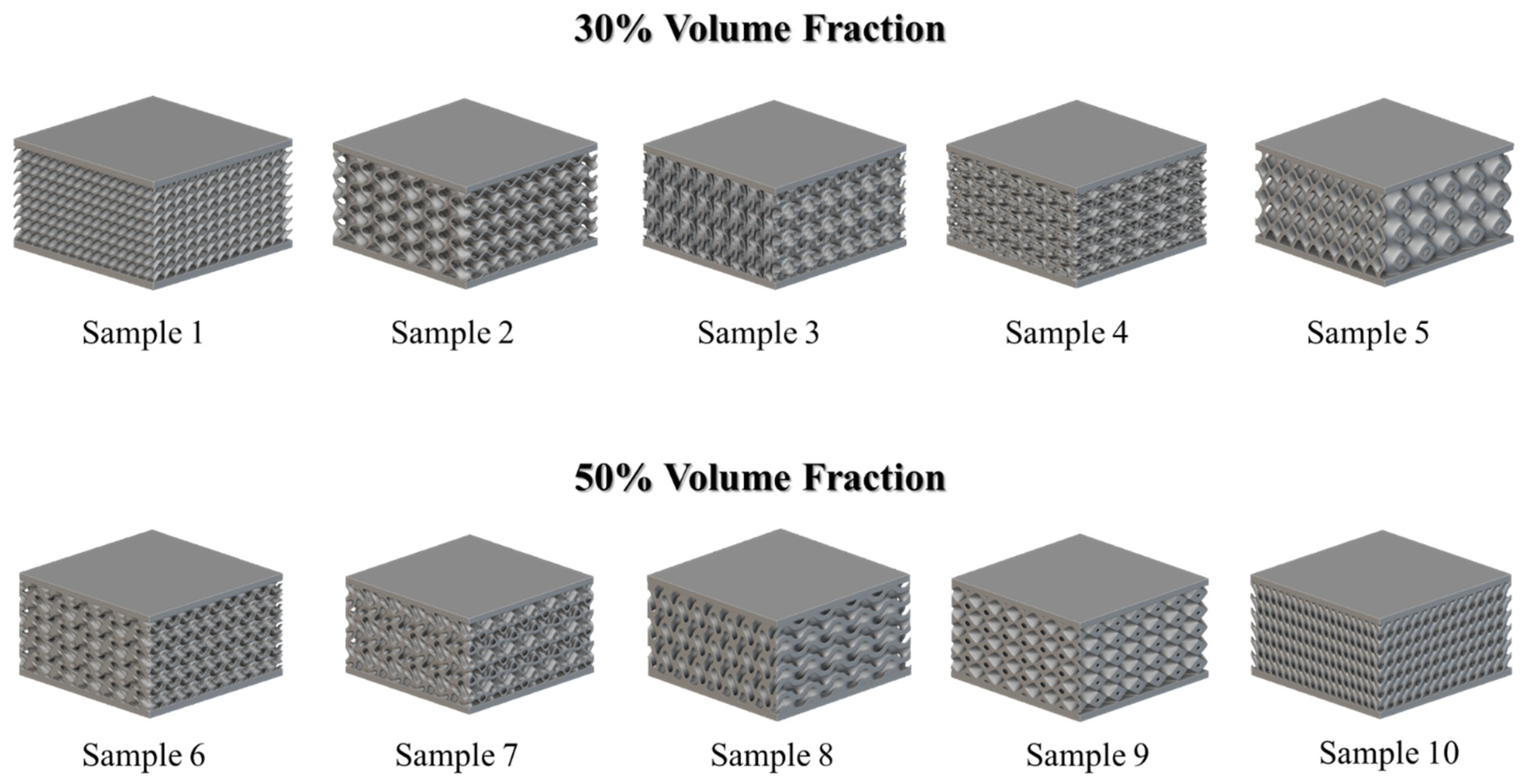

2.1. Design

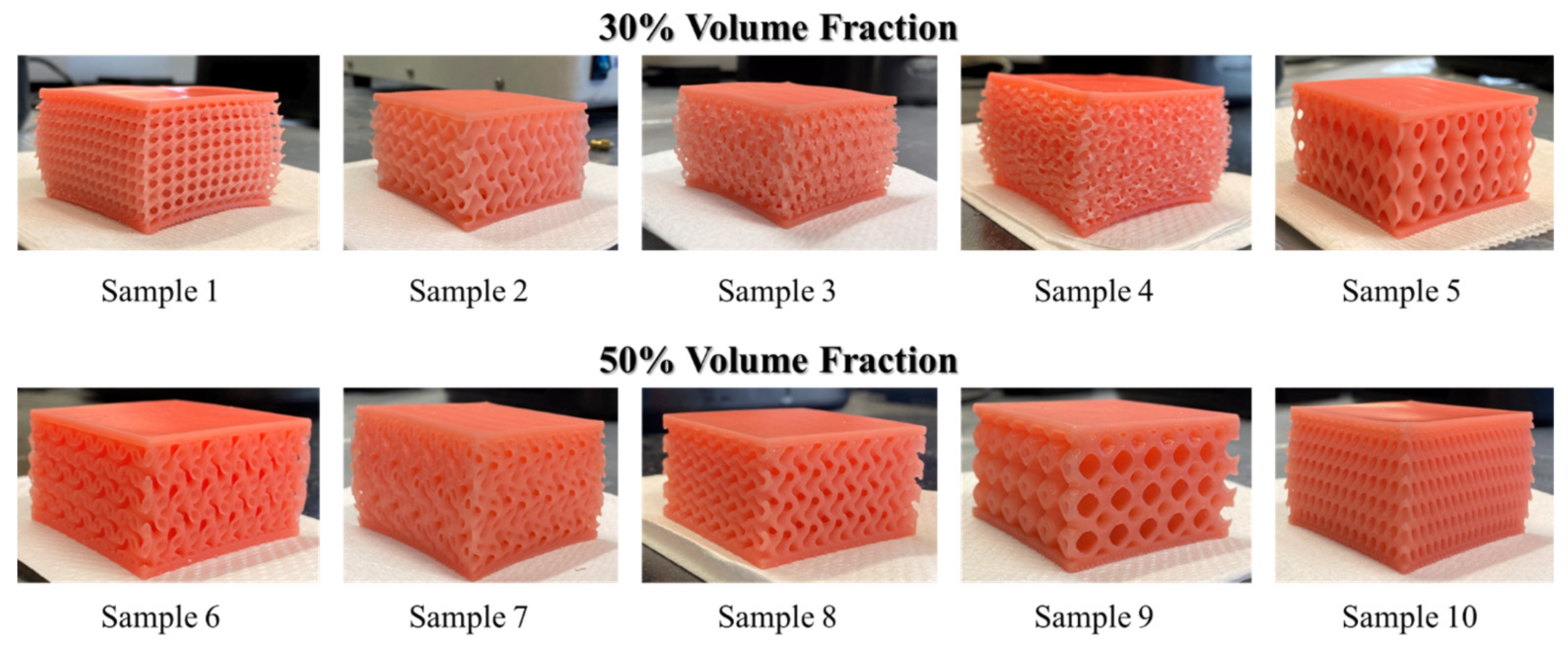

2.2. Additive Manufacturing

2.3. Compression Test

3. Result and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ashby, M.F. The properties of foams and lattices. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 364, 15–30. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.T. Polymeric Foams; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar] [CrossRef]

- Dinakaran, I.; Sakib-Uz-Zaman, C.; Rahman, A.; Khondoker, M.A.H. Controlling degree of foaming in extrusion 3D printing of porous polylactic acid. Rapid Prototyp. J. 2023, 29, 1958–1968. [Google Scholar] [CrossRef]

- Pizzorni, M.; Lertora, E.; Mandolfino, C. Energy absorption properties of a 3D-printed lattice-core foam composite under compressive and low-velocity impact loading. Mater. Today Commun. 2023, 36, 106918. [Google Scholar] [CrossRef]

- de Souza, F.M.; Desai, Y.; Gupta, R.K. Introduction to Polymeric Foams. In ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2023; Volume 1439, pp. 1–23. [Google Scholar] [CrossRef]

- Suethao, S.; Shah, D.U.; Smitthipong, W. Recent Progress in Processing Functionally Graded Polymer Foams. Materials 2020, 13, 4060. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, V.; Srivastava, R. On the polymeric foams: Modeling and properties. J. Mater. Sci. 2014, 49, 2681–2692. [Google Scholar] [CrossRef]

- Rahimidehgolan, F.; Altenhof, W. Compressive behavior and deformation mechanisms of rigid polymeric foams: A review. Compos. B Eng. 2023, 253, 110513. [Google Scholar] [CrossRef]

- Abdullah, M.; Ramtani, S.; Yagoubi, N. Mechanical properties of polyurethane foam for potential application in the prevention and treatment of pressure ulcers. Results Eng. 2023, 19, 101237. [Google Scholar] [CrossRef]

- Alzoubi, M.F.; Al-Hallaj, S.; Abu-Ayyad, M. Modeling of Compression Curves of Flexible Polyurethane Foam with Variable Density, Chemical Formulations and Strain Rates. J. Solid Mech. 2014, 6, 82–97. Available online: https://www.researchgate.net/publication/266854162 (accessed on 28 March 2024).

- Ashby, M.F.; Medalist, R.F.M. The mechanical properties of cellular solids. Metall. Trans. A 1983, 14, 1755–1769. [Google Scholar] [CrossRef]

- Hooshmand, M.J.; Sakib-Uz-Zaman, C.; Khondoker, M.A.H. Machine Learning Algorithms for Predicting Mechanical Stiffness of Lattice Structure-Based Polymer Foam. Materials 2023, 16, 7173. [Google Scholar] [CrossRef]

- Koeppe, A.; Padilla, C.A.H.; Voshage, M.; Schleifenbaum, J.H.; Markert, B. Efficient numerical modeling of 3D-printed lattice-cell structures using neural networks. Manuf. Lett. 2018, 15, 147–150. [Google Scholar] [CrossRef]

- Ma, S.; Tang, Q.; Liu, Y.; Feng, Q. Prediction of Mechanical Properties of Three-Dimensional Printed Lattice Structures Through Machine Learning. J. Comput. Inf. Sci. Eng. 2022, 22, 031008. [Google Scholar] [CrossRef]

- Khondoker, M.A.H.; Sameoto, D. Direct coupling of fixed screw extruders using flexible heated hoses for FDM printing of extremely soft thermoplastic elastomers. Prog. Addit. Manuf. 2019, 4, 197–209. [Google Scholar] [CrossRef]

- Graziosi, S.; Ballo, F.M.; Libonati, F.; Senna, S. 3D printing of bending-dominated soft lattices: Numerical and experimental assessment. Rapid Prototyp. J. 2022, 28, 51–64. [Google Scholar] [CrossRef]

- Peloquin, J.; Kirillova, A.; Rudin, C.; Brinson, L.C.; Gall, K. Prediction of tensile performance for 3D printed photopolymer gyroid lattices using structural porosity, base material properties, and machine learning. Mater. Des. 2023, 232, 112126. [Google Scholar] [CrossRef]

- Rossiter, J.D.; Johnson, A.A.; Bingham, G.A. Assessing the Design and Compressive Performance of Material Extruded Lattice Structures. 3D Print. Addit. Manuf. 2020, 7, 19–27. [Google Scholar] [CrossRef]

- Al Rifaie, M.; Mian, A.; Srinivasan, R. Compression behavior of three-dimensional printed polymer lattice structures. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1574–1584. [Google Scholar] [CrossRef]

- Mishra, A.K.; Chavan, H.; Kumar, A. Effect of material variation on the uniaxial compression behavior of FDM manufactured polymeric TPMS lattice materials. Mater. Today Proc. 2021, 46, 7752–7759. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Perveen, A.; Talamona, D. Experimental investigation of mechanical properties and energy absorption capabilities of hybrid lattice structures manufactured using fused filament fabrication. Int. J. Adv. Manuf. Technol. 2023, 125, 2833–2850. [Google Scholar] [CrossRef]

- Isaenkova, M.G.; Yudin, A.V.; Rubanov, A.E.; Osintsev, A.V.; Degadnikova, L.A. Deformation behavior modelling of lattice structures manufactured by a selective laser melting of 316L steel powder. J. Mater. Res. Technol. 2020, 9, 15177–15184. [Google Scholar] [CrossRef]

- Dar, U.A.; Mian, H.H.; Abid, M.; Topa, A.; Sheikh, M.Z.; Bilal, M. Experimental and numerical investigation of compressive behavior of lattice structures manufactured through projection micro stereolithography. Mater. Today Commun. 2020, 25, 101563. [Google Scholar] [CrossRef]

- Babamiri, B.B.; Askari, H.; Hazeli, K. Deformation mechanisms and post-yielding behavior of additively manufactured lattice structures. Mater. Des. 2020, 188, 108443. [Google Scholar] [CrossRef]

- Amani, Y.; Dancette, S.; Delroisse, P.; Simar, A.; Maire, E. Compression behavior of lattice structures produced by selective laser melting: X-ray tomography based experimental and finite element approaches. Acta Mater. 2018, 159, 395–407. [Google Scholar] [CrossRef]

- Park, J.-H.; Park, K. Compressive behavior of soft lattice structures and their application to functional compliance control. Addit. Manuf. 2020, 33, 101148. [Google Scholar] [CrossRef]

- ASTM D3574-17; Standard Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams. ASTM International: West Conshohocken, PA, USA, 2017.

| Sample | Lattice Type | X (mm) | Y (mm) | Z (mm) | Thickness (mm) | Volume Fraction |

|---|---|---|---|---|---|---|

| 1 | Diamond | 6.2 | 7.7 | 6.0 | 0.8 | 30 |

| 2 | Gyroid | 9.5 | 6.3 | 5.9 | 1.1 | |

| 3 | Lidinoid | 6.3 | 7.6 | 7.8 | 0.6 | |

| 4 | SplitP | 9.5 | 8.6 | 5.2 | 0.9 | |

| 5 | Schwarz | 5.5 | 9.6 | 8.0 | 0.7 | |

| 6 | Lidinoid | 9.7 | 5.6 | 5.8 | 1.1 | 50 |

| 7 | SplitP | 9.6 | 8.5 | 9.4 | 1.8 | |

| 8 | Gyroid | 6.3 | 9.8 | 8.0 | 2.1 | |

| 9 | Schwarz | 7.3 | 7.8 | 5.1 | 1.0 | |

| 10 | Diamond | 5.1 | 6.9 | 8.3 | 1.5 |

| Lattice Type | Volume Fraction = 30% | Volume Fraction = 50% | ||||

|---|---|---|---|---|---|---|

| εy (%) | k (N/mm) | Fmax (N) | εy (%) | k (N/mm) | Fmax (N) | |

| Diamond | 3.37 | 4.5283 | 422.1011 | 6.51 | 15.442 | 2394.9089 |

| Gyroid | 4.04 | 3.6397 | 287.8259 | 2.44 | 15.458 | 1060.1224 |

| Lidinoid | 2.11 | 1.8592 | 206.6092 | 5.97 | 16.011 | 1637.1638 |

| Schwarz | 1.71 | 11.749 | 407.1946 | 6.77 | 7.6923 | 634.6938 |

| SplitP | 4.04 | 2.4217 | 290.6495 | 5.31 | 13.764 | 1147.599 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hooshmand, M.J.; Khondoker, M.A.H. Mechanical Characterization of Ultra-Violet-Curable Resin-Based Polymer Foams Containing Triply Periodic Minimal Surface Lattice Structures. Eng. Proc. 2024, 76, 55. https://doi.org/10.3390/engproc2024076055

Hooshmand MJ, Khondoker MAH. Mechanical Characterization of Ultra-Violet-Curable Resin-Based Polymer Foams Containing Triply Periodic Minimal Surface Lattice Structures. Engineering Proceedings. 2024; 76(1):55. https://doi.org/10.3390/engproc2024076055

Chicago/Turabian StyleHooshmand, Mohammad Javad, and Mohammad Abu Hasan Khondoker. 2024. "Mechanical Characterization of Ultra-Violet-Curable Resin-Based Polymer Foams Containing Triply Periodic Minimal Surface Lattice Structures" Engineering Proceedings 76, no. 1: 55. https://doi.org/10.3390/engproc2024076055

APA StyleHooshmand, M. J., & Khondoker, M. A. H. (2024). Mechanical Characterization of Ultra-Violet-Curable Resin-Based Polymer Foams Containing Triply Periodic Minimal Surface Lattice Structures. Engineering Proceedings, 76(1), 55. https://doi.org/10.3390/engproc2024076055