Foam Injection Molding of Poly(Lactic Acid) with Azodicarbonamide-Based Chemical Blowing Agent †

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Foam Injection Molding

2.3. Characterization

3. Results and Discussions

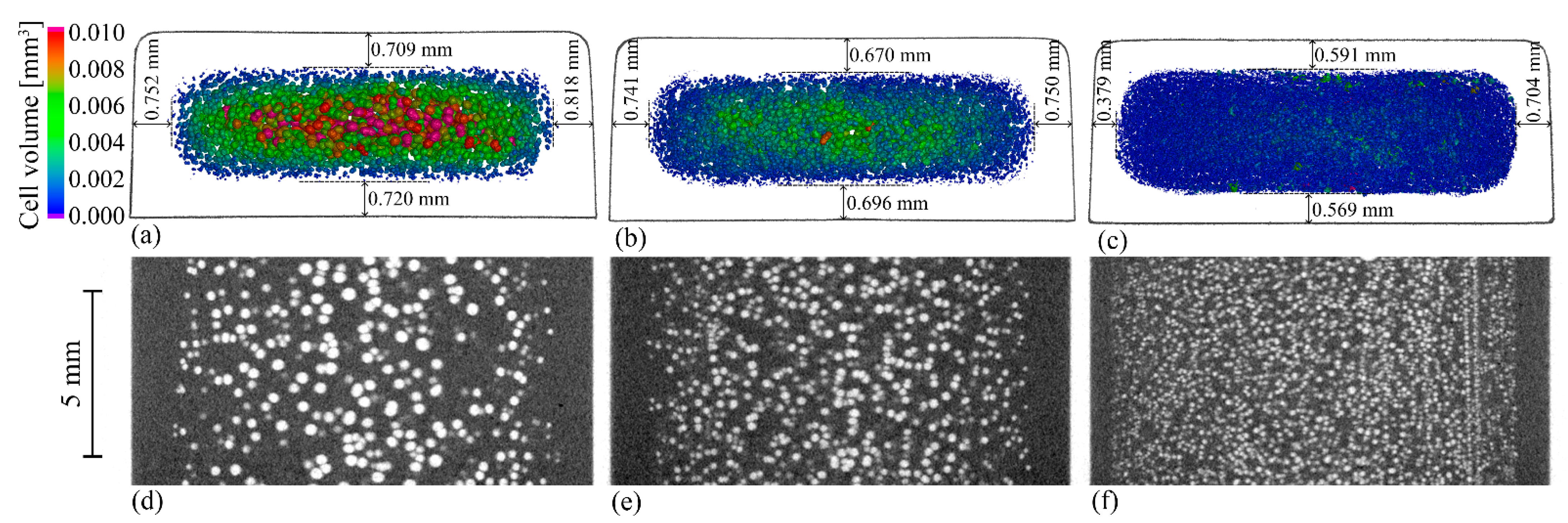

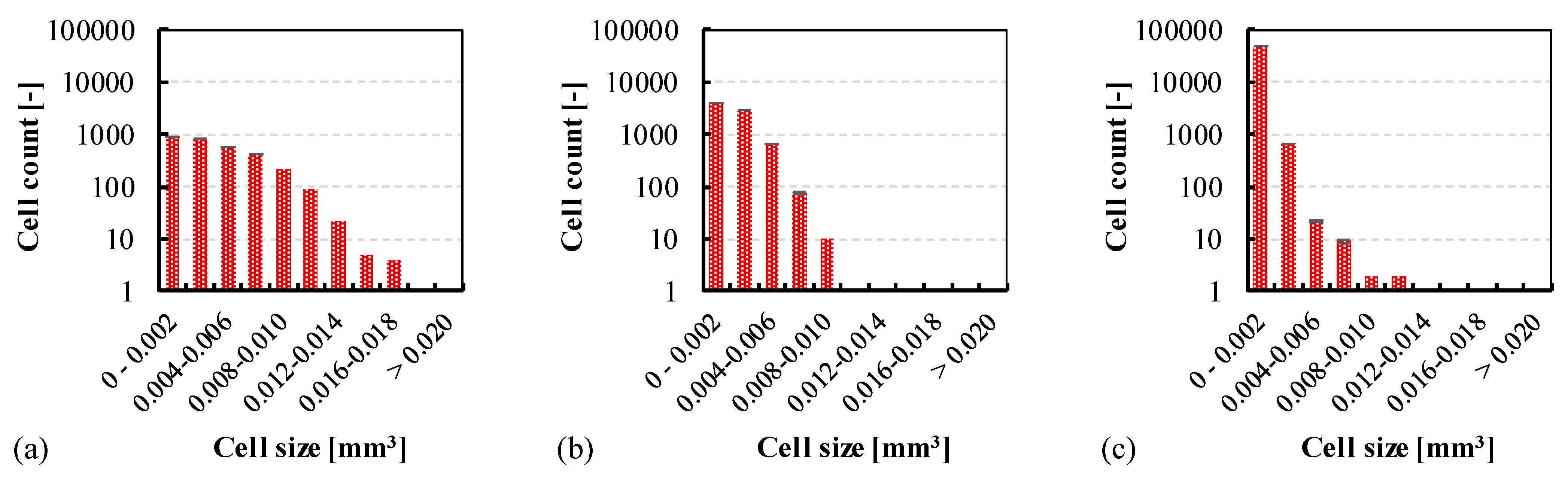

3.1. Density and Foam Structure

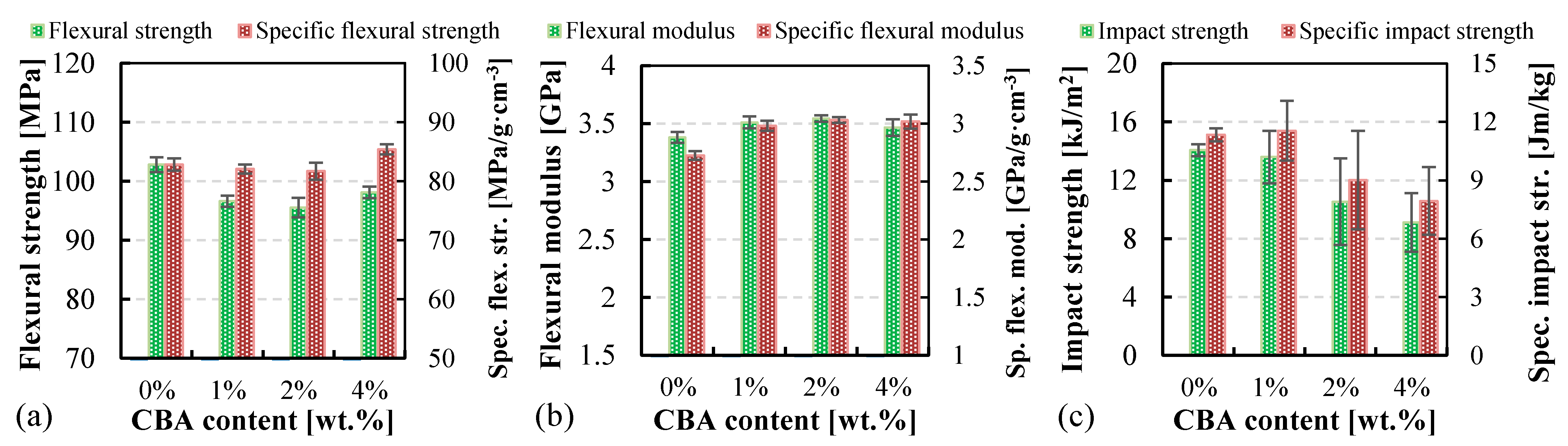

3.2. Flexural and Impact Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Simon, S.A.; Hain, J.; Osswald, T. Effect of gas pressure on the microstructure of parts foamed with the novel microcellular injection molding technology Ku-Fizz™. SPE Polym. 2021, 2, 311–324. [Google Scholar] [CrossRef]

- Joost, W.J. Reducing Vehicle Weight and Improving U.S. Energy Efficiency Using Integrated Computational Materials Engineering. JOM 2012, 64, 1032–1038. [Google Scholar] [CrossRef]

- Ranjbar, Z.; Ranjbar, B.; Foroughirad, S. Biopolymers in Automotive Industry. In Biopolymers: Recent Updates, Challenges and Opportunities; Nadda, A.K., Sharma, S., Bhat, R., Eds.; Springer International Publishing: Cham, Siwtzerland; Berlin/Heidelberg, Germany, 2022; pp. 271–288. [Google Scholar]

- Sharma, S.; Sharma, B.; Manral, A.; Bajpai, P.K.; Jain, P. Chapter 11—Biopolymers in the automotive and adhesive industries. In Biopolymers and Their Industrial Applications; Thomas, S., Gopi, S., Amalraj, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 261–280. [Google Scholar]

- Khan, I.; Neeraj, K.; Yadav, J.S.; Choudhary, M.; Chauhan, A.; Singh, T. Utilization of waste slate powder in poly(lactic acid) based composite for 3D printer filament. J. Mater. Res. Technol. 2023, 24, 703–714. [Google Scholar] [CrossRef]

- Lendvai, L.; Fekete, I. Preparation and characterization of poly(lactic acid)/boehmite alumina composites for additive manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2020, 903, 012057. [Google Scholar] [CrossRef]

- Jakab, S.K.; Singh, T.; Fekete, I.; Lendvai, L. Agricultural by-product filled poly(lactic acid) biocomposites with enhanced biodegradability: The effect of flax seed meal and rapeseed straw. Compos. C Open Access 2024, 14, 100464. [Google Scholar] [CrossRef]

- Kang, H.; Kim, D.S. A study on the crystallization and melting of PLA nanocomposites with cellulose nanocrystals by DSC. Polym. Compos. 2023, 44, 7727–7736. [Google Scholar] [CrossRef]

- Standau, T.; Zhao, C.; Murillo Castellón, S.; Bonten, C.; Altstädt, V. Chemical Modification and Foam Processing of Polylactide (PLA). Polymers 2019, 11, 306. [Google Scholar] [CrossRef] [PubMed]

- Litauszki, K.; Kmetty, Á. Characterization of chemically foamed poly(lactic acid). IOP Conf. Ser. Mater. Sci. Eng. 2020, 903, 012018. [Google Scholar] [CrossRef]

- Jakab, S.K.; Dogossy, G. Effect of Injection Molding Parameters on the Chemical Foaming of Acrylonitrile Butadiene Styrene (ABS) Using Breathing Mold Technology. Chem. Eng. Trans. 2023, 107, 247–252. [Google Scholar]

- Szabó, V.A.; Dogossy, G. Structure and properties of closed-cell foam prepared from rPET. IOP Conf. Ser. Mater. Sci. Eng. 2018, 426, 012043. [Google Scholar] [CrossRef]

- ISO 527-2; Plastics—Determination of Tensile Properties, Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- ISO 1183-1; Plastics—Methods for Determining the Density of Non-Cellular Plastics, Part 1: Immersion Method, Liquid Pycnometer Method and Titration Method. ISO: Geneva, Switzerland, 2019.

- ISO 178; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2019.

- ISO 179; Plastics—Determination of Charpy Impact Properties. ISO: Geneva, Switzerland, 2023.

| CBA content [wt.%] | 0 | 1 | 2 | 4 |

| Density [g/cm3] | 1.24 | 1.18 | 1.17 | 1.15 |

| Density reduction [%] | 0 | 5.1 | 5.8 | 7.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lendvai, L.; Dogossy, G.; Jakab, S.K.; Fekete, I. Foam Injection Molding of Poly(Lactic Acid) with Azodicarbonamide-Based Chemical Blowing Agent. Eng. Proc. 2024, 79, 44. https://doi.org/10.3390/engproc2024079044

Lendvai L, Dogossy G, Jakab SK, Fekete I. Foam Injection Molding of Poly(Lactic Acid) with Azodicarbonamide-Based Chemical Blowing Agent. Engineering Proceedings. 2024; 79(1):44. https://doi.org/10.3390/engproc2024079044

Chicago/Turabian StyleLendvai, László, Gábor Dogossy, Sándor Kálmán Jakab, and Imre Fekete. 2024. "Foam Injection Molding of Poly(Lactic Acid) with Azodicarbonamide-Based Chemical Blowing Agent" Engineering Proceedings 79, no. 1: 44. https://doi.org/10.3390/engproc2024079044

APA StyleLendvai, L., Dogossy, G., Jakab, S. K., & Fekete, I. (2024). Foam Injection Molding of Poly(Lactic Acid) with Azodicarbonamide-Based Chemical Blowing Agent. Engineering Proceedings, 79(1), 44. https://doi.org/10.3390/engproc2024079044