Development of Proportional-Integral-Derivative Based Self-Balancing Robot Using ESP32 for STEM Education †

Abstract

:1. Introduction

2. Literature Review

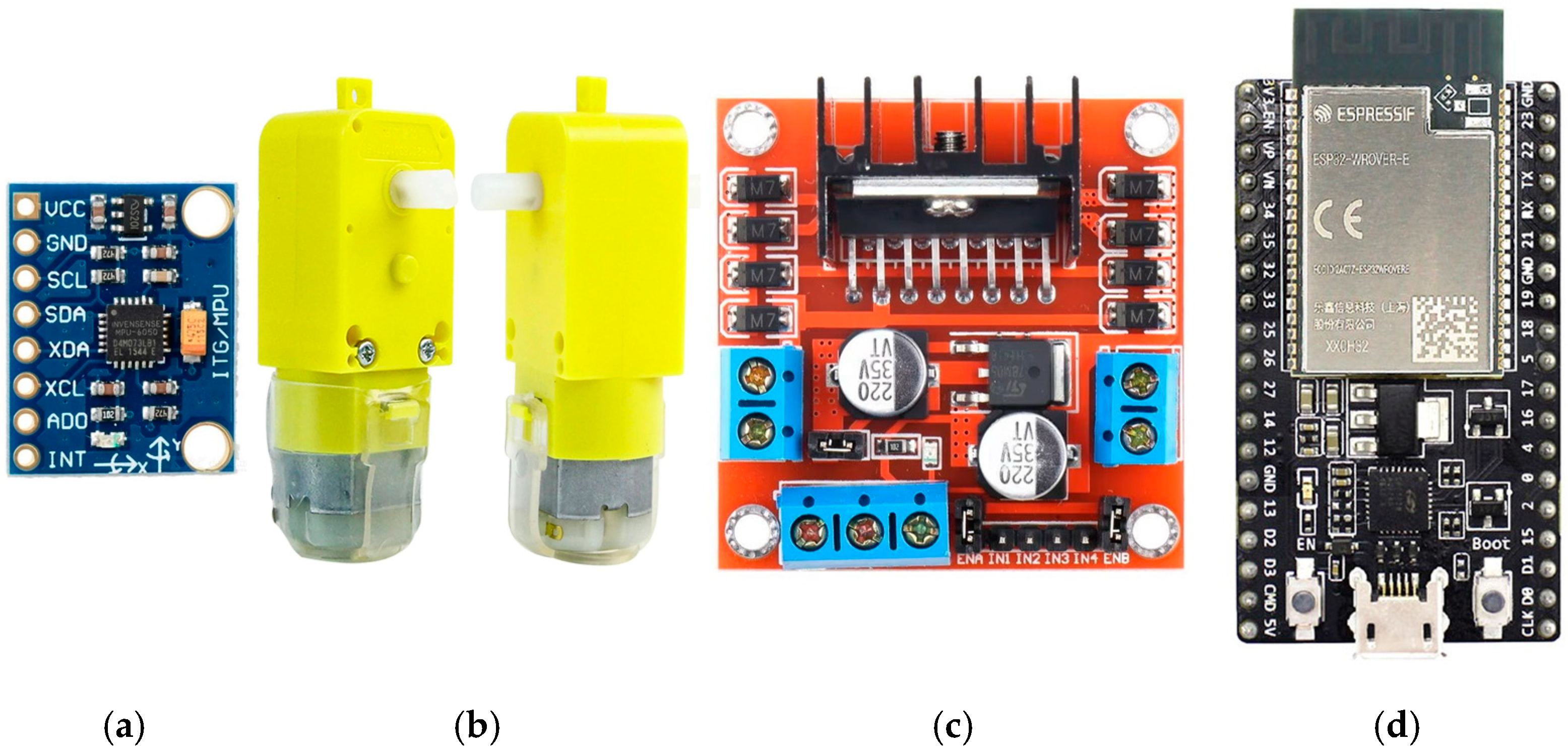

3. Hardware

3.1. Motion Tracking Sensor

3.2. DC Gear Motors

3.3. Motor Driver

3.4. Microcontroller

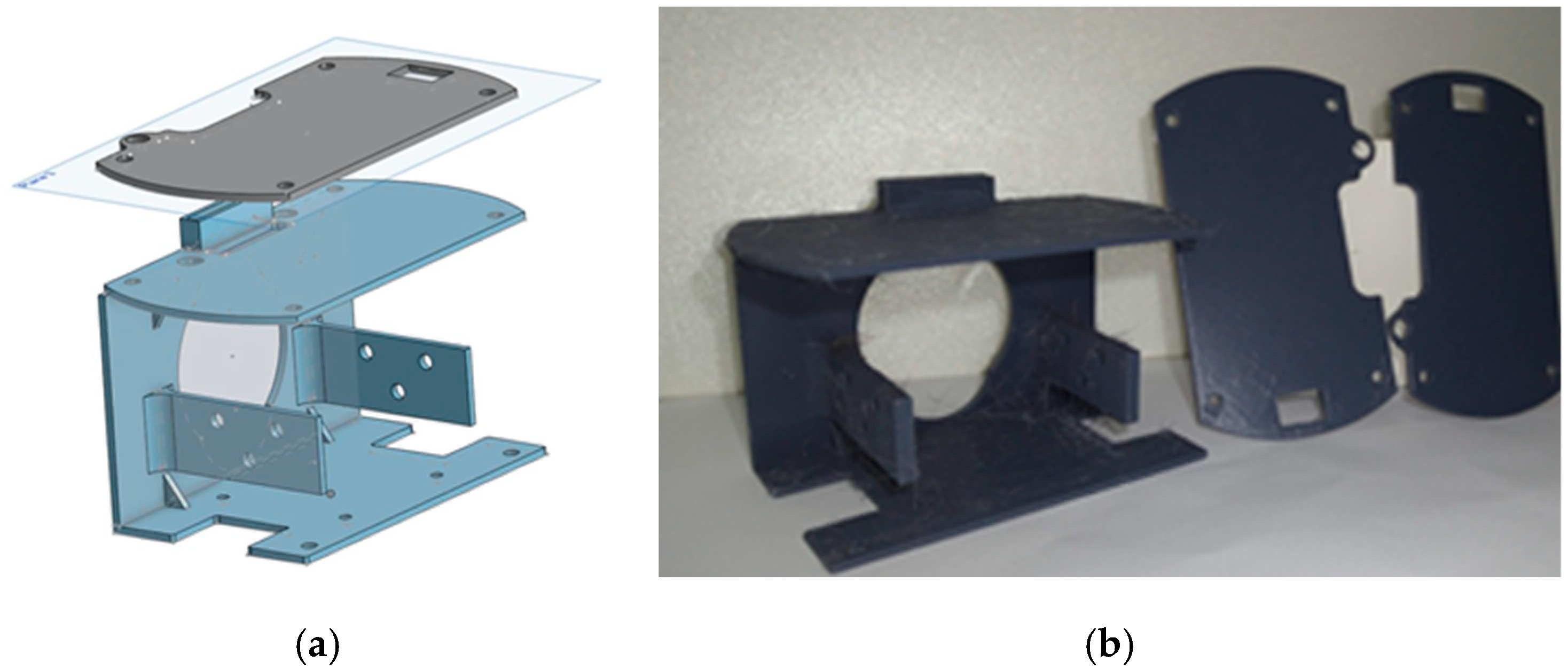

3.5. Robot Frame

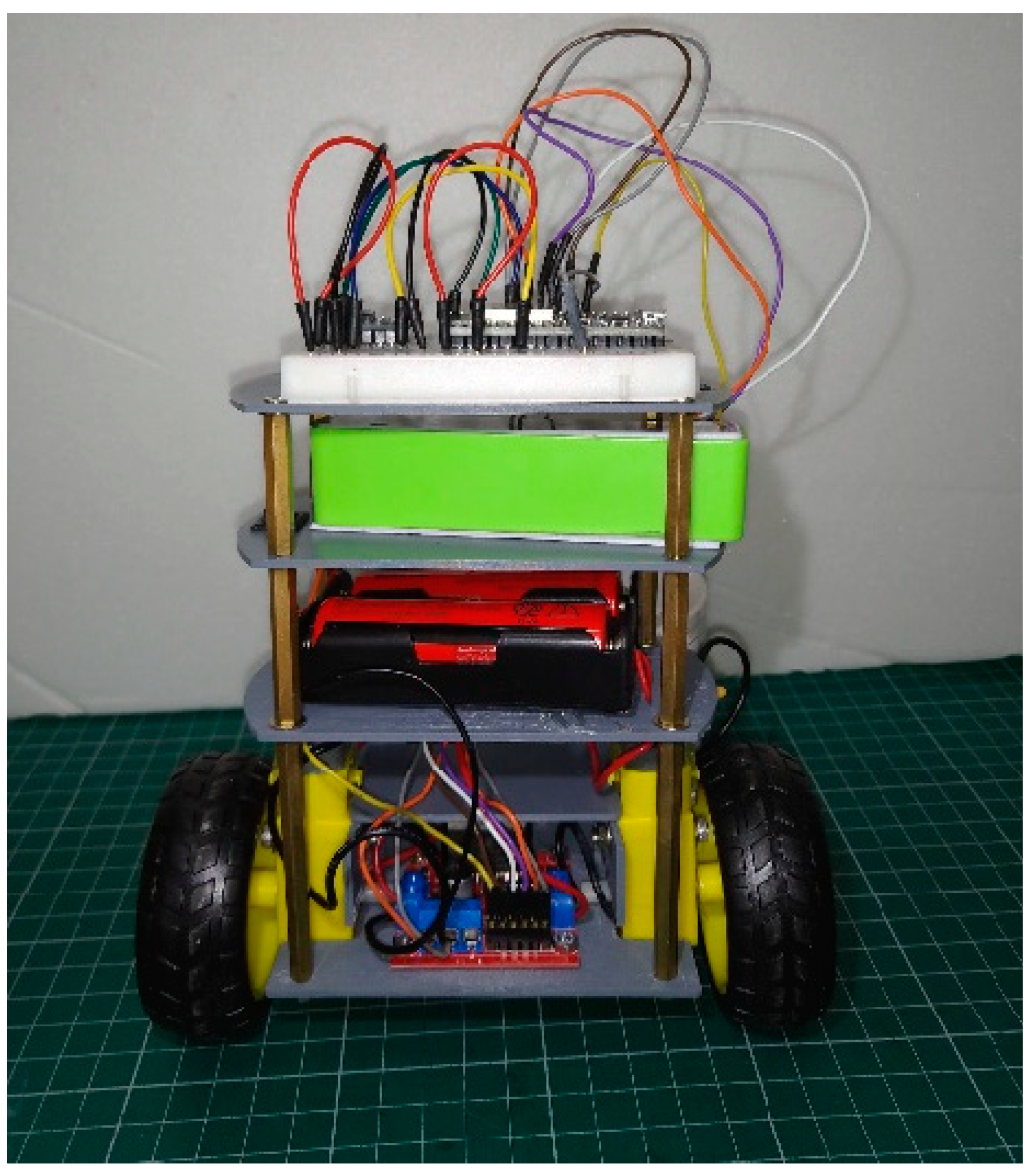

4. Robot System

4.1. PID Controller

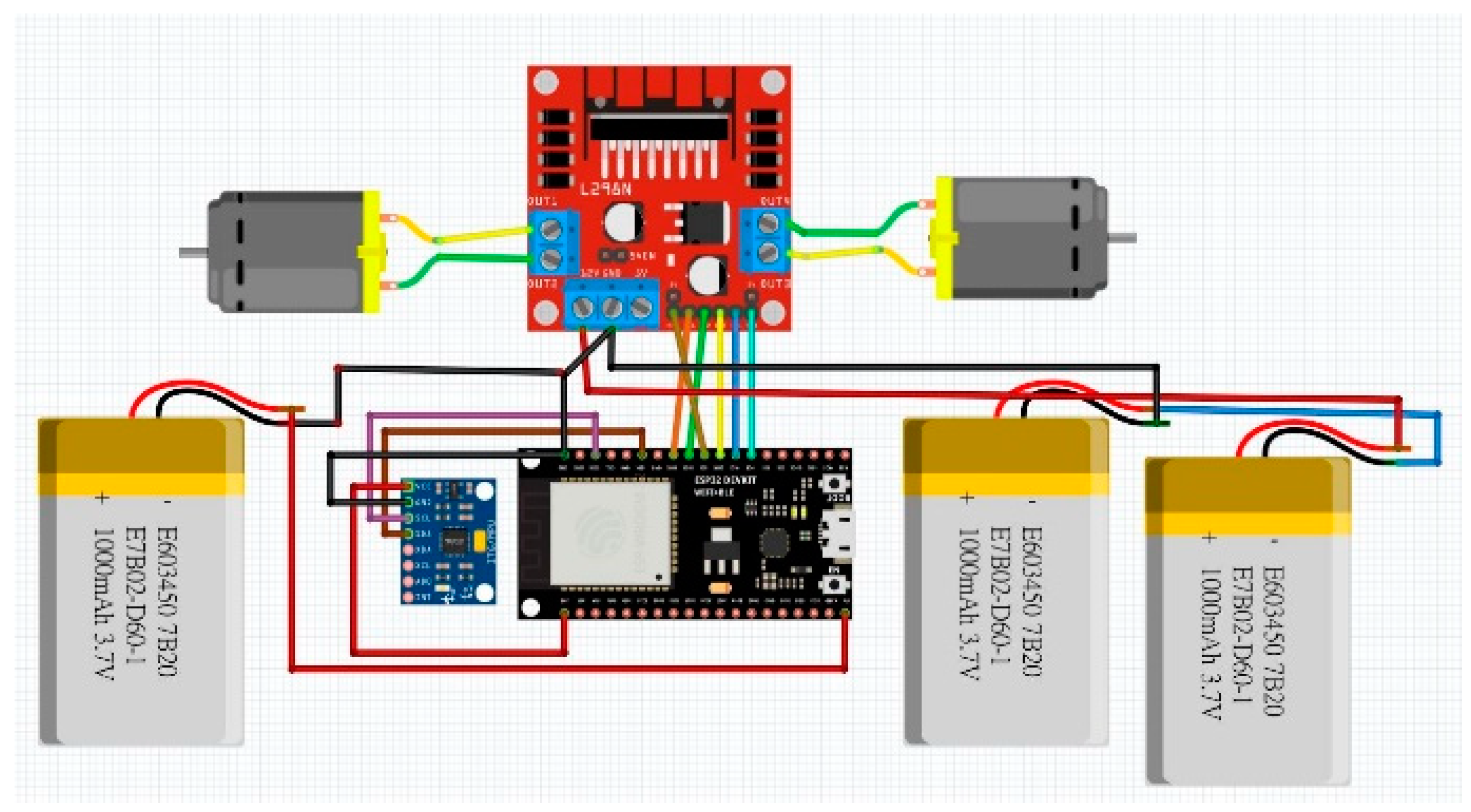

4.2. Electronic Device Wiring

4.3. Firmware and PID Tuning

- Gyroscope sensor calibration: After the robot hardware was installed completely, a sensor calibration is needed. The MPU6050 sensor was calibrated using calibration codes available on the Internet. This calibration guarantees that the sensor provides accurate and correct title angle to the robot micro-controller for further application.

- PID tuning: The Ziegler-Nichols tuning method, Cohen-Coon tuning method, Kappa-Tau tuning method, Lambda tuning method, and Trial and Error method are used for PID tuning. This study used the Trial and Error method to obtain proportional, integrated, and derivative gains. The method gained the proportional gain first, and then integrated and derivative gains. This tuning process will be arranged to be a part of STEM activity. Students can learn PID control theory via adjusting PID parameters and testing the robot personally.

5. Results and Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Afari, E.; Khine, M.S. Robotics as an Educational Tool: Impact of Lego Mindstorms. Int. J. Inf. Educ. Technol. 2017, 7, 6. [Google Scholar] [CrossRef]

- Barker, B.S. Robots in K-12 Education: A New Technology for Learning: A New Technology for Learning; Information Science Reference: Hershey, PA, USA, 2012. [Google Scholar]

- Hsieh, C.T. Developing Programmable Robot for K12 STEAM Education. In Proceedings of the Eighth International Multi Conference on Engineering and Technology Innovation 2019, Kaohsiung, Taiwan, 15–19 November 2019. [Google Scholar]

- Hsieh, C.-T. Low Cost Quadrupedal Robots for the STEM Education. In Proceedings of the 17th International Conference on Automation Technology (Automation 2020), Hualien, Taiwan, 12–14 November 2020. [Google Scholar]

- Grasser, F.; D’Arrigo, A.; Colombi, S.; Rufer, A.C. JOE: A mobile, inverted pendulum. IEEE Trans. Ind. Electron. 2002, 49, 107–114. [Google Scholar] [CrossRef]

- Pajpach, M.; Haffner, O.; Kucera, E.; Drahos, P. Low-Cost Education Kit for Teaching Basic Skills for Industry 4.0 Using Deep-Learning in Quality Control Tasks. Electronics 2022, 11, 230. [Google Scholar] [CrossRef]

- Hartono, R.; Kim, S.B.; Kalend, P.T.A.; Baik, N.K.; Shin, K.J. Design of Self-balancing Model-size Electrical Motorbike Robot Using Control Moment Gyroscope. Sens. Mater. 2023, 35, 347–363. [Google Scholar] [CrossRef]

- Tomasic, T.; Demetlika, A.; Crnekovic, M. Self-Balancing Mobile Robot Tilter. Trans. FAMENA 2012, 36, 23–32. [Google Scholar]

- Bennett, S. Nicholas Minorsky and the automatic steering of ships. IEEE Control Syst. Mag. 1984, 4, 10–15. [Google Scholar] [CrossRef]

- Huba, M.; Chamraz, S.; Bistak, P.; Vrancic, D. Making the PI and PID Controller Tuning Inspired by Ziegler and Nichols Precise and Reliable. Sensors 2021, 21, 6157. [Google Scholar] [CrossRef] [PubMed]

- Azimi, M.M.; Koofigar, H.R. Model predictive control for a two wheeled self balancing robot. In Proceedings of the 2013 First RSI/ISM International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 13–15 February 2013; pp. 152–157. [Google Scholar] [CrossRef]

- Junfeng, W.; Wanying, Z. Design of fuzzy logic controller for two-wheeled self-balancing robot. In Proceedings of the 2011 6th International Forum on Strategic Technology, Harbin, China, 22–24 August 2011; Volume 2, pp. 1266–1270. [Google Scholar] [CrossRef]

- Simon, J. Fuzzy Control of Self-Balancing, Two-Wheel-Driven, SLAM-Based, Unmanned System for Agriculture 4.0 Applications. Machines 2023, 11, 467. [Google Scholar] [CrossRef]

- Zhang, A.; Zhou, R.; Zhang, T.; Zheng, J.; Chen, S. Balance Control Method for Bipedal Wheel-Legged Robots Based on Friction Feedforward Linear Quadratic Regulator. Sensors 2025, 25, 1056. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsieh, C.-T. Development of Proportional-Integral-Derivative Based Self-Balancing Robot Using ESP32 for STEM Education. Eng. Proc. 2025, 92, 24. https://doi.org/10.3390/engproc2025092024

Hsieh C-T. Development of Proportional-Integral-Derivative Based Self-Balancing Robot Using ESP32 for STEM Education. Engineering Proceedings. 2025; 92(1):24. https://doi.org/10.3390/engproc2025092024

Chicago/Turabian StyleHsieh, Cheng-Tiao. 2025. "Development of Proportional-Integral-Derivative Based Self-Balancing Robot Using ESP32 for STEM Education" Engineering Proceedings 92, no. 1: 24. https://doi.org/10.3390/engproc2025092024

APA StyleHsieh, C.-T. (2025). Development of Proportional-Integral-Derivative Based Self-Balancing Robot Using ESP32 for STEM Education. Engineering Proceedings, 92(1), 24. https://doi.org/10.3390/engproc2025092024