1. Introduction

All around the world, the expectation for Governments and organisations to provide enhanced transparency and disclosure of environmental impacts, such as greenhouse gas (GHG) emissions, has been growing. This follows the landmark COP 21 Paris Agreement in 2015 in which all nations agreed to ambitiously pursue efforts to combat climate change and its effects [

1].

To deliver the ambitions of the Paris Agreement and keep global average temperature rise well below 2 °C, all sectors of the economy must decarbonize [

1]. Currently, buildings account for 39% of energy related global CO

2 emissions [

2], demonstrating the importance of the building and construction sector in fulfilling these ambitions. Of this sector contribution, 28% comes from operational carbon, with 11% arising from the energy used to produce building and construction materials, usually referred to as embodied carbon [

2].

At the same time, the global demand for construction materials is also growing due to worldwide population growth and an increase in urbanisation. As a key input into concrete, the most widely used construction material in the world, cement is a major contributor to climate change [

3]. The chemical and thermal combustion processes involved in the production of cement are a large source of carbon dioxide (CO

2) emissions. Each year, more than 4 billion tonnes of cement are produced, accounting for around 8 per cent of global CO

2 emissions [

3]. This clearly demonstrates both the essential need for construction materials now and in the future, as well as the necessity for the construction materials industry to be a leading part of the solution addressing climate change.

The first Environmental Product Declarations (EPDs) for ready-mix concrete in Australia (ViroDecsTM) constituted a major investment in comprehensively analysing and communicating to customers the embodied environmental impacts of Holcim’s ready-mix concrete.

The development of a concrete EPD is a critical “missing” piece to having all key infrastructure and building products represented by an EPD in Australia. Its publication supports designers and developers to drive improved sustainable procurement and materials selection.

Prior to the publication of the first EPDs for ready-mix concrete, sustainability professionals and procurement managers in the built environment sector were forced to rely on dated national average data for information on the Global Warming Potential (i.e., embodied carbon) of ready-mix concrete. This created a blurred picture for understanding the various embodied impacts of ready-mix concrete, affecting everything from the Infrastructure Sustainability (IS) Materials Calculator to whole-building Life Cycle Assessments under Green Star and carbon abatement strategies for organisations seeking Science Based Targets.

Not only affecting strategic and design work, the lack of company-specific (let alone mix-specific) data also constrained the built environment sector in the manner in which it specified and procured low-carbon concrete. Proxies such as Portland cement reduction and percentage of supplementary cementitious materials (SCM) used were widely adopted as a compromise position.

The publication of Australia’s first EPD for ready-mix concrete has led to exciting new opportunities to improve the way low-carbon concrete is specified in tenders and contracts. With the ability to provide mix-specific third-party verified data, Holcim is leading the way for construction contractors and clients to send a clear signal of intent for embodied carbon reduction in the concrete supply chain.

2. Materials and Methods

Data collected from across Holcim’s Australian operations, including over 190 concrete batching plant sites and 46 quarries was fed into an ISO14044-compliant Life Cycle Assessment (LCA) model by specialist practitioners to generate an Environmental Product Declaration (EPD) to ISO 14025 and EN 15804, which have been independently reviewed by an approved third-party verifier.

The primary data for the LCA are based on 2017 calendar year production data. SimaPro (v8.4) was used for the LCA modelling, using background data from:

The Australian National Life Cycle Inventory Database (AusLCI) (2017);

ecoinvent 3.4 (2017);

World Business Council for Sustainable Development (WBCSD) Cement Sustainability Initiative (CSI) Tool Project database (international version) (2018);

Product specific EPDs for admixtures and fibres.

Allocation was necessary to proportion inputs and outputs to intermediate flows at the quarry and processes at the batching plant level. As much as possible, intermediate flows were allocated physically based on weight (quarries) or based on m3 of concrete (at the batching plant). At the quarry level, whenever physical allocation was not possible, economic allocation was carried out based on Holcim’s internal cost system.

Regarding inputs, it was assumed that fly ash and silica fumes are waste products and therefore burden-free. Ground granulated blast furnace slag from steel blast furnace production was allocated economically. BS EN 16757:2017 specifically lists the following materials relevant to the study as co-products:

As such, the above materials are considered as coproducts of their production process, and the impacts for their production process are allocated according to PCR 2012:01 Construction Products and Construction Services (co-produced goods, multi-output allocation). Default background data from LCA databases were used to model the above co-products:

Fly ash: the AusLCI process for fly ash treats it as a waste material and only includes transport impacts.

Ground granulated blast furnace slag: the AusLCI process for slag is allocated based on economic value, as the product has significant economic value at the point of collection.

Silica fume: the ecoinvent process for silica fume treats it as a waste material and only includes transport impacts.

The allocation approach of the AusLCI LCA database was adopted as a default for secondary data and processes (e.g., secondary fuel in cement production). The AusLCIdataset conforms to EN 15804 when applying allocation to its various processes and sub-processes. Data quality for the foreground data was assessed in terms of geographic and temporal representativeness is shown in

Figure 1. All data sources were scored at medium or higher.

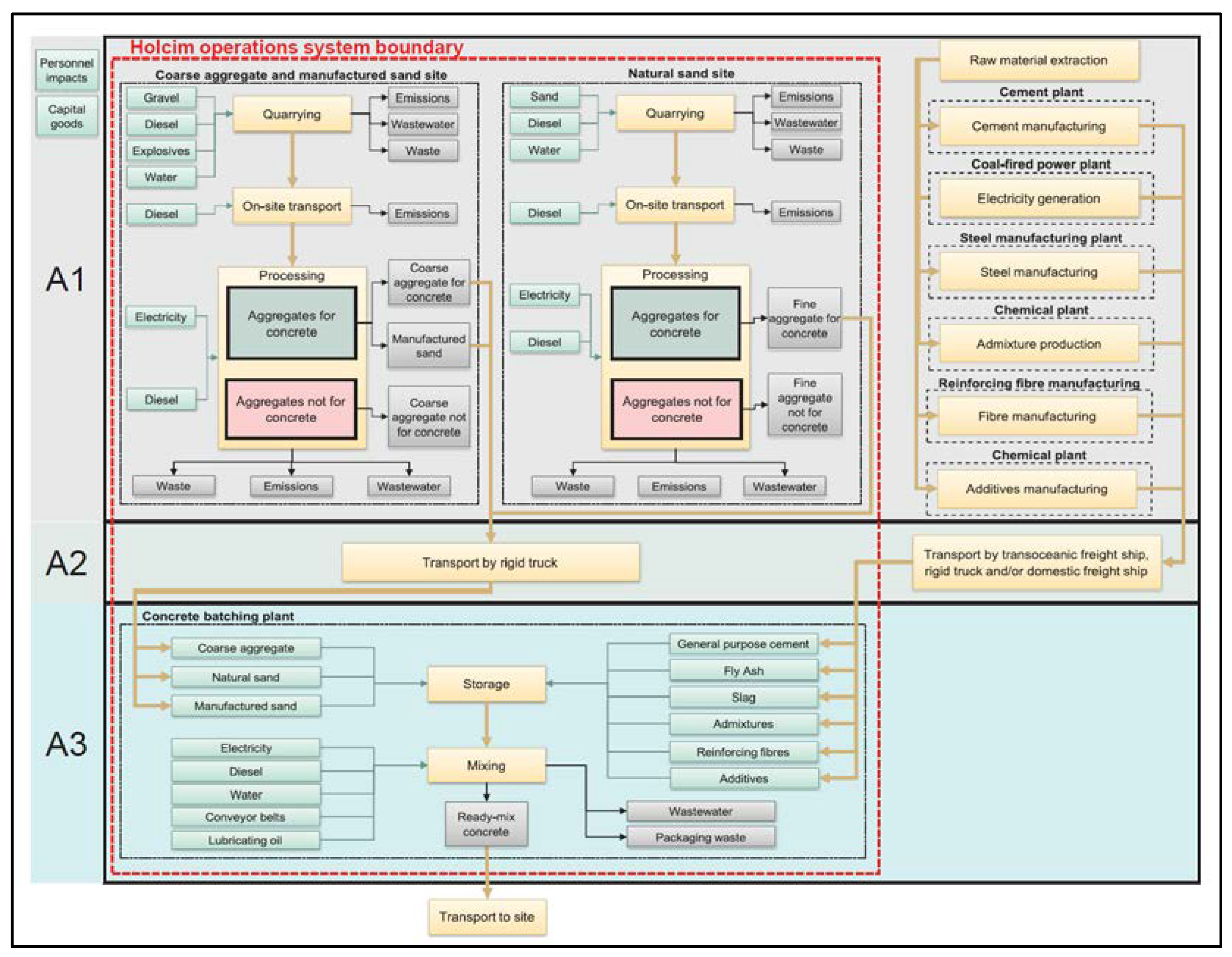

The processes included in the LCA are presented in a process diagram in

Figure 2 below.

The key assumptions and limitations of the EPD LCA are outlined and assessed in

Figure 3.

3. Results

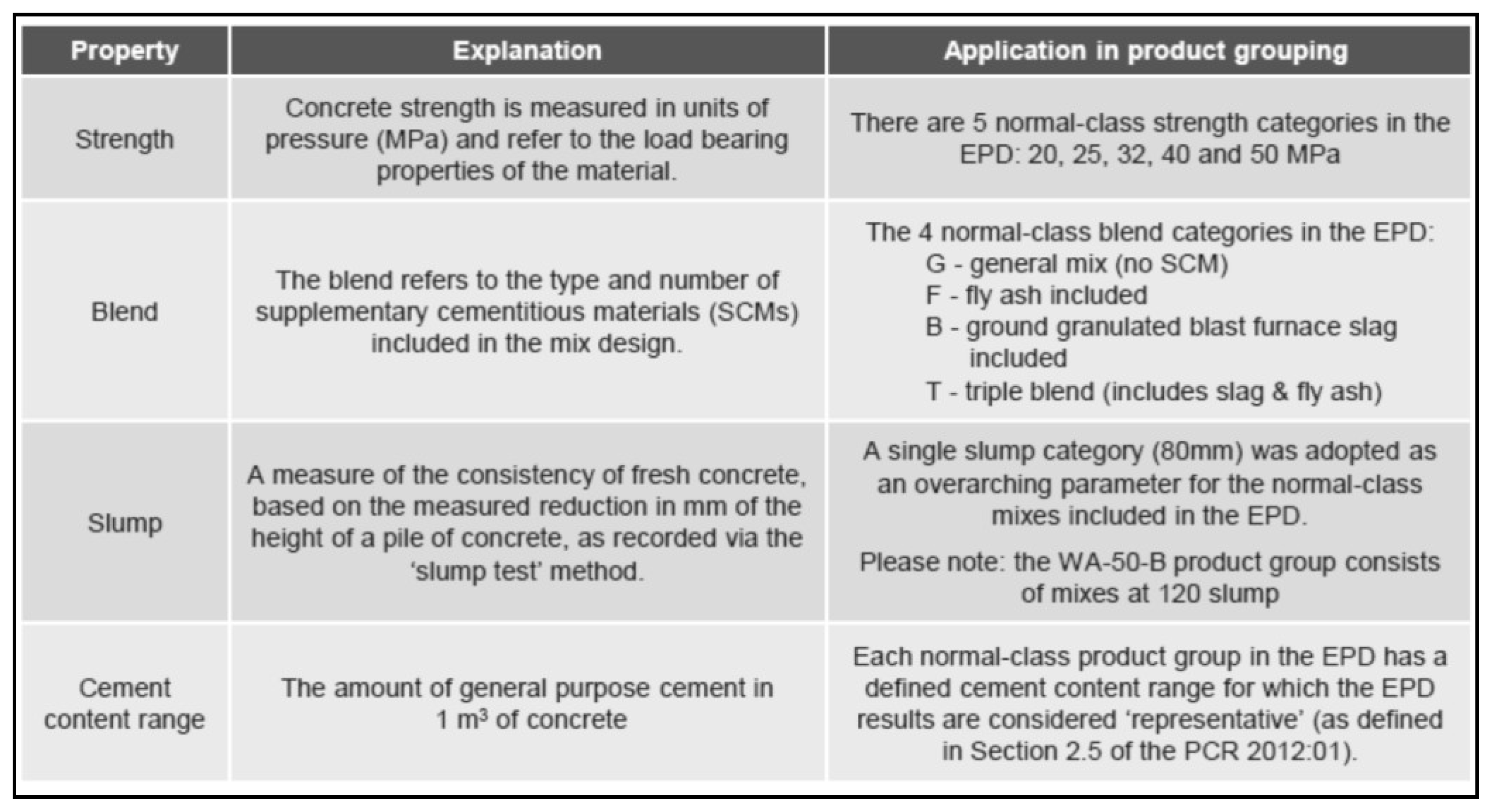

The Holcim’s normal-class concrete products included in this EPD have been grouped according to a set of key properties outlined in

Figure 4.

The global warming potential (GWP) environmental impacts (unit kg CO

2 equivalents (GWP100)) for 1 m

3 of Holcim ViroDecs

TM normal-class ready-mix in New South Wales (NSW) and the Australian Capital Territory (ACT) are shown in

Figure 5.

It was found that Holcim’s normal-class ready-mix concrete has a range of greenhouse gas (GHG) emissions across each different states, strengths, and blend, covered by the EPD (

Figure 6). The GHG emissions associated with 1 m

3 of Holcim normal-class ready-mix concrete in New South Wales (NSW) and the Australia Capital Territory (ACT) Australia are shown in

Figure 6 for:

Holcim ViroDecsTM—General Portland Cement;

Holcim ViroDecsTM—Fly Ash Blend;

Holcim ViroDecsTM—Blast Slag Blend;

Holcim ViroDecsTM—Triple Blend.

4. Discussion

To evaluate the performance of Holcim’s ViroDecs

TM normal-class ready-mix concrete range, the EPD results were benchmarked against the Green Star concrete reference case, IS materials calculator default concrete mix, and the Australian National Life Cycle Inventory Database (AusLCI). The following figure shows the results (

Figure 7).

The modelling showed that in comparison to the Australian National Life Cycle Inventory Database’s (AusLCI) general ready-mix concrete with no cement substitution:

Holcim’s ViroDecsTM General had up to 28% less CO2-equivalent than the Australian average;

Holcim’s ViroDecsTM Fly Ash Blend had up to 42% less CO2-equivalent than the Australian average;

Holcim’s ViroDecsTM Slag Blend had up to 52% less CO2-equivalent than the Australian average;

Holcim’s ViroDecsTM Triple Blend had up to 57% less CO2-equivalent than the Australian average.

Highlighting the potential benefits of the lower carbon concrete with a 57% reduction in embodied carbon, on a hypothetical 500,000 m

3 large scale infrastructure project, using 50 MPa ready-mix concrete instead of the equivalent normal-class concrete could reduce greenhouse gas emissions by up to 170,000 tonnes of CO

2-equivalent. This is a GHG emissions reduction equivalent to removing 32,635 cars from Australian roads (based on 0.401 kg CO

2-eq per km of car travel (AusLCI) and an average travel distance 13,400 km per car in FY17/18 (ABS:

https://www.abs.gov.au/ausstats/abs@.nsf/mf/9208.0 (accessed on 4 December 2019))) or powering 24,285 Australian homes with renewable energy sources (based on an average greenhouse gas impact of seven tonnes CO

2-eq for an Australian household per year from energy use (

http://www.yourhome.gov.au/energy) (accessed on 4 December 2019)) for a year.

In March 2020, in another Australian-first for Holcim and the construction industry, Holcim used the EPD to gain certification from Australian Government’s National Carbon Offset Program ‘Climate Active’ to sell certified carbon neutral ready-mix concrete. Climate Active is a program administered by the Australian Federal Government to support businesses committed to sustainability, innovation, and industry leadership to drive voluntary climate action. The Climate Active certification enables Holcim to offset the remaining embodied carbon of its ready-mix concrete products on behalf of its customers on an opt-in basis through a transparent third party assured process, which ultimately results in carbon neutral ready-mix concrete (Holcim’s ViroDecs Zero).

For a large infrastructure project in Australia (500,000 m

3), the difference between using Holcim’s ViroDecs Zero Carbon Neural ready-mix concrete and the Australian average for general blend concrete with no cement substitution could be as much as 313,000 tonnes of CO

2e. This is the same as taking over 58,000 Australian cars (based on 0.401 kg CO

2-eq per km of car travel (AusLCI) and an average travel distance 13,400 km per car in FY17/18 (ABS:

https://www.abs.gov.au/ausstats/abs@.nsf/mf/9208.0) (accessed on 4 December 2019)) off the road for a year.

It is noted that in addition to reducing carbon emissions, the offset projects also have the potential to bring additional benefits, including environmental (e.g., habitat and biodiversity protection), economic (e.g., income from the sale of offset units and employment to manage the project), and social (e.g., capacity building and health improvements in local communities).

5. Conclusions

In 2019, Holcim Australia set out to shake up the concrete industry by publishing the first ready-mix concrete Environmental Product Declaration (EPD) in the Australian market. Prior to the publication of the first EPD for ready-mix concrete in Australia, sustainability professionals and procurement managers in the built environment sector were forced to rely on dated national average data for information on the Global Warming Potential (i.e., embodied carbon) of ready-mix concrete. This created a blurred picture for understanding the various embodied impacts of ready-mix concrete, affecting everything from the Infrastructure Sustainability (IS) Materials Calculator to whole-building Life Cycle Assessments under Green Star and carbon abatement strategies for organisations seeking Science Based Targets.

Not only affecting strategic and design work, the lack of company-specific (let alone mix-specific) data also constrained the built environment sector in the manner in which it specified and procured low-carbon concrete. Proxies such as Portland cement reduction and supplementary cementitious materials (SCM) fractions were widely adopted as a compromise position.

The publication of the first EPD for ready-mix concrete in Australia has led to exciting new opportunities to improve the way low-carbon concrete is specified in tenders and contracts. With the ability to provide mix-specific third-party verified data, EPDs are leading the way for construction contractors and clients to send a clear signal of intent for embodied carbon reduction in the concrete supply chain.

Using EPDs as a building block, concrete can be specified in terms of global warming potential (measured in kg CO2-eq). This opens up the opportunity for suppliers to promote their low embodied carbon products, creating healthy competition that benefits projects and the economy, as well as the environment.

The publication of EPDs for a number of construction materials in Australia highlights the importance and benefits of a standardised evidence-based approach to environmental claims and the evaluation and selection of materials based on their true sustainability performance.