Gearbox Fault Diagnosis Using Industrial Machine Learning Techniques †

Abstract

1. Introduction

2. Methodology

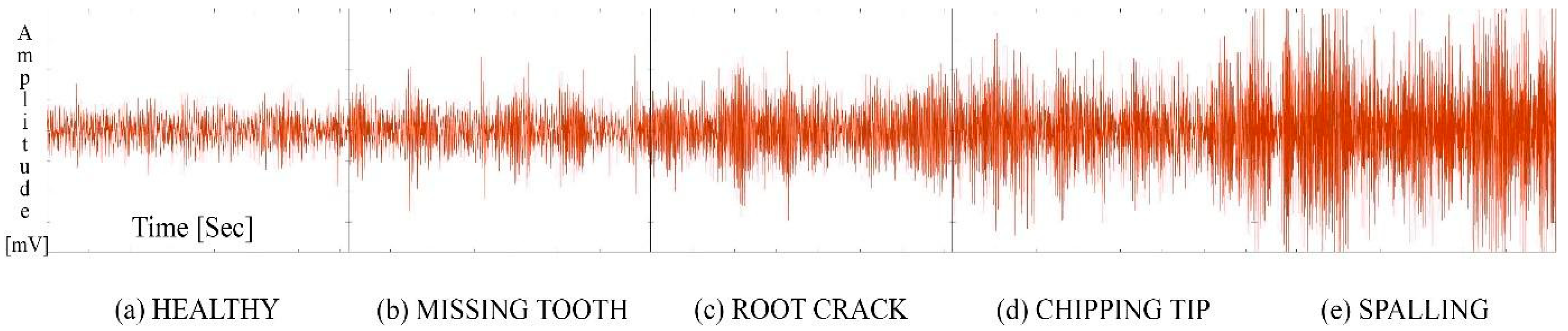

2.1. Data Collection

2.2. Image-Processing Technique

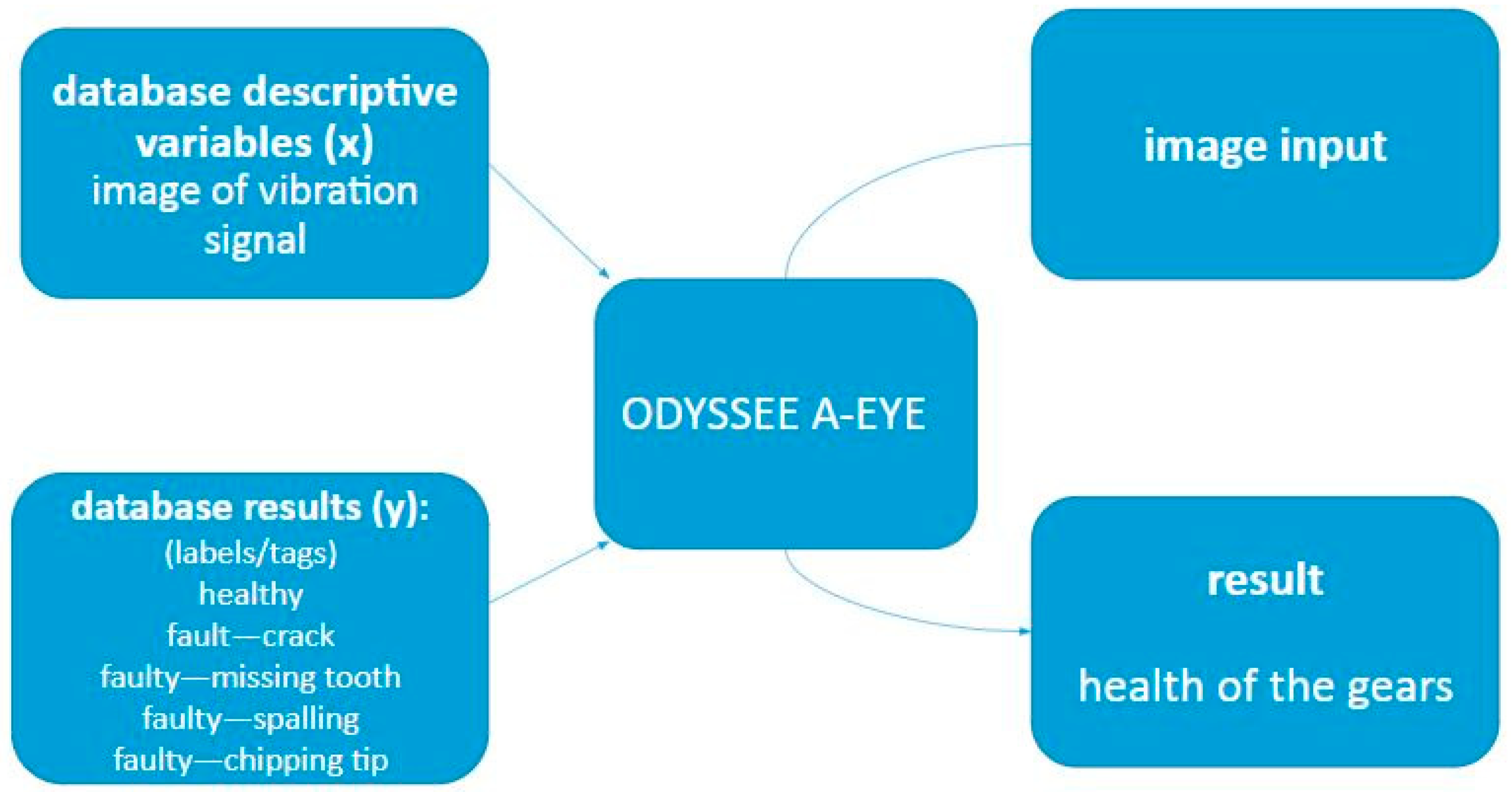

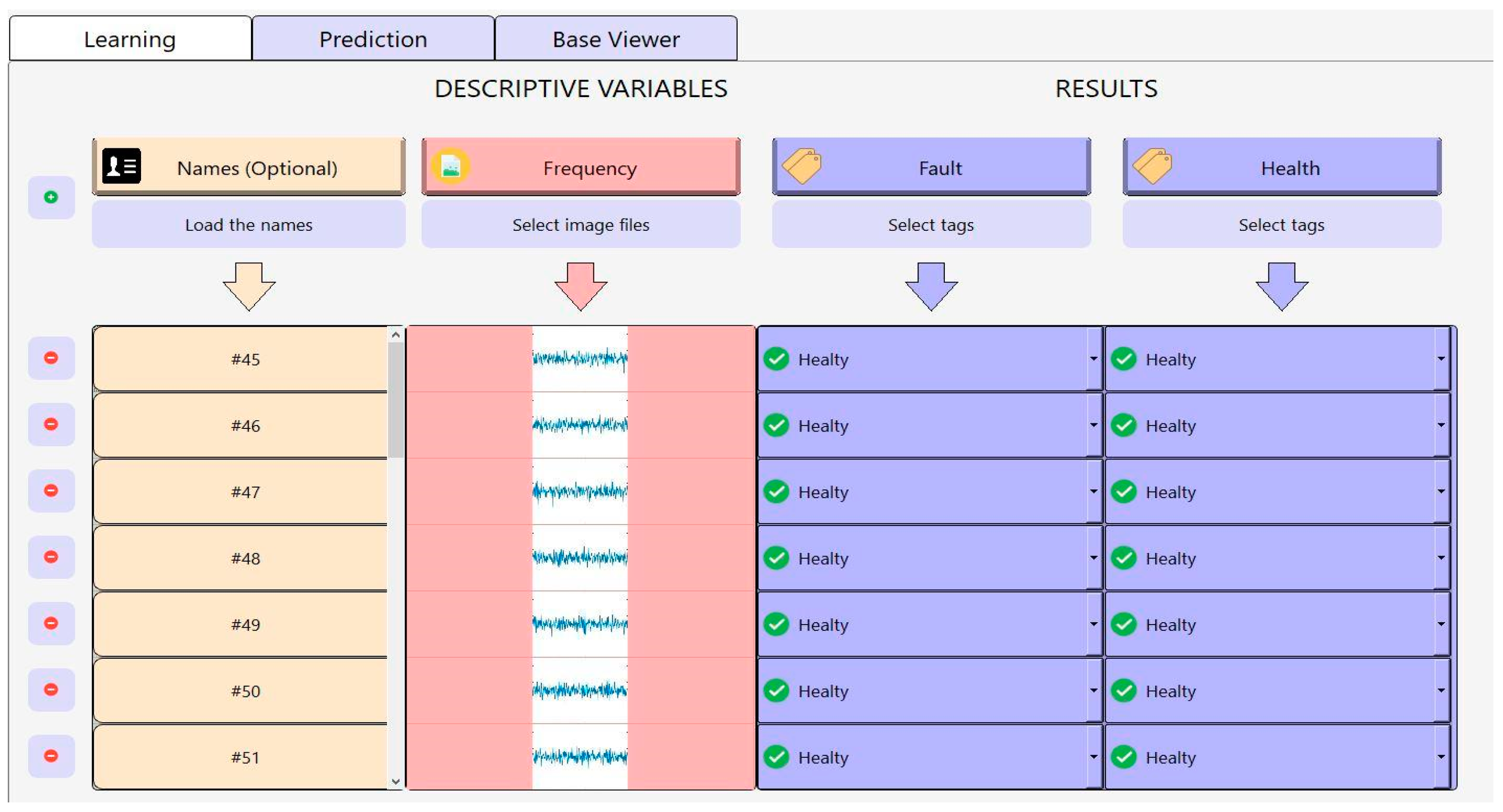

2.3. Machine Learning Model

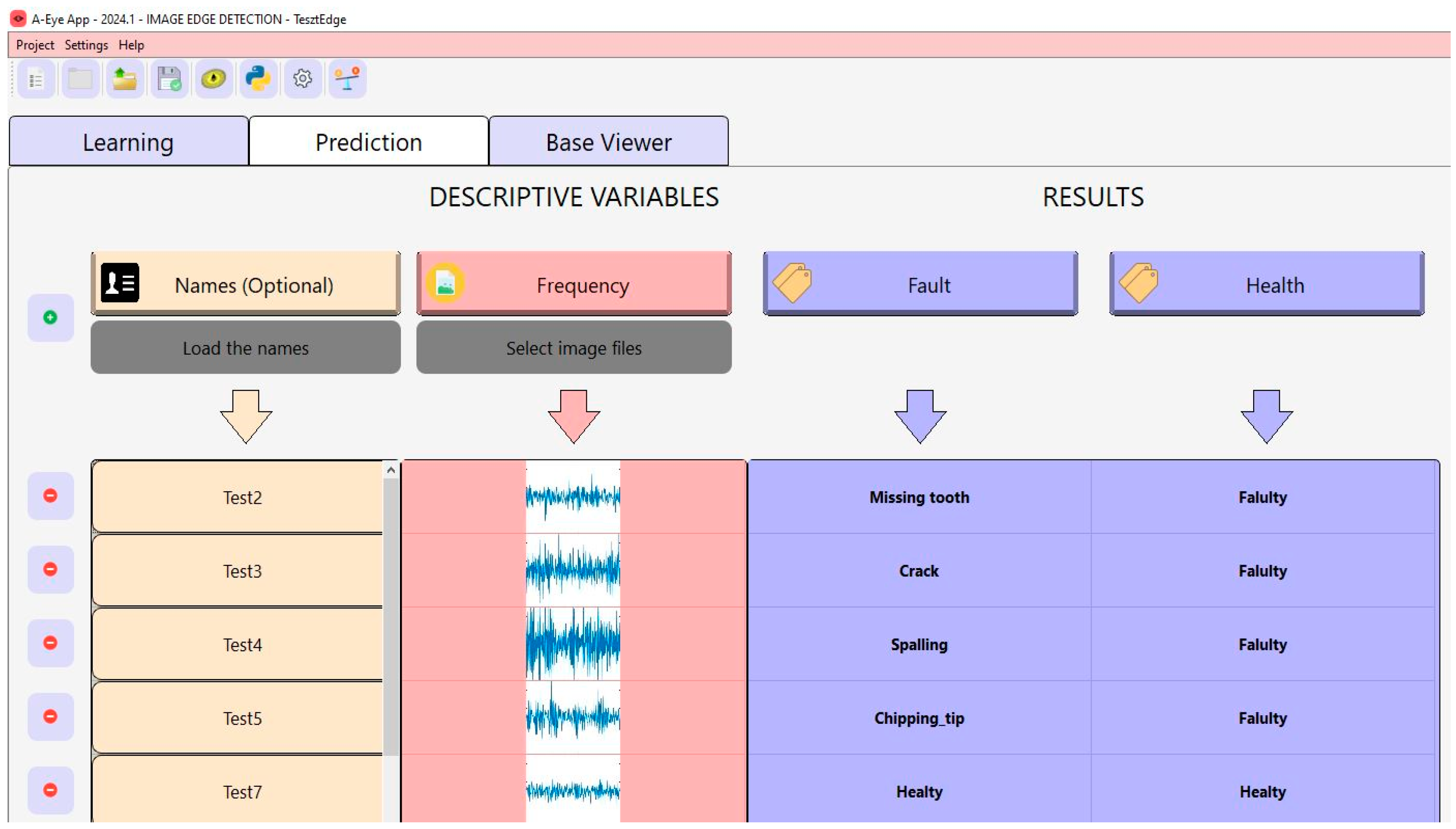

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, X.; Zuo, M.; Feng, Z. Dynamic modeling of gearbox faults: A review. Mech. Syst. Signal Process. 2018, 98, 852–876. [Google Scholar] [CrossRef]

- Praveenkumar, T.; Saimurugan, M.; Krishnakumar, P.; Ramachandran, K. Fault Diagnosis of Automobile Gearbox Based on Machine Learning Techniques. Procedia Eng. 2014, 97, 2092–2098. [Google Scholar] [CrossRef]

- Raghav, M.S.; Sharma, R.B. A Review on Fault Diagnosis and Condition Monitoring of Gearboxes by Using AE Technique. Arch. Comput. Methods Eng. 2021, 28, 2845–2859. [Google Scholar] [CrossRef]

- Morenas, J.d.L.; Moya-Fernández, F.; López-Gómez, J. The Edge Application of Machine Learning Techniques for Fault Diagnosis in Electrical Machines. Sensors 2023, 23, 2649. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Tian, K. Edge Detection Algorithm Optimization and Simulation Based on Machine Learning Method and Image Depth Information. IEEE Sens. J. 2020, 20, 11770–11777. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, Y. An Approach to Fault Diagnosis for Gearbox Based on Image Processing. Shock Vib. 2016, 1, 5898052. [Google Scholar] [CrossRef]

- Zhou, K.; Tang, J. Gear dataset. Mendeley Data 2022, V1. [Google Scholar] [CrossRef]

- Zhou, K.; Diehl, E.; Tang, J. Deep convolutional generative adversarial network with semi-supervised learning enabled physics elucidation for extended gear fault diagnosis under data limitations. Mech. Syst. Signal Process. 2023, 185, 109772. [Google Scholar] [CrossRef]

- Hexagon ODYSSEE A-Eye Index Page. Available online: https://hexagon.com (accessed on 1 July 2024).

- Ansari, M.; Kurchaniya, D.; Dixit, M. A Comprehensive Analysis of Image Edge Detection Techniques. Int. J. Multimed. Ubiquitous Eng. 2017, 12, 1–12. [Google Scholar] [CrossRef]

- You, H.; Tian, S.; Yu, L.; Ma, X.; Xing, Y.; Xin, N. A New Multiple Max-pooling Integration Module and Cross Multiscale Deconvolution Network Based on Image Semantic Segmentation. arXiv 2020, arXiv:2003.11213. [Google Scholar] [CrossRef]

- Aherwar, A. An investigation on gearbox fault detection using vibration analysis techniques: A review. Aust. J. Mech. Eng. 2012, 10, 169–184. [Google Scholar] [CrossRef]

- Jing, M.; Wu, J. Fast image interpolation using directional inverse distance weighting for real-time applications. Opt. Commun. 2013, 286, 111–116. [Google Scholar] [CrossRef]

- Dropka, N.; Holena, M.; Thieme, C.; Chou, T.-S. Development of the VGF Crystal Growth Recipe: Intelligent Solutions of Ill-Posed Inverse Problems using Images and Numerical Data. Cryst. Res. Technol. 2023, 58, 2300125. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Horváth, K.; Zelei, A. Gearbox Fault Diagnosis Using Industrial Machine Learning Techniques. Eng. Proc. 2024, 79, 36. https://doi.org/10.3390/engproc2024079036

Horváth K, Zelei A. Gearbox Fault Diagnosis Using Industrial Machine Learning Techniques. Engineering Proceedings. 2024; 79(1):36. https://doi.org/10.3390/engproc2024079036

Chicago/Turabian StyleHorváth, Krisztián, and Ambrus Zelei. 2024. "Gearbox Fault Diagnosis Using Industrial Machine Learning Techniques" Engineering Proceedings 79, no. 1: 36. https://doi.org/10.3390/engproc2024079036

APA StyleHorváth, K., & Zelei, A. (2024). Gearbox Fault Diagnosis Using Industrial Machine Learning Techniques. Engineering Proceedings, 79(1), 36. https://doi.org/10.3390/engproc2024079036