Abstract

The activity of moving LPG gas cylinders at PT XYZ is carried out manually The unloading of 3 kg LPG gas cylinders from the truck to the floor occurs repeatedly. Workers must bend down when moving the cylinder, and a twisting body, so it can cause injuries such as musculoskeletal disorders (MSDs). This activity involved four workers, but those observed were workers 2 and 4 who were tasked with unloading gas cylinders from the truck. This research aims to analyze the MSDs of worker complaints using the Nordic Body Map (NBM) questionnaire, determine the level of risk using the National Institute for Occupational Safety and Health (NIOSH) Multi-Task Method, and provide suggestions for improvement. The research results show that the NBM values for workers 2 and 4 are 59 and 61, respectively, in the medium category, which means they require immediate corrective action. Meanwhile, in the CLI (Composite Lifting Index) origin for the second worker, all gas cylinder stacks are >3, whereas in the CLI destination, all stacks are >2. During the CLI origin and destination of the fourth worker, all stacks have a value of >3, which means the risk of injury is high..Recommendations for improvement are given by reducing the horizontal lifting distance, reducing asymmetrical angles, and using material handling equipment such as the hand trolley.

1. Introduction

Despite the prevailing trend towards the increased automation and digitalization of industrial processes, manual material handling (MMH) remains significant in numerous industries. MMH activities are necessary in various sectors of work. This job has the potential to cause musculoskeletal disorders (MSDs); therefore, evaluation is needed to reduce this risk [1]. MMH equipment can be used as one of the alternatives to minimize those risks and is an important component in any industry [2]. Risk occurrences in the material handling tasks are significantly associated with work-related musculoskeletal ailments. Nonetheless, numerous issues have to be addressed in the precise identification of risk occurrences [3]. Excessive workloads and improper lifting activities, including unnatural postures or stances at work can lead to stress and negatively impact workers’ health, spinal injuries, or illnesses in workers [4,5].

On the other hand, MMH causes injuries because it often requires workers to perform tasks such as pushing, pulling, lifting, and lowering. These activities cause muscle tension and awkward postures, putting workers at risk of musculoskeletal disorders (MSDs) [6,7]. In ergonomics, musculoskeletal disorders refer to disorders related to the musculoskeletal system, which occur when muscles are subjected to prolonged loads over an extended period [8,9]. Common complaints among industrial workers include pain in the wrists, elbows, neck, back, and legs [10].

The National Institute for Occupational Safety and Health (NIOSH) developed the Revised NIOSH Lifting Equation (RNLE) to measure the Recommended Weight Limit (RWL) and the Lifting Index (LI), which are used to estimate the physical demands of manual material handling activities [11]. This mathematical model, developed by the NIOSH, helps identify and assess lifting activities that pose a risk of MSDs for workers [6]. Waters et al. [12,13] explained that, in manual material handling tasks involving repetitive lifting, it is essential to consider the risk of injury by applying ergonomic principles, such as the Composite Lifting Index (CLI) provided by the Revised NIOSH Lifting Equation. The CLI provides information on the risk associated with multi-task lifting jobs.

At PT XYZ, workers handle LPG gas cylinders manually. There are four workers responsible for manual material handling, and the transfer of 3 kg LPG gas cylinders from the truck is performed by two workers at a time. This transfer occurs repeatedly across 13–15 different LPG stations in a day. The conditions for handling the 3 kg LPG gas cylinders are relatively similar at each station, with the cylinders unloaded from the side or rear of the truck onto the flat ground, stacking them vertically in four layers. The frequency of lifting 3 kg LPG gas cylinders from the truck to the ground ranges from 30 to 100 cylinders per station. Each truck carries 560 cylinders, and the total number of cylinders transferred in a day is 1120. The activity is shared between two workers: Worker 1 positions the cylinders within reach inside the truck, while Worker 2 lowers the cylinders from the truck to the ground at the LPG station. Each LPG gas cylinder weighs 8 kg, with the empty cylinder weighing 5 kg and the LPG content weighing 3 kg. Lifting these cylinders manually, if performed improperly, can lead to injuries.

The workers’ posture during this task involves excessive bending of the spine and twisting the body while lifting and lowering the cylinders, which can lead to injuries such as musculoskeletal disorders (MSDs). When body parts move further from their natural or central gravity position, such as raised arms, hunched backs, or heads tilted upwards, the risk of musculoskeletal complaints increases [14]. According to the 2021 World Health Organization (WHO) report, musculoskeletal disorders (MSDs) are the leading cause of disability worldwide, with lower back pain being the primary contributor.

Given these issues, it is necessary to analyze the musculoskeletal complaints experienced by workers using the Nordic Body Map method. The results from the Nordic Body Map questionnaire can serve as a basis for improving work postures to reduce the risk of MSDs, which can affect work productivity and make the work environment more comfortable. Additionally, an evaluation of the load should be conducted to determine a safe weight limit for workers and assess the level of risk involved. Recommendations for improvement can then be made to mitigate the risk of musculoskeletal disorders (MSDs) using the NIOSH (National Institute of Occupational Safety and Health) recommended method. The Revised NIOSH Lifting Equation (RNLE) was developed to identify and evaluate risk factors associated with manual material handling activities based on lifting, in order to reduce the potential for MSDs and lower back pain (LBP) The Multi-Task method is used in this case study because it involves repetitive lifting with varying vertical and horizontal lifting distances [15].

2. Methods

2.1. Research Object

The object of this research involves workers from PT XYZ who manually unload 3 kg filled LPG cylinders from the truck stacks and place them in piles on the floor at the LPG station.

2.2. Research Stages

The research stages begin with field studies, reviews of the literature, problem identification, problem formulation, and defining the research objectives. The next stage is data collection, which uses methods such as questionnaires, observation, and interviews. Data collection employs the Nordic Body Map questionnaire, which was distributed to workers who unload LPG cylinders onto the floor at the LPG station before and after their work shift. This is performed to assess any complaints or discomfort in workers’ bodies both before and after working, to ensure more valid results. Respondents are asked to mark (√) the 28 body segments that correspond to the discomfort felt during their work activity. The 28 body segments are directly shown to the respondents to ensure clear boundaries and prevent mistakes in completing the questionnaire. The Likert scale used in the questionnaire is as follows [16]:

- No Pain—when the respondent does not feel any discomfort or pain in a particular body part (score 1).

- Mild Pain—when the respondent feels slight discomfort or pain in a particular body part (score 2).

- Moderate Pain—when the respondent feels discomfort in a particular body part (score 3).

- Severe Pain—when the respondent feels significant discomfort in a particular body part (score 4).

Data collection through observation was conducted by observing the research object to gather information regarding the weight of the load being lifted, horizontal distance, vertical distance, vertical displacement distance, asymmetric angle, coupling, the frequency of lifting and lowering, and the duration of lifting and lowering. Interviews are conducted with workers to gather information about the number of 3 kg filled LPG cylinders unloaded and the history of any illnesses the workers have suffered.

The next stage is processing the Nordic Body Map questionnaire data, starting by calculating the score for each respondent. Then, the risk level was classified based on the individual’s total score to determine whether corrective actions are needed. The risk level classification can be found in Table 1.

Table 1.

Risk level classification based on total individual score.

Data processing using the NIOSH Multi-Task method is carried out with the following steps [15]:

- Calculating multiplier values:

- Horizontal Multiplier (HM) = 25/HThe horizontal location (H) is measured from the midpoint of the line connecting the inner ankle bones to the point projected on the floor directly below the midpoint of the hand grasp.

- Vertical Multiplier (VM) = 1 − (0.003 |V − 75|)The vertical location (V) is measured vertically from the floor to the midpoint between the hand grasp.

- Distance Multiplier (DM) = 0.82 + 4.5/DThe vertical travel distance (D) is defined as the vertical distance that the hands travel between the origin and destination of the lift.

- Asymmetric Multiplier (AM) = 1–0.0032 AThe asymmetric angle is the measure of how far the object is moved from the front of the worker’s body at the start or end of the lift, measured in degrees.

- Frequency Multiplier (FM)The frequency multiplier values can be found in Table 2. The literature review was conducted to gather relevant information or references related to the research topic, which then serves as the basis for problem solving. The sources of data in the literature review come from journals, books, and previous research reports.

Table 2. Frequency Multiplier (FM).

Table 2. Frequency Multiplier (FM). - Coupling Multiplier (CM), where the type of coupling is determined by observing the hand grip on the lifted load to assess comfort and ease of grip. The coupling multipliers are shown in Table 3.

Table 3. Coupling Multiplier.

Table 3. Coupling Multiplier.

- Calculate the Frequency Independent Recommended Weight Limit (FIRWL) using the formula FIRWL = LC × HM × VM × DM × AM × CM.

- Calculate the Single-Task Recommended Weight Limit (STRWL) using the formula STRWL = FIRWL × FM.

- Calculate the Frequency Independent Lifting Index (FILI) using the formula FILI = L/FIRWL.

- Calculate the Single-Task Lifting Index (STLI) using the formula STLI = L/STRWL.

- Calculate the Composite Lifting Index (CLI) for the entire task using the formula CLI = STLI₁ + ∑ΔLI.

where

3. Results and Discussion

3.1. Nordic Body Map Analysis

The processing of the Nordic Body Map questionnaire results shows that, before performing manual material handling tasks, none of the four workers experienced any pain or discomfort in any part of their bodies. Each worker had a total score of 28, which falls into the low-risk category. Interviews conducted regarding workers’ medical histories confirmed that none of the four workers had previous health issues in the body parts identified in the Nordic Body Map questionnaire.

After performing manual material handling tasks, the Nordic Body Map questionnaire results showed that Worker 1 had a total score of 55, Worker 2 scored 59, Worker 3 scored 58, and Worker 4 scored 61. The final scores for all four workers fall into the moderate-risk category, as they are within the score range of 50–70, suggesting that corrective actions may soon be necessary. The workers reported musculoskeletal disorders with varying levels of discomfort, from “no pain” to “mild pain” and “pain.” None of the workers reported experiencing “severe pain.” A summary of the mild and painful discomfort levels, along with their percentages, is provided in Table 4.

Table 4.

Recapitulation and percentage of worker complaints.

The pain complaints experienced by workers, as shown in Table 4, include the highest percentage of complaints at 100%, specifically in the back and waist areas. This is primarily due to the workers’ posture when lifting 3 kg LPG cylinders, which often involves bending forward and twisting, leading to muscle strain and musculoskeletal discomfort. According to Evadariyanto and Dwiyanti [10], the waist is a vulnerable area of the body because it acts as a pivotal point that bears the greatest pressure on the spinal structure. The amount of pressure exerted on the body’s pivot point is influenced by the weight being lifted and the distance from the body when the load is lifted.

Additionally, there were 100% pain complaints in the left and right wrists, as well as in both hands. The next highest pain complaints, at 50%, were in the upper left arm, upper right arm, left elbow, right elbow, lower left arm, lower right arm, left knee, and right knee. Furthermore, 25% of the workers reported pain in the upper and lower neck. These complaints are linked to the repetitive and monotonous task of moving the 3 kg LPG cylinders using both hands while standing and with the neck bent. Pain in the left and right elbows may result from excessive elbow flexion while carrying the load. Complaints in the lower arm are associated with tension in the upper arm muscles, which directly impact the lower arm muscles [17]. Many studies show that workers experiencing significant ergonomic problems, such as musculoskeletal disorders, during manual handling activities—including lifting, lowering, pushing, pulling [18]. Lower neck pain can be caused by simultaneous pain in the back, as the lower neck is directly connected to the back [17]. Meanwhile, the highest percentage of mild pain complaints, at 100%, was in the left and right ankles. This is also likely due to the workers’ posture while lifting, which involves bending and standing. Prolonged standing during work can cause leg pain, foot swelling, varicose veins, muscle fatigue, lower back pain, and stiffness in the neck and shoulders. These issues arise from non-ergonomic workstations, causing problems such as excessive bending, which leads to back pain. Standing for extended periods makes muscles stiff, reducing blood supply to the muscles and resulting in fatigue and pain in certain body parts.

A study conducted by Evadariyanto and Dwiyanti [10] found a strong correlation between work posture and musculoskeletal disorders (MSDs). Additionally, Surya’s [14] research on musculoskeletal disorders in manual material handling activities for palm oil workers identified mild pain complaints in body parts supporting the process, such as the calves, ankles, and elbows. The pain category, however, mainly affected body parts directly involved in the work, such as the hands, back, shoulders, and neck.

3.2. NIOSH Lifting Equation Analysis

The results of the Composite Lifting Index (CLI) calculated for Worker 2 during the task of moving 30 filled 3 kg LPG cylinders showed a CLI value > 3 for the origin condition from stack levels 1 to 8. At the destination, the CLI value exceeded three for stack levels 2, 3, 4, 6, and 8, while stack levels 1, 5, and 7 had a CLI value > 2. For Worker 4, who moved 80 filled LPG cylinders, the CLI value at the origin condition for stacks 1 through 20 was >3. At the destination, the CLI exceeded three for 19 stack levels, with only stack 18 having a CLI value > 2. A CLI value greater than one indicates that the task of moving filled 3 kg LPG cylinders from the truck to the LPG depot floor poses a risk of injury to Workers 2 and 4. A CLI value greater than three indicates a high risk of injury. Worker 2’s highest risk at the origin condition was at stack level 7, with a CLI of 5.42. At the destination, the highest risk was at stack level 3, with a CLI of 3.34. For Worker 4, the highest risk at the origin condition was at stack level 10, with a CLI of 4.74, while the highest risk at the destination was at stack level 3, with a CLI of 3.42. The calculation was based on the number of filled LPG cylinders unloaded at the depot, with varying stack heights, as there is no minimum number of LPG cylinders or a set number per pallet.

Lifting or lowering tasks with a Lifting Index (LI) > 1.0 increases the risk of lower back pain. Therefore, lifting tasks should be designed to achieve an LI ≤ 1.0 . Experts agree that the majority of workers engaged in heavy lifting activities are at high risk when the LI is ≥3.0 [13]. This is due to factors such as excessive horizontal distance, large asymmetric angles, the non-standard lifting of 3 kg LPG cylinders, high lifting frequency, and poor ergonomic conditions in the work environment or facilities. The contribution of CLI value to musculoskeletal complaints is 43.4% and the rest is caused by other factors. Work-related musculoskeletal disorders (WMSDs) are primarily induced by manual handling, strenuous physical labour, uncomfortable postures, repetitive upper-limb movements or exertions, and vibrations [19]. While the direction of a positive relationship means that the higher the CLI value, the greater the risk of musculoskeletal complaints. Composite Lifting Index (CLI) obtained by measuring the Recommended Weight Limit (RWL) has a significant relationship to musculoskeletal complaints of workers. The work requires improvement in the parameters that cause high CLI. It is stated by [20] that CLI, which is a component of the NIOSH Ergonomic index specified in ISO 11228-1, is able to analyze biomechanical risks related to manual lifting tasks.

There is currently no standardization for the work process, such as the standardized time or target time for unloading LPG cylinders in a day. The order in which manual tasks are performed to complete the work target also varies. For example, the sequence of moving filled 3 kg LPG cylinders from truck stacks consisting of five levels differs, with no set standard for the order of lifting. Therefore, it is essential to propose improvements to reduce the potential for worker injury. These improvements should address both the manual material handling process and lifting variables identified by the NIOSH, which can be modified to reduce risks.

3.3. Proposed Improvements

The proposed improvements focus on adjustments to the hand action at both the origin and destination points. According to Waters et al. [13], improvements can be made by bringing the load closer to the worker to increase the Horizontal Multiplier (HM) and reducing the rotation angle to improve the Asymmetry Multiplier (AM) by moving the origin and destination points closer or farther apart. This is because variables that can be improved in the LPG cylinder handling process include the horizontal distance and the asymmetric angle.

Improvements can be achieved by carrying the load closer to the worker or reducing the horizontal distance at both the origin and destination points. The smaller the horizontal distance, the higher the HM value. Additionally, improving the horizontal distance can help reduce the lifting asymmetry, thus increasing the AM value. A simulation of these improvements to the hand actions at both the origin and destination points is shown in Figure 1.

Figure 1.

Simulation of improvements in hand action at origin and destination.

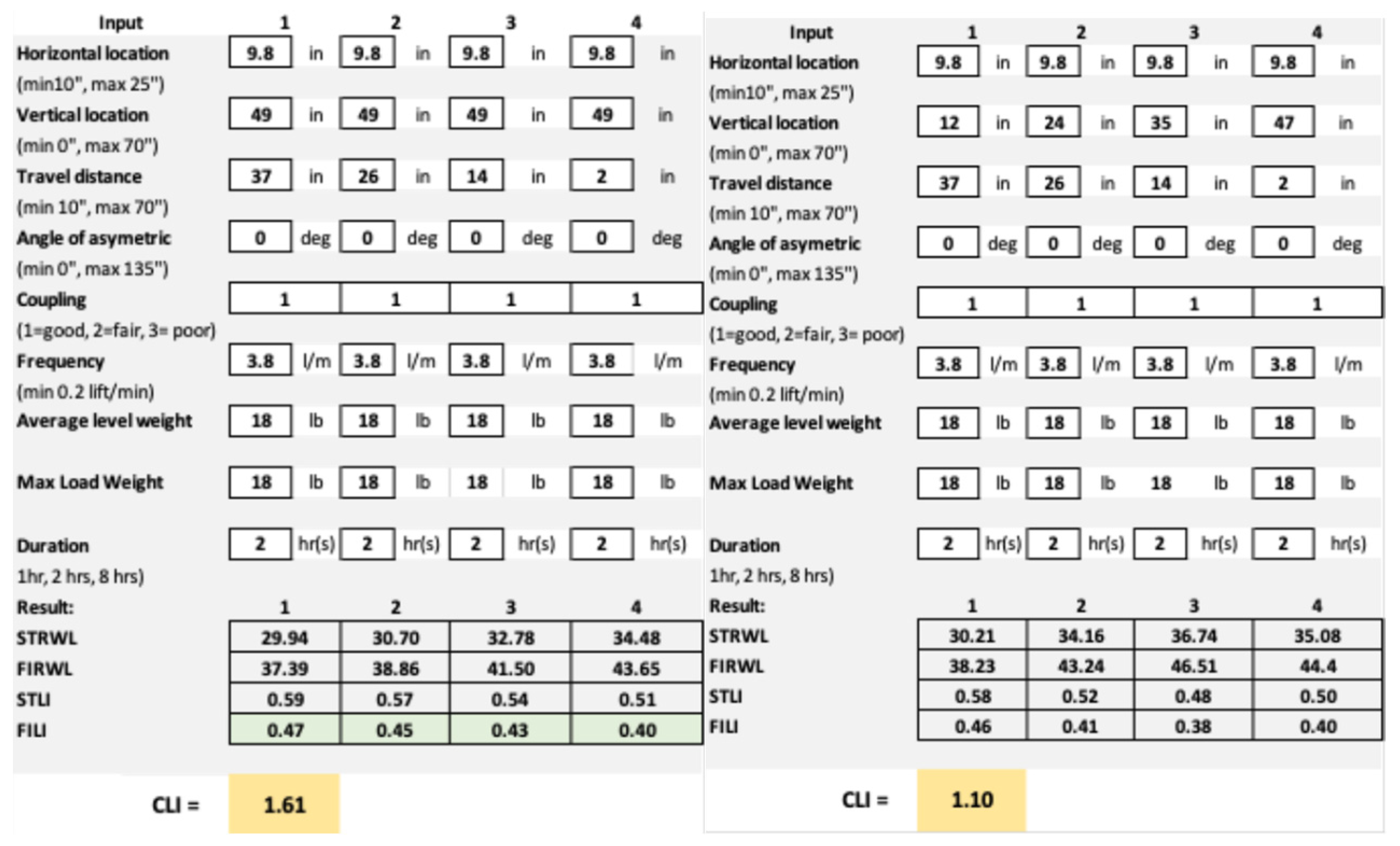

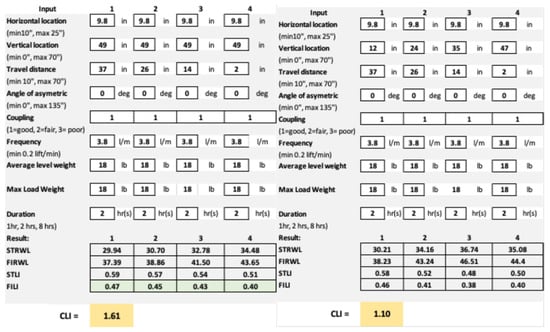

The following presents the NIOSH variable data, data processing at the origin and destination points, and the Composite Lifting Index values during the LPG cylinder handling activity with the simulated improvements, as shown in Table 5 and Figure 2.

Table 5.

NIOSH variable data for the improvement simulation.

Figure 2.

Composite lifting index at origin and destination improvement simulation.

Based on the calculation of the Composite Lifting Index (CLI) values shown in Figure 2, both at the origin and destination points, the improvement simulation demonstrates a reduction in the CLI compared to the pre-improvement values. This reduction indicates a lower risk of injury for workers. However, the post-improvement CLI values still remain greater than one, primarily due to the high vertical stacking of LPG cylinders at the origin point and the low stacking at the destination, as well as the high frequency of lifting. The proposed improvements were communicated to the company and have been implemented by workers at PT XYZ. However, one worker has yet to adopt the improvements, likely due to a lack of awareness regarding the importance of proper working posture for health, which can affect productivity. There is a need for clear, written policies from the company that are easy for workers to understand, along with providing workers with the knowledge of safe working postures based on ergonomic principles through regular training and awareness programs. This would enable workers to perform manual material handling tasks without the risk of injury.

Additional proposed improvements include enhancing manual handling activities through the use of material handling equipment, such as hand trolleys. The solution to improper manual handling techniques, which can result in injury, is to redesign the manual handling process and replace it with mechanical lifting techniques, such as using a trolley. The recommended hand trolley is shown in Figure 3.

Figure 3.

Material handling equipment.

The use of material handling equipment, such as a hand trolley, is expected to ease manual material handling tasks and reduce the risk of spinal injuries for workers when moving LPG cylinders. This is because workers would no longer need to manually lift the LPG cylinders or bend over to place them from the truck onto the ground. With the trolley, workers can move a stack of LPG cylinders all at once from the truck.

The trolley is equipped with wheels for mobility and a handle for workers to grip and push. To operate the trolley, workers position the bottom part of the trolley under the lowest LPG cylinder in the stack. Once the trolley supports the stack, it is tilted backward, allowing the worker to push the trolley off the truck using a ramp or inclined surface placed beside the truck. Workers can push the trolley, carrying up to five stacked LPG cylinders, to the warehouse or storage area at the LPG depot. To unload the stacked LPG cylinders from the trolley, the worker positions the trolley upright at a 90° angle and pulls it back until the bottom cylinder touches the ground. Using the hand trolley provides a safer working posture when moving LPG cylinders and completes the task in less time. The trolley and the ramp can be stored in the truck bed, making it easy to transport and use at various LPG depots. This proposed improvement was discussed with the company, which responded positively. The company is currently reviewing the budget for the purchase and use of hand trolleys for this activity.

4. Conclusions

4.1. Conclusions

Based on the data analysis, it can be concluded that the results from the Nordic Body Map (NBM) questionnaire before performing manual material handling show that none of the four workers experienced any pain or discomfort in any part of their body. However, after performing the manual material handling tasks, the NBM questionnaire results revealed total scores of 55 for Worker 1, 59 for Worker 2, 58 for Worker 3, and 61 for Worker 4. These final scores fall within the moderate category (score range 50–70), indicating that immediate corrective action may be necessary. The workers reported pain in the back, waist, left wrist, right wrist, right hand, and left hand.

The Composite Lifting Index (CLI) value for Worker 2, who handled 30 filled 3 kg LPG cylinders, was greater than three for stacks 1 through 8 at the origin point, while, at the destination point, CLI values were greater than three for stacks 2, 3, 4, 6, and 8, and greater than two for stacks 1, 5, and 7. For Worker 4, who handled 80 filled 3 kg LPG cylinders, CLI values were greater than three for stacks 1 through 20 at the origin, while, at the destination point, CLI values were greater than three for 19 stacks and greater than two for stack 18. A CLI value greater than one indicates a risk of injury for workers handling the LPG cylinders, while a CLI value greater than three signifies a high risk of injury.

Proposed improvements include reducing the horizontal distance and asymmetry angle during lifting at both the origin and destination points. The simulation results show a decrease in risk after these adjustments, indicating a reduction in the risk of injury for workers. Additionally, improvements in manual handling activities can be achieved through the use of material handling equipment, such as a hand trolley.

4.2. Recommendations

Based on this research, several recommendations are offered. The company should implement standardized work procedures to improve productivity and reduce the risk of injury for workers. Workers should adopt the proposed improvements to minimize the risk of serious injury. The company is also advised to provide material handling equipment, such as trolleys, to assist workers in moving LPG cylinders, thereby further reducing the risk of injury.

Author Contributions

Conceptualization, E.M. and N.D.H., methodology: N.D.H., M.A. and M.D.; software by M.T.N. and S.N., validation by F.W., M.F. and D.S.R., formal analysis, investigation and resources by N.D.H., E.M., writing and preparation of original draft by E.M. and N.D.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Research and Innovation Institute, Muhammadiyah University of Surakarta. Grant Number [1185] and APC are funded by the Scientific Publishing and Publication Institute, Muhammadiyah University of Surakarta [Sem-3988].

Institutional Review Board Statement

In this study, we measured dan simulate distance parameters while the subjects were working. Do not measure on human body directly.

Informed Consent Statement

Written consent was obtained from the company to publish this paper.

Data Availability Statement

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to their containing information that could compromise the privacy of research participants.

Acknowledgments

The authors would like to express their gratitude to the Faculty of Engineering and Research and Innovation Institute for their support of this research through the Hibah Integrasi Tridharma (HIT) scheme. This support has been instrumental in providing the necessary resources and encouragement to conduct this study successfully. We are thankful for the opportunity to contribute to the university’s dedication to advancing research, education, and community engagement.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Glock, C.H.; Grosse, E.H.; Neumann, W.P.; Feldman, A. Assistive devices for manual materials handling in warehouses: A systematic literature review. Int. J. Prod. Res. 2021, 59, 3446–3469. [Google Scholar] [CrossRef]

- Amjath, M.; Kerbache, L.; Elomri, A.; Smith, J.M.G. Queueing network models for the analysis and optimisation of material handling systems: A systematic literature review. Flex. Serv. Manuf. J. 2024, 36, 668–709. [Google Scholar] [CrossRef]

- Duan, P.; Zhou, J.; Tao, S. Risk events recognition using smartphone and machine learning in construction workers’ material handling tasks. Eng. Constr. Archit. Manag. 2023, 30, 3562–3582. [Google Scholar]

- Purbasari, A.; Purnomo, A.J. Penilaian Beban Fisik Pada Proses Assembly Manual Menggunakan Metode Fisiologis. Sigma Tek. 2019, 2, 123. [Google Scholar] [CrossRef]

- Widodo, L.; Daywin, F.J.; Nadya, M. Ergonomic risk and work load analysis on material handling of PT. XYZ. IOP Conf. Ser. Mater. Sci. Eng. 2019, 528, 012030. [Google Scholar] [CrossRef]

- Peter, A. Ergonomic Analysis of Manual Material Handling of Freights in a Trailer for Shipping; University of Wisconsin-Stout: Menomonie, WI, USA, 2019; pp. 1–60. [Google Scholar]

- Djunaidi, M.; Ramadhani, Q.A.; Anis, M.; Munawir, H. Analysis of Employee Work Posture and Physical Workload Using del Riesgo Individual Evalution and Cardio-Vascular Load Methods. SHS Web Conf. 2024, 189, 01032. [Google Scholar] [CrossRef]

- Pratiwi, I.; Huda Al Addin, M.; Djunaidi, M.; Fitriadi, R. Posture Analysis of Workers in Bare Core Production Workers using the Index and Job Strain Method Assessment of Repetitive Task Tool. TEST Eng. Manag. 2019, 2191–2200. [Google Scholar]

- Fahmi, A.A.; Putri, A.S.; Dwiyanto, R. Improvement of working posture in the metal casting industry to prevent musculoskeletal disorders. J. Eng. Appl. Technol. 2023, 4, 21–32. [Google Scholar] [CrossRef]

- Evadarianto, N. Postur Kerja Dengan Keluhan Musculoskeletal Disorders Pada Pekerja Manual Handlingbagian Rolling Mill. Indones. J. Occup. Saf. Heal. 2017, 6, 97. [Google Scholar] [CrossRef]

- Putri, N.T.; Zadry, H.R.; Mahata, M.E.; Amrina, E.; Yuliandra, B.; Humaida, N. Ergonomics Evaluation of Manual Material Handling Activities in the Section of Feeding Laying Hens at Poultry Farm. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1003, 012074. [Google Scholar] [CrossRef]

- Waters, T.R.; Putz-Anderson, V.; Garg, A.; Fine, L.J. Revised NIOSH equation for the design and evaluation of manual lifting tasks. Ergonomics 1993, 36, 749–776. [Google Scholar] [CrossRef] [PubMed]

- Waters, T.R.; Putz-Anderson, V.; Garg, A. Applications Manual for the Revised NIOSH Lifting Equation. Available online: https://www.cdc.gov/niosh/docs/94-110/ (accessed on 21 January 2025).

- Surya, R.Z. Pemetaan Potensi Muskuloskletal Disorders (MSDs) pada Aktivitas Manual Material Handling (MMH) Kelapa Sawit. JIEMS (J. Ind. Eng. Manag. Syst.) 2017, 10, 25–33. [Google Scholar] [CrossRef][Green Version]

- Prassetiyo, H. Analisis Sikap Kerja Operator Pengisian Botol Lithos dengan Mengganakan Metode Rekomendasi Weight Limit (RWL) (Studi Kasus di PT. Pertamina Unit Produksi Cilacap). Semin. Nas. Mesin dan Ind. 2010, 1–9. [Google Scholar]

- Wijaya, K. Identifikasi Risiko Ergonomi Dengan Metode Nordic Body Map Terhadap Pekerja Konveksi Sablon Baju. Semin. dan Konf. Nas. IDEC 2019, 1, 1–9. [Google Scholar]

- Affa, M.N.; Putra, B.I. Analisis Manual Material Handling Pada Pekerja Borongan Di PT. JC dengan Metode NBM dan RWL. PROZIMA (Product. Optim. Manuf. Syst. Eng.) 2017, 1, 22–32. [Google Scholar] [CrossRef]

- Rajendran, M.; Sajeev, A.; Shanmugavel, R.; Rajpradeesh, T. Ergonomic evaluation of workers during manual material handling. Mater. Today Proc. 2021, 46, 7770–7776. [Google Scholar] [CrossRef]

- Colombini, D.; Occhipinti, E.; Fox, R.R.; Alvarez-Casado, E.; Michaloski, A.O. The Multitask General Exposure Index (MultiGEI): An original model for analysing biomechanical risk factors in multitask jobs featuring weekly, monthly and annual macro-cycles. Int. J. Ind. Ergon. 2021, 86, 103212. [Google Scholar] [CrossRef]

- Varrecchia, T.; Motta, F.; Chini, G.; Galli, M.; Ranavolo, A. Enhanced Biomechanical Risk Assessment in Manual Lifting: Comparing Inertial Measurement Units with Optoelectronic Systems for Composite Lifting Index Calculation. Appl. Sci. 2024, 14, 11292. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).