Investigating the Friction Coefficient of Titanium Bolts with Vegetable Oils as Lubricants †

Abstract

:1. Introduction

2. Methodology

2.1. Materials

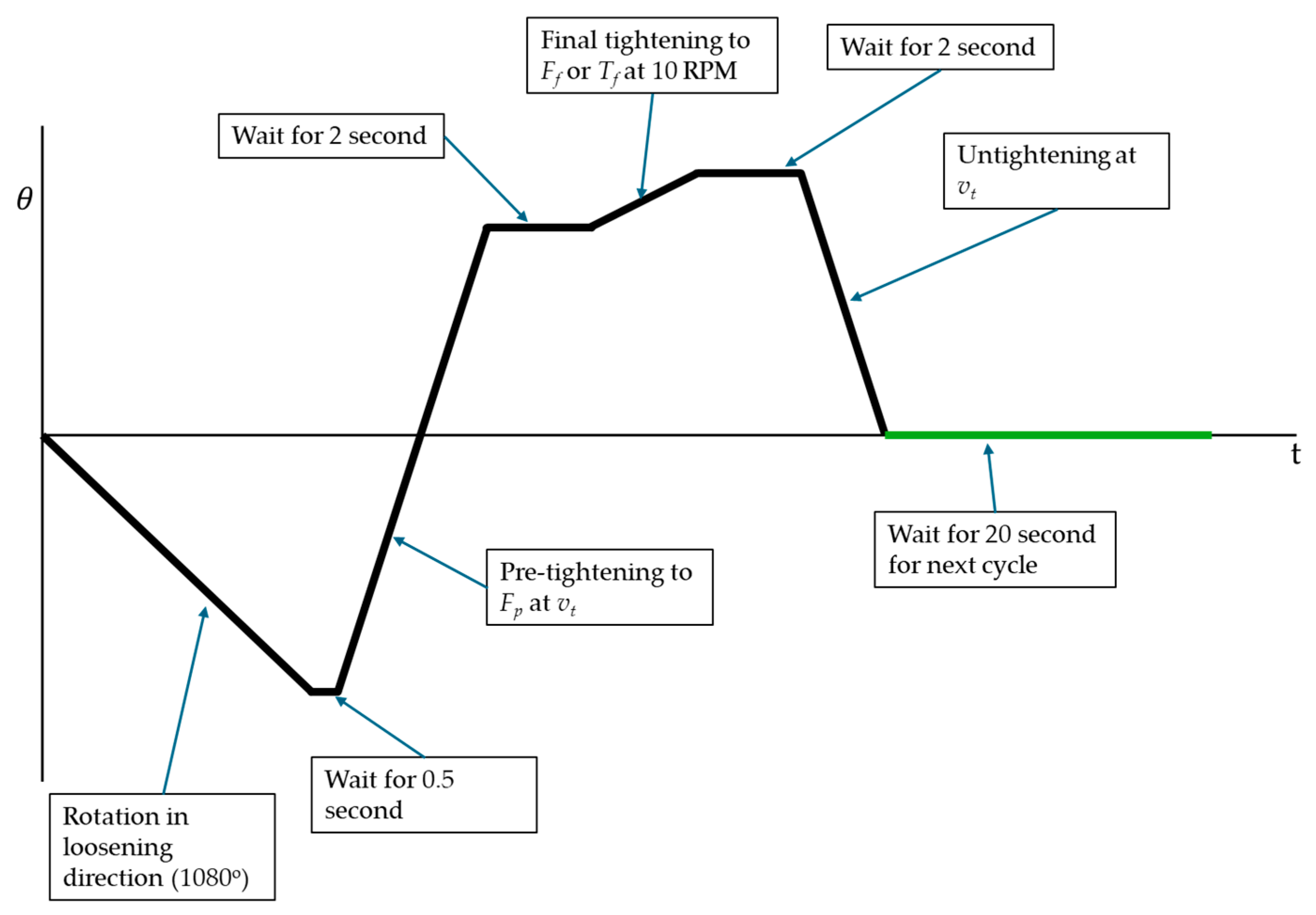

2.2. Tribological Tests

2.3. Design of the Experiments

3. Results and Discussion

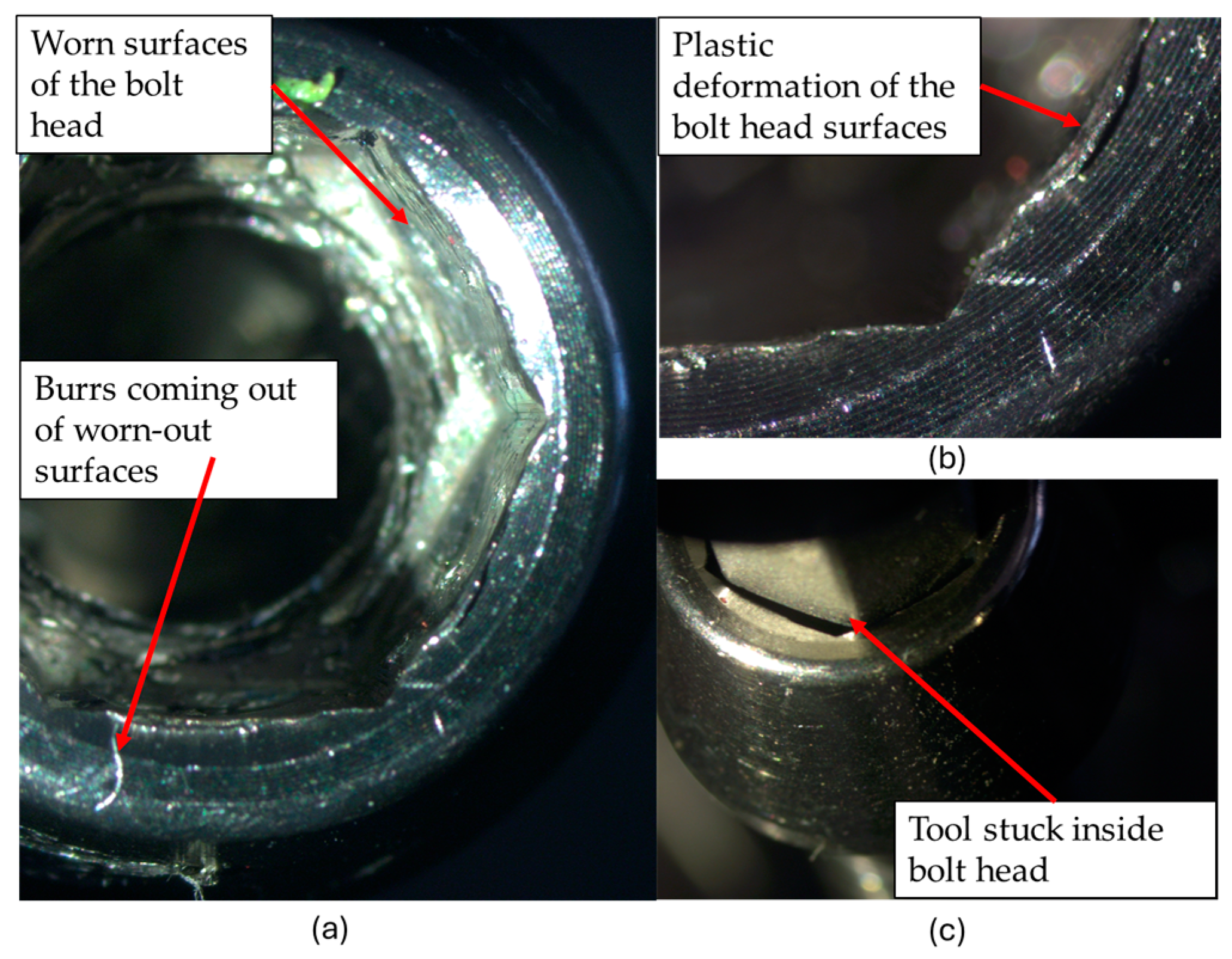

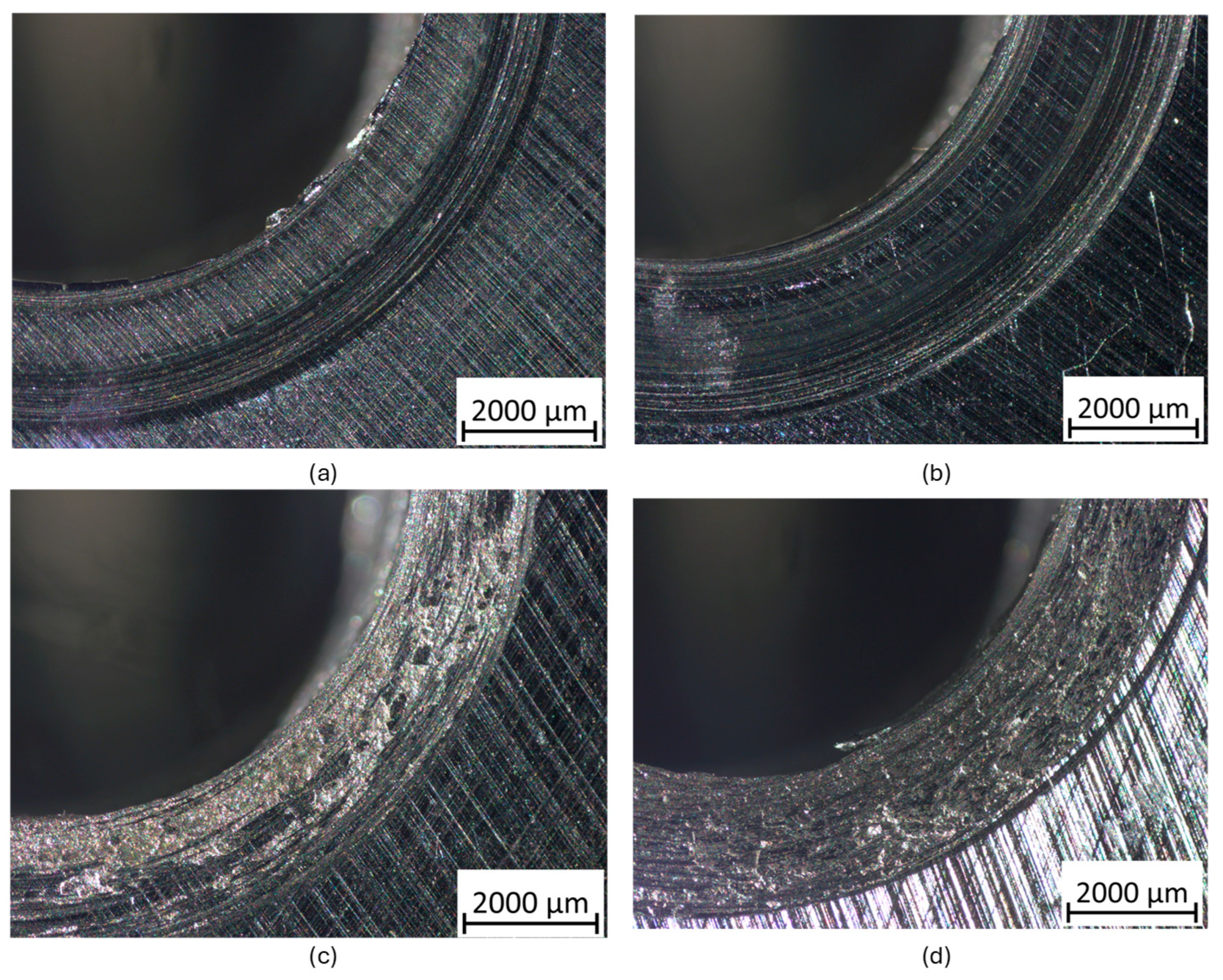

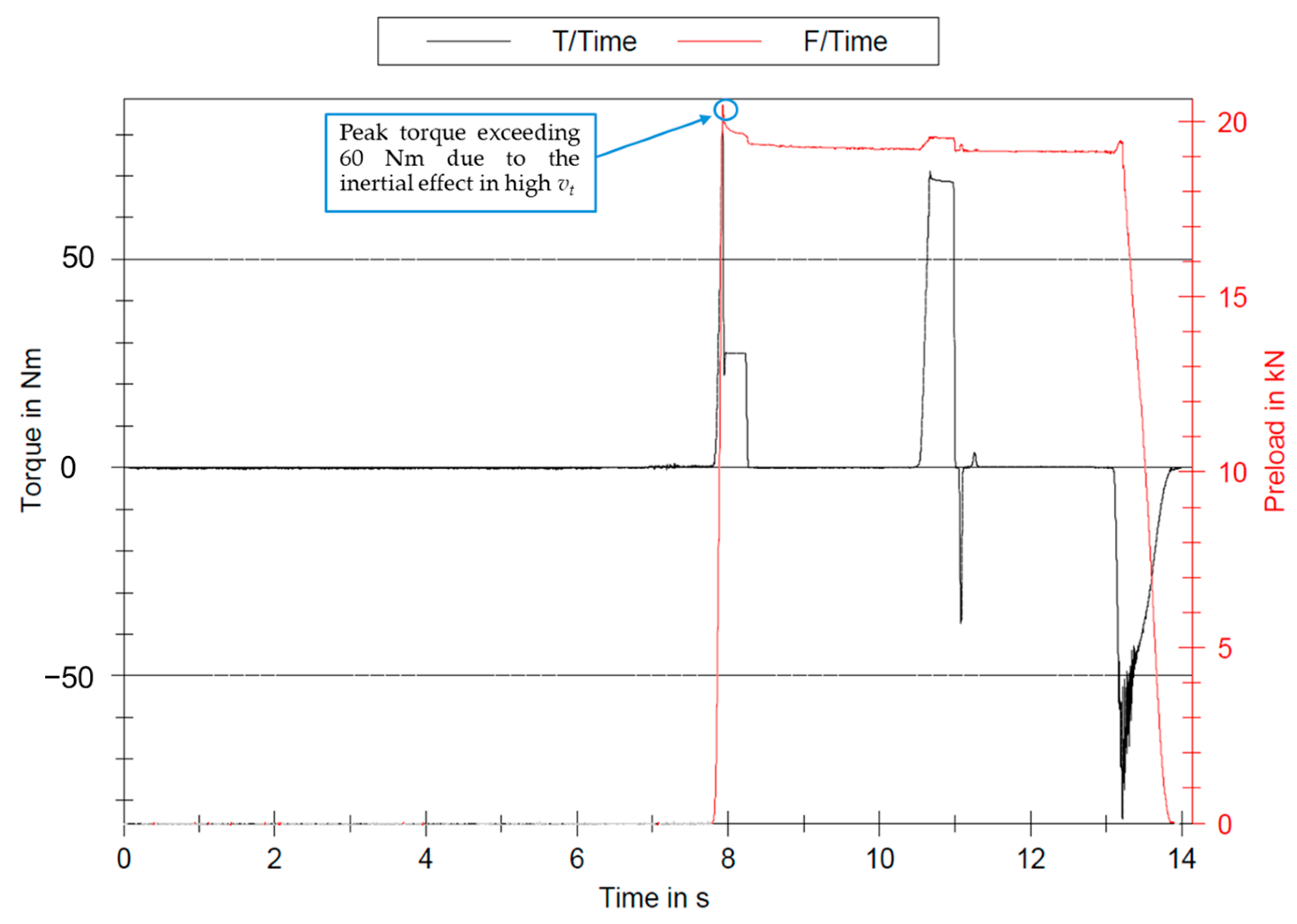

3.1. Preliminary Tests

3.2. Tribological Tests

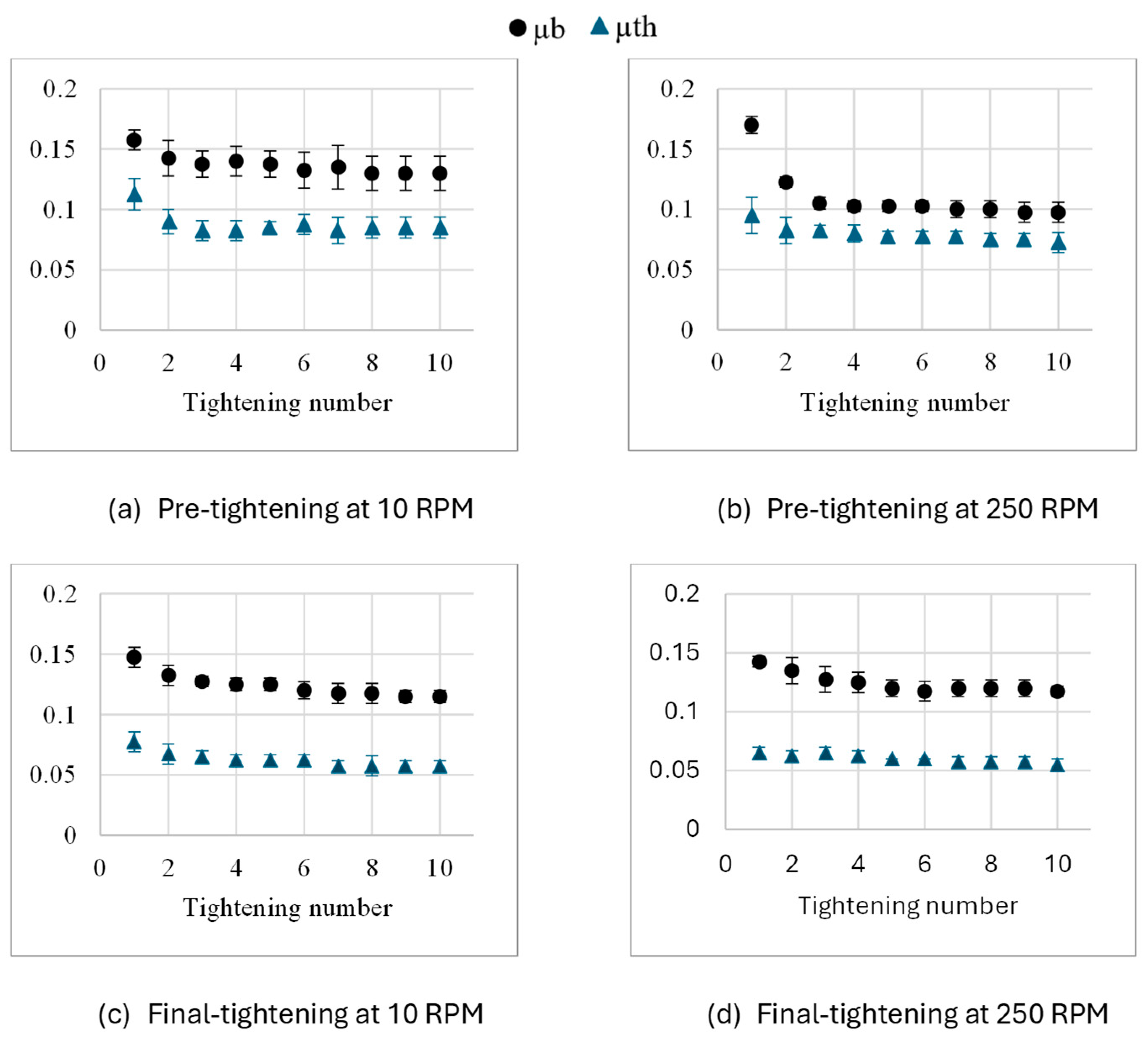

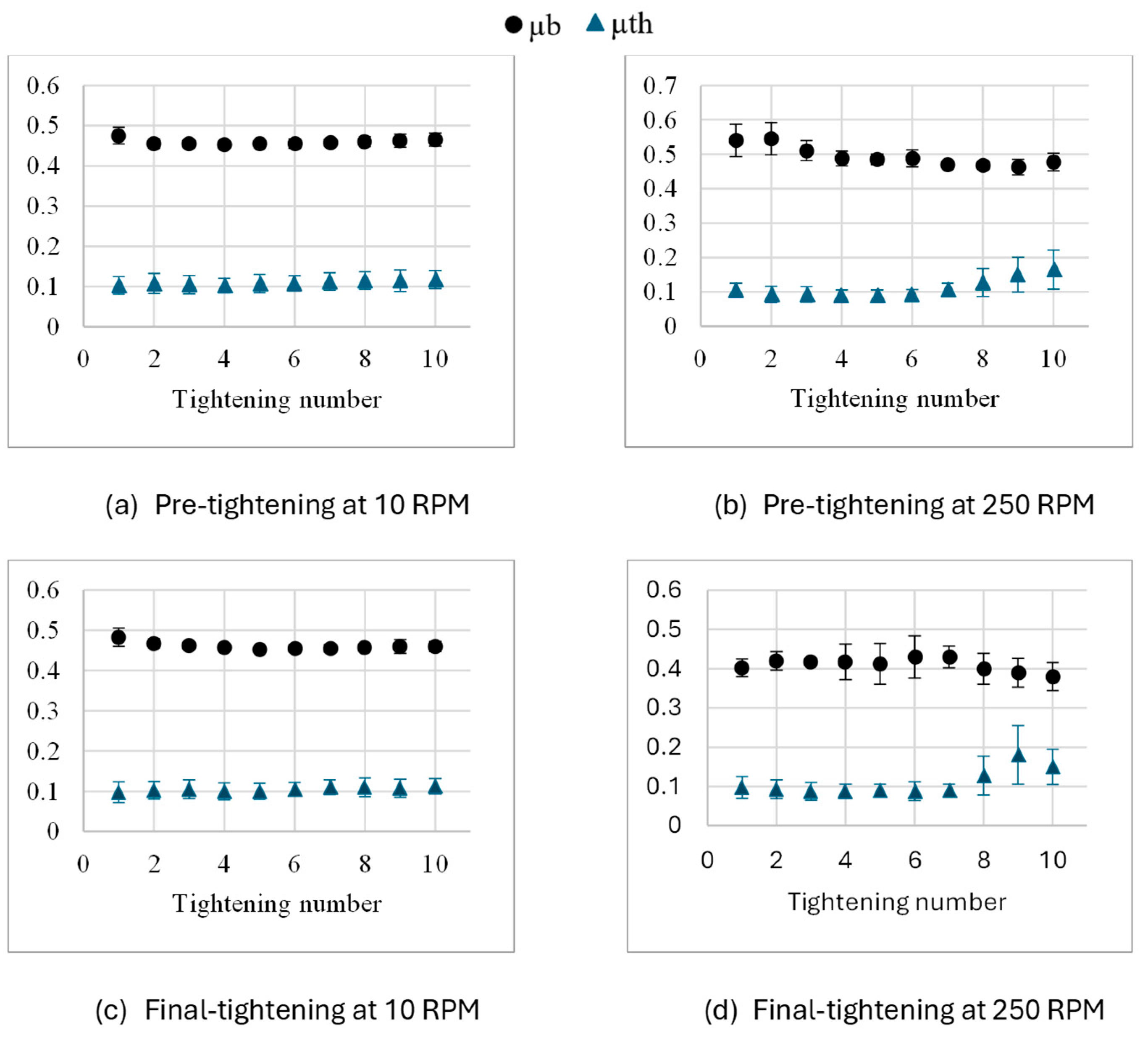

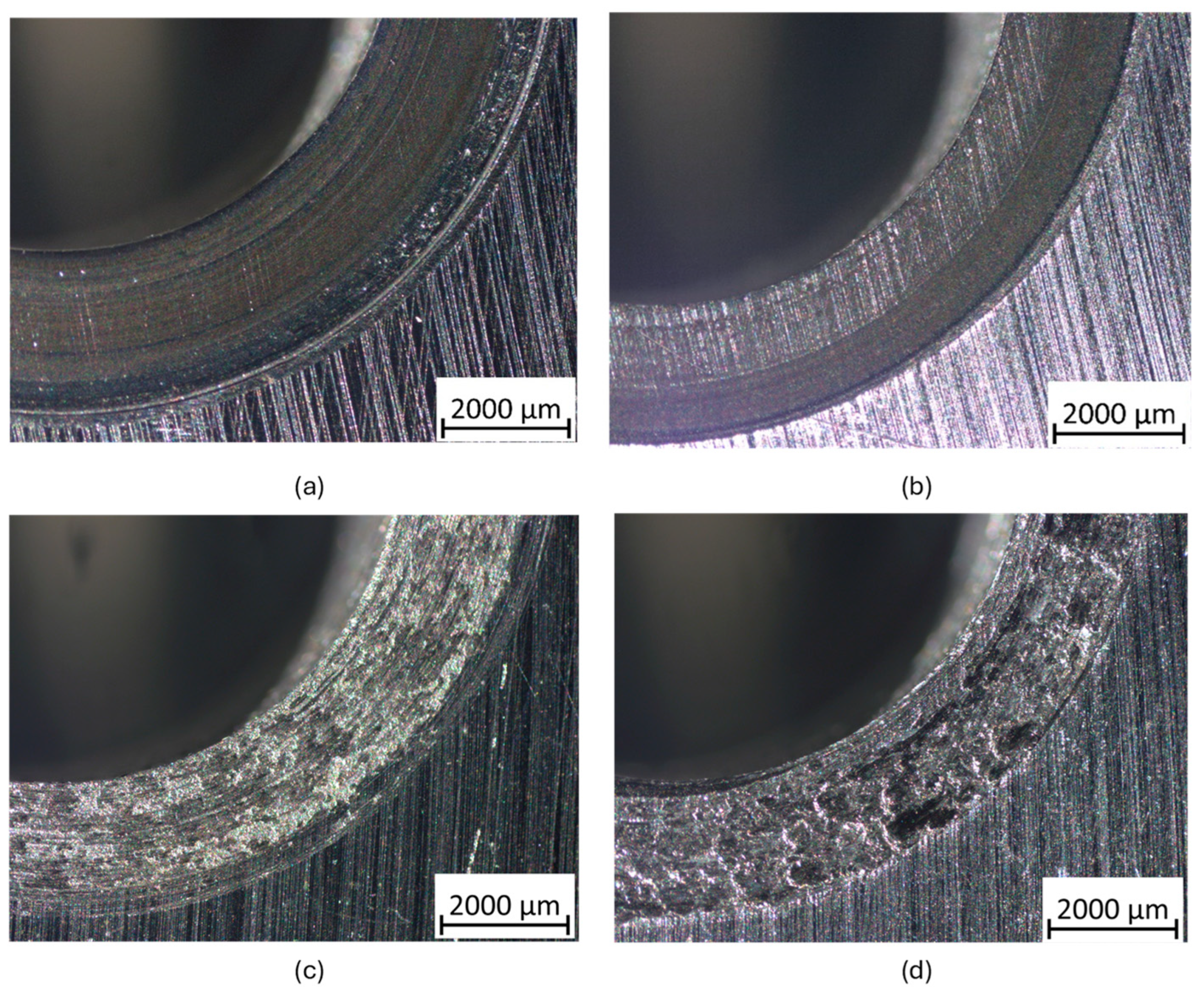

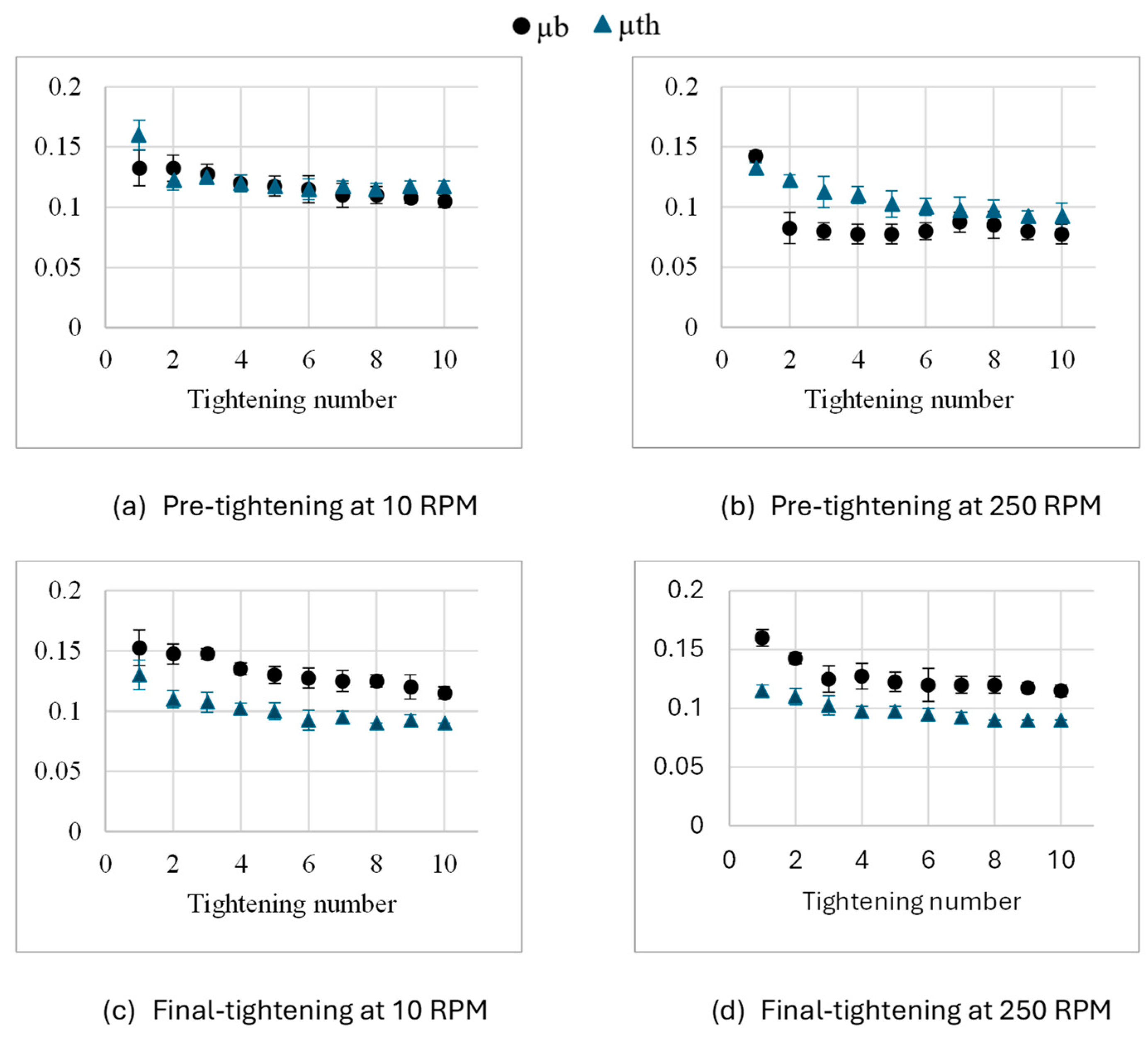

3.2.1. VG46

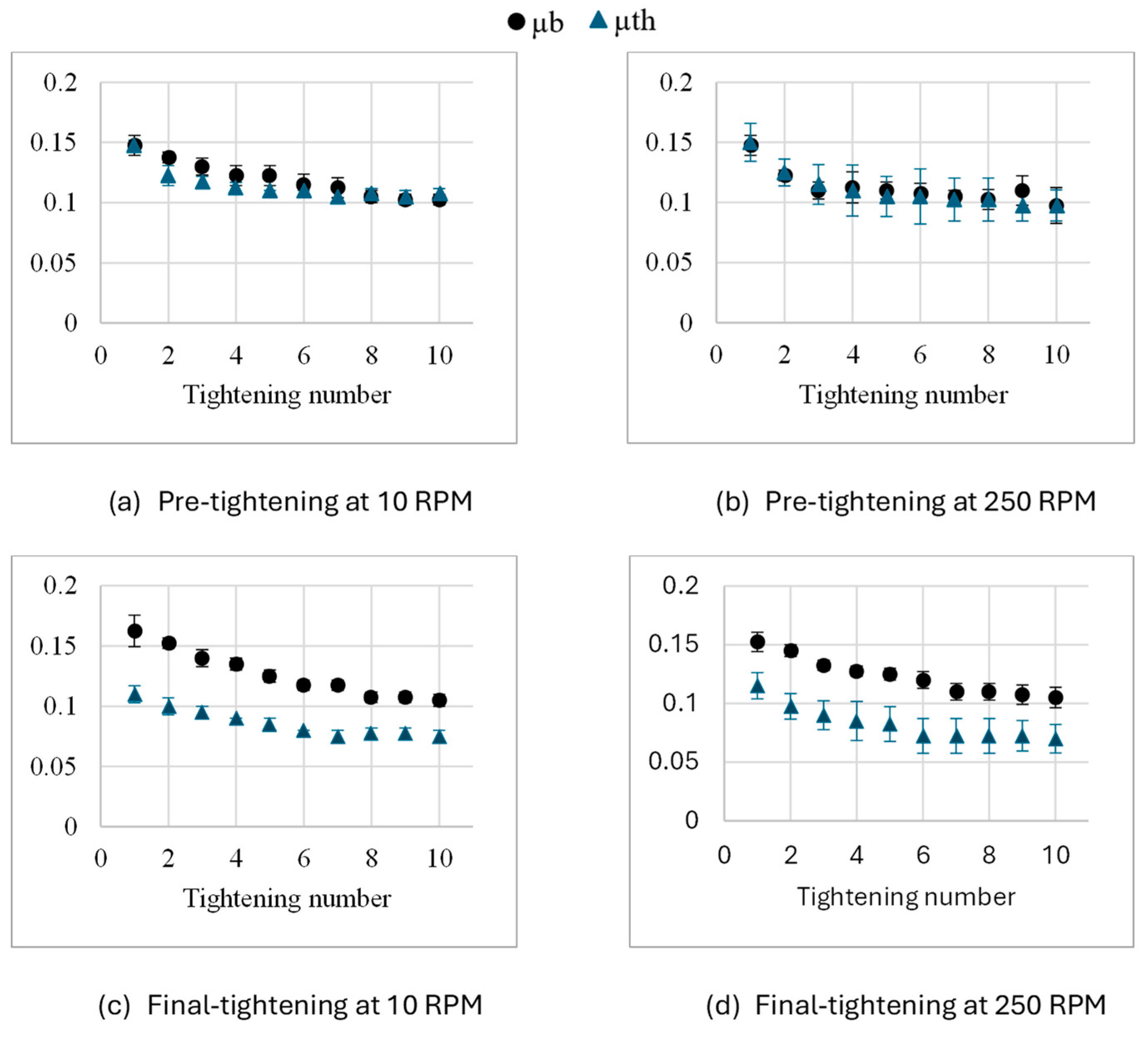

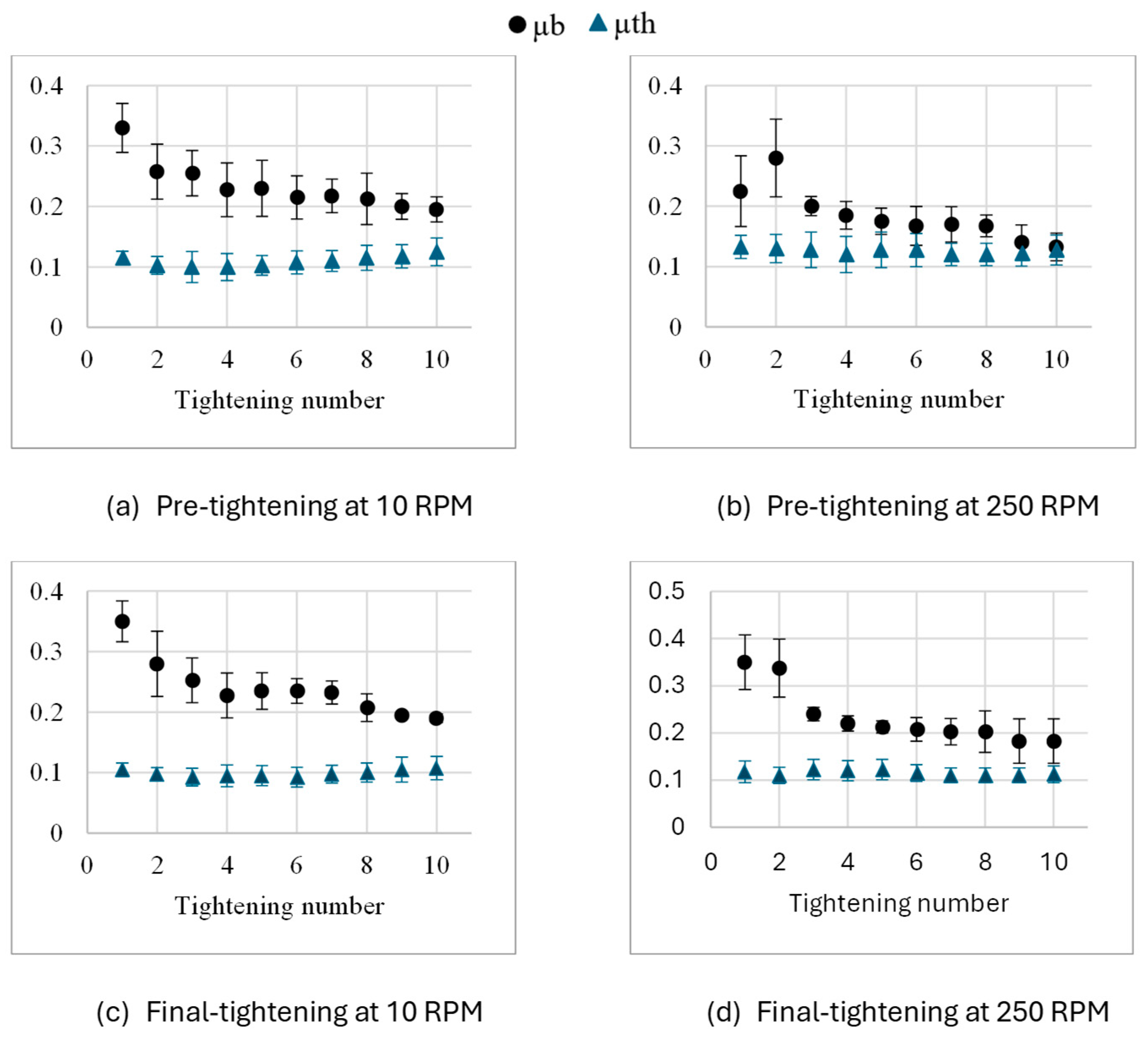

3.2.2. Fractionated Coconut Oil

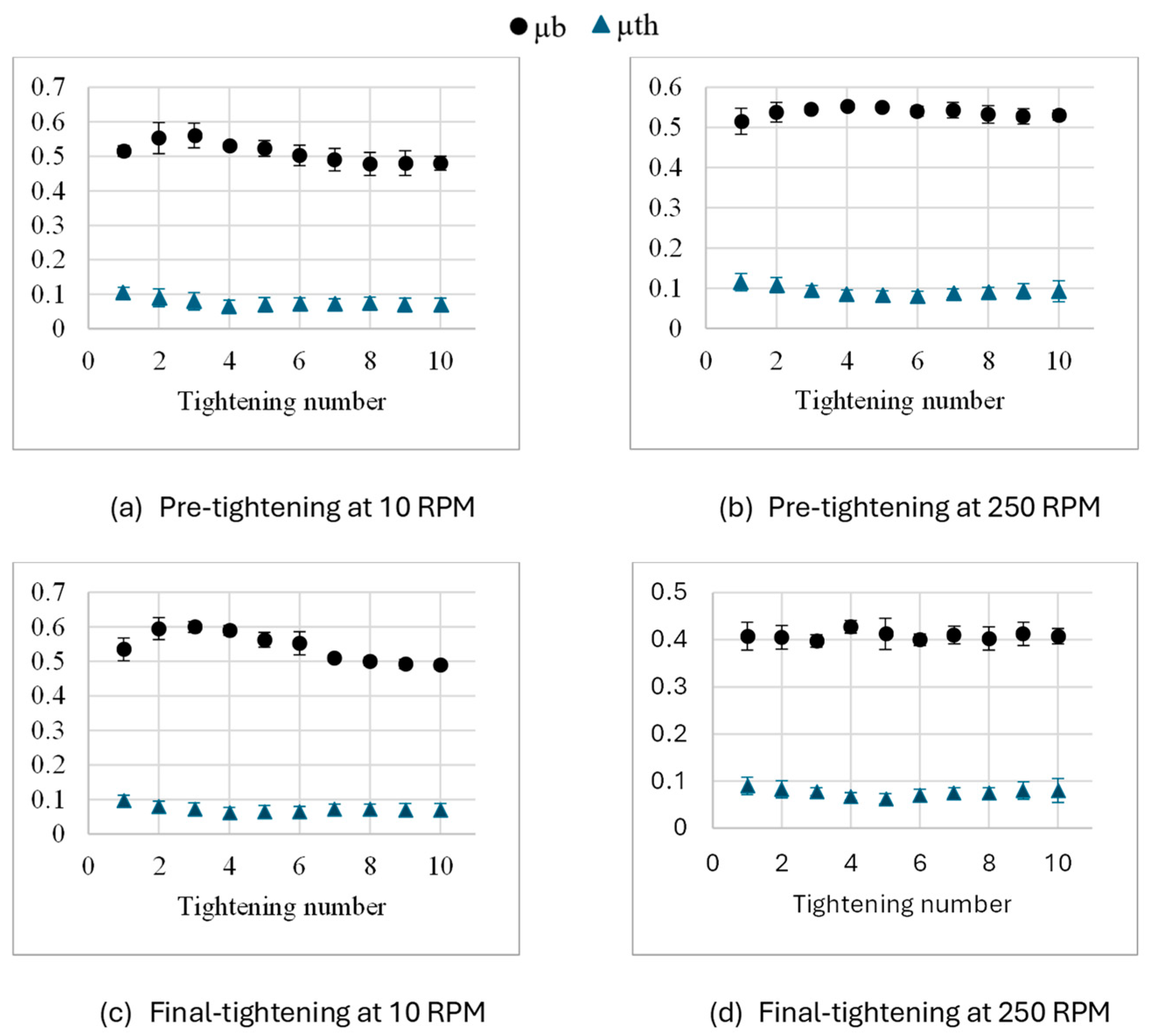

3.2.3. Castor Oil

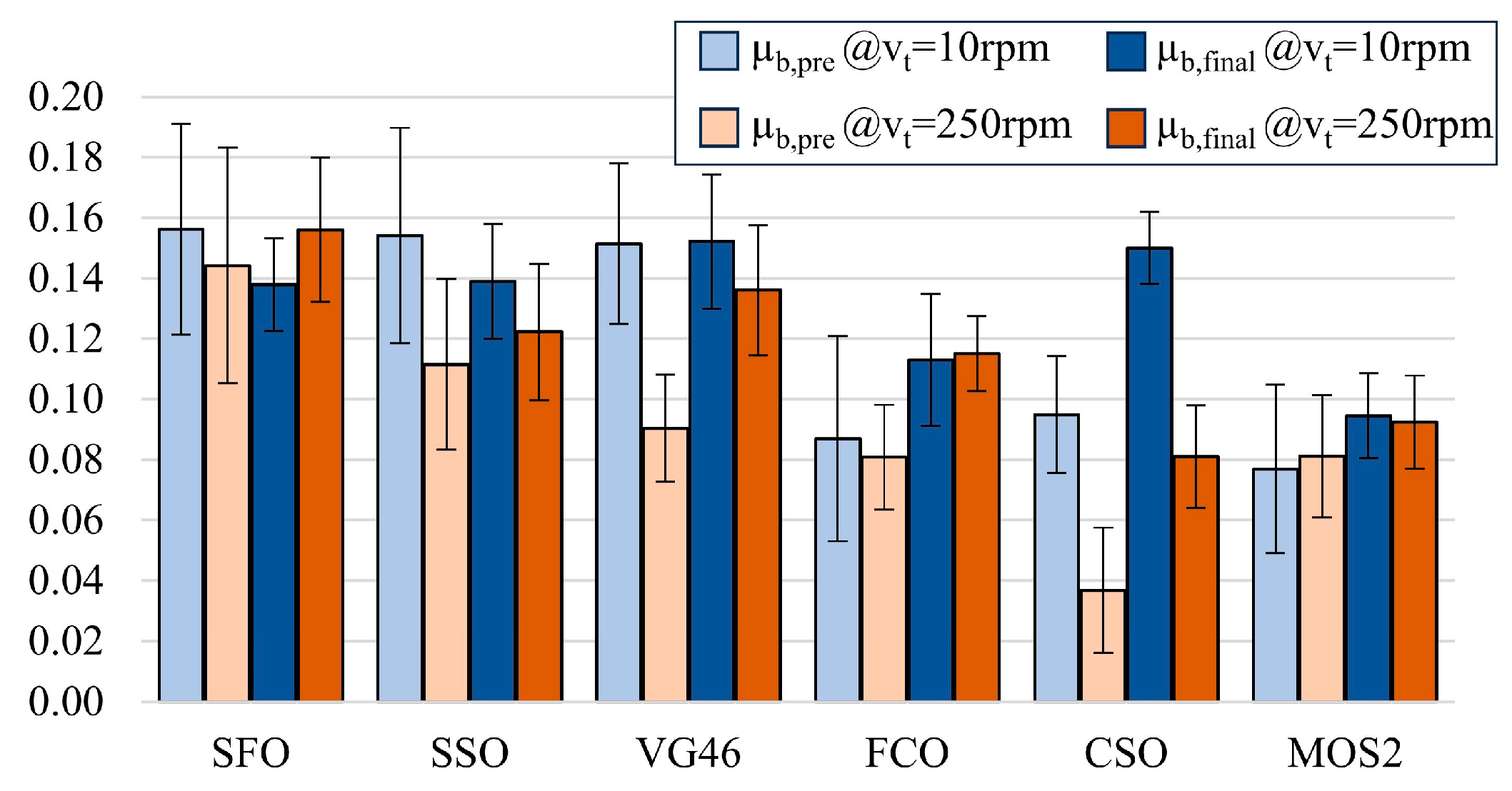

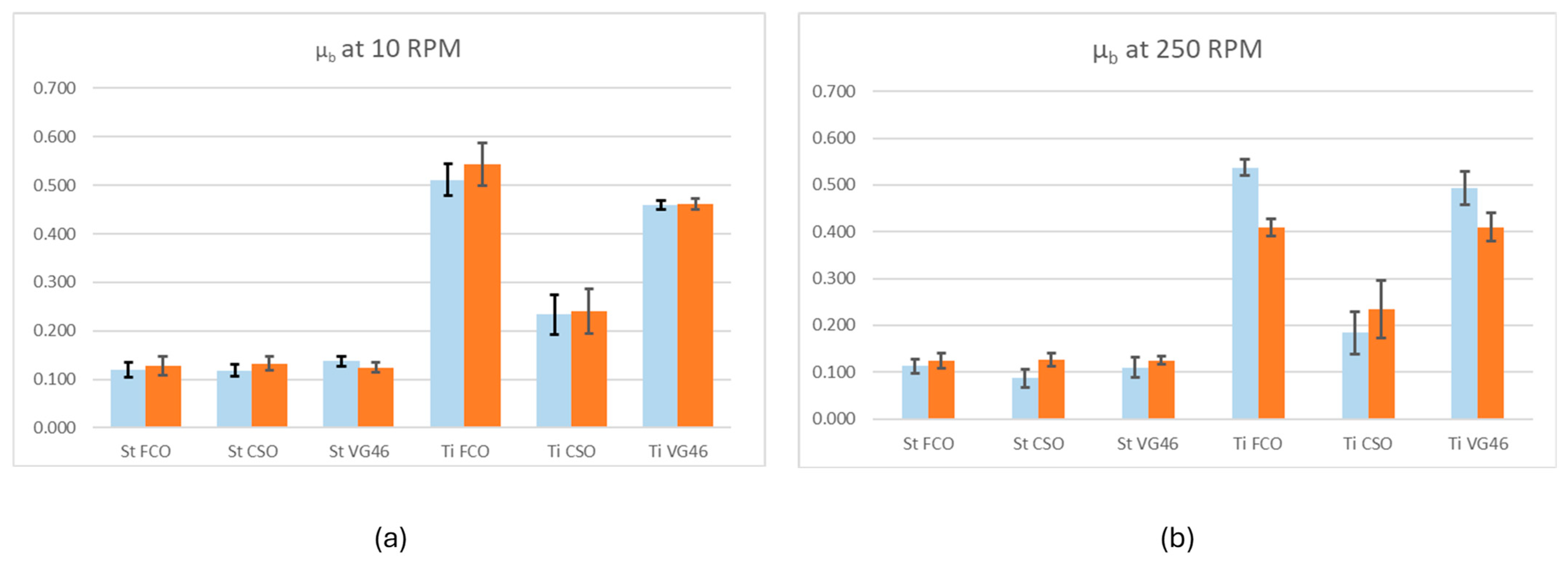

3.2.4. Comparison

4. Conclusions

- The performance of FCO is characterized by higher coefficients of friction in comparison to VG46. Moreover, the influence of the number of tightenings on Ti screws is also significant for FCO, unlike VG46, as demonstrated by ANOVA. This suggests that VG46 provides enhanced stability over the number of tightenings. Despite its enhanced stability, VG46 exhibits remarkably elevated friction coefficients, resulting in significant surface wear, thereby hindering the practical application of lubricants in real-world scenarios;

- In contrast, CSO not only serves as an effective substitute but also demonstrates superior performance to the commercial lubricant, VG46. Particularly, it would be useful for high-loaded threaded joints, as it yields coefficients of friction that are considerably lower than those of VG46;

- The repeatability of Castor oil was observed to stabilize after approximately five retightenings in the present study. This stability may be attributed to the settling of the lubricant within the material or a change in the chemical composition of the oil upon heating, which requires further investigation. In an industrial context, this behavior necessitates pre-tightening cycles in line before delivering the parts;

- A comparison with previous studies indicates that the performances of screws lubricated with vegetable oil significantly vary with the final load and the hardness of the bearing plate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Croccolo, D.; De Agostinis, M.; Fini, S.; Olmi, G.; Scapecchi, C.; Vincenzi, N. Tribological Behaviour in the Underhead for High Strength Socket-Head Screws Coupled With Cast Iron and Tightened in Dry and Lubricated Condition. In Proceedings of the ASME 2023 Pressure Vessels & Piping Conference, Atlanta, GA, USA, 16–21 July 2023; Volume 2. [Google Scholar] [CrossRef]

- ISO 68-1; General Purpose Screw Threads Basic Profile. ISO: Geneva, Switzerland, 2023.

- Zou, Q.; Sun, T.S.; Nassar, S.A.; Barber, G.C.; Gumel, A.K. Effect of lubrication on friction and torque-tension relationship in threaded fasteners. In Proceedings of the STLE/ASME 2006 International Joint Tribology Conference, San Antonio, TX, USA, 23–25 October 2006; Available online: https://asmedigitalcollection.asme.org/IJTC/proceedings-abstract/IJTC2006/42592a/591/318546 (accessed on 21 September 2024).

- Croccolo, D.; De Agostinis, M.; Fini, S.; Mele, M.; Olmi, G. Effect of different underhead shot-peening and lubrication conditions on high-strength screws undergoing multiple tightenings. Tribol. Int. 2024, 188, 108874. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Fini, S.; Olmi, G.; Paiardini, L.; Robusto, F. Threaded fasteners with applied medium or high strength threadlockers: Effect of different tightening procedures on the tribological response. Taylor Fr. 2019, 96, 64–89. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Fini, S.; Olmi, G. Tribological properties of bolts depending on different screw coatings and lubrications: An experimental study. Tribol. Int. 2024, 107, 199–205. [Google Scholar] [CrossRef]

- Claus, L.; Weitzel, S. Self-Tapping Fasteners for Lightweight Designs. 2014. Available online: https://www.sae.org/publications/technical-papers/content/2014-01-0785/ (accessed on 21 September 2024).

- Kopfer, H.; Friedrich, C.; De Agostinis, M.; Croccolo, D. Friction Characteristics in Light Weight Design Focusing Bolted Joints. 2012. Available online: https://asmedigitalcollection.asme.org/IMECE/proceedings-abstract/IMECE2012/839/288805?casa_token=9fcoHqs0W18AAAAA:DEI0d3UINhKPA3HMgE2M_MjzJxX9b4SC_2gk1RAQSBKUpcwkyfTEd3pmh42CpNh5iQVD (accessed on 21 September 2024).

- Croccolo, D.; De Agostinis, M.; Vincenzi, N. Influence of tightening procedures and lubrication conditions on titanium screw joints for lightweight applications. Tribol. Int. 2012, 55, 68–76. [Google Scholar] [CrossRef]

- VDI 2230 Blatt 1:2003-02; Systematic Calculation of High Duty Bolted Joints—Joints with One Cylindrical Bolt. Verlag des Vereins Deutscher Ingenieure: Düsseldorf, Germany, 2003.

- Kato, S.; Marui, E.; Kobayashi, A.; Senda, S. The Influence of Lubricants on Static Friction Characteristics Under Boundary Lubrication. J. Tribol. 1985, 107, 188–194. [Google Scholar] [CrossRef]

- Zhu, L.; Hong, J.; Yang, G.; Jiang, X. Experimental study on initial loss of tension in bolted joints. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2015, 230, 1685–1696. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Vincenzi, N. Failure analysis of bolted joints: Effect of friction coefficients in torque–preloading relationship. Eng. Fail. Anal. 2011, 18, 364–373. [Google Scholar] [CrossRef]

- Liu, Z.; Zheng, M.; Yan, X.; Zhao, Y.; Cheng, Q.; Yang, C. Changing behavior of friction coefficient for high strength bolts during repeated tightening. Tribol. Int. 2020, 151, 106486. [Google Scholar] [CrossRef]

- Zheng, M.; Liu, Z.; Yan, X.; Niu, N.; Zhang, T.; Li, Y. Initial losing behavior of pre-tightening force for threaded fastener during repeated tightening. Eng. Fail. Anal. 2022, 134, 106021. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Fini, S.; Olmi, G.; Robusto, F.; Vincenzi, N. Effect of Material and Lubrication Conditions on the Underhead Frictional Response in High Strength Socket-Head Screws. In Proceedings of the ASME 2020 Pressure Vessels & Piping Conference, Virtual, 3 August 2020; Volume 2, p. V002T02A024. [Google Scholar] [CrossRef]

- Pawar, R.V.; Hulwan, D.B.; Mandale, M.B. Recent advancements in synthesis, rheological characterization, and tribological performance of vegetable oil-based lubricants enhanced with nanoparticles for sustainable lubrication. J. Clean. Prod. 2022, 378, 134454. [Google Scholar] [CrossRef]

- Reeves, C.J.; Siddaiah, A.; Menezes, P.L. A review on the science and technology of natural and synthetic biolubricants. J. Bio-Tribo-Corros. 2017, 3, 1–27. [Google Scholar] [CrossRef]

- Uppar, R.; Dinesha, P.; Kumar, S. A critical review on vegetable oil-based bio-lubricants: Preparation, characterization, and challenges. Environ. Dev. Sustain. 2023, 25, 9011–9046. [Google Scholar] [CrossRef]

- Zainal, N.A.; Zulkifli, N.W.M.; Gulzar, M.; Masjuki, H.H. A review on the chemistry, production, and technological potential of bio-based lubricants. Renew. Sustain. Energy Rev. 2018, 82, 80–102. [Google Scholar] [CrossRef]

- Mobarak, H.M.; Mohamad, E.N.; Masjuki, H.H.; Kalam, M.A.; Al Mahmud, K.A.H.; Habibullah, M.; Ashraful, A.M. The prospects of biolubricants as alternatives in automotive applications. Renew. Sustain. Energy Rev. 2014, 33, 34–43. [Google Scholar] [CrossRef]

- Singh, Y.; Farooq, A.; Raza, A.; Mahmood, M.A.; Jain, S. Sustainability of a non-edible vegetable oil-based bio-lubricant for automotive applications: A review. Process Saf. Environ. Prot. 2017, 111, 701–713. [Google Scholar] [CrossRef]

- Katna, M.S.R.; Agrawal, N. Nonedible vegetable oil-based cutting fluids for machining processes—A review. Mater. Manuf. Process. 2020, 35, 1–32. [Google Scholar] [CrossRef]

- Zareh-Desari, B.; Davoodi, B. Assessing the lubrication performance of vegetable oil-based nano-lubricants for environmentally conscious metal forming processes. J. Clean. Prod. 2016, 135, 1198–1209. [Google Scholar] [CrossRef]

- Kamalakar, K.; Rajak, A.K.; Prasad, R.B.N.; Karuna, M.S.L. Rubber seed oil-based biolubricant base stocks: A potential source for hydraulic oils. Ind. Crops Prod. 2013, 51, 249–257. [Google Scholar] [CrossRef]

- Regueira, T.; Lugo, L.; Fandiño, O.; López, E.R.; Fernández, J. Compressibilities and viscosities of reference and vegetable oils for their use as hydraulic fluids and lubricants. Green Chem. 2011, 13, 1293–1302. [Google Scholar] [CrossRef]

- Singh, S.; Sharma, S.; Sarma, S.J.; Brar, S.K. A comprehensive review of castor oil-derived renewable and sustainable industrial products. Environ. Prog. Sustain. Energy 2023, 42, e14008. [Google Scholar] [CrossRef]

- Almasi, S.; Ghobadian, B.; Najafi, G.; Soufi, M.D. A review on bio-lubricant production from non-edible oil-bearing biomass resources in Iran: Recent progress and perspectives. J. Clean. Prod. 2021, 290, 125830. [Google Scholar] [CrossRef]

- Bongfa, B.; Atabor, P.A.; Barnabas, A.; Adeoti, M.O. Comparison of lubricant properties of castor oil and commercial engine oil. J. Tribol. 2015, 5, 1–10. [Google Scholar]

- Gerbig, Y.; Ahmed, S.; Gerbig, F.A.; Haefke, H. Suitability of vegetable oils as industrial lubricants. J. Synth. Lubr. 2004, 21, 177–191. [Google Scholar] [CrossRef]

- Tulashie, S.K.; Kotoka, F. The potential of castor, palm kernel, and coconut oils as biolubricant base oil via chemical modification and formulation. Therm. Sci. Eng. Prog. 2020, 16, 100480. [Google Scholar] [CrossRef]

- Dwivedi, M.C.; Sapre, S. Total vegetable-oil based greases prepared from castor oil. J. Synth. Lubr. 2002, 19, 229–241. [Google Scholar] [CrossRef]

- Jayadas, N.H.; Nair, K.P. Coconut oil as base oil for industrial lubricants—Evaluation and modification of thermal, oxidative and low temperature properties. Tribol. Int. 2006, 39, 873–878. [Google Scholar] [CrossRef]

- Mizera, Č.; Aleš, Z.; Herák, D.; Hrabě, P.; Kabutey, A.; Napitupulu, R.A.; Ungureanu, N. Mechanical Pressing of Coconut Oil and Evaluation of Its Lubricant Properties. Processes 2023, 11, 3034. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Fini, S.; Mele, M.; Nassar, S.; Olmi, G.; Scapecchi, C.; Khan, M.Y.; Tariq, M.H.B. Replacing non-renewable lubricants with vegetables oils in threaded joints. J. Adv. Join. Process. 2024, 10, 100234. [Google Scholar] [CrossRef]

- ASTM D4212-16; Standard Test Method for Viscosity by Dip-Type Viscosity Cups (D4212). ASTM International: West Conshohocken, PA, USA, 2023.

- ISO 4762:2004; Hexagon Socket Head Cap Screws. Available online: https://www.iso.org/standard/34460.html (accessed on 6 December 2024).

- ISO 4033:2023; Fasteners—Hexagon High Nuts (Style 2). Available online: https://www.iso.org/standard/75017.html (accessed on 6 December 2024).

- ISO 683-1:2016; Heat-Treatable Steels, Alloy Steels and Free-Cutting Steels—Part 1: Non-Alloy Steels for Quenching and Tempering. ISO: Geneva, Switzerland, 2016. Available online: https://www.iso.org/standard/70642.html (accessed on 21 September 2024).

- Palsdottir, H.; Arnarson, A. What Is Fractionated Coconut Oil Good For? Available online: https://www.healthline.com/nutrition/fractionated-coconut-oil (accessed on 24 August 2024).

- ISO 16047:2005(en); Fasteners—Torque/Clamp Force Testing. ISO: Geneva, Switzerland, 2005. Available online: https://www.iso.org/obp/ui/#iso:std:iso:16047:ed-1:v1:en (accessed on 3 December 2024).

- Group Volkswagen. VW 01131-1: Determination of Coefficients of Friction, Practice and Mounting-Oriented Testing; Tech. Rep.; Volkswagen Aktiengesellschaft: Wolfsburg, Germany, 2012. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

| Lubricant | Oil Viscosity @ 23 °C (cSt) | Viscosity @ 40 °C (cSt) | Viscosity @ 60 °C (cSt) |

|---|---|---|---|

| VG46 | 84 ± 0.00 | 49.13 ± 0.52 | 19.43 ± 0.52 |

| Fractionated Coconut oil | 19.80 ± 0.00 | 9.90 ± 0.00 | 5.50 ± 0.00 |

| Castor oil | 878.13 ± 6.98 | 409.47 ± 6.98 | 89.83 ± 1.65 |

| Parameter | Number of Variables | Detail of Variables |

|---|---|---|

| Lubrication | 3 | VG46, Castor oil, Coconut oil |

| Tightening speed | 2 | 10 rpm, 250 rpm |

| Number of tightenings | 10 | 1… 10 |

| Lubrication | p-Value of vt | p-Value of nt | p-Value of nt × vt |

|---|---|---|---|

| Ti VG46 | <1 × 10−5 | 0.8181 | 0.5994 |

| Ti FCO | <1 × 10−5 | <1 × 10−5 | <1 × 10−5 |

| Ti CSO | 0.4588 | <1 × 10−5 | 0.6701 |

| St VG46 | 0.8951 | <1 × 10−5 | 0.9619 |

| St FCO | 0.0404 | <1 × 10−5 | 0.5689 |

| St CSO | 0.0135 | <1 × 10−5 | 0.3035 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Croccolo, D.; De Agostinis, M.; Fini, S.; Khan, M.Y.; Mele, M.; Olmi, G.; Scapecchi, C.; Tariq, M.H.B. Investigating the Friction Coefficient of Titanium Bolts with Vegetable Oils as Lubricants. Eng. Proc. 2025, 85, 52. https://doi.org/10.3390/engproc2025085052

Croccolo D, De Agostinis M, Fini S, Khan MY, Mele M, Olmi G, Scapecchi C, Tariq MHB. Investigating the Friction Coefficient of Titanium Bolts with Vegetable Oils as Lubricants. Engineering Proceedings. 2025; 85(1):52. https://doi.org/10.3390/engproc2025085052

Chicago/Turabian StyleCroccolo, Dario, Massimiliano De Agostinis, Stefano Fini, Muhammad Yasir Khan, Mattia Mele, Giorgio Olmi, Chiara Scapecchi, and Muhammad Hassaan Bin Tariq. 2025. "Investigating the Friction Coefficient of Titanium Bolts with Vegetable Oils as Lubricants" Engineering Proceedings 85, no. 1: 52. https://doi.org/10.3390/engproc2025085052

APA StyleCroccolo, D., De Agostinis, M., Fini, S., Khan, M. Y., Mele, M., Olmi, G., Scapecchi, C., & Tariq, M. H. B. (2025). Investigating the Friction Coefficient of Titanium Bolts with Vegetable Oils as Lubricants. Engineering Proceedings, 85(1), 52. https://doi.org/10.3390/engproc2025085052